Automobile clutch cover forming coining die

A technology of clutch cover and fine pressing, which is applied in the direction of forming tools, manufacturing tools, vehicle parts, etc., can solve the problems of poor milling flatness and surface roughness, affecting product performance, etc., to ensure product performance, improve flatness and Effect of Surface Roughness Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

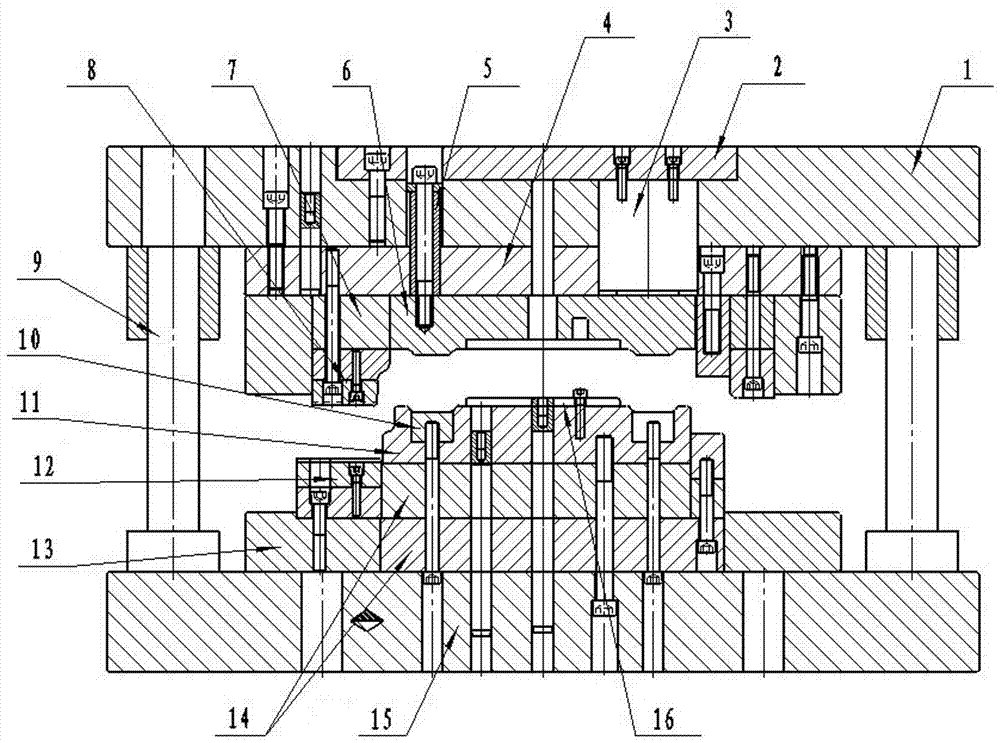

[0014] Such as figure 1 As shown, the fine pressing mold for forming the automobile clutch cover consists of an upper mold base 1, a nitrogen spring cover plate 2, a nitrogen spring 3, an upper backing plate 4, a contour sleeve 5, an upper mold core 6, a press block backing plate 7, an upper Press block 8, guide 9, lower mold core insert 10, lower mold core 11, lower pressure block 12, lower discharge plate 13, lower mold core backing plate 14, lower mold base 15, middle hole positioning 16, etc. Among them, the upper mold core 6 can move up and down through the nitrogen spring 3, the nitrogen spring cover plate 2 is locked on the upper mold base 1 by screws, which is convenient for disassembly and assembly, and the contour sleeve 5 ensures that the upper mold core 6 is vertical when it goes down, and the lower mold core is inlaid Part 10 can be taken out separately, and its precision is guaranteed by surface grinding, which is more convenient for adjusting the depth of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com