Method for realizing deep desulfurization during converter steelmaking through singly-blowing magnesium grain molten iron pretreatment

A technology of hot metal pretreatment and converter steelmaking, which is applied in the field of metallurgical steelmaking, can solve the problems of restricting the development of low-sulfur steel types, high sulfur content, and easy resulfurization, and achieve ideal deep desulfurization effects and optimized process effects

Inactive Publication Date: 2011-06-15

通化市通关达环保技术设备有限公司

View PDF1 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, most of the domestic iron and steel enterprises, when developing and producing low-sulfur steel grades, the desulfurization of molten iron is not complete, and the pass rate of deep desulfurization (sulfur content at the end of desulfurization ≤ 0.002%) is less than 30%. The lower the sulfur is, the easier it is to return sulfur in the converter process, especially when the molten iron sulfur is ≤0.020%, the converter basically has no desulfurization ability; the desulfurized molten iron is seriously returned to sulfur during the converter smelting process (returning sulfur> 0.006%), making the end point of converter smelting containing sulfur The amount of sulfur is too high, and the sulfur in the final finished steel exceeds the range, which limits the development of low-sulfur steel grades

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

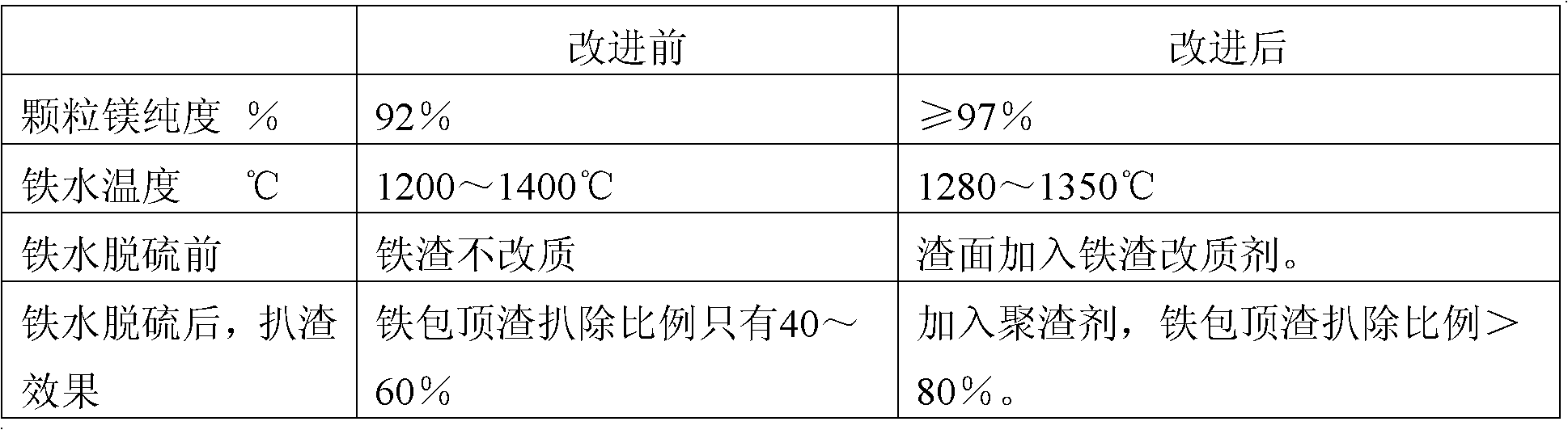

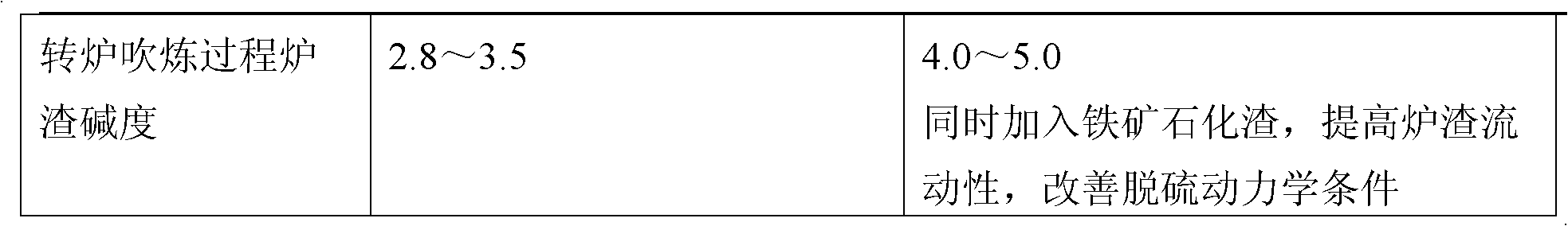

The invention relates to the metallurgical steelmaking field, in particular to a method for realizing deep desulfurization during converter steelmaking through the singly-blowing magnesium grain molten iron pretreatment. The method comprises the following steps: performing molten iron pretreatment, performing skimming of iron slag and smelting in a converter, wherein in the molten iron pretreatment, the temperature of molten iron is 1280-1350 DEG C, iron slag modifier is added in a ladle before molten iron is pouring in the ladle; the purity of singly-blowing magnesium grains is not less than 97%; slag conglomeration agent is added after the desulfurization of granulated magnesium, then the skimming of iron slag is performed; and the basicity of slag is 4.0-5.0 in the converting process of the converter. By adopting the method of the invention, the deep desulfurization qualification rate of molten iron pretreatment is more than 98%, the sulfur content of the treated molten iron remains stable, the recovered sulfur of molten iron is no more than 0.003% in the converting process, the average sulfur content of steel discharged by the converter is less than 0.005% and stable and ideal deep desulfurization effect can be realized.

Description

A method for deep desulfurization in converter steelmaking by pretreatment of single-blowing granular magnesium molten iron technical field The invention relates to the field of metallurgical steelmaking, that is, a method for realizing deep desulfurization in converter steelmaking by single-blowing granular magnesium molten iron pretreatment. Background technique In the prior art, converter steelmaking includes steps such as molten iron pretreatment, iron slag removal and converter smelting. Process flow of molten iron pretreatment: iron ladle is placed on the tipping car → the tipping car is driven to the injection position → the amount of powder injection is determined → the gun is lowered and sprayed → the spray gun is lifted and cleaned → sampling (S end point analysis) → the iron ladle is overturned , Slag removal operation → ladle reset → temperature measurement → S end point meets the requirements of the regulations, and the tipping car is driven out. At present, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21C7/064C21C7/00C21C5/28

Inventor 关云彪

Owner 通化市通关达环保技术设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com