Low-odor scraping-resistant polypropylene material and preparation method thereof

A polypropylene material, scratch-resistant technology, applied in the field of polypropylene materials, can solve the problems of not being able to remove odor well, adding more fluorine-containing polymers, increasing production costs, etc., to achieve superior product performance and good product performance , reduce the effect of sporadic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

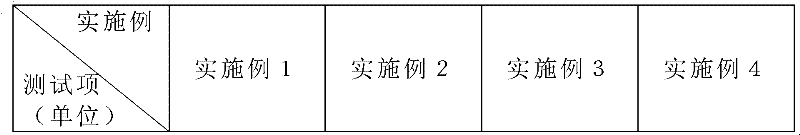

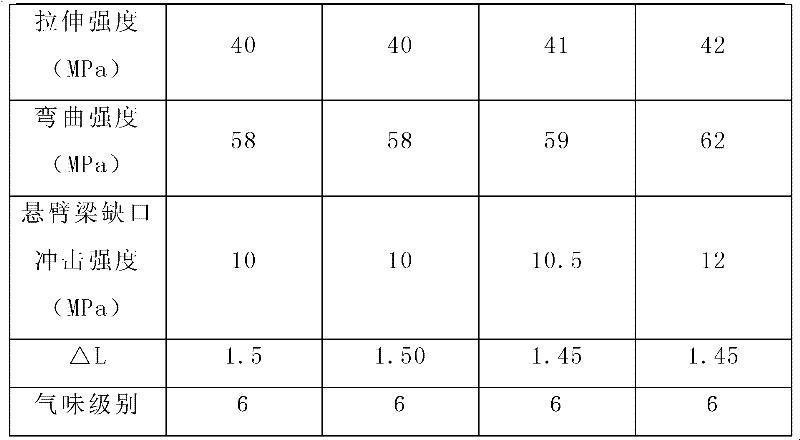

Embodiment 1

[0032] Prepare materials according to the following weight percentages:

[0033] Polypropylene resin: 67.5%; Nano silica: 3%; Ultrafine talc: 27%; Deodorant: 1%; Dispersed lubricant: 1%; Antioxidant: 0.3%; Hindered amine light stabilizer : 0.2%, wherein the nano-silicon dioxide is modified nano-silicon dioxide, which is obtained by surface treatment of nano-silicon dioxide with hexamethyldisilazane, and the modified nano-silicon dioxide The particle size of silicon is 16nm; the deodorant is organosilicon microporous zeolite, the dispersion lubricant is a mixture of polysiloxane and erucamide, and the molecular weight of the polysiloxane is greater than 1000, wherein polysiloxane The weight ratio of siloxane and erucamide is 1: 1; Above-mentioned antioxidant comprises main antioxidant and auxiliary antioxidant, and the weight ratio of main antioxidant and auxiliary antioxidant is 1: 2, The primary antioxidant is phenolic antioxidant 1010, the secondary antioxidant is phosphite...

Embodiment 2

[0038] Prepare materials according to the following weight percentages:

[0039] Polypropylene resin: 67.5%; Nano silica: 4%; Ultrafine talc: 26%; Deodorant: 1%; Dispersed lubricant: 1%; Antioxidant: 0.3%; Hindered amine light stabilizer : 0.2%, wherein the nano-silica is modified nano-silica, modified nano-silica adopts hexamethyldisilazane to surface treat nano-silica, modified nano-silica The particle size is 8nm; the deodorant is composed of organosilicon microporous zeolite and porous silica, wherein the weight ratio of organosilicon microporous zeolite to porous silica is 2:3, and the dispersion lubricant is poly A mixture of siloxane and stearic acid, the molecular weight of the polysiloxane is greater than 1000, wherein the weight ratio of polysiloxane to stearic acid is 2:1; the above-mentioned antioxidant includes the main antioxidant And auxiliary antioxidant, the weight ratio of main antioxidant and auxiliary antioxidant is 1: 2, and described main antioxidant is ...

Embodiment 3

[0044] Prepare materials according to the following weight percentages:

[0045] Polypropylene resin: 67.5%; Nano silica: 5%; Ultrafine talc: 25%; Deodorant: 1%; Dispersed lubricant: 1%; Antioxidant: 0.3%; Hindered amine light stabilizer : 0.2%, wherein the nano-silica is modified nano-silica, modified nano-silica adopts hexamethyldisilazane to surface treat nano-silica, modified nano-silica The particle size is 1nm; the deodorant is composed of organosilicon microporous zeolite and porous silica, wherein the weight ratio of organosilicon microporous zeolite to porous silica is 3:2, and the dispersion lubricant is poly A mixture of siloxane, erucamide and stearic acid, the molecular weight of the polysiloxane is greater than 1000, wherein the weight ratio of polysiloxane, erucamide and stearic acid is polysiloxane:mustard Acid amide: stearic acid is 2: 1: 1; Above-mentioned antioxidant comprises main antioxidant and auxiliary antioxidant, and the weight ratio of main antioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com