Method for manufacturing lining plastic composite carbon steel pipe

A manufacturing method and composite carbon technology are applied in the manufacturing field of environmentally friendly composite pipes, which can solve problems such as poor composite quality of composite pipes, and achieve the effects of good rigidity, low production cost, and overcoming destructive effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

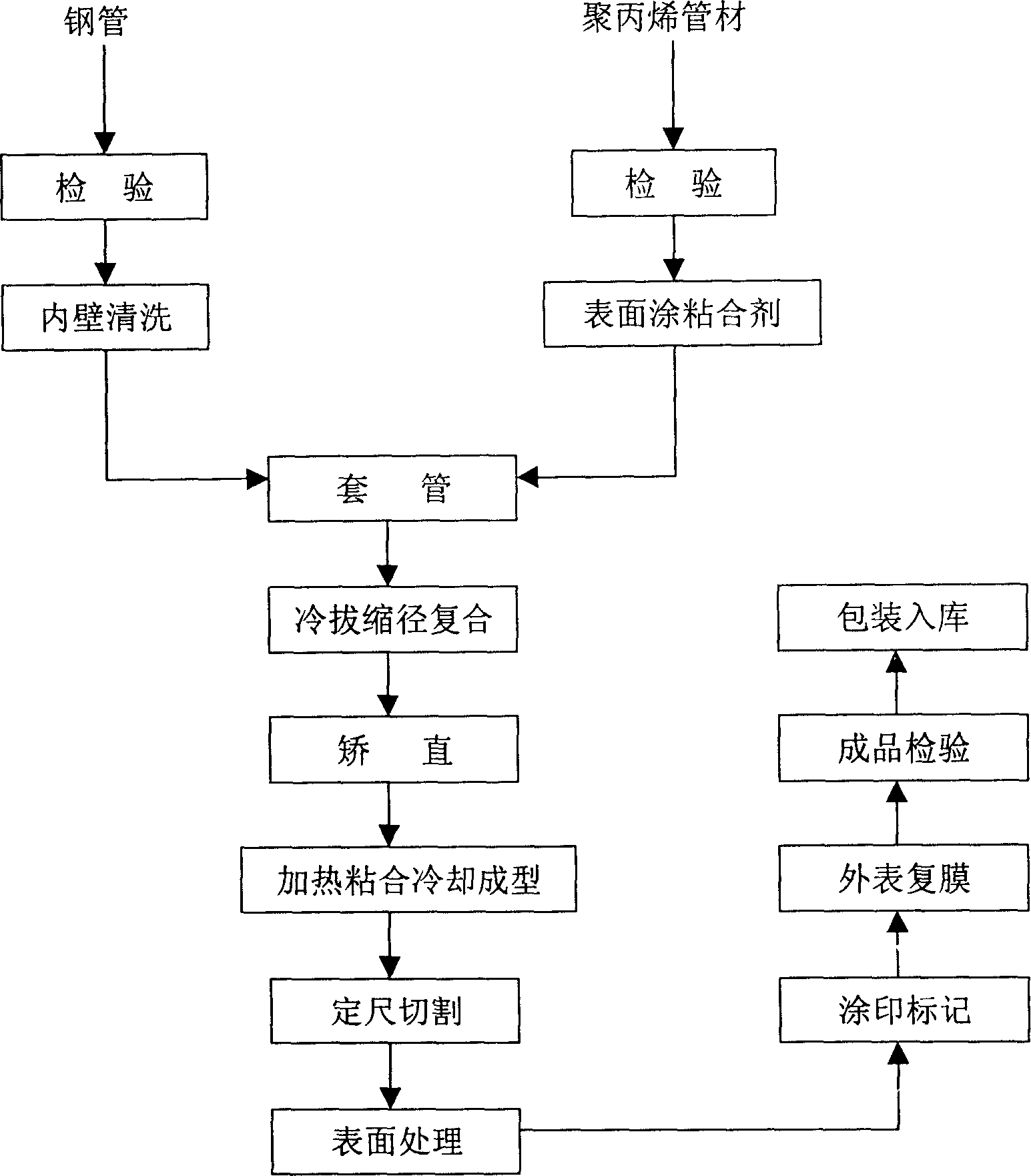

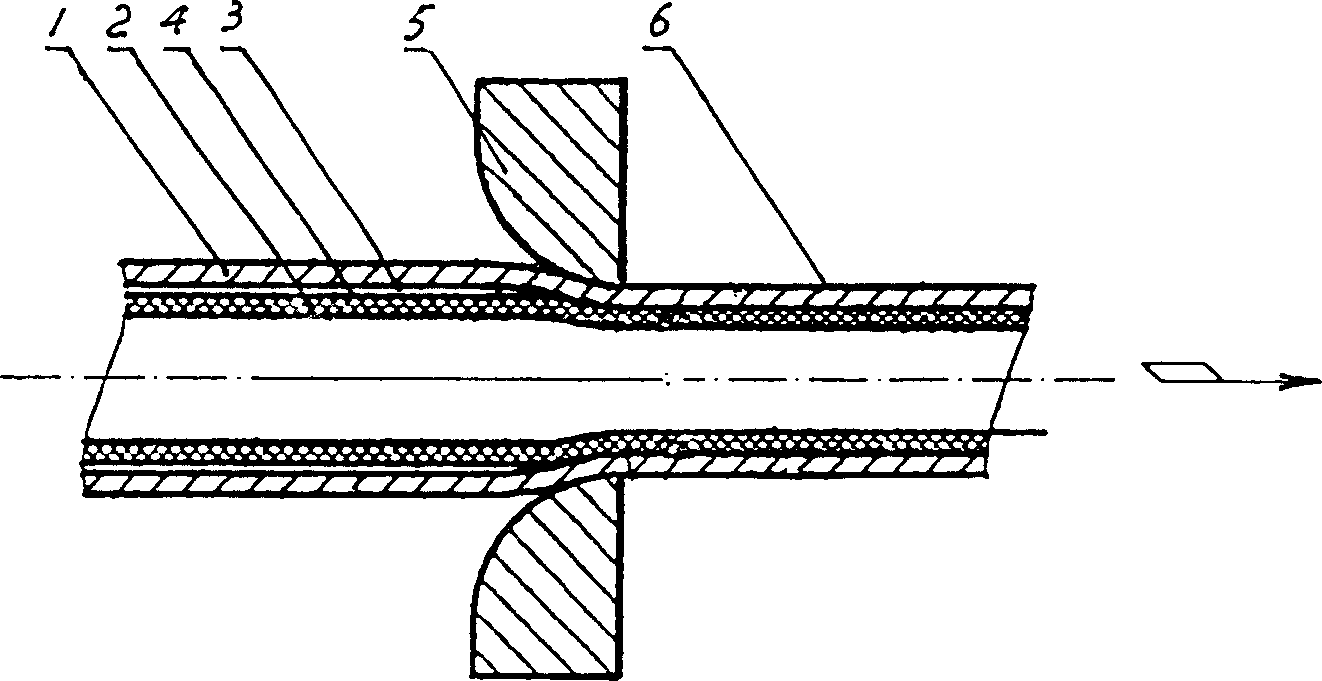

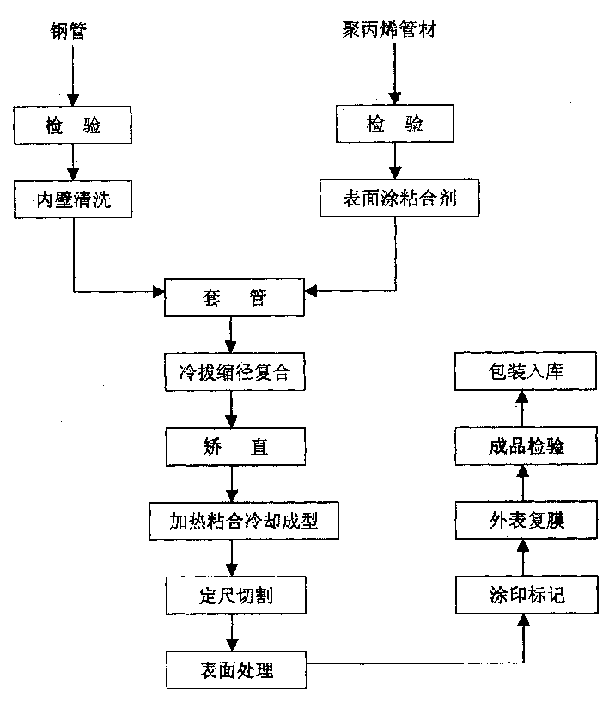

[0018] A method for manufacturing a liner composite carbon steel pipe. Firstly, the steel pipe 1 and the polypropylene plastic pipe 2 are inspected; the inner wall of the inspected steel pipe 1 is cleaned; the outer surface of the inspected polypropylene pipe 2 is coated with a glue machine. Apply a thin and uniform layer of adhesive 4 (that is, a hot melt that is solid at room temperature and melts when heated), and the thickness of the adhesive layer is controlled between 0.1 and 0.2 mm; the polypropylene tube 2 coated with adhesive Sleeve into the outer steel pipe 1, the sleeve gap 3 should be small and not large, so as not to damage the rubber layer; the fitted pipe is first sent to the general drawing machine to draw the mouth ring 5 compulsorily. pull out to reduce the diameter of the outer steel pipe 1, eliminate the casing gap 3, and properly make the polypropylene pipe 2 produce some elastic interference, so that the inner polypropylene pipe 2 and the outer steel pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com