Control device of continuous annealing furnace pressure alarming and method thereof

A continuous annealing furnace and control device technology, applied in the direction of self-adaptive control, general control system, control/regulation system, etc., can solve the problems of output, product performance, impact on smooth logistics, etc., and achieve the effect of smooth logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

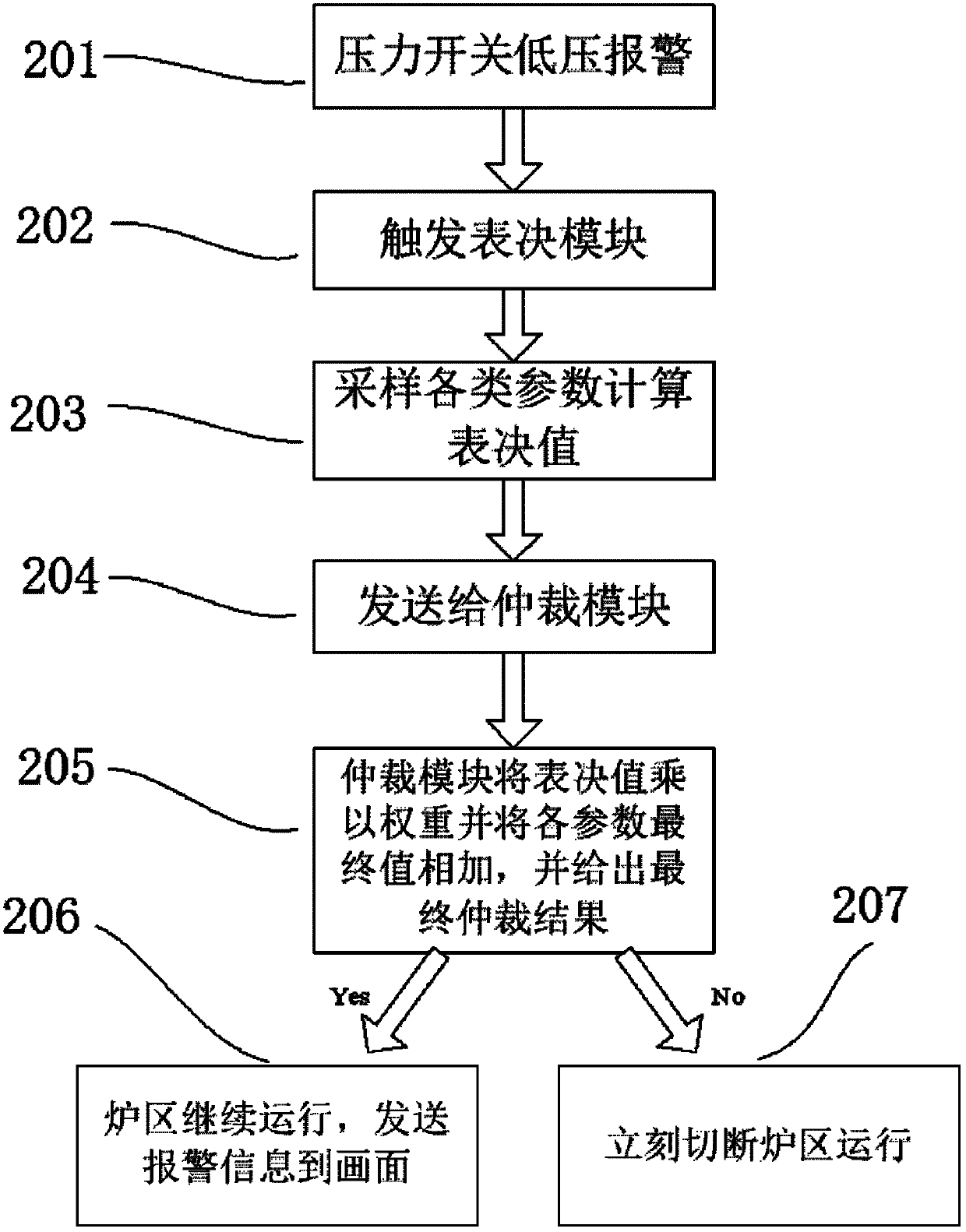

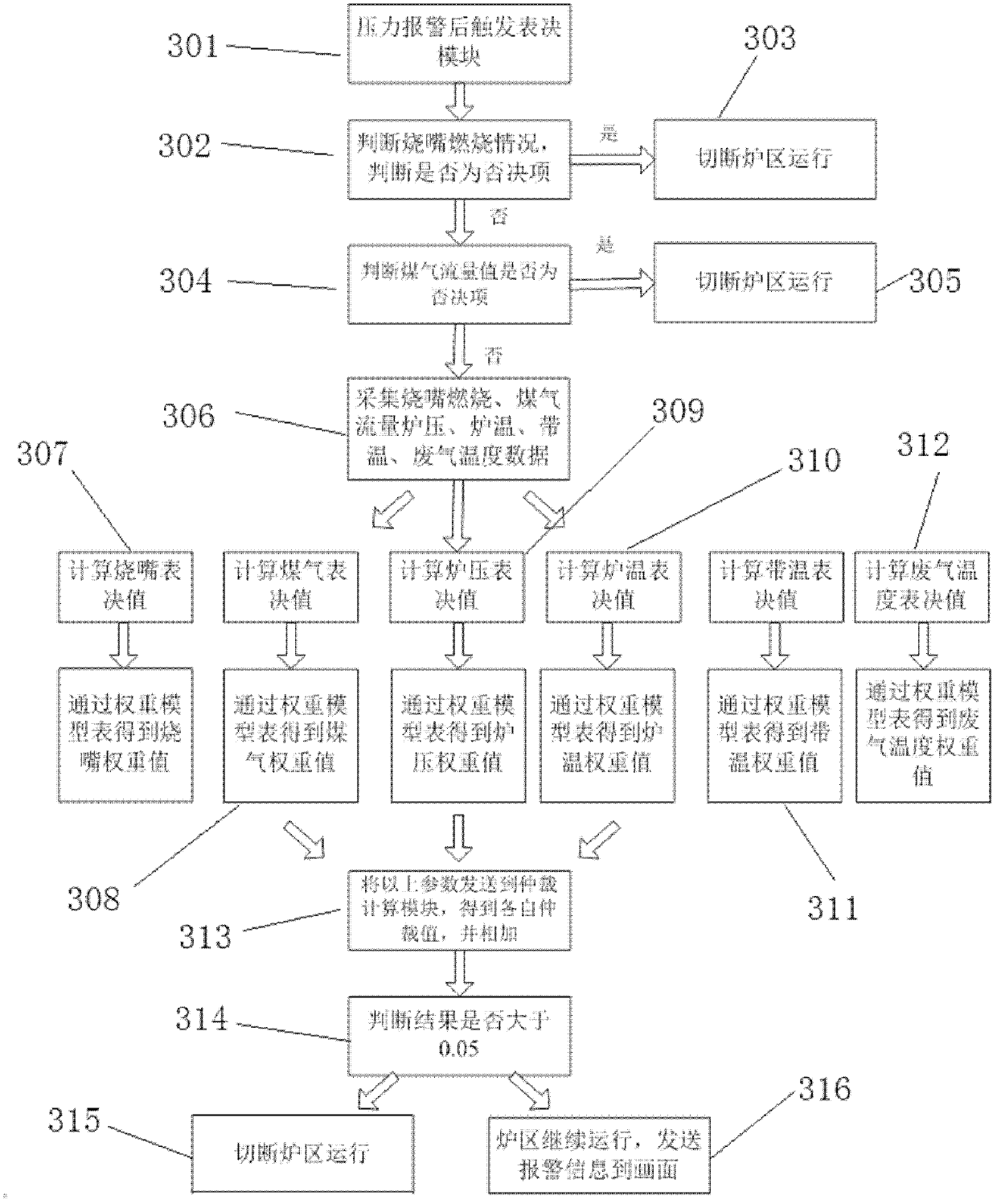

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

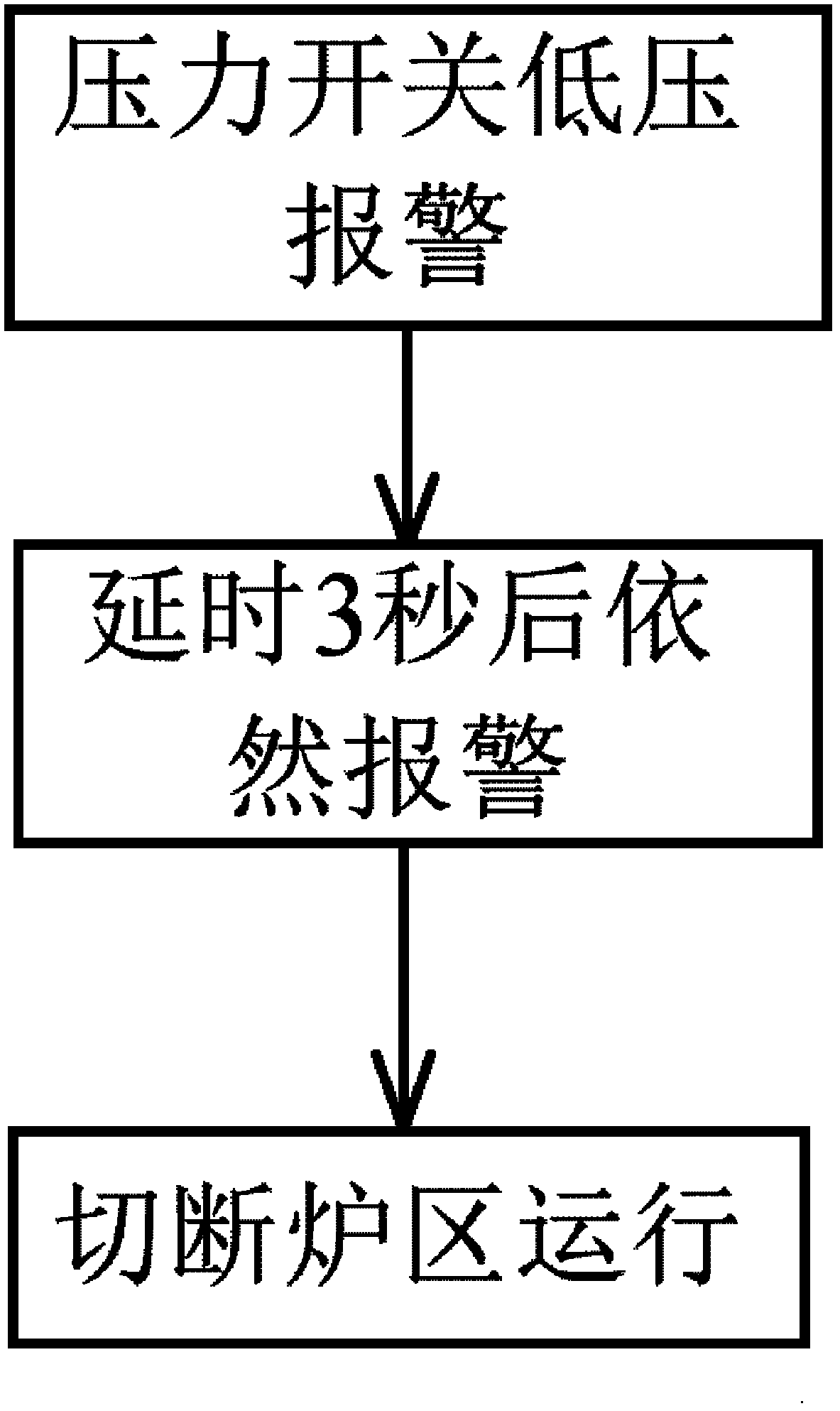

[0023] The control device for the pressure alarm of the continuous annealing furnace of the present invention mainly includes three modules, that is, a pressure switch low pressure alarm module, a voting module and an arbitration module. Utilizing these three modules, it can be seen that the control method of the continuous annealing furnace pressure alarm of the present invention does not directly cut off the operation of the entire furnace section when the gas pipeline pressure is low and alarms, but determines whether the multiple peripheral parameter values are normal, according to The importance is assigned weights and voted uniformly, and the final judgment is made by the arbitration module. If the arbitration module believes that the advantages are greater than the disadvantages according to the voting results, the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com