Gum rosin processing unit adopting vacuum filtration method

A technology of processing device and filtering device, which is applied in the field of rosin production, can solve the problems of long clarification process, production waste, and reduction of high-quality product rate, so as to reduce the chance of oxidation, scientific and reasonable process, and improve the effect of high-quality product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

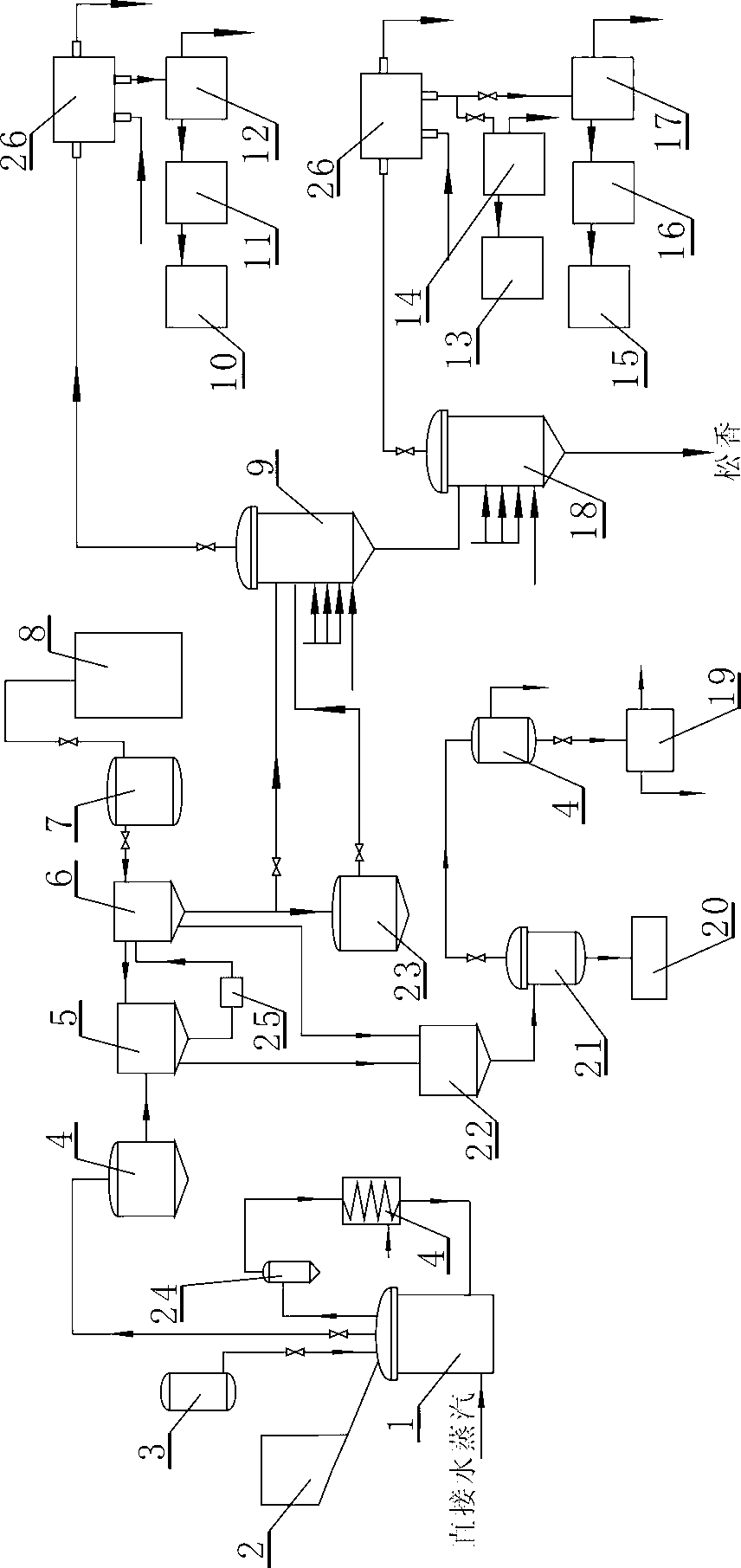

[0008] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

[0009] Such as figure 1 Shown, the vacuum filtration method gum rosin processing device of the present invention comprises dissolving device, clarification device, distillation device, and described dissolving device comprises dissolving still 1, hopper 2, refueling tank 3, and dissolving still 1 connects direct water Steam gas source; the clarification device includes a vacuum filter device and a supporting negative pressure device, the negative pressure device includes a vacuum cylinder 7 and a low-level water jet vacuum unit 8, and the distillation device includes a still, a fraction Purification device; the fat liquid outlet process of the dissolving kettle 1 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com