Preparation method and application of subsphaeroidal metal powder for anticorrosion repair spraying

A kind of metal powder, nearly spherical technology, applied in the direction of metal processing equipment, metal material coating process, coating, etc., can solve the problems of cost resource waste, high alloy composition, increase the impact and burden of the environment, etc., and achieve corrosion resistance Excellent performance, enhanced surface strength, and balanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

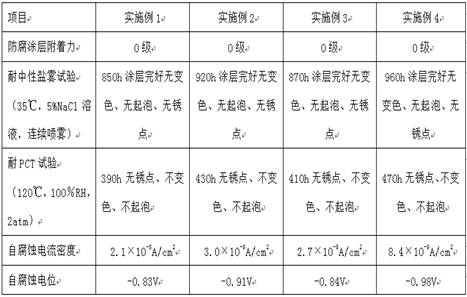

Examples

Embodiment 1

[0050] An application of a near-spherical metal powder for anti-corrosion repair spraying, which is used for anti-corrosion and repair of component surfaces. Including the following steps: surface treatment, spraying, cladding.

[0051] The surface treatment refers to the treatment of the parts that need to be anti-corrosion or repaired on the mechanical surface or inside of the component, to remove burrs and rust on the surface of the component, and to ensure that the derusting level of the surface of the component is not lower than Sa3.0.

[0052] In the spraying, the near-spherical metal powder for anti-corrosion restoration spraying is put into the spraying system, and the metal powder is thermally sprayed on the surface of the component to form a coating.

[0053] In the cladding, cladding treatment is performed on the sprayed coating.

[0054] The preparation method of the near-spherical metal powder for anti-corrosion repair spraying includes the following steps: mater...

Embodiment 2

[0078] An application of a near-spherical metal powder for anti-corrosion repair spraying, which is used for anti-corrosion and repair of component surfaces. Including the following steps: surface treatment, spraying, cladding.

[0079] The surface treatment refers to the treatment of the parts that need to be anti-corrosion or repaired on the mechanical surface or inside of the component, to remove burrs and rust on the surface of the component, and to ensure that the derusting level of the surface of the component is not lower than Sa3.0.

[0080] In the spraying, the near-spherical metal powder for anti-corrosion restoration spraying is put into the spraying system, and the metal powder is thermally sprayed on the surface of the component to form a coating.

[0081] In the cladding, cladding treatment is performed on the sprayed coating.

[0082] The preparation method of the near-spherical metal powder for anti-corrosion repair spraying includes the following steps: mater...

Embodiment 3

[0106] An application of a near-spherical metal powder for anti-corrosion repair spraying, which is used for anti-corrosion and repair of component surfaces. Including the following steps: surface treatment, spraying, cladding.

[0107] The surface treatment refers to the treatment of the parts that need to be anti-corrosion or repaired on the mechanical surface or inside of the component, to remove burrs and rust on the surface of the component, and to ensure that the derusting level of the surface of the component is not lower than Sa3.0.

[0108] In the spraying, the near-spherical metal powder for anti-corrosion restoration spraying is put into the spraying system, and the metal powder is thermally sprayed on the surface of the component to form a coating.

[0109] In the cladding, cladding treatment is performed on the sprayed coating.

[0110] The preparation method of the near-spherical metal powder for anti-corrosion repair spraying includes the following steps: mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com