Bimetal metallurgy composite bent pipe heat treatment technology

A composite elbow and bimetal technology, which is applied in the field of heat treatment, can solve the problem of difficulty in eliminating the reduction of mechanical properties, and achieve the effect of ensuring corrosion resistance, smooth inner wall and high service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

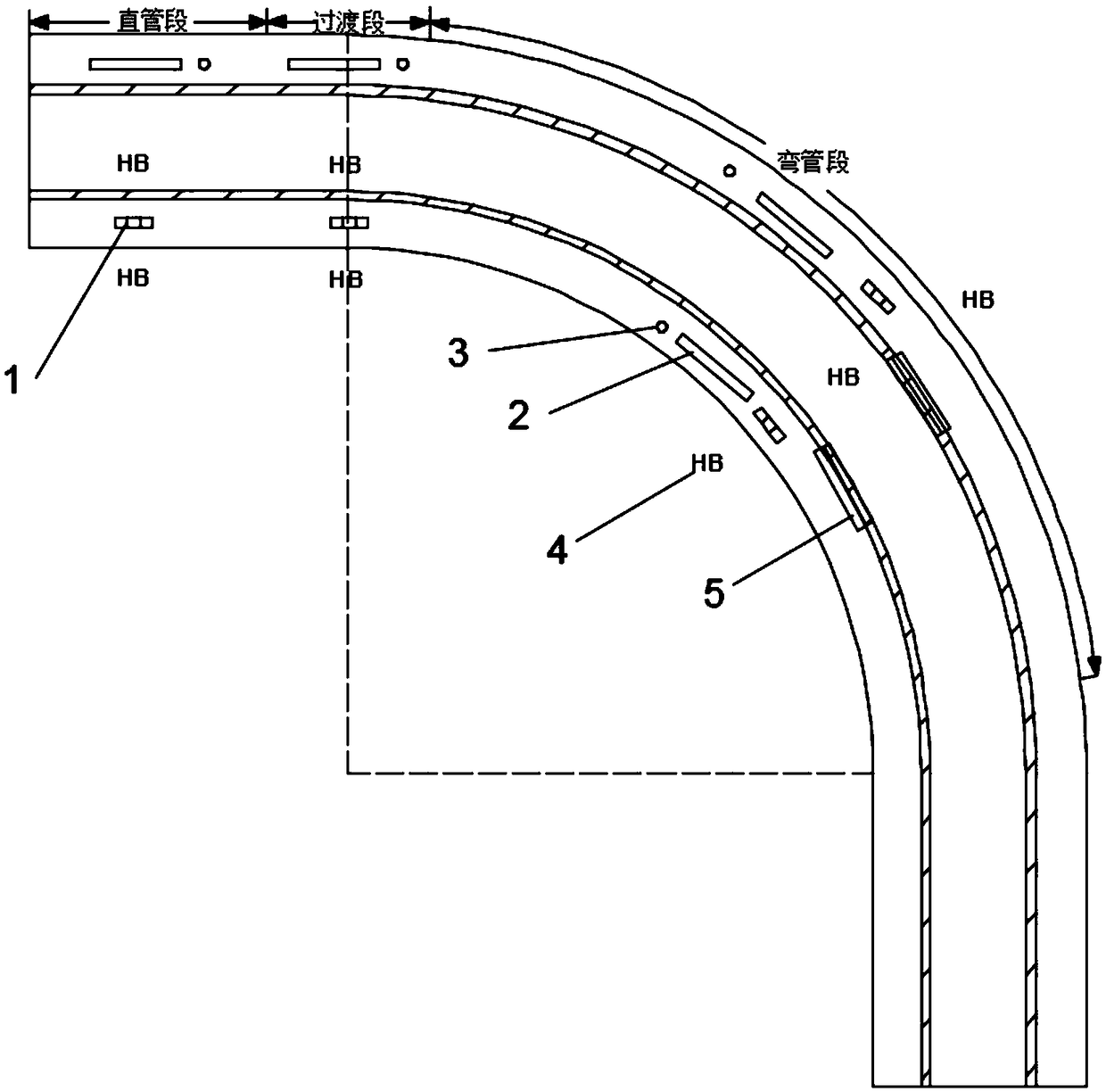

Image

Examples

Embodiment 1

[0019] A heat treatment process for a bimetallic metallurgical composite elbow, comprising the following steps:

[0020] Step 1: Overlay welding of the base pipe: take the bimetallic metallurgical composite pipe, machine the welding slope at both ends of the bimetallic metallurgical composite pipe, and surfacing metal of the same material as the bimetallic metallurgical composite pipe on the processed welding slope , and then form a surfacing layer by machine tool processing;

[0021] Step 2: pre-bending treatment: block one end of the bimetallic metallurgical composite pipe, and pour a medium with a temperature of 145°C into it;

[0022] Step 3: Bending: When the temperature of the medium in step 2 is cooled to 82°C, use a pipe bending machine to bend to make a bimetallic metallurgical composite bend;

[0023] Step 4: Quenching: Heat the bimetallic metallurgical composite elbow prepared in Step 3 to 890°C in the heating furnace, keep it warm for 45 minutes, and then quickly ...

Embodiment 2

[0027] A heat treatment process for a bimetallic metallurgical composite elbow, comprising the following steps:

[0028] Step 1: Overlay welding of the base pipe: take the bimetallic metallurgical composite pipe, machine the welding slope at both ends of the bimetallic metallurgical composite pipe, and surfacing metal of the same material as the bimetallic metallurgical composite pipe on the processed welding slope , and then form a surfacing layer by machine tool processing;

[0029] Step 2: Pre-treatment of bending: block one end of the bimetallic metallurgical composite pipe, and pour a medium with a temperature of 150°C into it;

[0030] Step 3: Bending: When the temperature of the medium in step 2 is cooled to 87°C, use a pipe bending machine to bend to make a bimetallic metallurgical composite bend;

[0031] Step 4: Quenching: Heat the bimetallic metallurgical composite elbow prepared in Step 3 to 890°C in a heating furnace, keep it warm for 50 minutes, and then quickly...

Embodiment 3

[0035] A heat treatment process for a bimetallic metallurgical composite elbow, comprising the following steps:

[0036] Step 1: Overlay welding of the base pipe: take the bimetallic metallurgical composite pipe, machine the welding slope at both ends of the bimetallic metallurgical composite pipe, and surfacing metal of the same material as the bimetallic metallurgical composite pipe on the processed welding slope , and then form a surfacing layer by machine tool processing;

[0037] Step 2: pre-bending treatment: block one end of the bimetallic metallurgical composite pipe, and pour a medium with a temperature of 155°C into it;

[0038] Step 3: Bending: When the temperature of the medium in step 2 is cooled to 90°C, use a pipe bender to bend to make a bimetallic metallurgical composite bend;

[0039] Step 4: Quenching: Heat the bimetallic metallurgical composite elbow prepared in Step 3 to 930°C in a heating furnace, keep it warm for 65 minutes, and then quickly cool it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com