Manufacturing method and production line for resin-coated aluminum pipe

A manufacturing method and production line technology, which are applied in the field of aluminum tube preparation, can solve the problems of decreased adhesion, low durability of resin-coated aluminum tubes, and decreased adhesion, so as to achieve mass production, improve product quality, and improve product quality. productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with specific embodiment:

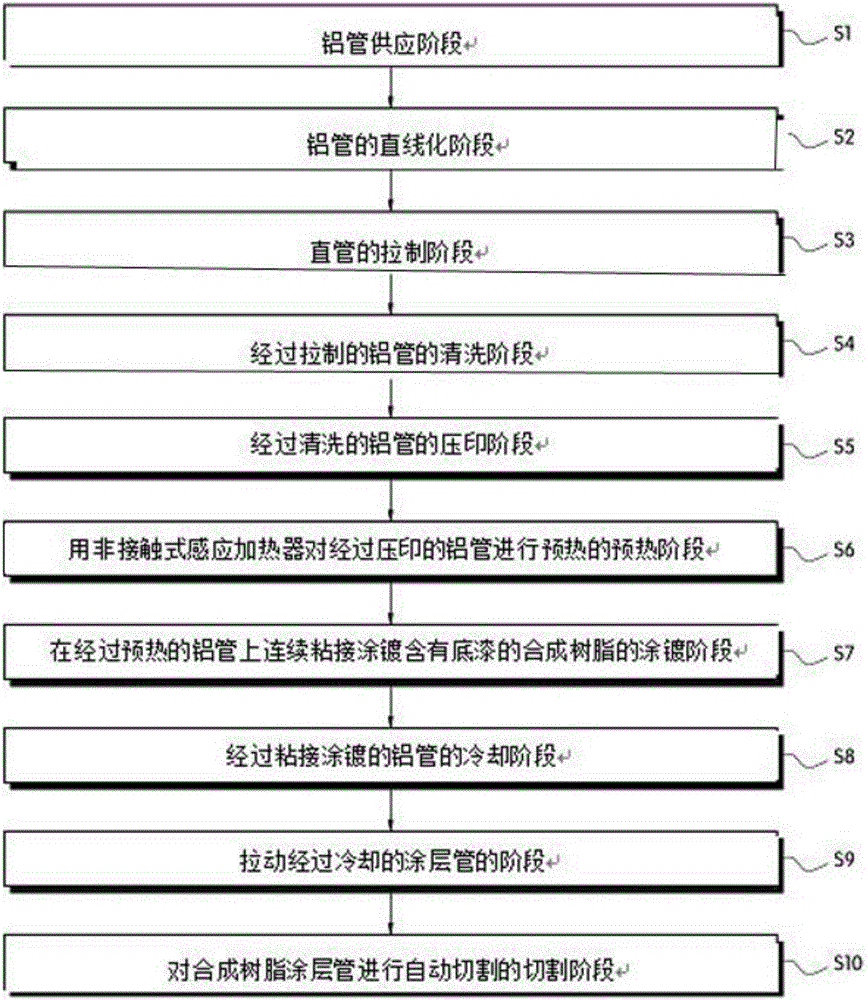

[0026] A method for manufacturing a resin-coated aluminum tube, comprising the steps of:

[0027] Aluminum tube supply stage S1;

[0028] The linearization stage S2 of the aluminum tube;

[0029] Straight pipe drawing stage S3;

[0030] Cleaning stage S4 of the drawn aluminum tube;

[0031] Stamping stage S5 of cleaned aluminum tubes;

[0032] Preheating stage S6 of preheating the embossed aluminum tube with a non-contact induction heater;

[0033] Coating stage S7 of continuous adhesive coating of synthetic resin containing primer on the preheated aluminum tube;

[0034] Cooling stage S8 of bonded and coated aluminum tubes;

[0035] The stage S9 of pulling the above-mentioned cooled coated tube;

[0036] Cutting stage S10 of automatic cutting of synthetic resin coated pipes.

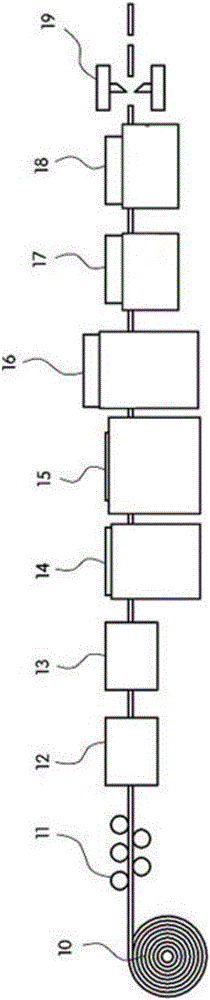

[0037] A production line for resin-coated aluminum tubes, the production line includes an uncoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com