A new formwork trolley for the second lining of the large-section parking line in the underground excavation of the subway section

A new formwork and large-section technology, which is applied in tunnel lining, wellbore lining, underground chamber, etc., can solve the problems of formwork not being reused, formwork support unreasonable, lining slab staggered, etc., and achieve safe and reliable formwork reinforcement Structure, good promotion and use value, reasonable template effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

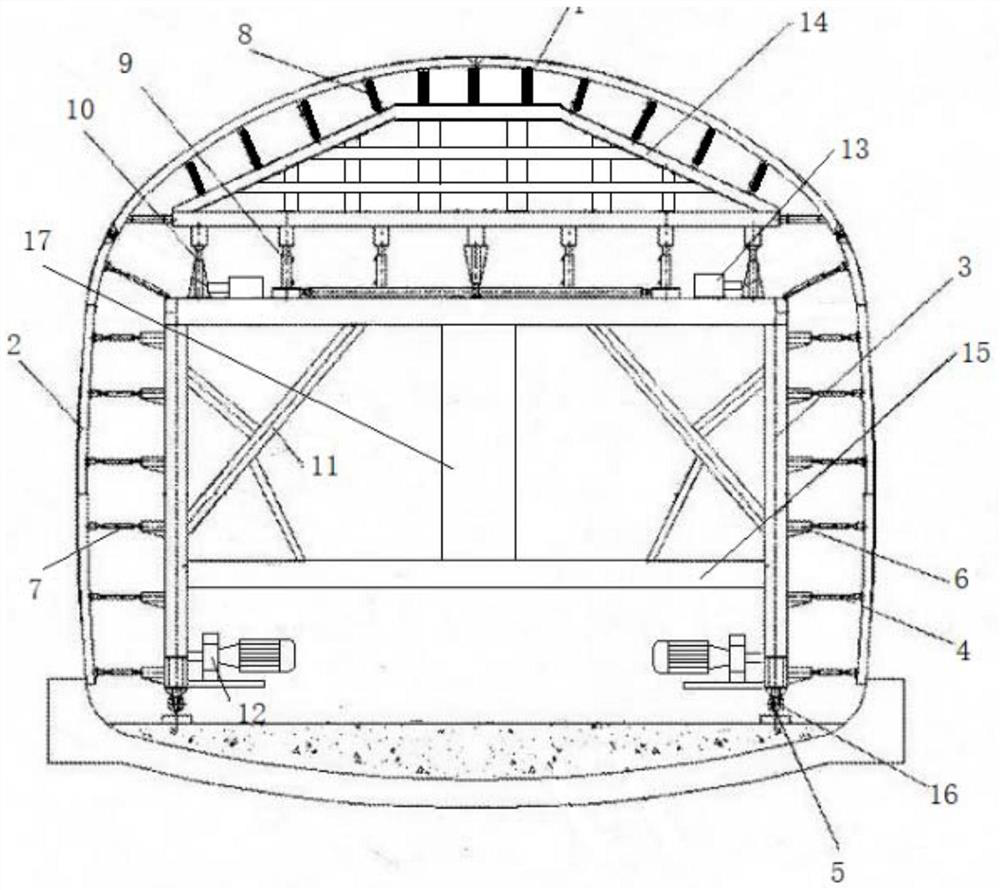

[0027] see figure 1 , a new formwork trolley for the second lining of the large-section parking line in the underground excavation subway section, including the upper formwork 1 of the tunnel, the side wall formwork 2 and the trolley frame 3, and the upper formwork 1 is set as a large-span curved formwork with a radian form; the side formwork 2 is arranged on both sides below the upper formwork 1 respectively, and the side formwork 2 is set in the form of a slightly curved formwork with a large span, the upper formwork 1 and the two side formwork 2 are hinged, and the two The template fixing structure 4 is arranged on the back; the traveling track 5 is arranged on the ground of the tunnel, and the trolley frame 3 is arranged on the traveling track 5;

[0028] Described trolley frame 3 comprises main body support frame and upper support frame 14, and described upper support frame 14 is arranged on the described main body support frame; Described main body support frame is suppo...

Embodiment 2

[0039] see figure 1 , a new formwork trolley for the second lining of the large-section parking line in the underground excavation subway section, including the upper formwork 1 of the tunnel, the side wall formwork 2 and the trolley frame 3, and the upper formwork 1 is set as a large-span curved formwork with a radian form; the side formwork 2 is arranged on both sides below the upper formwork 1 respectively, and the side formwork 2 is set in the form of a slightly curved formwork with a large span, the upper formwork 1 and the two side formwork 2 are hinged, and the two The template fixing structure 4 is arranged on the back; the traveling track 5 is arranged on the ground of the tunnel, and the trolley frame 3 is arranged on the traveling track 5;

[0040] Described trolley frame 3 comprises main body support frame and upper support frame 14, and described upper support frame 14 is arranged on the described main body support frame; Described main body support frame is suppo...

Embodiment 3

[0051] see figure 1 , a new formwork trolley for the second lining of the large-section parking line in the underground excavation subway section, including the upper formwork 1 of the tunnel, the side wall formwork 2 and the trolley frame 3, and the upper formwork 1 is set as a large-span curved formwork with a radian form; the side formwork 2 is arranged on both sides below the upper formwork 1 respectively, and the side formwork 2 is set in the form of a slightly curved formwork with a large span, the upper formwork 1 and the two side formwork 2 are hinged, and the two The template fixing structure 4 is arranged on the back; the traveling track 5 is arranged on the ground of the tunnel, and the trolley frame 3 is arranged on the traveling track 5;

[0052] Described trolley frame 3 comprises main body support frame and upper support frame 14, and described upper support frame 14 is arranged on the described main body support frame; Described main body support frame is suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com