Double-end saddle type welding groove machining production line

A welding groove and saddle-shaped technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inaccurate positioning, increased manufacturing cost, and uneven molding quality, so as to achieve high production efficiency, The effect of good processing quality and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

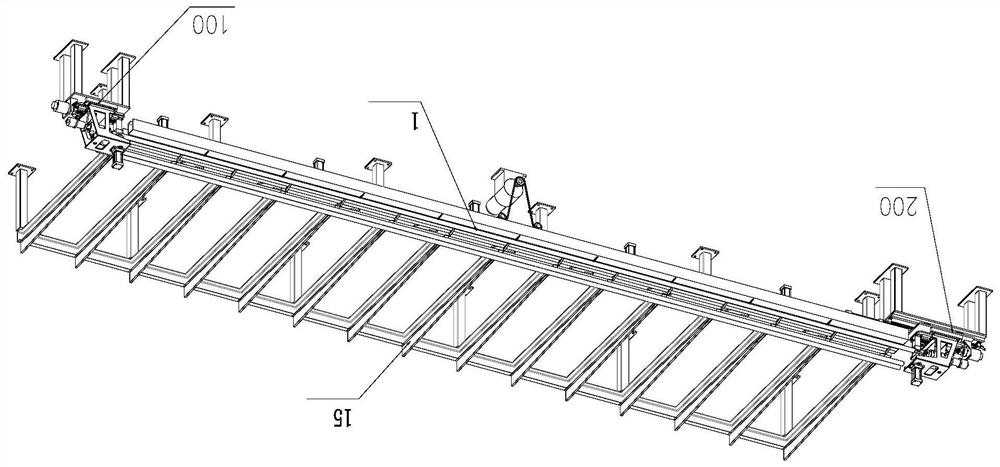

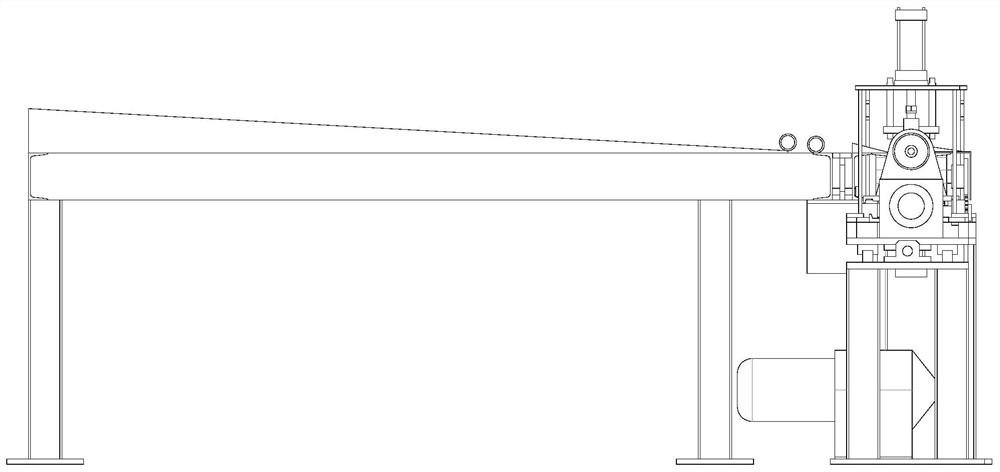

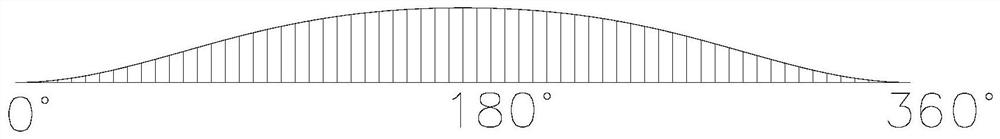

[0028] Such as Figure 1-9 As shown, in the embodiment of the present invention, the double-headed saddle type welding beveling production line includes a material channel 1, a fixed saddle beveling machine 100, a movable saddle beveling machine 200, a fixed saddle beveling machine 100, The movable saddle beveling machine 200 is respectively arranged at both ends of the feedway 1, and the central axis of the fixed saddle beveling machine 100 and the movable saddle beveling machine 200 are at the same height as the center line of the feeder passage, and the fixed saddle beveling machine 100 Fixed on the ground, the movable saddle beveling machine 200 is fixed on the movable seat, and the movable seat is fixed on the guide rail. The above movable seat is synchronously connected to the servo motor through the screw assembly, and the servo motor drives the screw assembly to move, so that the movable seat Reciprocating back and forth on the guide rail, the movable saddle beveling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com