Packing structure for RF microwave power amplifier

A packaging structure and RF power amplifier technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of thin-film circuit customization, low capacitance precision, and long R&D cycle, etc., to improve heat dissipation effect, Reduce the R&D cycle and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

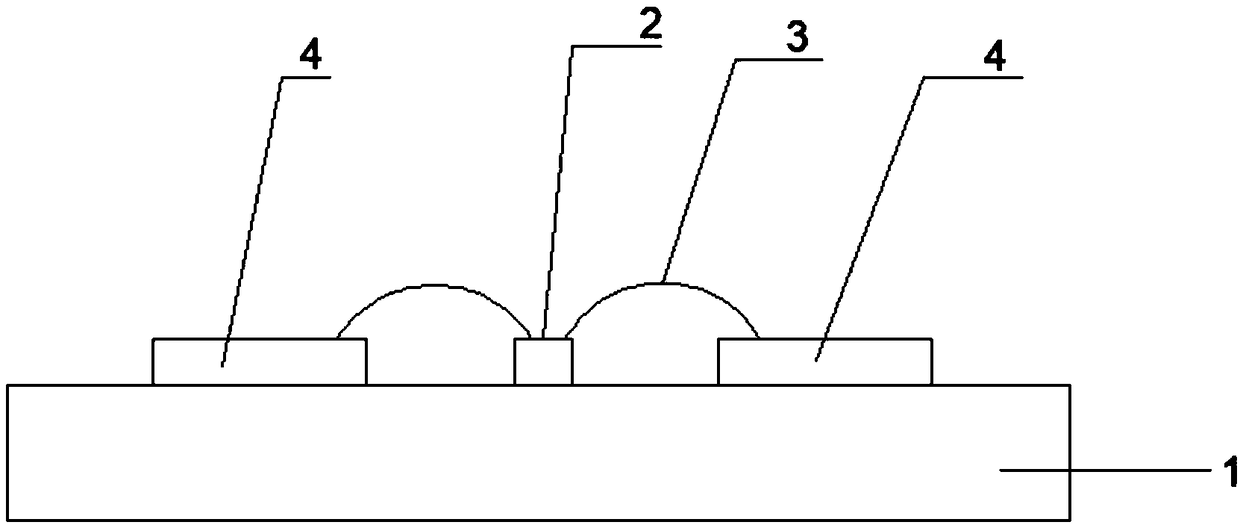

[0021] Such as figure 2 As shown, the present invention proposes a packaging structure for radio frequency microwave power amplifier devices, including a GaN radio frequency power amplifier chip 2, a PCB circuit board 4, a copper-containing metal substrate 1 and a passive device 5, and the GaN radio frequency power amplifier chip 2 is arranged on a copper-containing On the metal substrate 1, the passive device 5 is arranged on the PCB circuit board 4, the GaN radio frequency power amplifier chip 2 is electrically connected to the PCB circuit board 4 through the gold wire 3, and the inner surface of the copper-containing metal substrate 1 is provided with a first groove and a second groove. Two grooves, the PCB circuit board 4 is fixedly arranged in the first groove and the second groove, and the passive device 5 is one or more of capacitors, inductors, resistors or microstrip lines.

[0022] Through the use of copper-containing metal substrates, the heat dissipation of the ch...

Embodiment 2

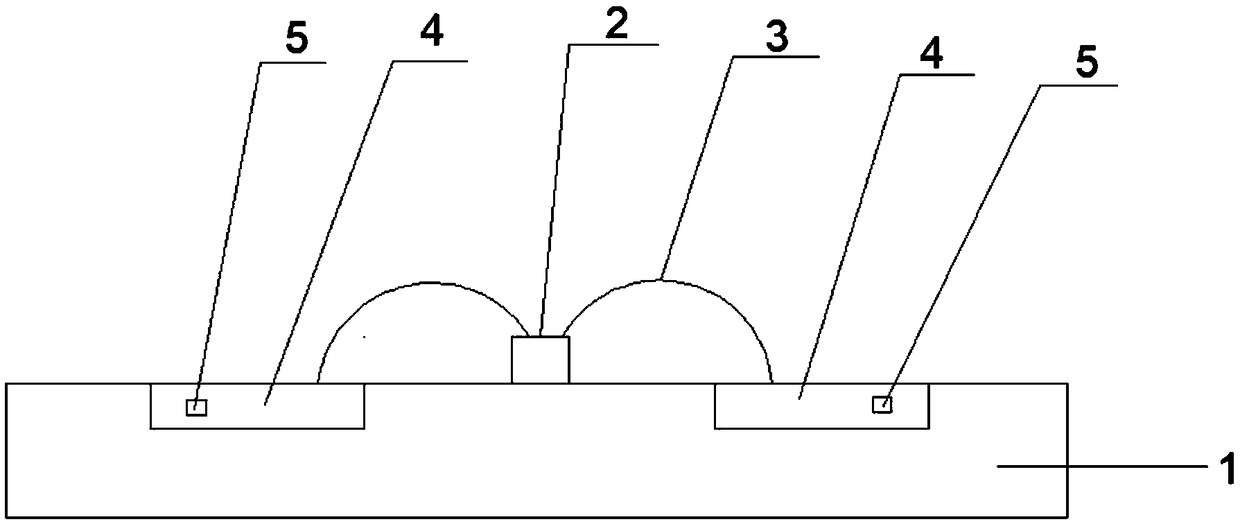

[0024] Such as figure 2 As shown, the present invention proposes a packaging structure for radio frequency microwave power amplifier devices, including a GaN radio frequency power amplifier chip 2, a ceramic circuit board 4, a copper-containing metal substrate 1 and a passive device 5, and the GaN radio frequency power amplifier chip 2 is arranged on a copper-containing On the metal substrate 1, the passive device 5 is arranged on the ceramic circuit board 4, the GaN radio frequency power amplifier chip 2 is electrically connected to the ceramic circuit board 4 through the copper wire 3, and the inner surface of the copper-containing metal substrate 1 is provided with a first groove and a second groove. Two grooves, the ceramic circuit board 4 is fixedly arranged in the first groove and the second groove, and the passive device 5 is one or more of capacitors, inductors, resistors or microstrip lines.

Embodiment 3

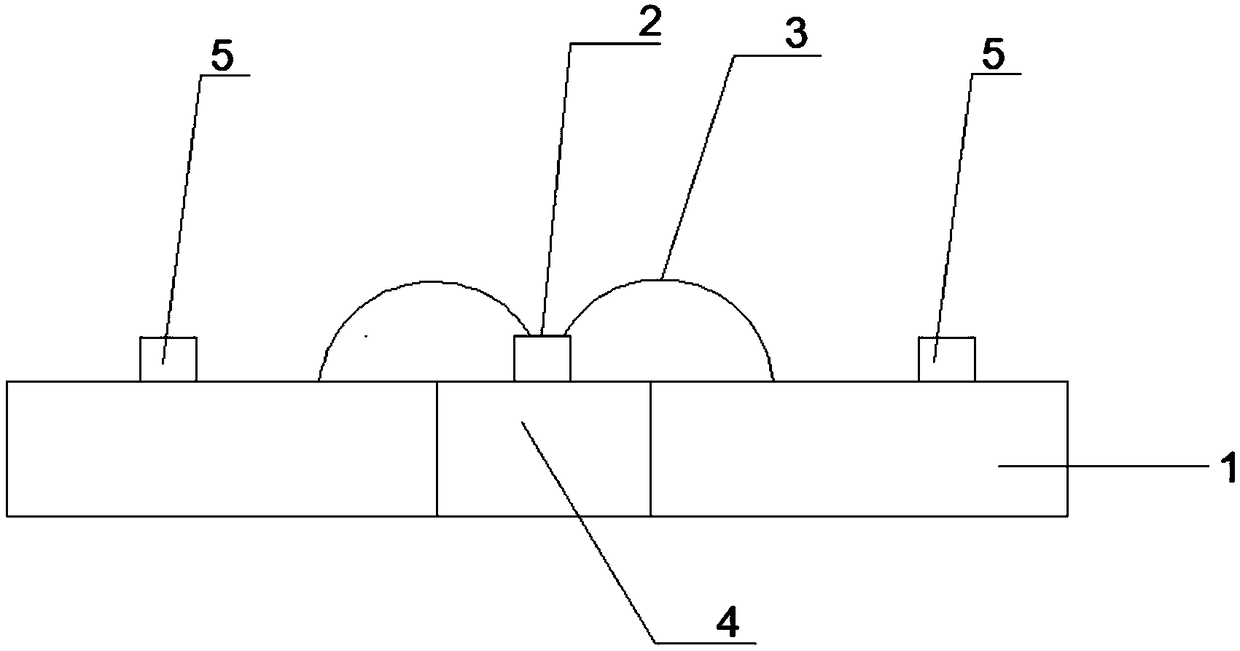

[0026] Such as image 3 As shown, the present invention proposes a packaging structure for radio frequency microwave power amplifier devices, including a PCB circuit board 1, a GaN radio frequency power amplifier chip 2, a copper substrate 4 and a passive device 5, and the GaN radio frequency power amplifier chip 2 is arranged on the copper substrate 4 , the passive device 5 is arranged on the PCB circuit board 1, the GaN radio frequency power amplifier chip 2 is electrically connected to the PCB circuit board 1 through the gold wire 3, the PCB circuit board 1 is provided with a cavity, and the copper substrate 4 is embedded in the cavity, without The source device 5 is one or more of capacitors, inductors, resistors or microstrip lines.

[0027] By adopting PCB circuit board, opening a hole in the middle of PCB circuit board, embedding copper substrate to improve the heat dissipation capability of GaN RF power amplifier chip, passive components connect the circuit through PCB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com