A spring testing system and method

A testing system and technology to be tested, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as increased working time, placement errors, and large manual operations, reducing production costs, The effect of reducing the number of uses and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0035] A spring testing system and method of the present invention can automatically carry out the automatic production line of conveying, identifying, testing, color marking, marking (optional), drying (optional), and classified export of springs, and can The spring placed at the specified position and direction of the conveyor chain is automatically subjected to a load test, and the spring can be classified into 5 categories (--, -, 0, +, ++) for identification according to the load test results.

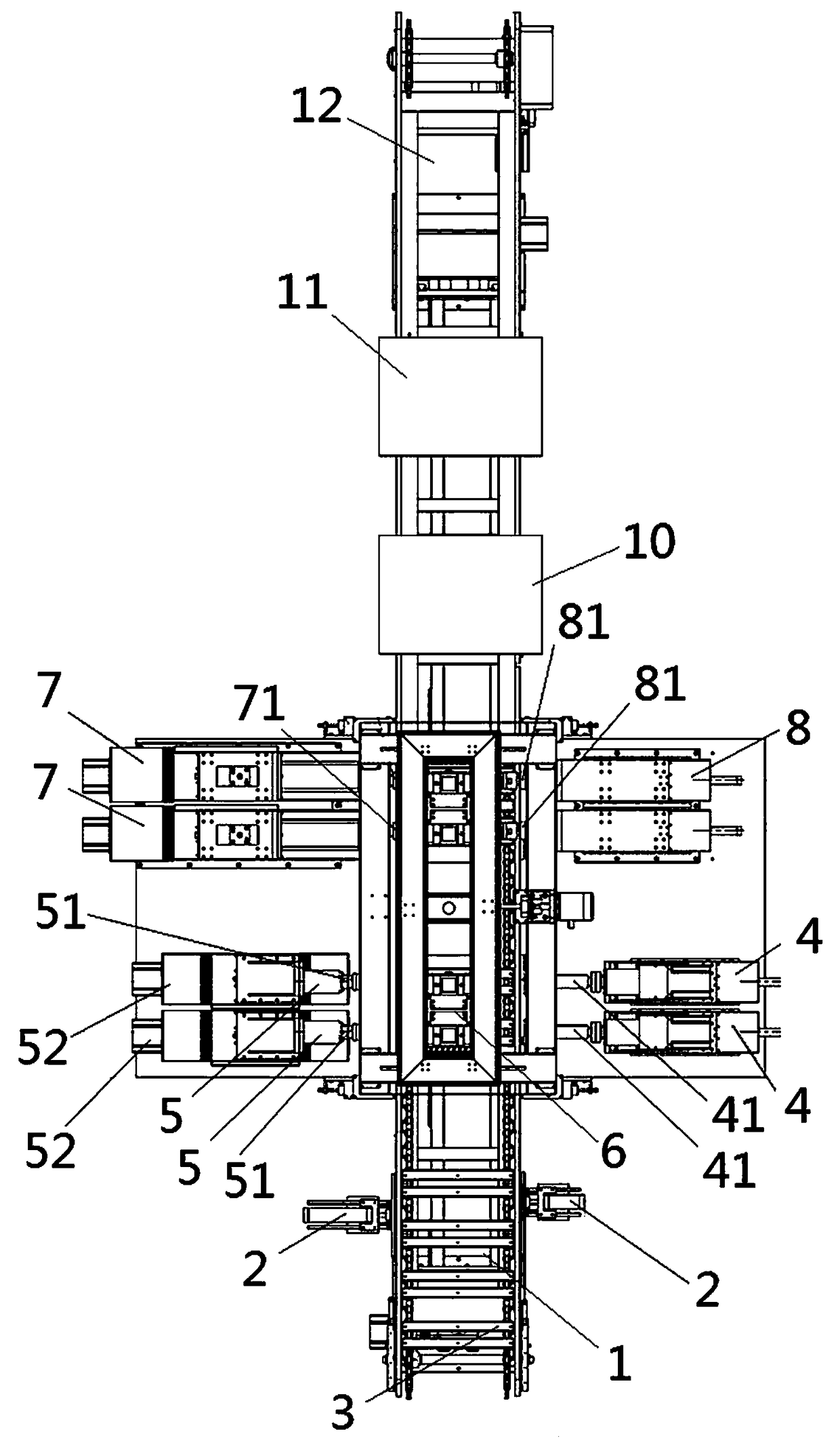

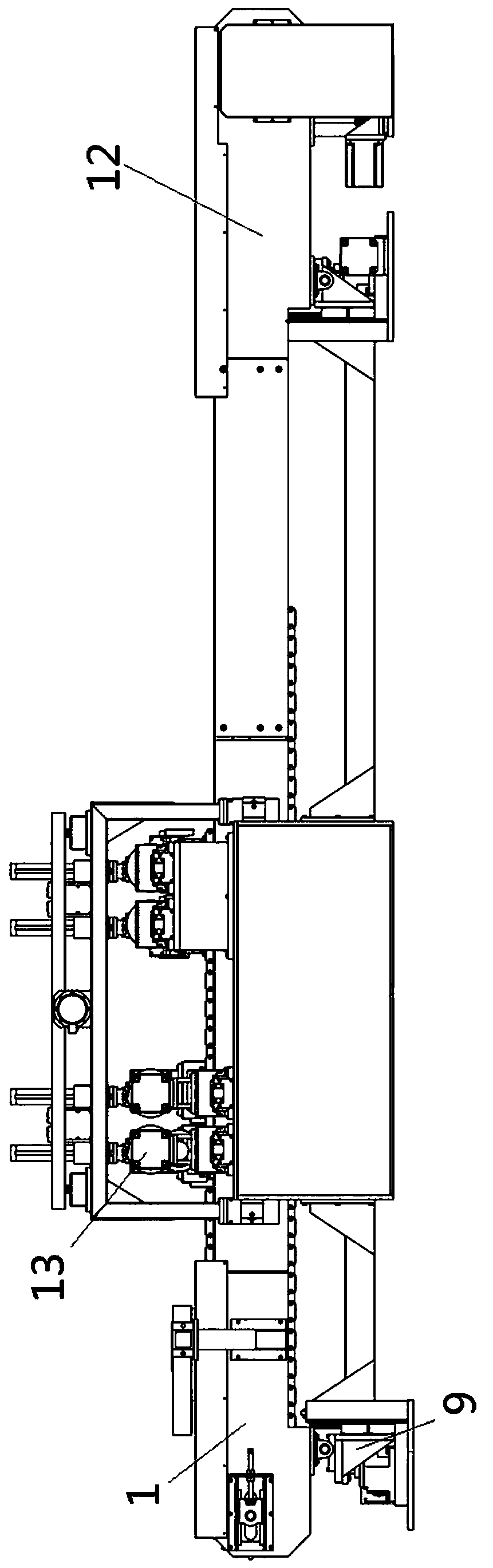

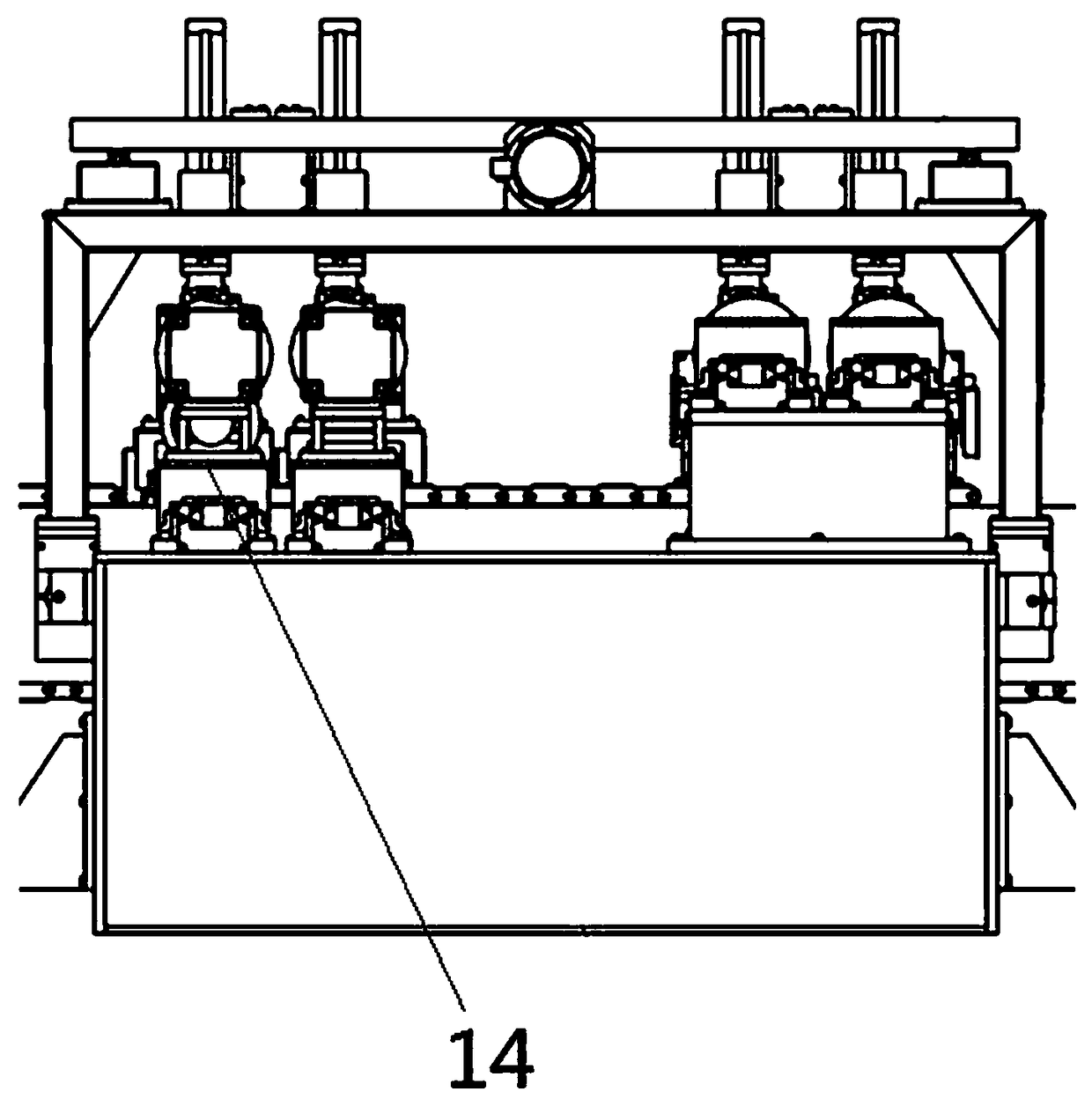

[0036] Such as Figure 1 to Figure 8 As shown, a kind of spring testing system of the present invention comprises conveying device 1 and control device, and conveying device 1 is provided with end positioning device 2 controlled by control device successively along conveying direction, recognition device 5, testing device 7, coloring Marking device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com