Production method for preparing sodium m-aminobenzene sulfonate by means of continuous hydrogenation reduction

A technology of sodium sulfanilate and sodium nitrobenzenesulfonate, which is applied in the field of continuous hydrogenation reduction to prepare sodium m-aminobenzenesulfonate, which can solve the problems of unstable continuous hydrogenation process, high cost of hydrogenation catalyst, low reaction The problem of low concentration of substances can be solved to achieve the effect of increasing production capacity and equipment utilization rate, reducing production cost and equipment investment, and not reducing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1Pt-V-Mg / C catalyst preparation

[0025] Weigh 4.1g of activated carbon, place it in a 250ml round-bottomed flask, put it into a magnetic stirrer, add 200ml of concentrated nitric acid (65-68%), stir at 100-120°C for 4-16 hours, cool to deionize Wash and filter with water until the pH of the filtrate is neutral, and then dry in an oven at 50-120° C. for 12 hours to obtain 4 g of nitric acid-treated activated carbon. 0.32g chloroplatinic acid (H 2 PtCl 6 6H 2 O) Dissolve in 4ml of concentrated hydrochloric acid and add 40ml of water to dilute. Add 240ml of water and 4g of activated carbon treated with nitric acid into a 500ml four-necked bottle, add the pre-prepared chloroplatinic acid solution dropwise under stirring at 50°C, control the dropping time for about 2 hours, and continue stirring for 30 minutes after the dropping It is completely impregnated with activated carbon. Use saturated sodium carbonate solution to adjust the pH value between 7 and 8,...

Embodiment 2

[0027] Embodiment 2 adopts Pt-V-Mg / C catalyst continuous hydrogenation to prepare sodium m-aminobenzenesulfonate

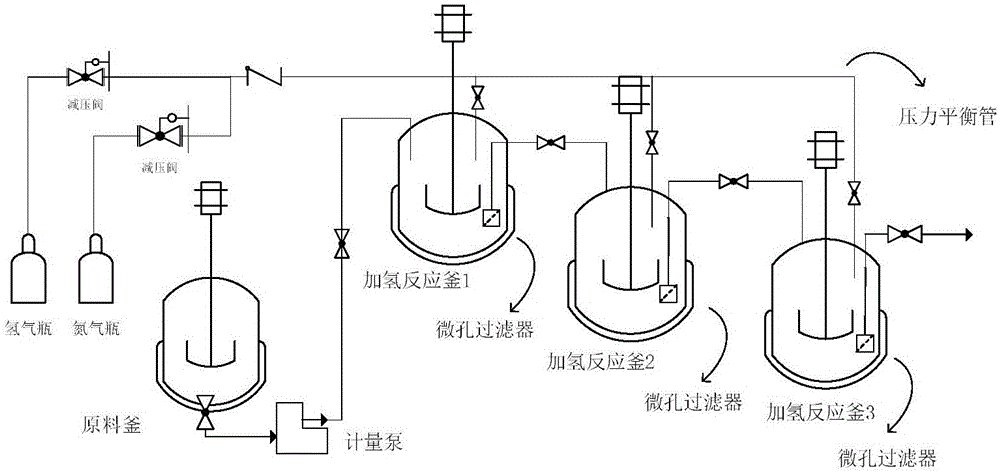

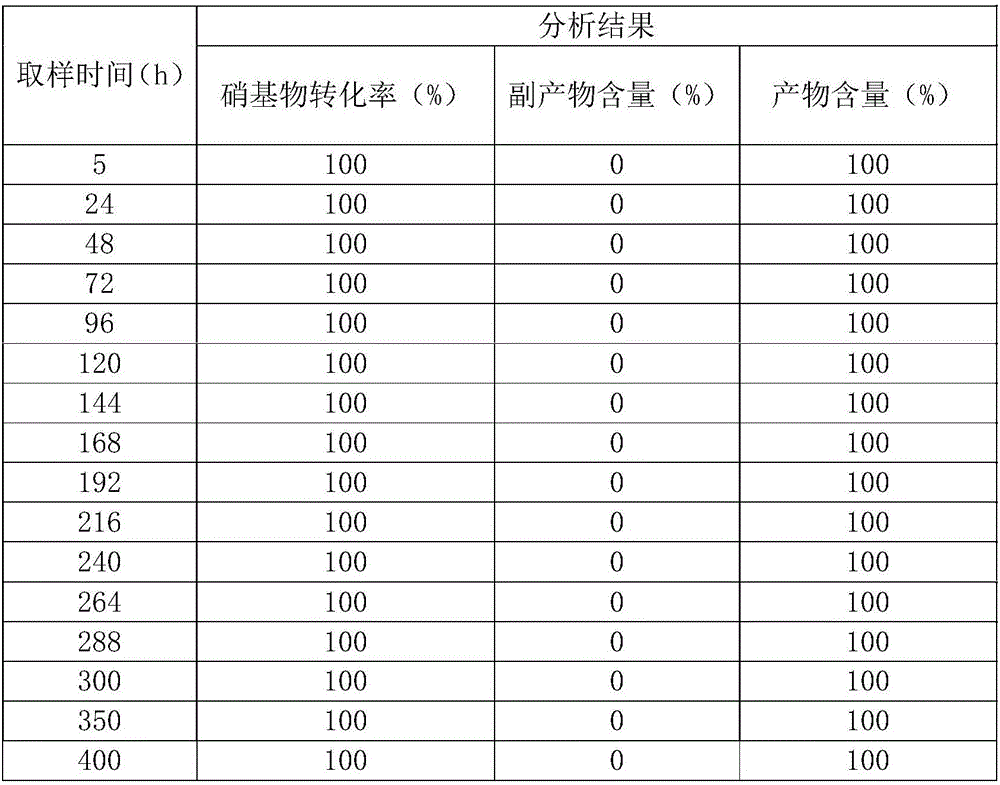

[0028]Add 600ml of sodium m-nitrobenzenesulfonate aqueous solution (45%) to three hydrogenation reactors (1L) respectively, add respectively the Pt-V-Mg / C catalyst 0.8g prepared in Example 1 simultaneously, and replace the system with nitrogen After 3 times of air, hydrogen was introduced to replace nitrogen 3 times, the hydrogen pressure in the kettle was adjusted to 1.5Mpa, stirring was started, the temperature was raised to 130°C, the metering pump was turned on, and the sodium m-nitrobenzenesulfonate solution was pumped into a The flow rate of the three-stage hydrogenation kettle is controlled at 1L / h, and the temperature and pressure of the three reactors are kept the same. The method of continuously feeding hydrogen, continuous feeding and continuous discharging is adopted. The material solution after the reaction is discharged from the third-stage reactor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com