Catalytic oxidation device for water treatment, its manufacturing method and water treatment process

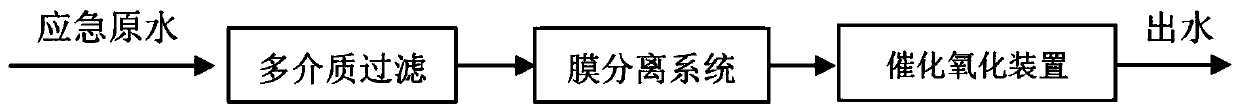

A technology of catalytic oxidation and production method, which is applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of difficult to remove pollution and low efficiency of organic pollutants in water purification, and achieve the goal of maintaining catalysis Performance and adsorption performance, good regeneration effect, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

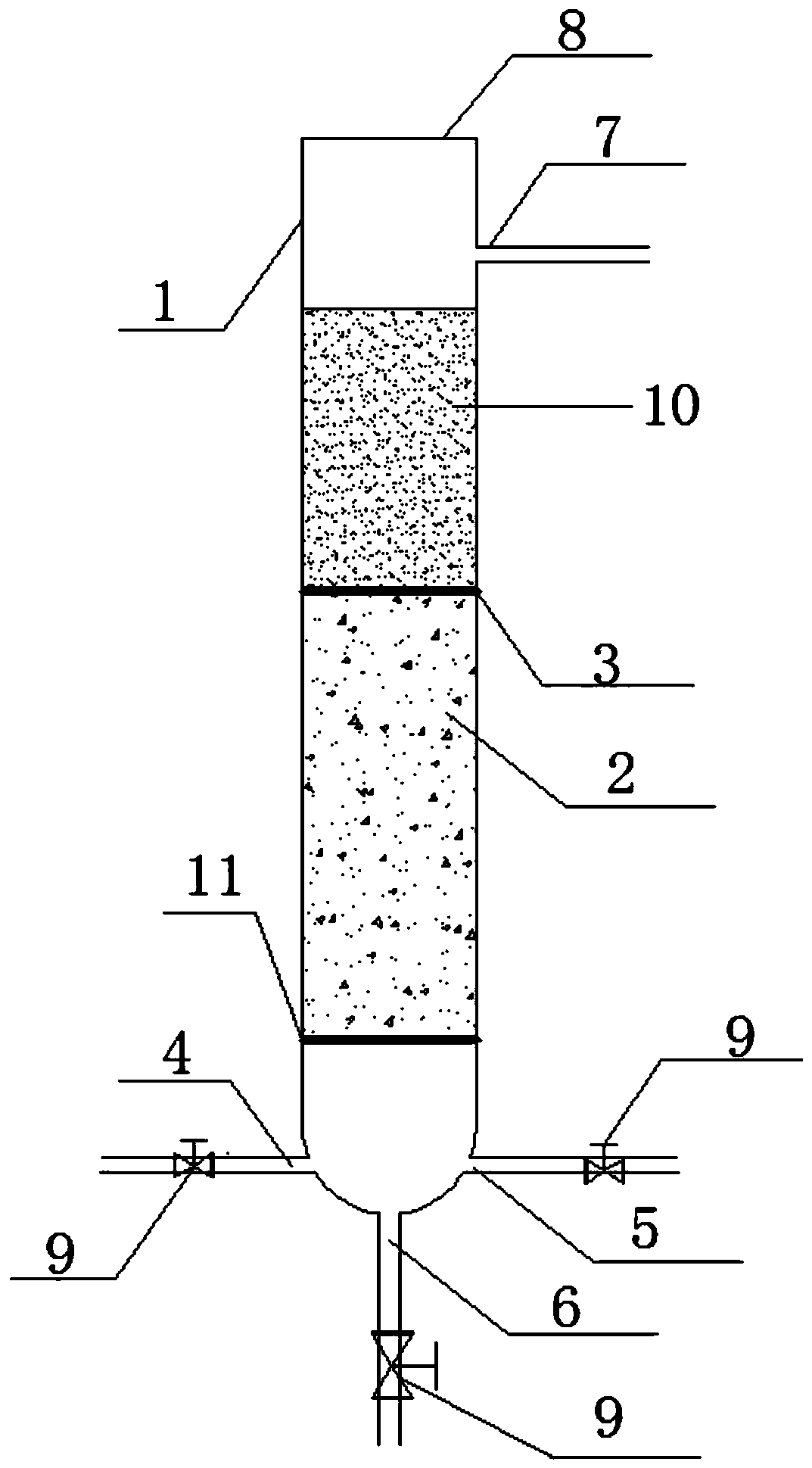

[0044] A catalytic oxidation device for emergency water treatment in this embodiment consists of a shell 1 of the reactor, a catalytic oxidation filler 2 filled in the shell 1, an activated carbon adsorption layer 10 filled in the upper part of the shell 1, stainless steel Nets 3 and 11, cover plate 8 and water stop valve 9, the housing 1 is a cylindrical pipe made of plexiglass, the lower end of the housing 1 is provided with an emptying port 6, and the two sides of the lower part of the housing 1 are respectively A water inlet 4 and a hydrogen peroxide inlet 5 are provided, and a water outlet 7 is provided on one side of the upper part of the housing 1. The upper and lower ends of the catalytic oxidation filler 2 are respectively provided with stainless steel meshes 3 and 11, and the upper end of the housing 1 A cover plate 8 is provided, and a water stop valve 9 is respectively provided on the water inlet 4, the hydrogen peroxide inlet 5 and the emptying port 6, and the cata...

Embodiment 2

[0060] A catalytic oxidation device for emergency water treatment in this embodiment consists of a shell 1 of the reactor, a catalytic oxidation filler 2 filled in the shell 1, an activated carbon adsorption layer 10 filled in the upper part of the shell 1, stainless steel Nets 3 and 11, cover plate 8 and water stop valve 9, the housing 1 is a cylindrical pipe made of stainless steel, the lower end of the housing 1 is provided with an emptying port 6, and the two sides of the lower part of the housing 1 are respectively provided with There is a water inlet 4 and a hydrogen peroxide inlet 5, the upper side of the housing 1 is provided with a water outlet 7, the upper and lower ends of the catalytic oxidation filler 2 are respectively provided with stainless steel mesh 3 and 11, and the upper end of the housing 1 is provided with There is a cover plate 8, the water inlet 4, the hydrogen peroxide inlet 5 and the emptying port 6 are respectively provided with a water stop valve 9, ...

Embodiment 3

[0070] A catalytic oxidation device for emergency water treatment in this embodiment consists of a shell 1 of the reactor, a catalytic oxidation filler 2 filled in the shell 1, an activated carbon adsorption layer 10 filled in the upper part of the shell 1, stainless steel Nets 3 and 11, cover plate 8 and water stop valve 9, the housing 1 is a cylindrical pipe made of stainless steel, the lower end of the housing 1 is provided with an emptying port 6, and the two sides of the lower part of the housing 1 are respectively provided with There is a water inlet 4 and a hydrogen peroxide inlet 5, the upper side of the housing 1 is provided with a water outlet 7, the upper and lower ends of the catalytic oxidation filler 2 are respectively provided with stainless steel mesh 3 and 11, and the upper end of the housing 1 is provided with There is a cover plate 8, the water inlet 4, the hydrogen peroxide inlet 5 and the emptying port 6 are respectively provided with a water stop valve 9, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com