Straightener capable of changing rolls quickly

A straightening machine, fast technology, applied in the field of straightening machines, to achieve the effect of improving the efficiency of roll changing and equipment utilization, simple and convenient roll changing operation, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

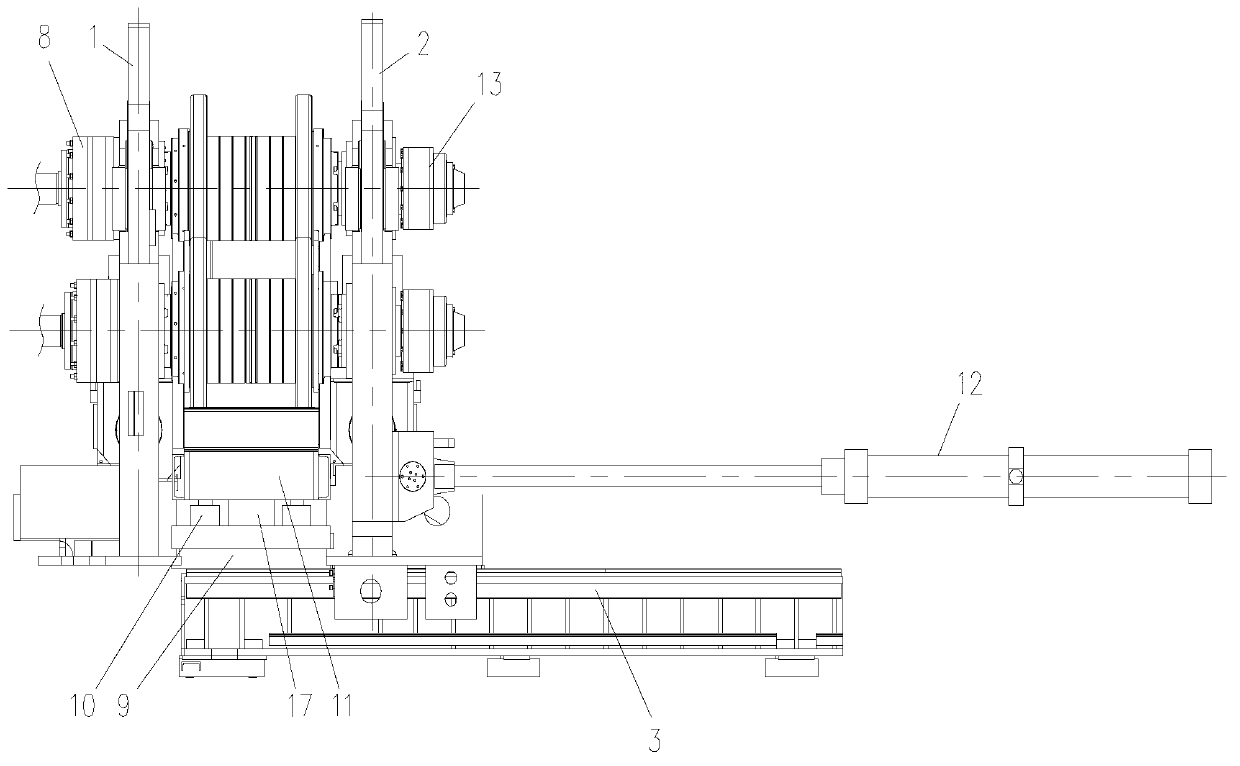

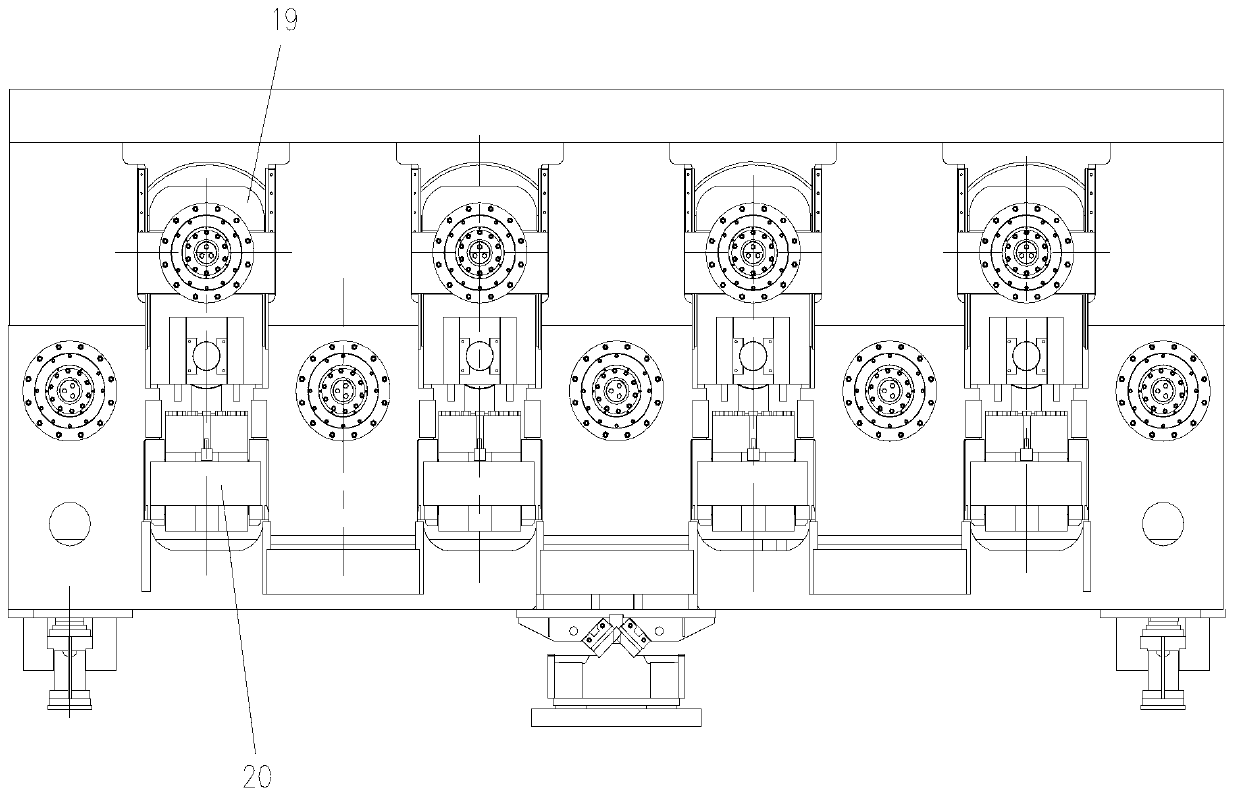

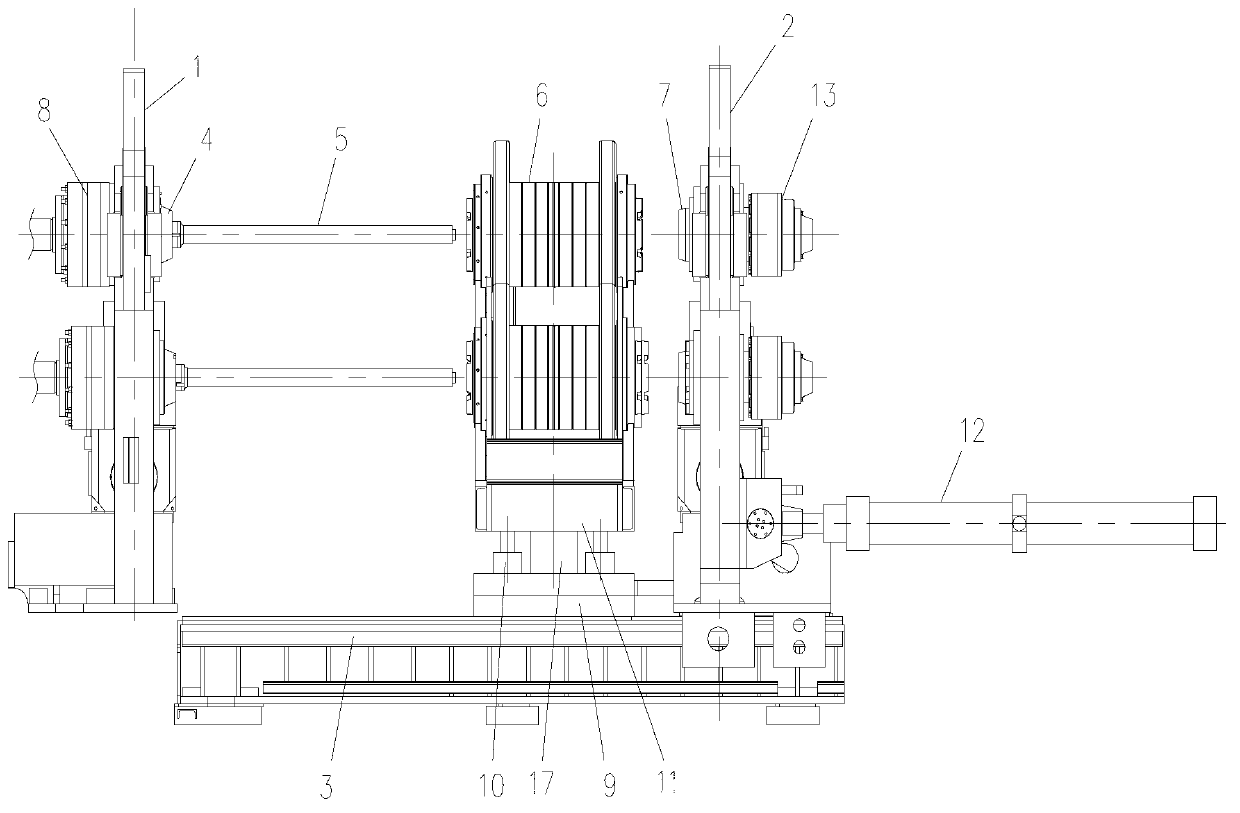

[0028] As shown in the figure, the straightening machine capable of rapid roll change in this embodiment includes the transmission side frame 1, the roller ring assembly 6, the sliding seat 3, and the operation that is arranged on the sliding seat 3 and cooperates with the sliding seat 3 in a linear reciprocating sliding manner. The side frame 2 and the traversing device 12 for driving and operating the side frame 2 to slide on the sliding seat 3 also include an on-machine roll changing device, and the on-machine roll changing device includes a roll changing trolley 9, a roller that is arranged on the roller changing trolley 9 The lifting device 10 and the roller ring storage platform 11 located directly below the roller ring assembly 6, the roller ring storage platform 11 is placed on the lifting device 10, and the roller ring storage platform 11 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com