Motor mandrel surface strengthening layer compound technology

A technology of surface strengthening layer and composite technology, which is applied in the field of composite technology, can solve problems such as roughening of the working surface of the bearing position, scrapping and replacement of the mandrel, and affecting the working environment, so as to prolong the service life, save production costs, and avoid interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

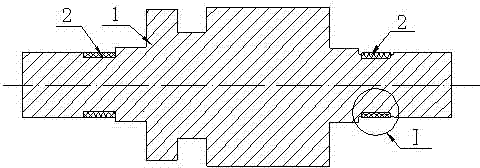

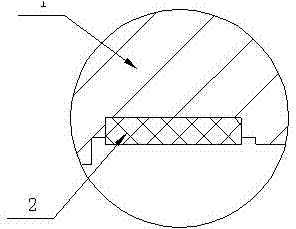

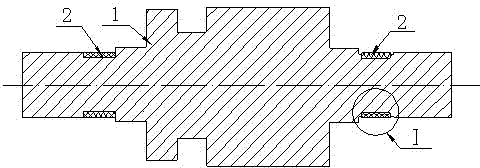

Image

Examples

Embodiment 1

[0026] The motor mandrel surface strengthening layer composite process provided by the present invention goes through the following process steps:

[0027] A. According to routine, pour industrial grade alcohol and acetone sequentially on the working surface at both ends of the motor mandrel with medium carbon quenched and tempered steel as the body, to clean the oil and impurities on the working surface;

[0028] B. Use a conventional blowtorch to heat the working surface of the motor mandrel treated in step A to 40°C;

[0029] C. Adopt a conventional pneumatic powder feeding device to send austenitic stainless steel powder with a particle size of 100 mesh to the working surface of the motor mandrel in step B with argon gas with a purity of 99.99%;

[0030] D. Under the rotation speed of the motor mandrel is 400mm / min, use a conventional laser to irradiate the equipment, and within the spot range with a power of 3.5KW and a bandwidth of 3mm in diameter, the laser irradiates t...

Embodiment 2

[0033] The motor mandrel surface strengthening layer composite process provided by the present invention goes through the following process steps:

[0034] A. According to routine, pour industrial grade alcohol and acetone sequentially on the working surface at both ends of the motor mandrel with medium carbon quenched and tempered steel as the body, to clean the oil and impurities on the working surface;

[0035] B. Use a conventional blowtorch to heat the working surface of the motor mandrel treated in step A to 100°C;

[0036] C, adopting conventional pneumatic powder feeding device, the martensitic stainless steel powder with a particle size of 300 mesh is sent to the working surface of the motor mandrel in step B with argon gas with a purity of 99.99%;

[0037] D. Under the rotation speed of the motor mandrel is 700mm / min, use a conventional laser to irradiate the equipment, and within the spot range with a power of 3.5KW and a bandwidth of 3mm in diameter, the laser irra...

Embodiment 3

[0040] The motor mandrel surface strengthening layer composite process provided by the present invention goes through the following process steps:

[0041] A. According to routine, pour industrial grade alcohol and acetone sequentially on the working surface at both ends of the motor mandrel with medium carbon quenched and tempered steel as the body, to clean the oil and impurities on the working surface;

[0042] B. Use a conventional gas furnace to heat the working surface of the motor mandrel treated in step A to 70°C;

[0043] C. Adopt a conventional pneumatic powder feeding device to send the duplex stainless steel powder with a particle size of 200 mesh to the working surface of the motor mandrel in step B with argon gas with a purity of 99.99%;

[0044] D. Under the rotational speed of the motor mandrel at 500mm / min, use a conventional laser to irradiate the equipment, and within the spot range with a power of 3.5KW and a bandwidth of 3mm in diameter, the laser irradiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com