Preparation method of electrolyte for vanadium redox battery (VRB)

A technology for all-vanadium redox flow batteries and electrolytes, which is applied in the field of preparation of electrolytes for all-vanadium redox flow batteries, can solve the problems of low solubility, small preparation volume, and difficult purification, and achieve the effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

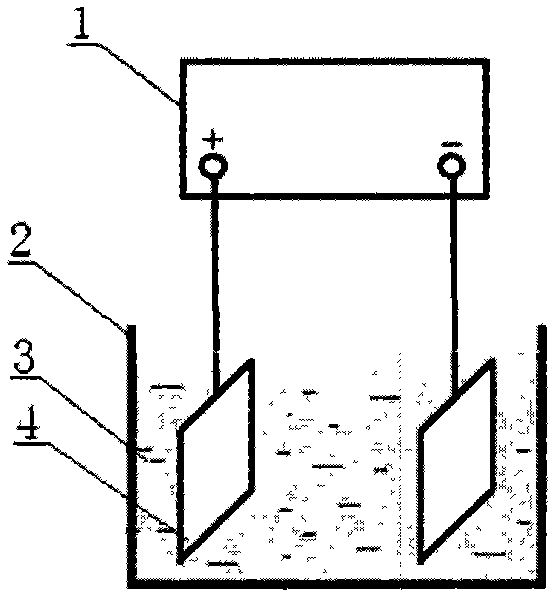

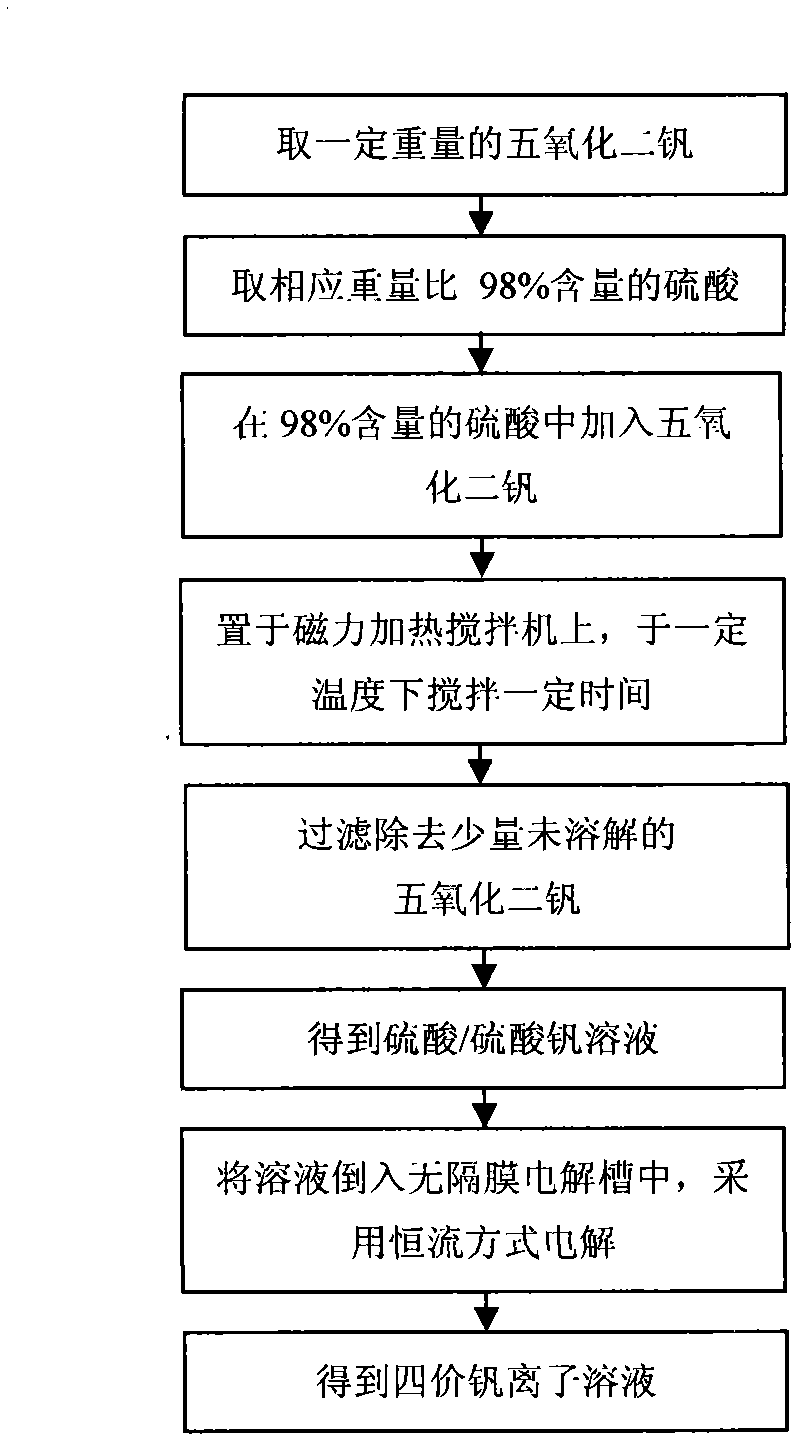

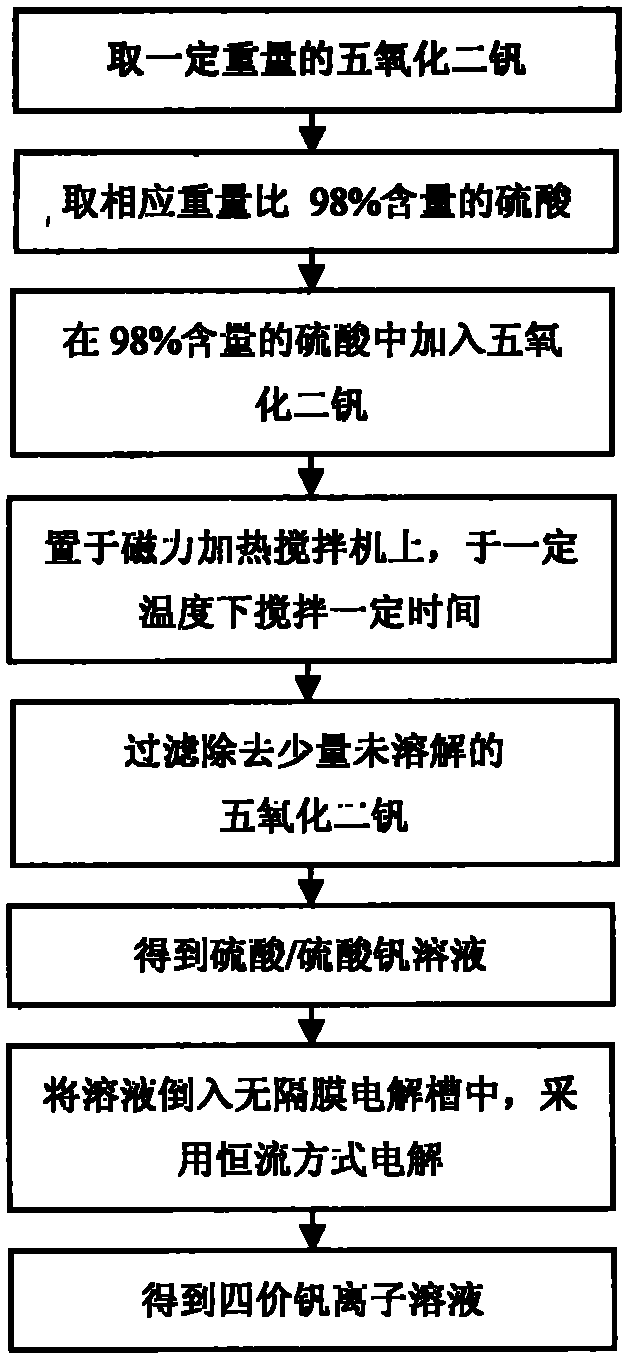

Embodiment 1

[0033] Take by weighing 50g of vanadium pentoxide, 125g of 98% sulfuric acid and appropriate amount of distilled water. Add 50g of vanadium pentoxide powder to 165.6g of 98% sulfuric acid, place it on a magnetic heating stirrer, stir at 140°C for 0.5h, filter out a small amount of insoluble vanadium pentoxide, and obtain sulfuric acid and vanadium sulfate the mixed solution 3; get 50ml of this mixed solution and add it into the electrolytic cell 2 without diaphragm, use the direct current constant voltage constant current power supply 1, put the lead plate electrode 4 that is connected with the direct current constant voltage constant current power supply 1 into the place filled with sulfuric acid and In the electrolytic cell 2 without diaphragm of the vanadium sulfate mixed solution 3, a constant current electrolysis method is adopted, and the current density is 300mA / cm 2 After 20 hours of electrolysis, a solution of tetravalent vanadium ions was obtained; the electrolytic s...

Embodiment 2

[0035] Weigh 50g of vanadium pentoxide, 200g of 98% sulfuric acid and appropriate amount of distilled water according to the proportioning ratio. Add vanadium pentoxide powder to 165.6g of 98% sulfuric acid, place it on a magnetic heating stirrer, stir at 120°C for 1 hour, filter out a small amount of insoluble vanadium pentoxide, and obtain a mixture of sulfuric acid and vanadium sulfate Solution 3: Take 50ml of the mixed solution and add it to the electrolytic cell 2 without a diaphragm, use a DC constant voltage and constant current power supply 1, and put the lead plate electrode 4 connected with the DC constant voltage and constant current power supply 1 into a tank containing sulfuric acid and vanadium sulfate In the electrolytic cell 2 without diaphragm of the mixed solution 3, a constant current electrolysis method is adopted, and the current density is 200mA / cm 2, electrolyzed for 19 hours to obtain a solution of tetravalent vanadium ions; the electrolytic solution wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com