Method and system for monitoring motor temperature as well as method and system for controlling motor power

A technology of motor temperature and motor power, applied in the field of automotive power systems, can solve the problems of small power range, low system reliability and maintenance-free, and power changes are not smooth enough to achieve smooth power control, improve reliability and avoidance. The effect of maintainability, high accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order for those skilled in the art to better understand the technical solution of the present invention, the motor temperature monitoring method and system and the motor power control method and system provided by the present invention will be described in detail below with reference to the accompanying drawings.

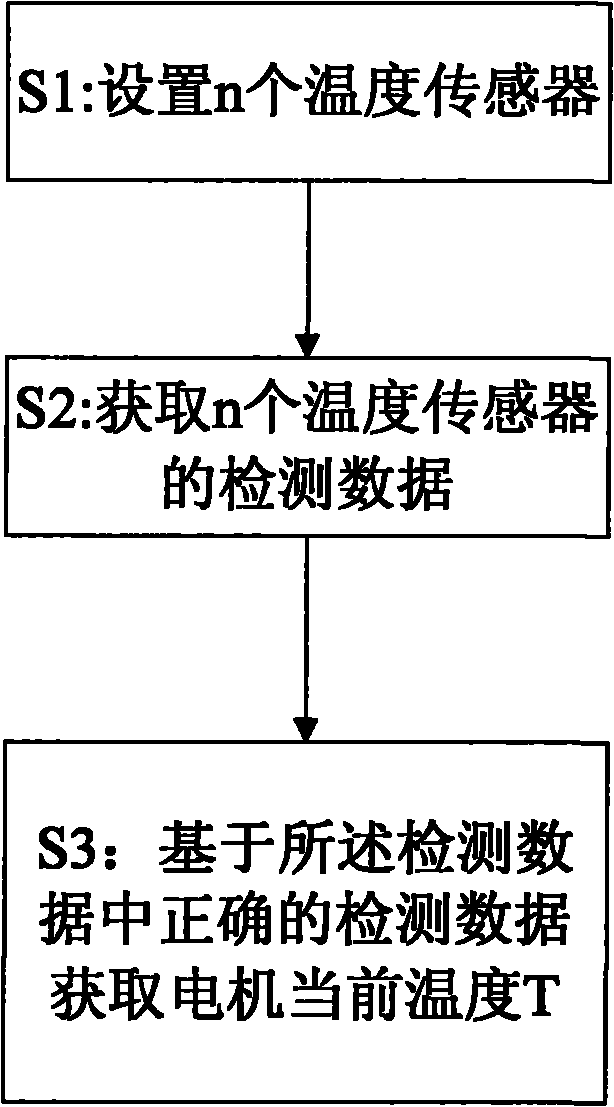

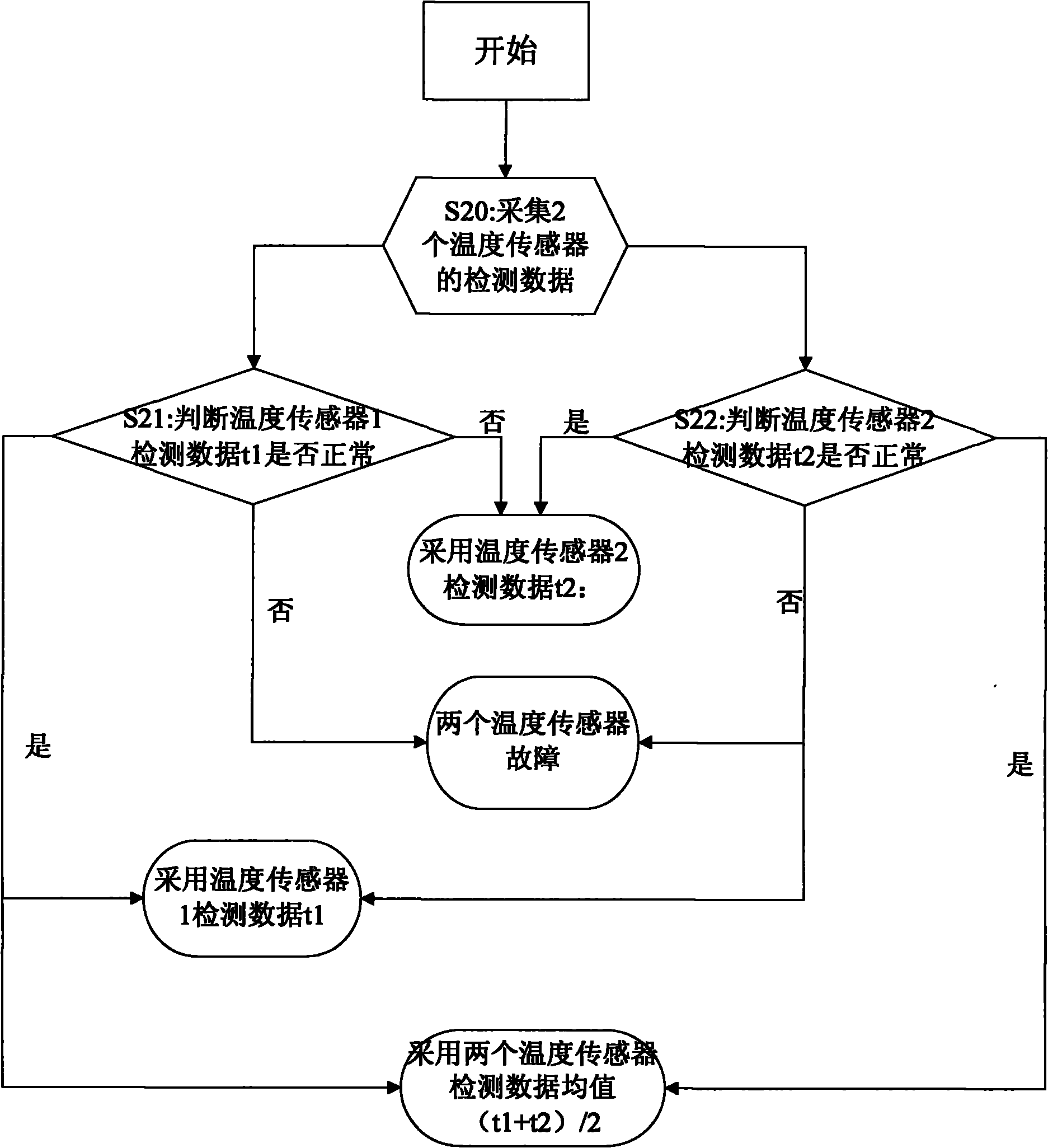

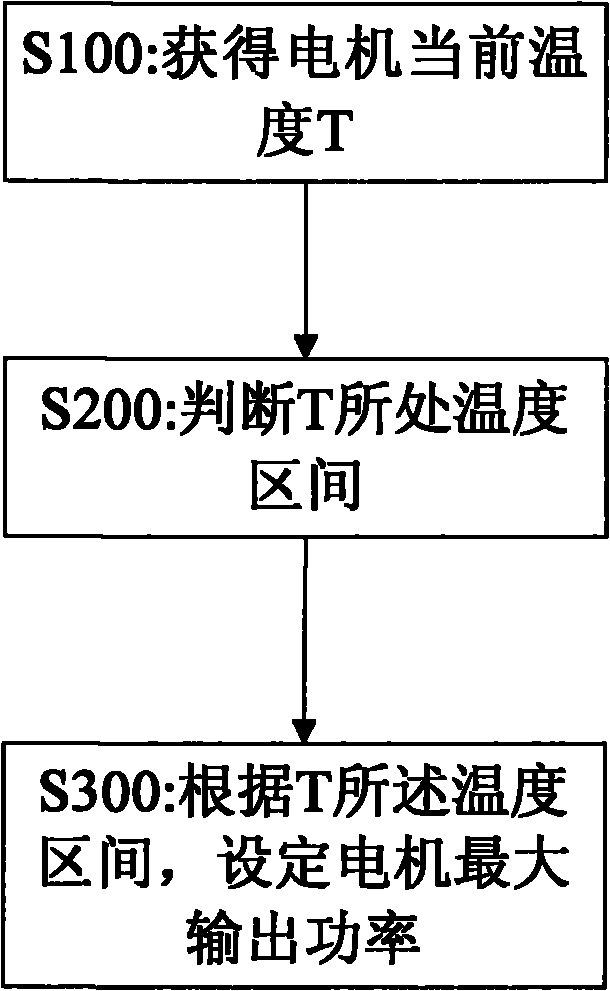

[0030] Such as figure 1 Shown is a flow chart of the motor temperature monitoring method of the present invention. In step S1, set n temperature sensors for detecting the current temperature T of the motor, where n≥2; in step S2, read the detection data of the n temperature sensors; in step S3, based on the n The current temperature T of the motor is obtained from the detection data of a temperature sensor that is working normally among the temperature sensors, where the temperature sensor includes: a temperature sensor, a thermocouple, and an infrared temperature sensor.

[0031] Wherein, since the current temperature T of the motor is obtained based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com