Low-temperature thermosetting waterborne peelable adhesive and preparation method thereof

A low-temperature heat, water-based technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem that the film cannot be well adapted to CNC processing, cannot ensure that the plastic back cover is not damaged, and the protection of special-shaped workpieces Insufficient strength and other problems to achieve the effect of ensuring the modification effect and product performance, improving brightness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

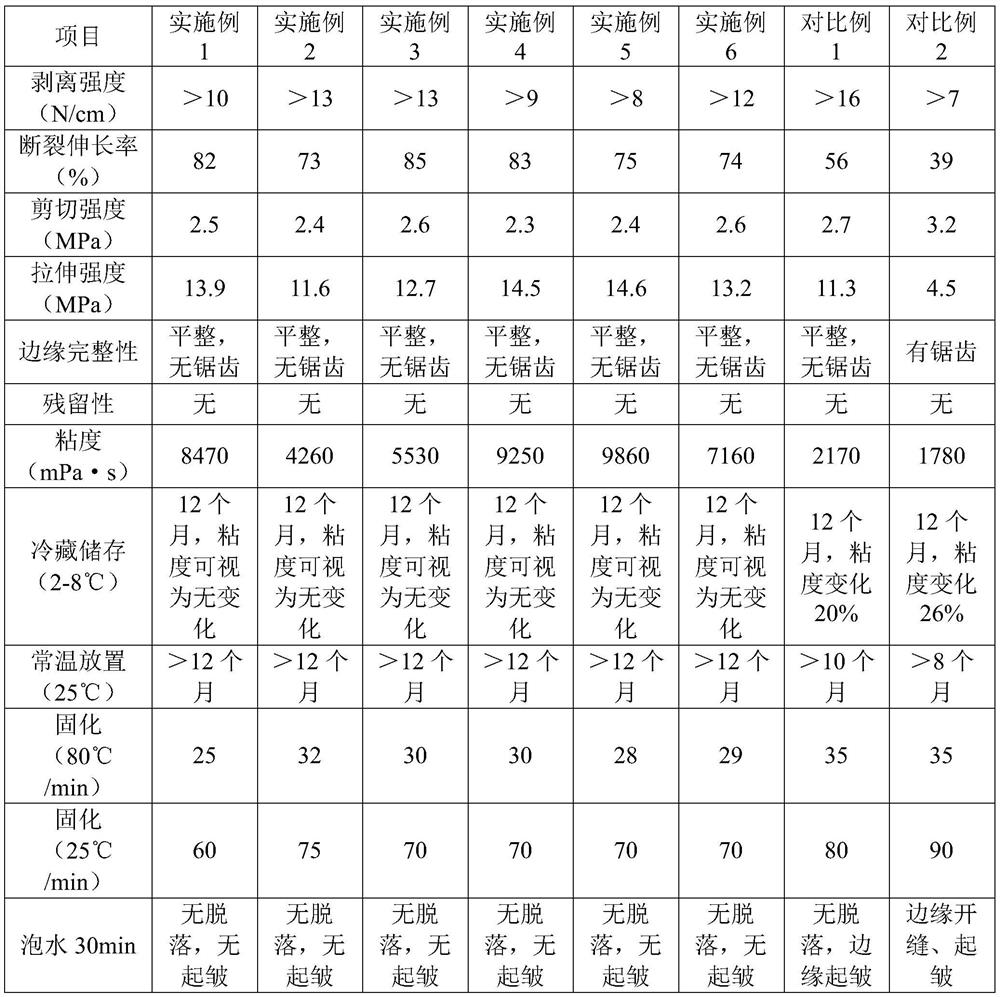

Examples

preparation example Construction

[0033] The preparation method of the low-temperature thermosetting water-based peelable adhesive comprises the following steps:

[0034] Step 1, taking the raw material components of formula quantity;

[0035] Step 2, dilute the thickener with water by 1 to 2 times; add nano-graphene and dispersant to 20 parts of water, and stir evenly to obtain a graphene dispersion;

[0036] Step 3. Add 1 / 3 water-based polyurethane resin and 1 / 3 graphene dispersion in turn while stirring in the reactor, stir well and then add 1 / 3 water-based polyurethane resin, stir well and then add 1 / 3 graphene dispersion , repeat the above operations until the water-based polyurethane resin and graphene dispersion are added and stirred evenly, then add silane coupling agent, film forming agent, wetting agent, defoamer, color paste and thickener in turn while stirring, and stir After it is uniform, add filler while stirring until it is evenly stirred to obtain a low-temperature thermosetting water-based p...

Embodiment 1

[0038] This embodiment provides a low-temperature thermosetting water-based peelable adhesive, including the following components: 60 parts of water-based polyurethane resin, 3.5 parts of silane coupling agent, 5 parts of nano-graphene, 1.5 parts of dispersant, 2 parts of film-forming agent, 0.5 parts of wet agent, 1.5 parts of defoamer, 2 parts of thickener, 0.3 parts of color paste, 20 parts of filler.

[0039] The preparation method of the above-mentioned low-temperature thermosetting water-based peelable adhesive, the steps include:

[0040] Step 1, taking the raw material components of formula quantity;

[0041] Step 2, dilute the thickener with water by 1 to 2 times; add nano-graphene and dispersant to 20 parts of water, and stir evenly to obtain a graphene dispersion;

[0042] Step 3. Add 1 / 3 water-based polyurethane resin and 1 / 3 graphene dispersion in turn while stirring in the reactor, stir well and then add 1 / 3 water-based polyurethane resin, stir well and then add 1...

Embodiment 2

[0044] This embodiment provides a low-temperature thermosetting water-based peelable adhesive, which includes the following components: 50 parts of water-based polyurethane resin, 3 parts of silane coupling agent, 3 parts of nano-graphene, 1.2 parts of dispersant, 3 parts of film-forming agent, 0.3 parts of wet agent, 1.3 parts of defoamer, 1 part of thickener, 0.4 parts of color paste, 25 parts of filler.

[0045] The preparation method of the above-mentioned low-temperature thermosetting water-based peelable adhesive, the steps include:

[0046] Step 1, taking the raw material components of formula quantity;

[0047] Step 2, dilute the thickener with water by 1 to 2 times; add nano-graphene and dispersant to 20 parts of water, and stir evenly to obtain a graphene dispersion;

[0048] Step 3. Add 1 / 3 water-based polyurethane resin and 1 / 3 graphene dispersion in turn while stirring in the reactor, stir well and then add 1 / 3 water-based polyurethane resin, stir well and then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com