Granular material dividing boxing machine

A cartoning machine and granular material technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of abnormal quality of granular materials and high quality requirements, and achieve the effects of convenient operation, product quality assurance, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

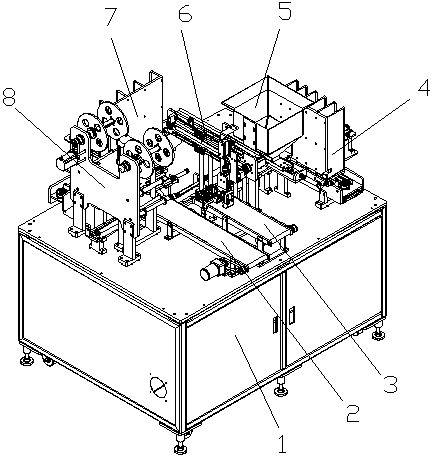

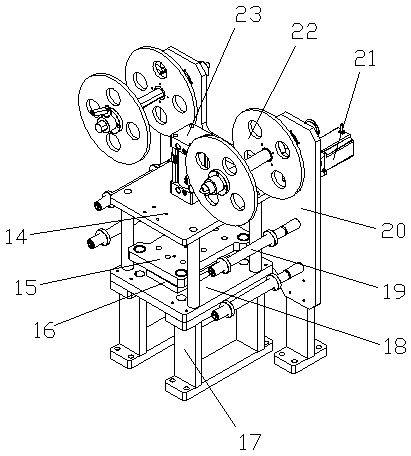

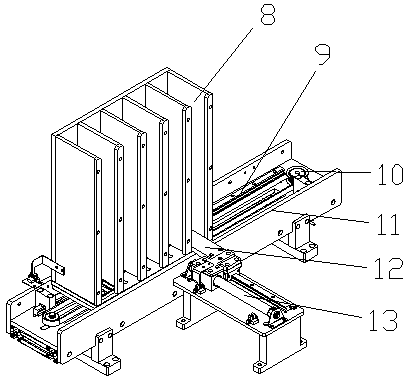

[0036] like Figure 1-Figure 10 As shown, the structure of the present invention is: a kind of granular material distributing cartoning machine, it comprises frame 1, control box, and described frame 1 is provided with box feeding device 4, material boxing device 5, handling Device 6, cover feeding device 7, foam cutting device 8, the finished product discharge track 2 is arranged below the foam cutting device 8, and the box feeding device 4 and the cover feeding device 7 both include a storage box 9. Belt pulley 10, feeding track 11, material pushing plate 12, material pushing cylinder 13, said pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com