Dual air gap grinding head through grinding machine for grinding magnetic core

A double air gap and air gap technology is applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, electrical components, etc., which can solve the problems of insufficient utilization, time-consuming and labor-intensive, etc., to save time and cost, and ensure product quality performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

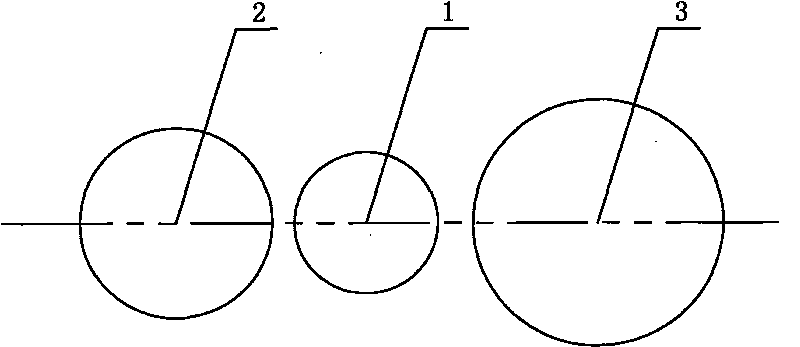

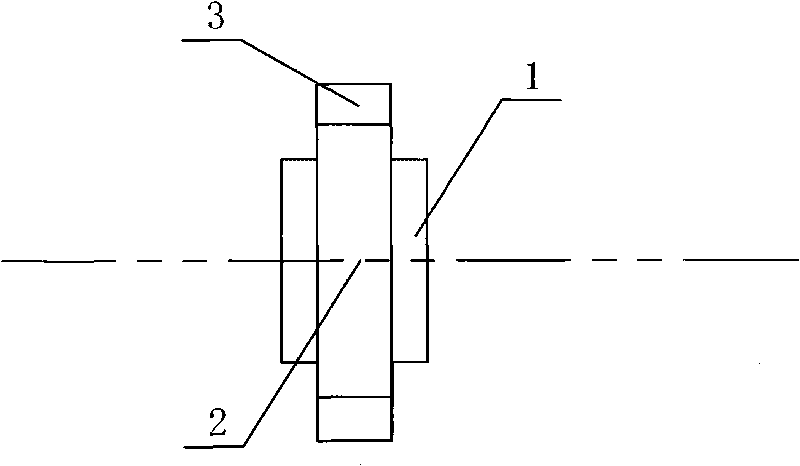

[0020] Such as figure 1 and figure 2 As shown, a double-air-gap grinding head pass-through grinding machine for grinding magnetic cores includes a main shaft grinding wheel 1, a first air-gap grinding wheel 2 arranged in front of the main shaft grinding wheel 1, and a second air-gap grinding wheel is arranged behind the main shaft grinding wheel 1 3. The centers of the first air-gap grinding wheel 2 and the second air-gap grinding wheel 3 are on the same horizontal line, and the diameter of the second air-gap grinding wheel 3 is larger than the diameter of the first air-gap grinding wheel 2 . Keep the bottom end position of the second air gap grinding wheel 3 lower than the bottom end position of the first air gap grinding wheel 2 .

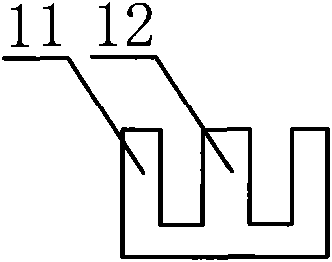

[0021] In actual operation, such as image 3 , is the unprocessed E-shaped magnetic core, after the first air-gap grinding wheel 2, the middle foot 12 of the E-shaped magnetic core is ground off by 1.5mm to form as Figure 4 State, and then ...

Embodiment 2

[0023] Such as Figure 7 and Figure 8 As shown, a double-air-gap grinding head pass-through grinding machine for grinding magnetic cores includes a main shaft grinding wheel 1, a first air-gap grinding wheel 2 arranged in front of the main shaft grinding wheel 1, and a second air-gap grinding wheel is arranged behind the main shaft grinding wheel 1 3. The diameter of the first air-gap grinding wheel 2 is the same as that of the second air-gap grinding wheel 3 , and the center of the second air-gap grinding wheel 3 is lower than the center of the first air-gap grinding wheel 2 . Keep the bottom end position of the second air gap grinding wheel 3 lower than the bottom end position of the first air gap grinding wheel 2 . Compared with Embodiment 1, the second air-gap grinding wheel 2 in this embodiment does not need to use a large-diameter grinding wheel, which saves costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com