Sand blasting process of aviation fire-extinguishing bottle dome

A technology of fire extinguisher head and fire extinguisher, which is applied in the field of aviation fire extinguisher, can solve the problems of uneven wall thickness, increased overall weight of fire extinguisher, affecting the performance and use effect of aeroengine fire extinguisher, etc., so as to reduce product weight and guarantee The effect of product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

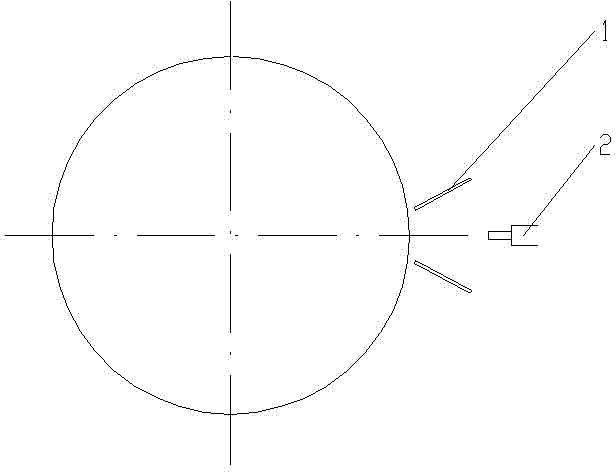

[0014] see figure 1 , Embodiment 1: a kind of sand blasting process of aviation fire extinguishing bottle head, comprises the following steps:

[0015] a. Pretreatment: inspect the sandblasting machine, air compressor and sandblasting nozzle 2, and feed 0.5MPa compressed air into the air compressor;

[0016] b. Sandblasting: sandblasting the head of the fire extinguisher to remove the scale, welding slag and oil stains on the fire extinguisher, set baffles 1 on both sides of the sandblasting nozzle 2, and during the sandblasting process, the sandblasting nozzle 2 moves slowly , and the fire extinguisher rotates at a constant speed of 1 revolution per minute;

[0017] c. Cleaning: Blow out dry compressed air through the air compressor to clean up the sand and ash on the surface of the head of the fire extinguisher;

[0018] d. Inspection: Check the roughness of the surface of the head of the fire extinguisher. The head should have uniform roughness, the roughness is Sa2.5...

Embodiment 2

[0019] Embodiment 2: a kind of sand blasting process of aviation fire extinguishing bottle head, comprises the following steps:

[0020] a. Pretreatment: check the sandblasting machine, air compressor and sandblasting nozzle 2, and feed 0.55MPa compressed air into the air compressor;

[0021] b. Sandblasting: sandblasting the head of the fire extinguisher to remove the scale, welding slag and oil stains on the fire extinguisher, set baffles 1 on both sides of the sandblasting nozzle 2, and during the sandblasting process, the sandblasting nozzle 2 moves slowly , and the fire extinguisher rotates at a constant speed of 2 revolutions per minute;

[0022] c. Cleaning: Blow out dry compressed air through the air compressor to clean up the sand and ash on the surface of the head of the fire extinguisher;

[0023] d. Inspection: Check the roughness of the surface of the head of the fire extinguisher. The head should have uniform roughness, the roughness is Sa2.5, and there shou...

Embodiment 3

[0024] Embodiment 3: a kind of sandblasting process of aviation fire extinguishing bottle head, comprises the following steps:

[0025] a. Pretreatment: inspect the sandblasting machine, air compressor and sandblasting nozzle 2, and feed 0.6MPa compressed air into the air compressor;

[0026] b. Sandblasting: sandblasting the head of the fire extinguisher to remove the scale, welding slag and oil stains on the fire extinguisher, set baffles 1 on both sides of the sandblasting nozzle 2, and during the sandblasting process, the sandblasting nozzle 2 moves slowly , and the fire extinguisher rotates at a constant speed of 3 revolutions per minute;

[0027] c. Cleaning: Blow out dry compressed air through the air compressor to clean up the sand and ash on the surface of the head of the fire extinguisher;

[0028] d. Inspection: Check the roughness of the surface of the head of the fire extinguisher. The head should have uniform roughness, the roughness is Sa2.5, and there shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com