Sintering method of ceramic block

A sintering method and technology for ceramic blocks, which are applied in the field of ceramics, can solve the problems of long sintering time, few ceramic blocks, and low sintering capacity of ceramic blocks, and achieve the effects of increasing production capacity, ensuring product performance, and avoiding a lot of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make those skilled in the art better understand the technical solutions of the present application, the sintering method of the ceramic block provided by the present application will be described in further detail below with reference to specific embodiments.

[0040] The sintering method of the ceramic block of the present application can be applied to the preparation process of the dielectric resonator, but is of course not limited thereto. The preparation process of the dielectric resonator mainly includes the steps of configuring powder, pressing, sintering, metallizing, electrode making, SMA patch and debugging.

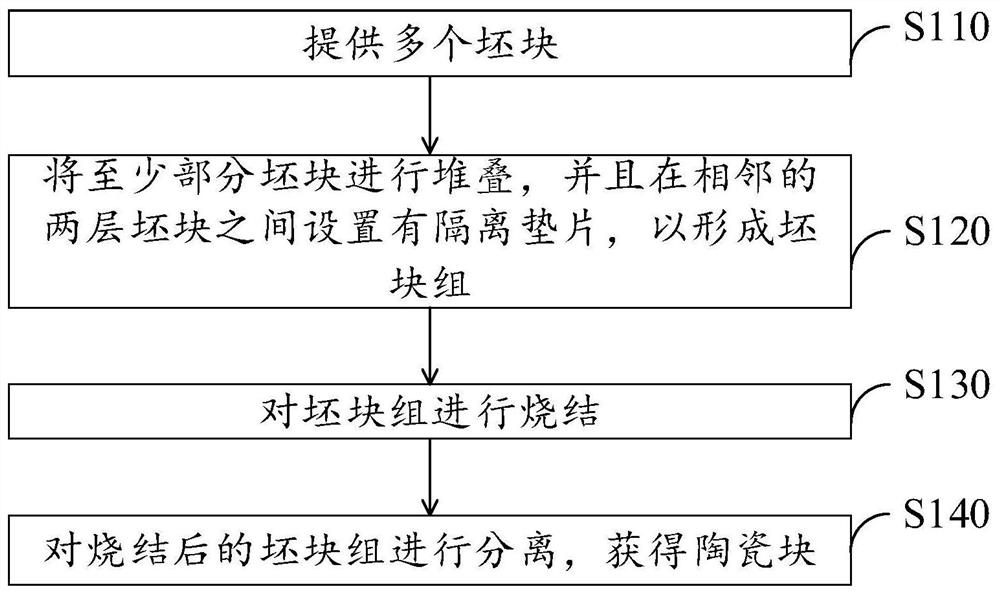

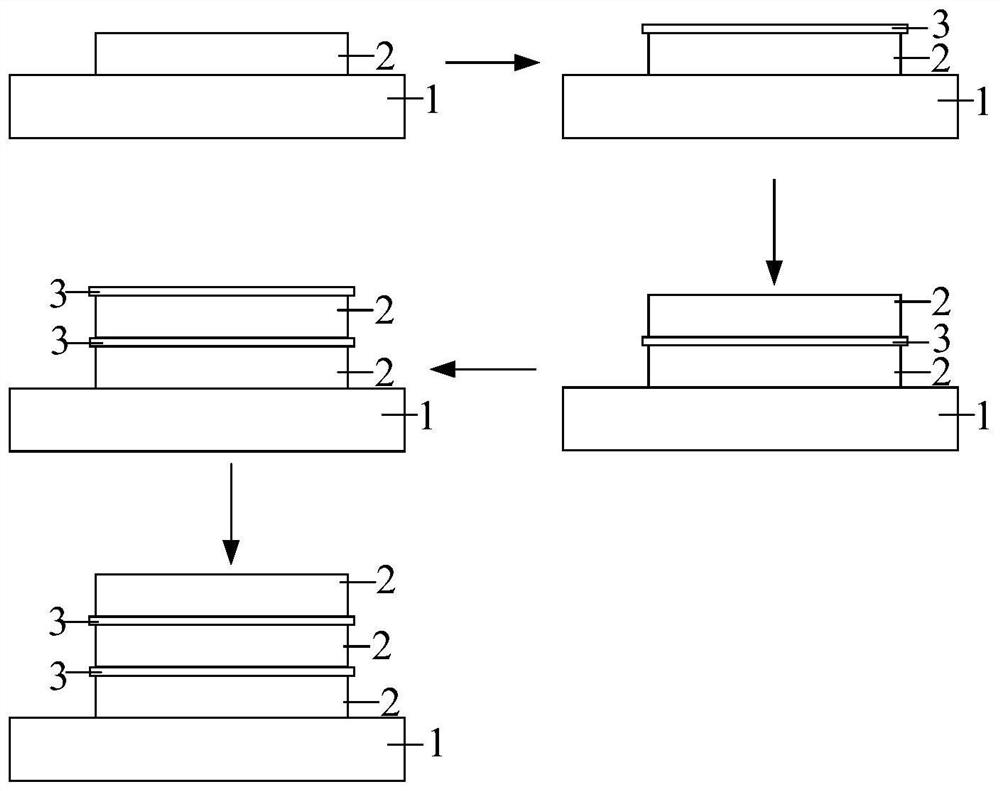

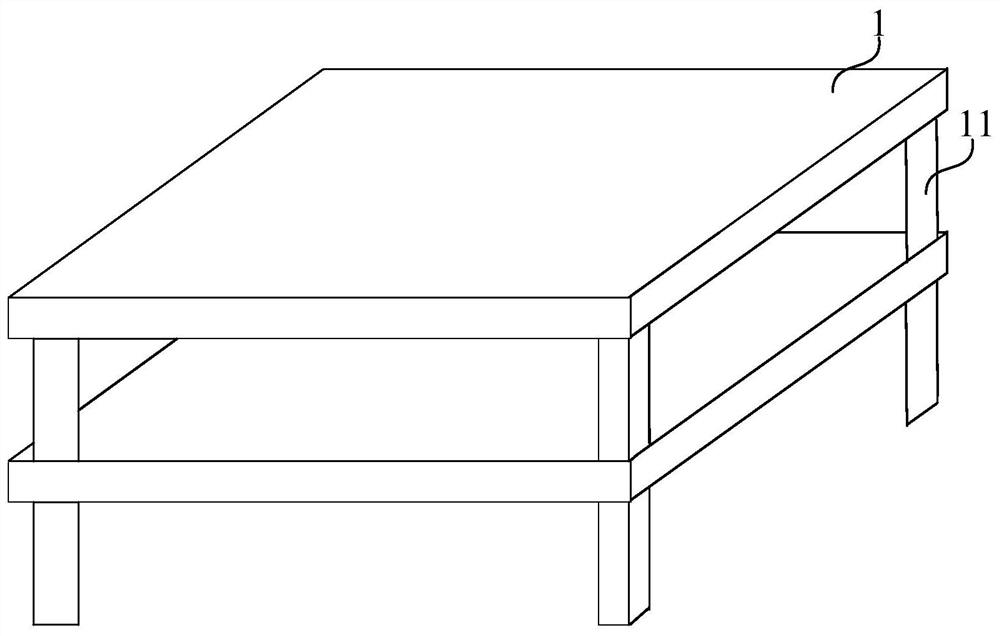

[0041] The powder is pressed into briquettes, and the briquettes need to be sintered at high temperature to form ceramic blocks with properties that meet the requirements. Generally speaking, single-layer compacts are placed on the sintering support plate during sintering, resulting in a relatively small number of compacts that can be accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com