A curved surface self-coupling automatic flaw detector for explosive welding and its application

An explosive welding and self-coupling technology, which is applied to instruments, scientific instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems that cannot meet the demand for flaw detection of explosive welding composite plates, and that curved plates cannot achieve probe coupling. Achieve the effect of realizing continuous automation, improving accuracy and reliability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the examples, but the protection scope of the present invention is not limited to the examples.

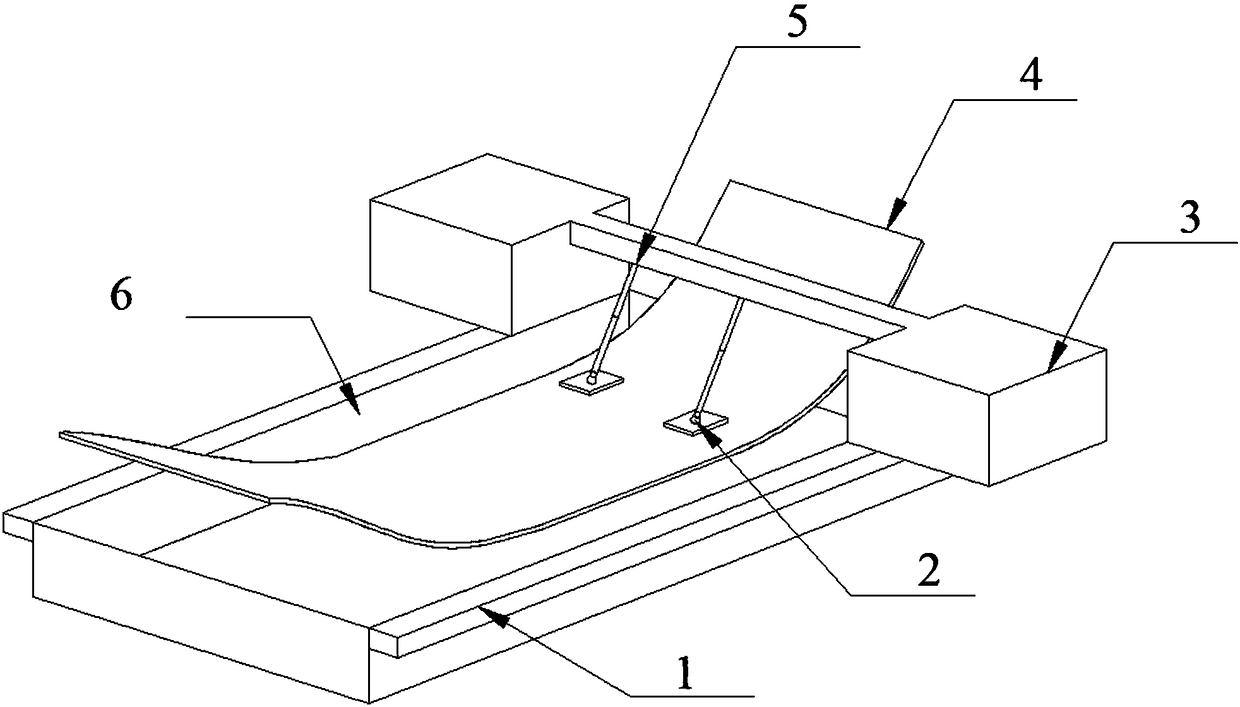

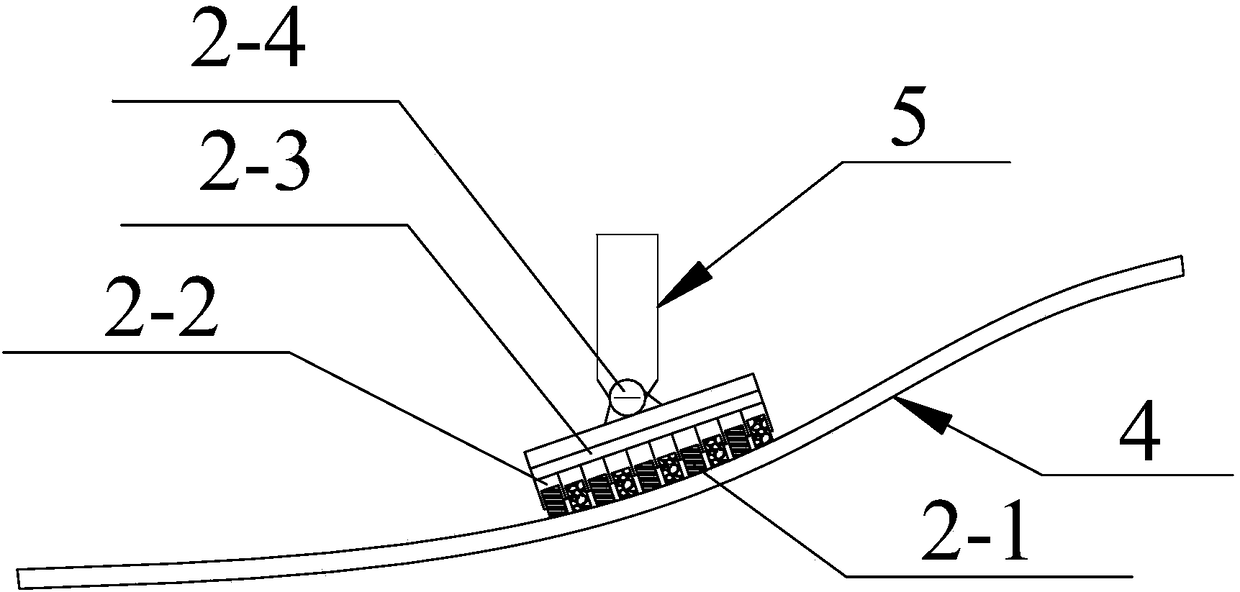

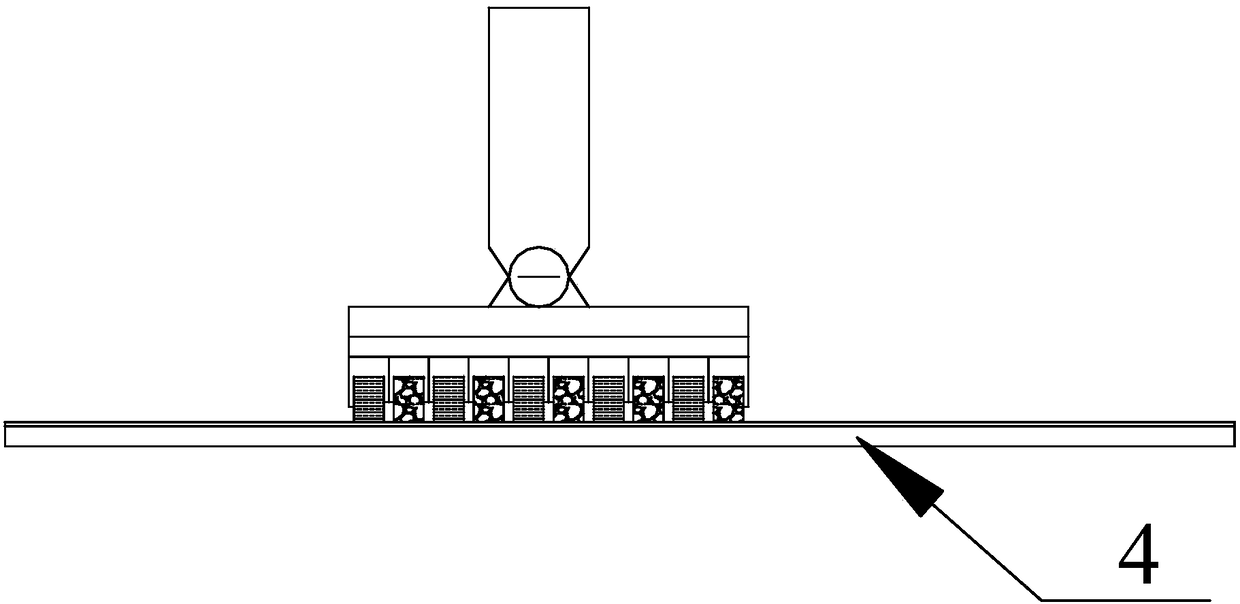

[0019] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a curved surface self-coupling automatic flaw detector for explosive welding has a flaw detection pool 6, a coupling probe 2 and an analyzer 3 arranged on both sides of the flaw detection pool. , and an analyzer 3 is set on each side. The two sides of the flaw detection cell 6 are provided with sliding rails 1 , and the bottom of the analyzer 3 slides on the sliding rail 1 , and the analyzers 3 on both sides are connected by a connecting rod. A rotating rod 5 is connected to the connecting rod. The bottom of the rotating rod 5 is connected to the coupling probe 2. One rotating rod 5 is connected to one coupling probe 2. The number of rotating rods 5 can be increased or decreased according to actual needs. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com