Device and method for solid-liquid separation in continuous production of rare-earth carbonate

A solid-liquid separation, rare earth carbonate technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of a large number of transfer tanks, long operation cycle, low efficiency, etc., to reduce labor intensity, reduce labor intensity, The effect of failure point reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

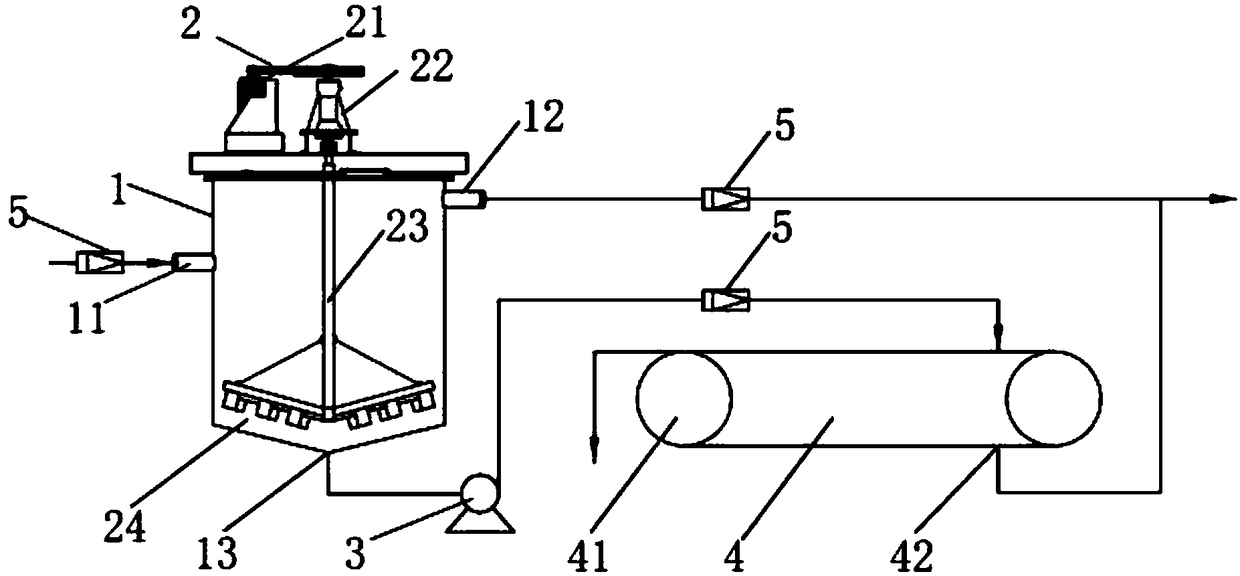

[0045] The lanthanum chloride feed solution and the precipitating agent ammonium bicarbonate are continuously precipitated and reach the end of the reaction, and the generated slurry enters the 20m 3 The solid-liquid separation tank 1, the flow rate of the entering slurry is 10m 3 / h; turn on the rake agitator 2 to stir, and require the solid-liquid volume ratio of the thick slurry outlet 13 to be 1:2, adjust the frequency of the frequency conversion motor 21 to 4Hz, and control the rotating speed to 6r / min; wait until the liquid level reaches the mother liquor outlet 12 and when the mother liquor flows out, turn on the pump 3 for pumping out the thick slurry, and adjust the frequency of the pump with a frequency converter so that the pumping flow is 3.5m 3 / h, the mother liquor flow rate in the upper part is 6.5m 3 / h;

[0046] The slurry extracted by the thick slurry extraction pump 3 is directly filtered through the vacuum filter 4 to obtain lanthanum carbonate with a tot...

Embodiment 2

[0049] The cerium chloride feed solution and the precipitating agent ammonium bicarbonate are continuously precipitated and reach the end of the reaction, and the generated slurry enters the 20m 3 In the solid-liquid separation tank 1, the incoming slurry flow rate is 12m 3 / h, start the rake agitator 2 to stir, require the solid-liquid volume ratio of the slurry at the thick slurry outlet 13 to be 1:2.5, adjust the frequency of the frequency conversion motor 21 to 5Hz, and control the rotating speed to 8r / min; wait until the liquid level reaches the mother liquor outlet 12 When the mother liquor flows out, turn on the pump 3 for pumping out the thick slurry, and adjust the frequency of the pump with a frequency converter so that the pumping flow is 3.8m 3 / h, the mother liquor flow rate in the upper part is 8.2m 3 / h;

[0050] The slurry extracted by the thick slurry extraction pump 3 is directly filtered through the vacuum filter 4 to obtain cerium carbonate with a total a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com