Inorganic paste for internal thermal insulation of buildings and preparation method thereof

A technology of inorganic cementitious materials in buildings, applied in the field of inorganic paste for thermal insulation in buildings and its preparation, can solve problems such as easy cracking, poor fire resistance, environmental pollution, etc., to ensure product quality, good heat insulation and noise reduction , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

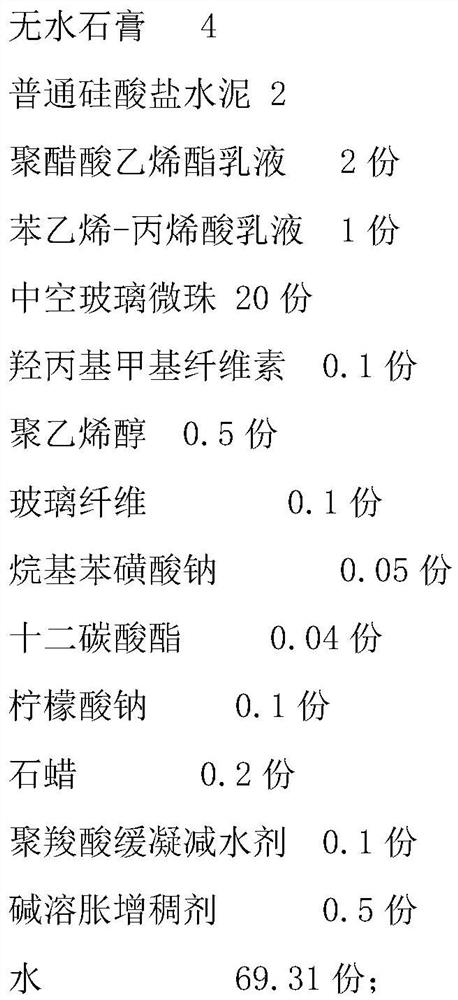

Embodiment 1

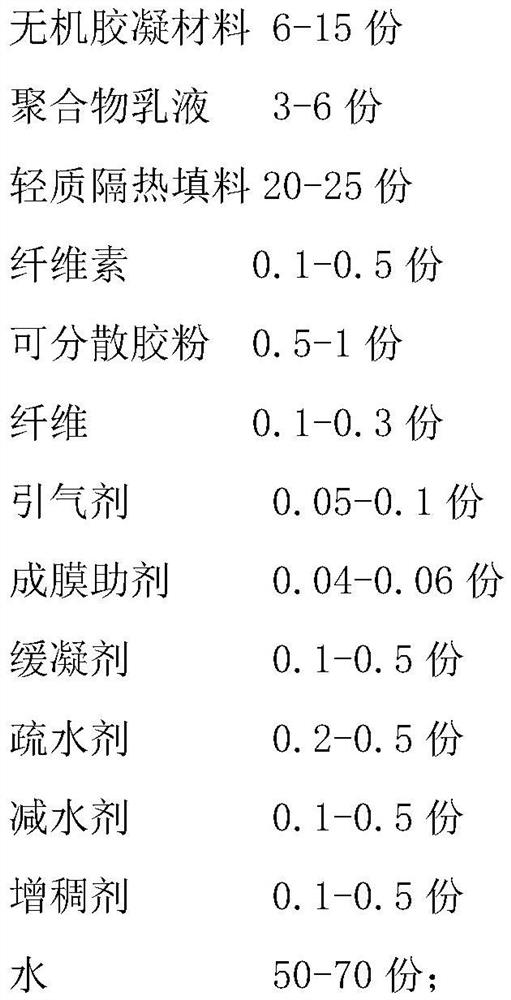

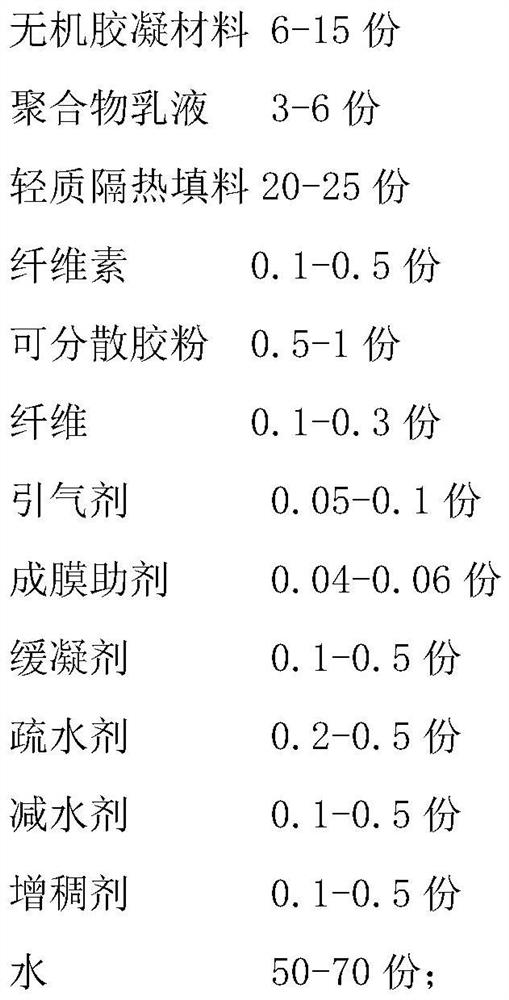

[0047] An inorganic paste for thermal insulation in buildings according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0048]

[0049] The fiber length of the glass fibers is 4 mm.

[0050] The preparation method of the inorganic paste for thermal insulation in the building mainly includes the following steps carried out in sequence:

[0051] (1) Preparation of inorganic gelling materials:

[0052] Mix anhydrite and ordinary Portland cement evenly according to the mass ratio to make the inorganic gelling material; (2) Prepare inorganic paste for building interior insulation:

[0053] (1) Mix and stir hollow glass microspheres, inorganic gelling materials, hydroxypropyl methylcellulose, sodium citrate, polyvinyl alcohol, polycarboxylate retarding water reducer and paraffin;

[0054] (2) Fully mix water, alkali swelling thickener, dodecyl carbonate, sodium alkylbenzene sulfonate, polyvinyl ...

Embodiment 2

[0057] An inorganic paste for thermal insulation in buildings according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0058]

[0059] The fibers are inorganic mineral fibers with a fiber length of 3 mm.

[0060] The preparation method of the inorganic paste for thermal insulation in the building mainly includes the following steps carried out in sequence:

[0061] (1) Preparation of inorganic gelling materials:

[0062] Mix anhydrite and ordinary Portland cement evenly according to the mass ratio to make the inorganic gelling material; (2) Prepare inorganic paste for building interior insulation:

[0063] (1) Mix and stir hollow glass microspheres, inorganic gelling materials, hydroxypropyl methylcellulose, sodium citrate, polyvinyl alcohol, polycarboxylate retarding water reducer and paraffin;

[0064] (2) Fully mix water, polyurethane thickener, dodecyl carbonate, rosin resin, polyviny...

Embodiment 3

[0067] An inorganic paste for thermal insulation in buildings according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0068]

[0069] The fibers are inorganic mineral fibers with a fiber length of 6 mm.

[0070] The preparation method of the inorganic paste for thermal insulation in the building mainly includes the following steps carried out in sequence:

[0071] (1) Preparation of inorganic gelling materials:

[0072] Mix anhydrite and ordinary portland cement uniformly according to the mass ratio to make the inorganic cementitious material;

[0073] (2) Preparation of inorganic paste for thermal insulation in buildings:

[0074] (1) Mix and stir hollow glass microspheres, inorganic gelling materials, hydroxypropyl methylcellulose, hexadecanoate, polyvinyl alcohol, polycarboxylic acid retarding water reducer and polyolefin;

[0075] (2) Fully mix water, alkali swelling thickener, hexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com