Patents

Literature

37results about How to "Fast clarification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhancing filtration yields in tangential flow filtration

InactiveUS6350382B1High precision separationEasy to separateLiquid separation auxillary apparatusMembranesEngineeringPeak pressure

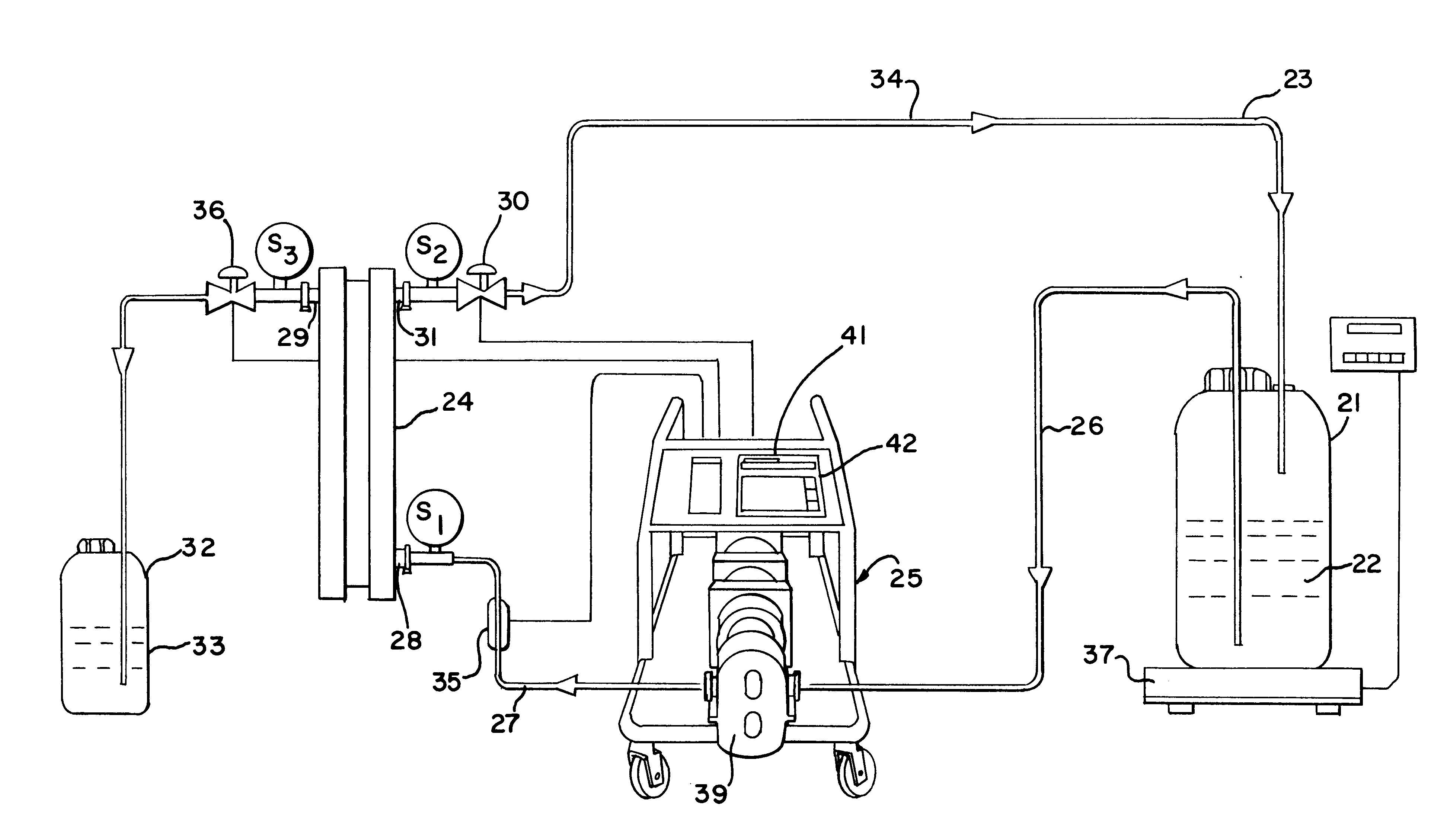

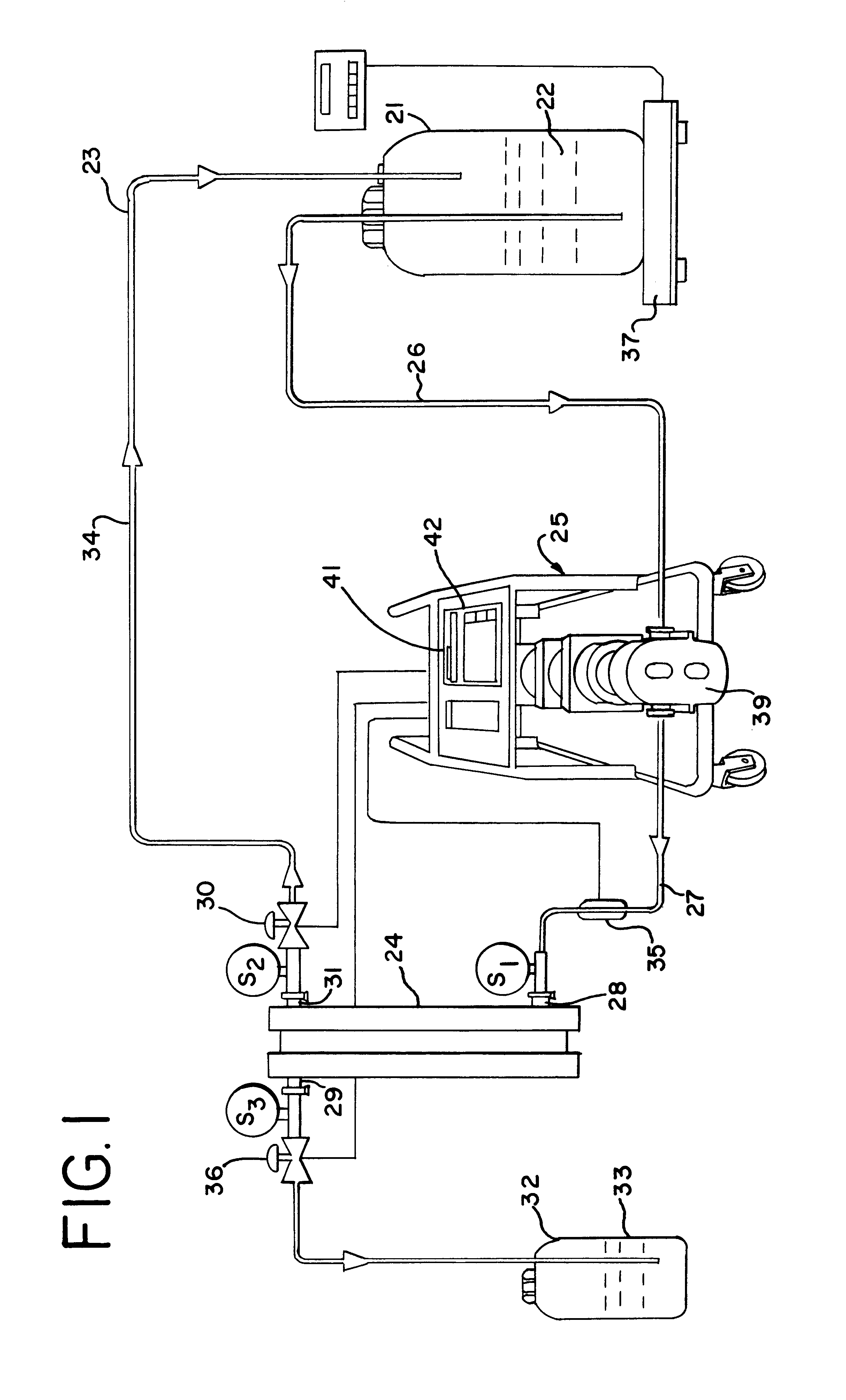

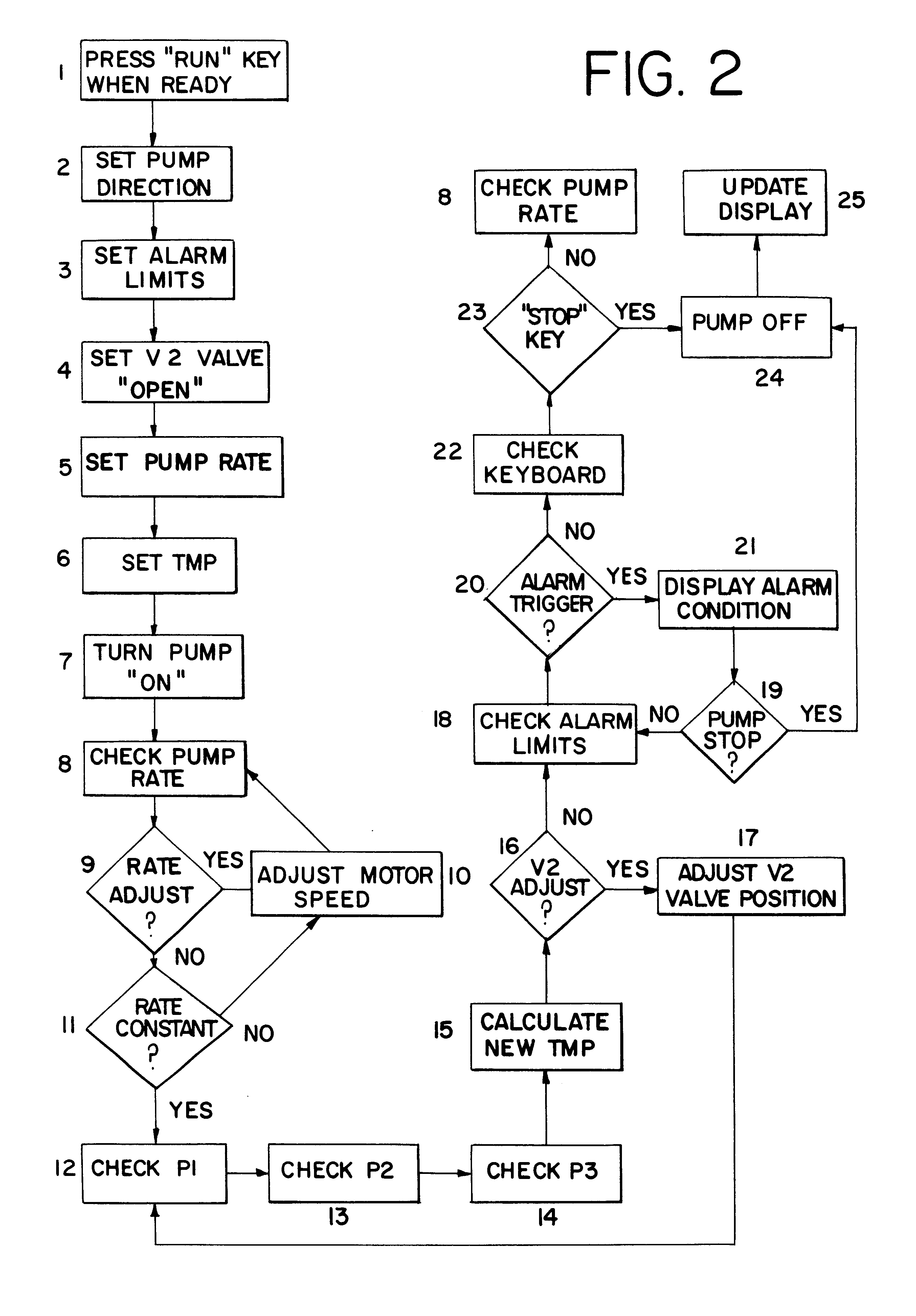

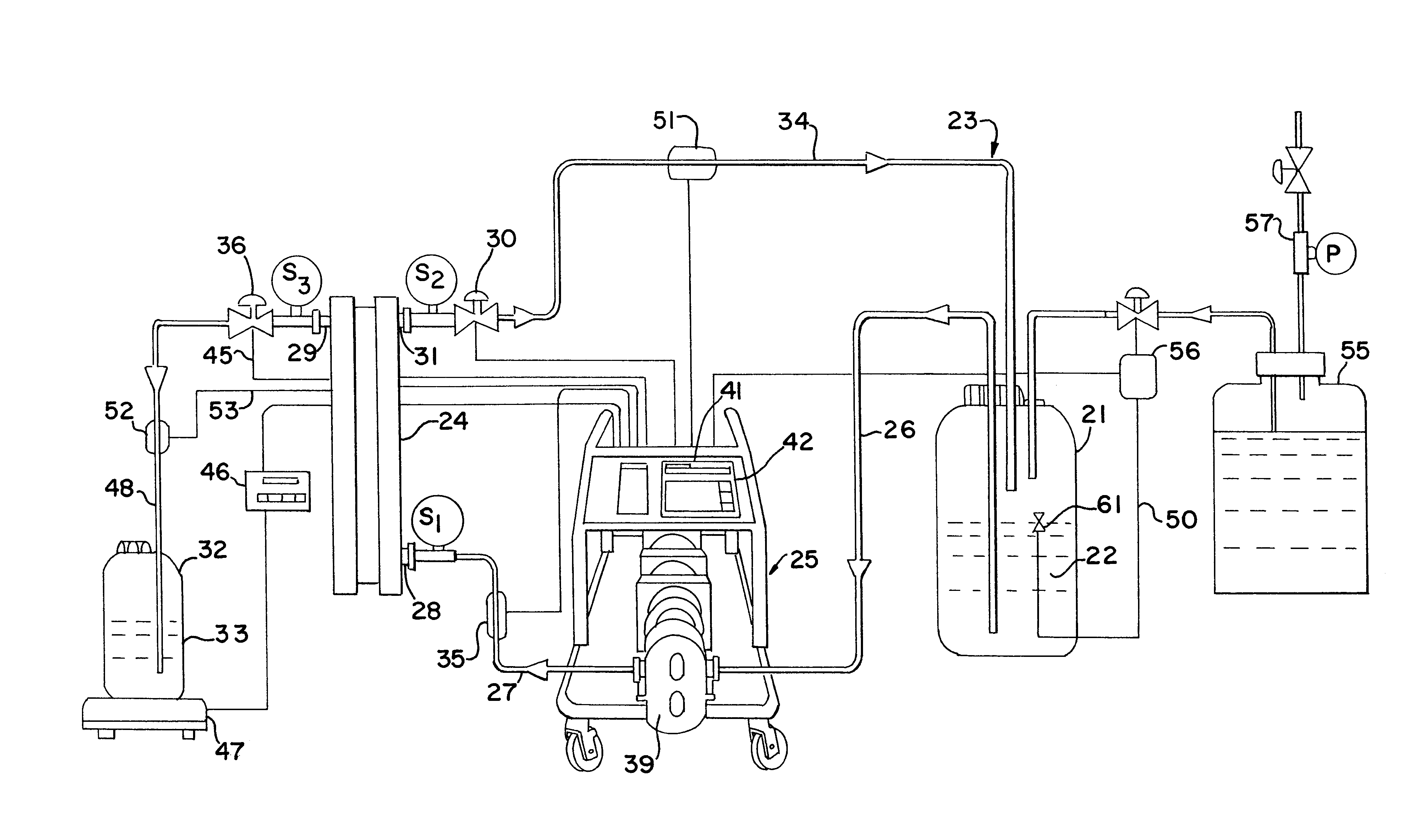

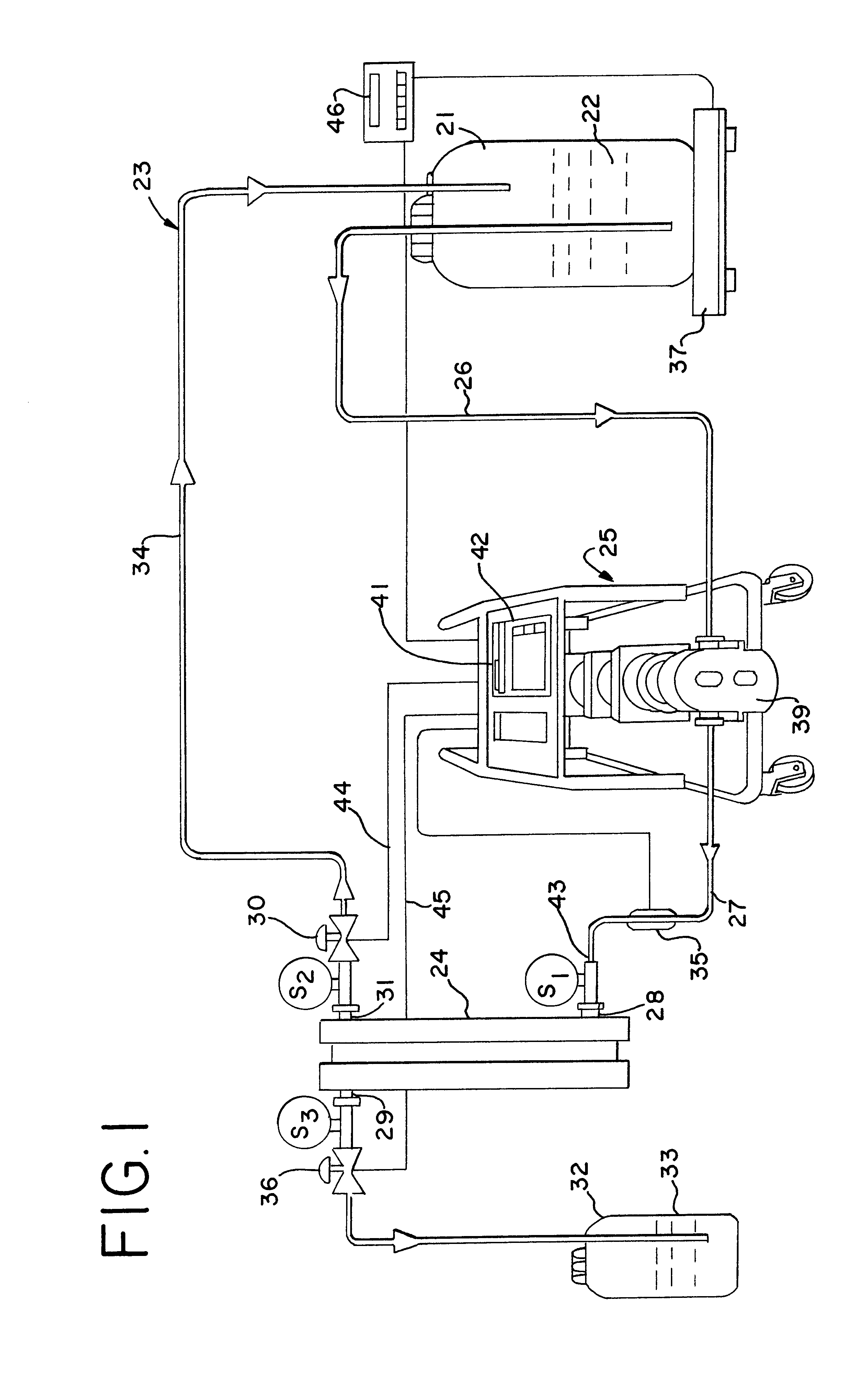

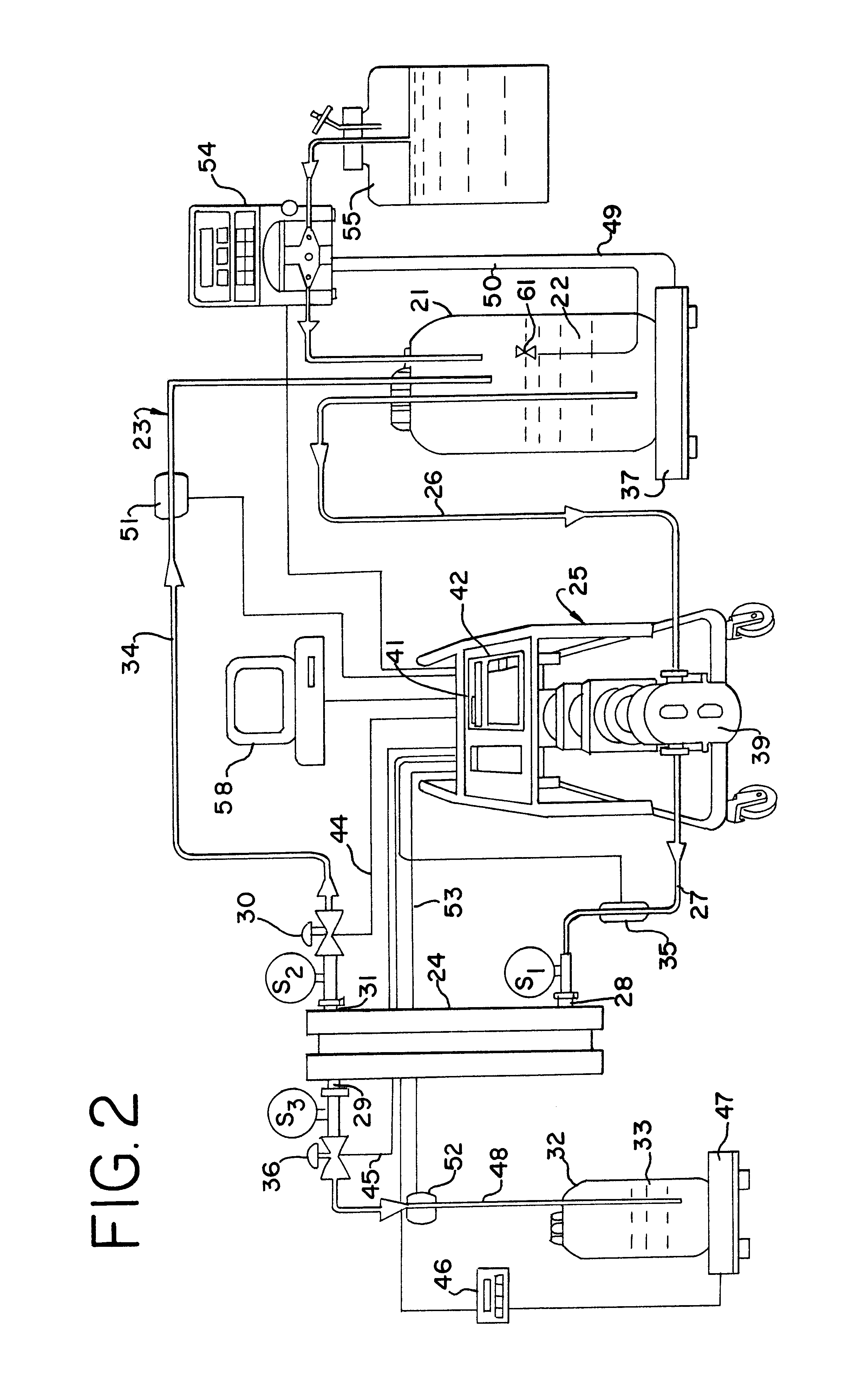

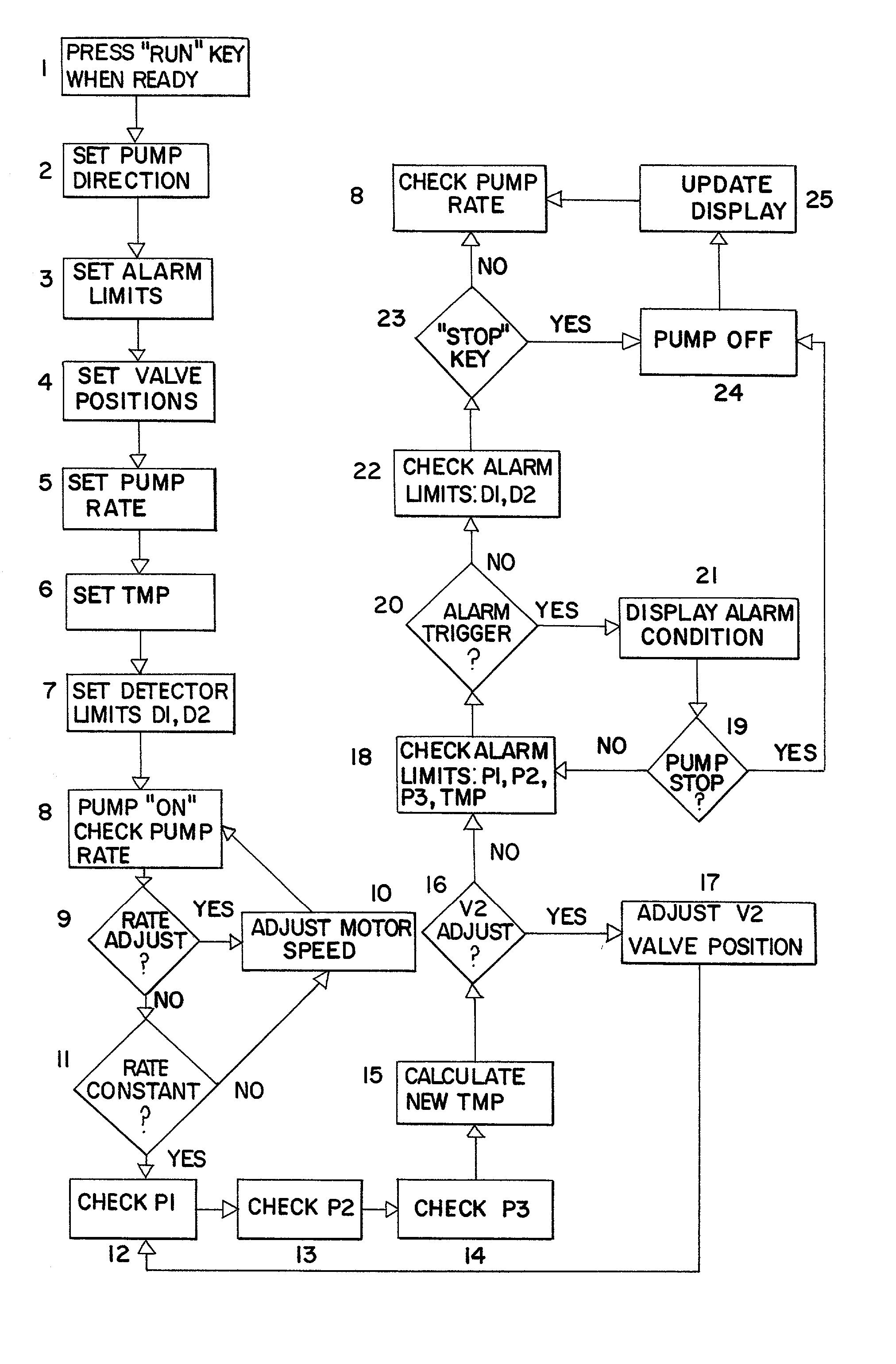

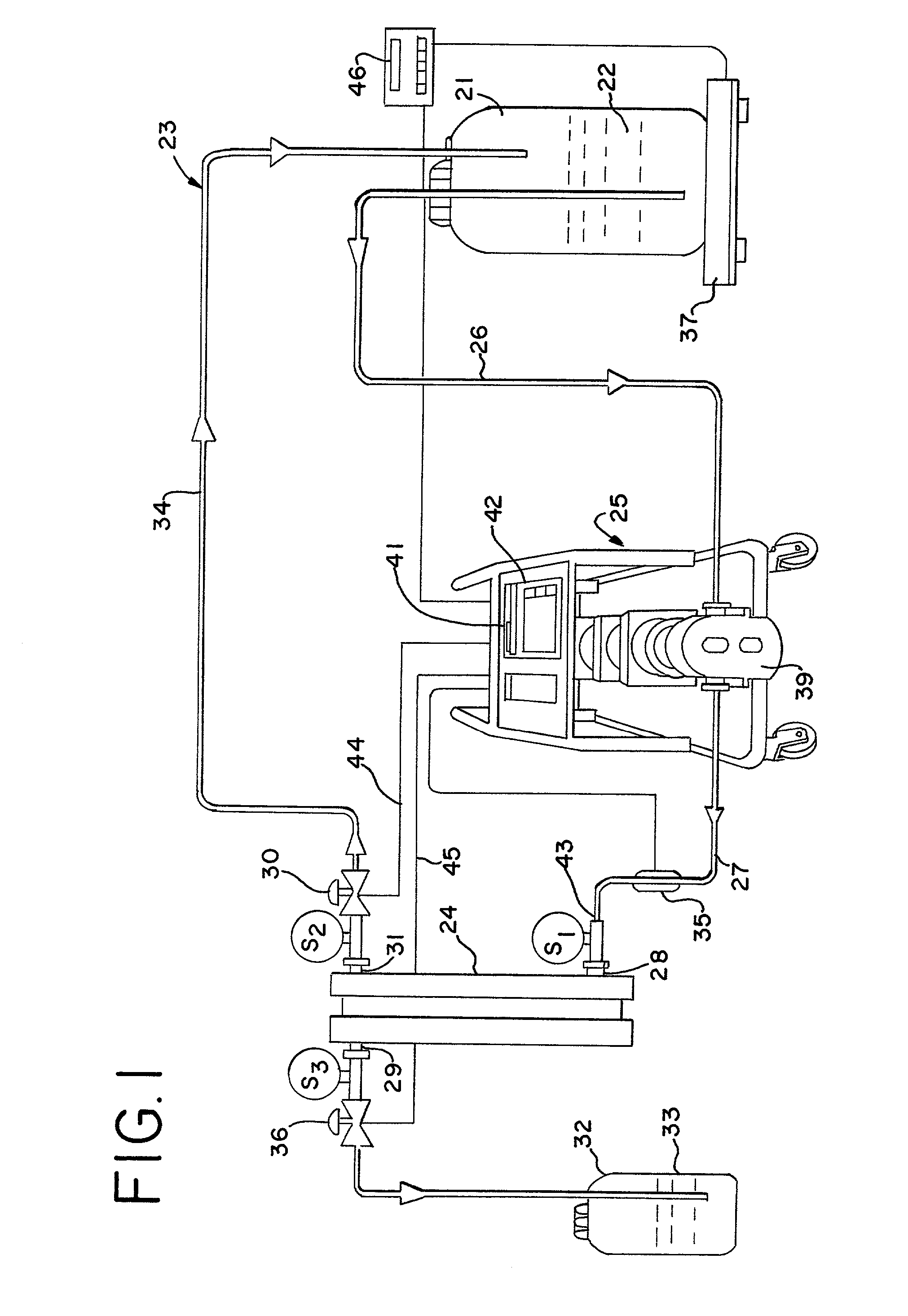

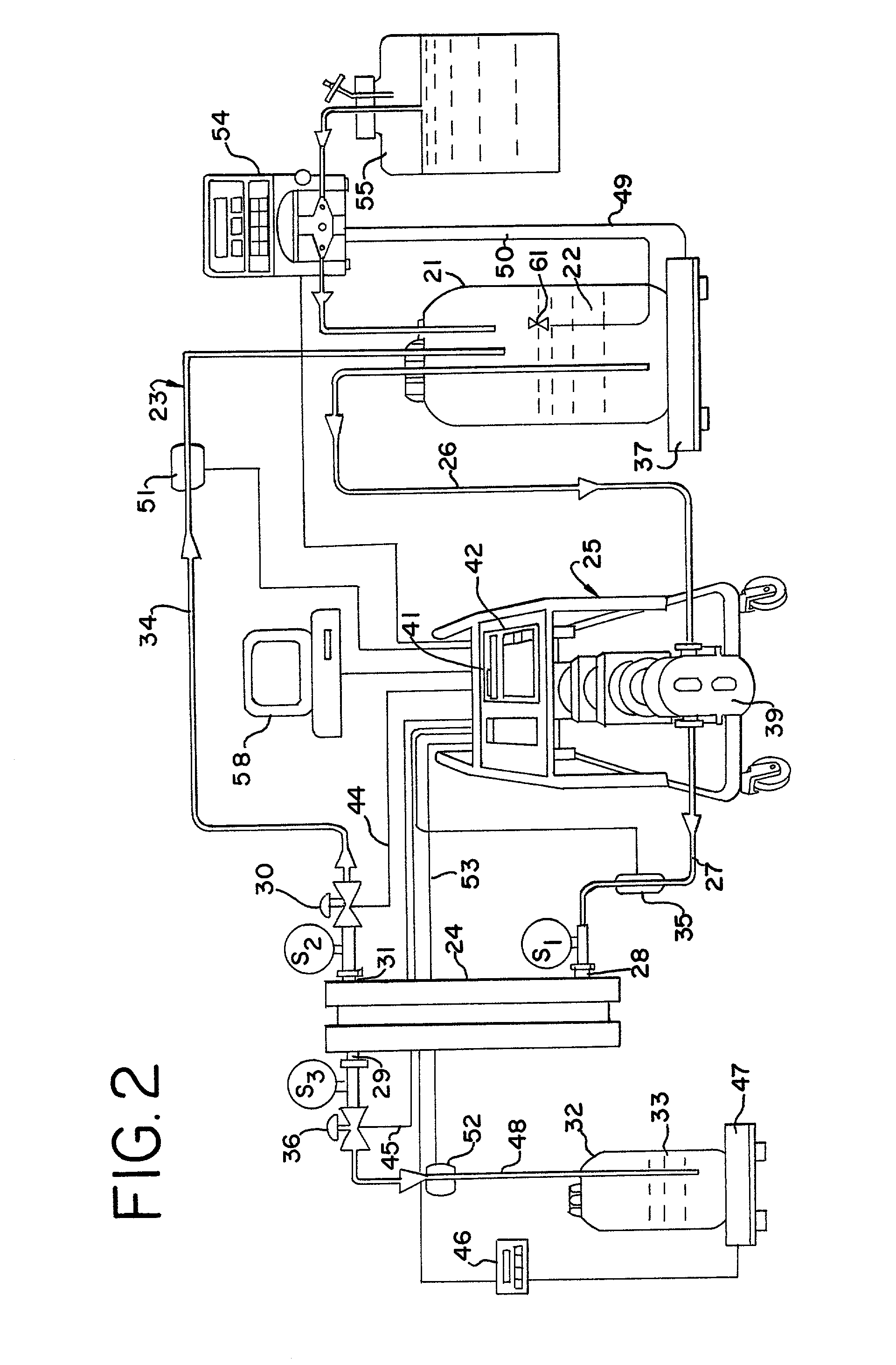

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained. Approaches also are described for determining optimal filtration conditions, including trans-membrane pressure and feed rate. Also described is a system and method for determining pressures in a pulsating system with enhanced accuracy by using a peak pressure mode.

Owner:PARKER INTANGIBLES LLC

Method and apparatus for enhancing filtration yields in tangential flow filtration

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained.

Owner:PARKER INTANGIBLES LLC

Method and apparatus for enhancing filtration yields in tangential flow filtration

InactiveUS20020043487A1High precision separationEasy to separateMembranesUltrafiltrationFiltrationEngineering

A system is provided for proceeding with filtration of liquids in a manner having enhanced control characteristics. Yields are enhanced. The system and method can be used to maintain a substantially constant trans-membrane pressure. When desired, that constant trans-membrane pressure is especially well-suited to yield enhancement for the particular liquid being filtered, concentrated or collected, while minimizing a risk of damage to or loss of valuable components. Additionally, a constant feed rate or pump output can be maintained.

Owner:PARKER INTANGIBLES LLC

Broad spectrum quick clarifying method

The present invention relates to broad spectrum quick clarifying method, and relates to food, medicine and water treating technology. Chitosan and xanthan gum are combined for clarifying liquid matter. Chitosan and xanthan gum dissolved separately are added into liquid matter to be clarified so as to adsorb and include protein, fat, pectin, suspended matter, etc. through mutual action, the flocculated matter floats fast to separate from the mother liquid, and the floated flocculated matter may be then eliminated with screen, filter fabric, etc. to obtain clarified liquid. The said method is suitable for clarifying liquid matter with high or low turbidity.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

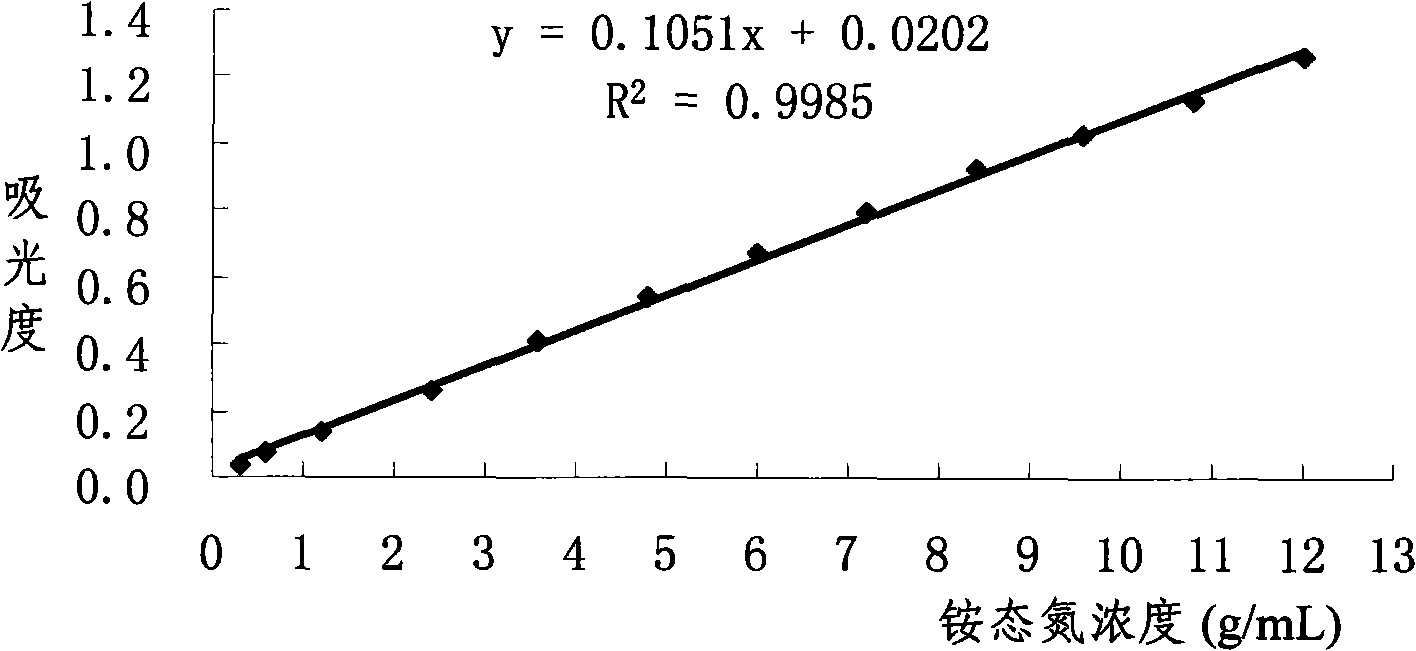

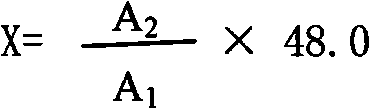

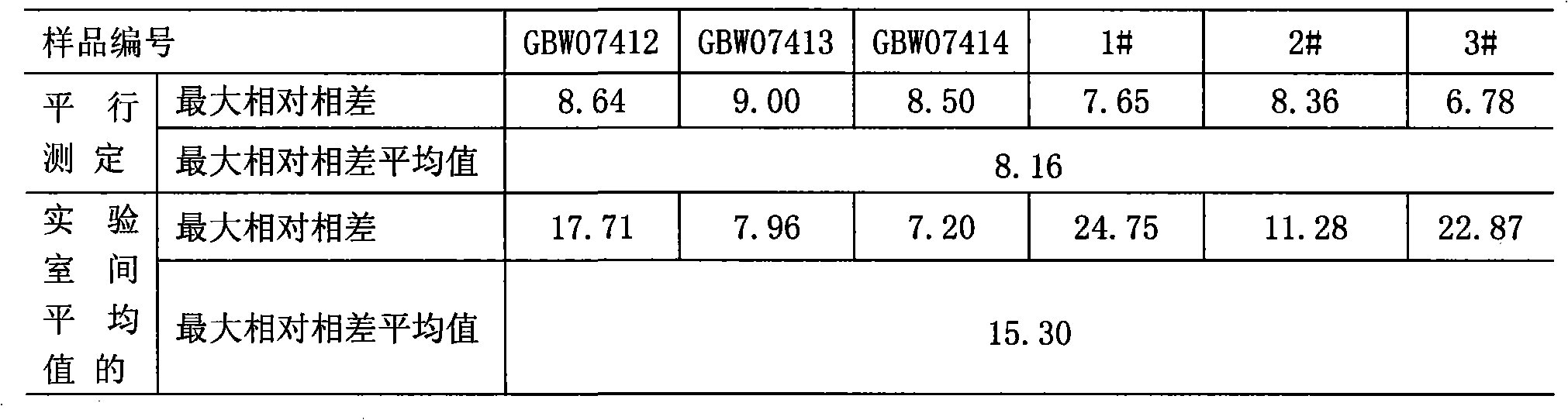

Novel nessler's reagent and method for rapidly measuring soil ammonium nitrogen

InactiveCN101319999AControl pHSlow down chemical reactionsMaterial analysis by observing effect on chemical indicatorPotassium hydroxideColor reaction

The invention discloses a novel Nyquist reagent and a method using the reagent for rapidly determining soil ammonium. The main improvement of the novel Nyquist reagent lies in that proper amount of solid potassium hydroxide or sodium hydroxide is directly added in solution after the complete reaction of potassium iodide and mercuric chloride during the preparation; the novel Nyquist reagent is used for determining the soil ammonium; tartaric acid potassium sodium alkaline solution is used as masking agent, the novel Nyquist reagent is added in Arabic gum medium solution for the color reaction with ammonium ions. Alkaline is added for adjusting the alkalinity of a color reaction system for the colorimetric determination after the color is stable. The Nyquist reagent has the advantages of wide linear range, long shelf life, color stability and easy preparation. The determination method of the invention has the advantages of easy operation, good reproducibility, small error and rapid test speed and is applied to bases and agricultural extension departments.

Owner:河南农大迅捷测试技术有限公司

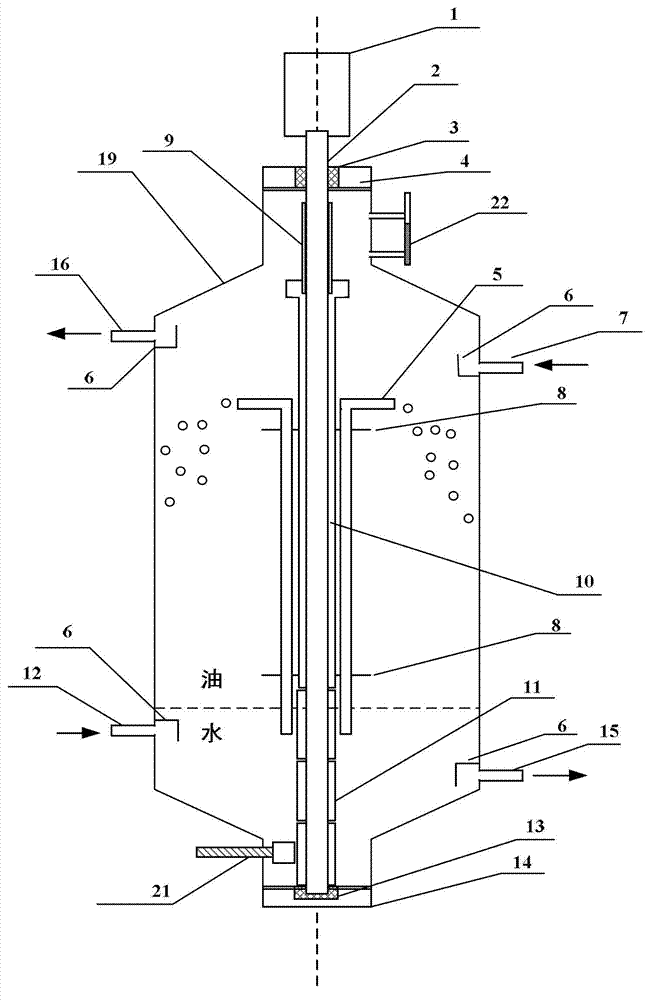

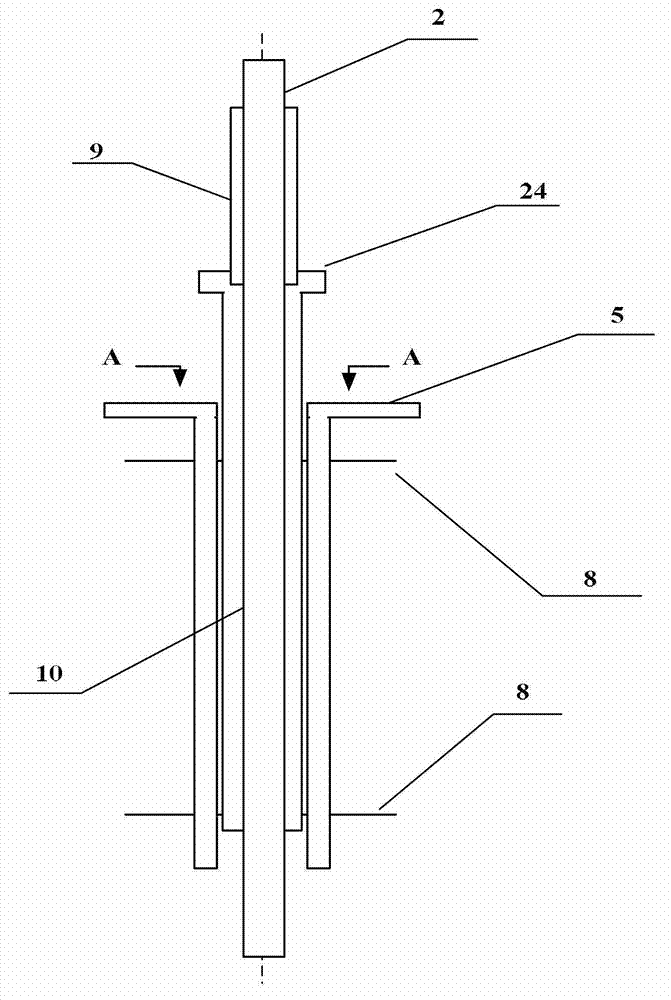

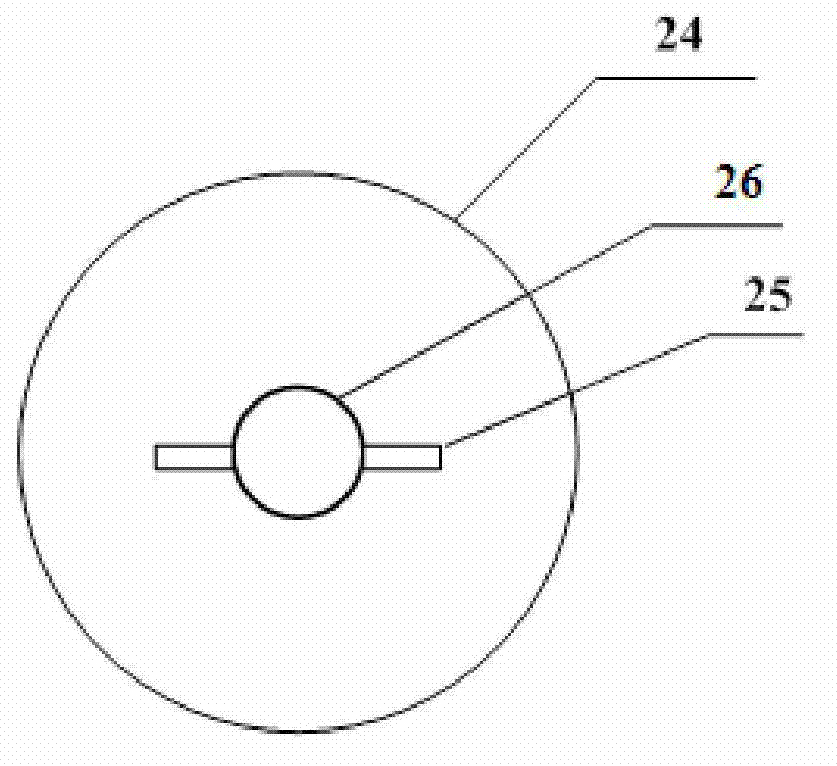

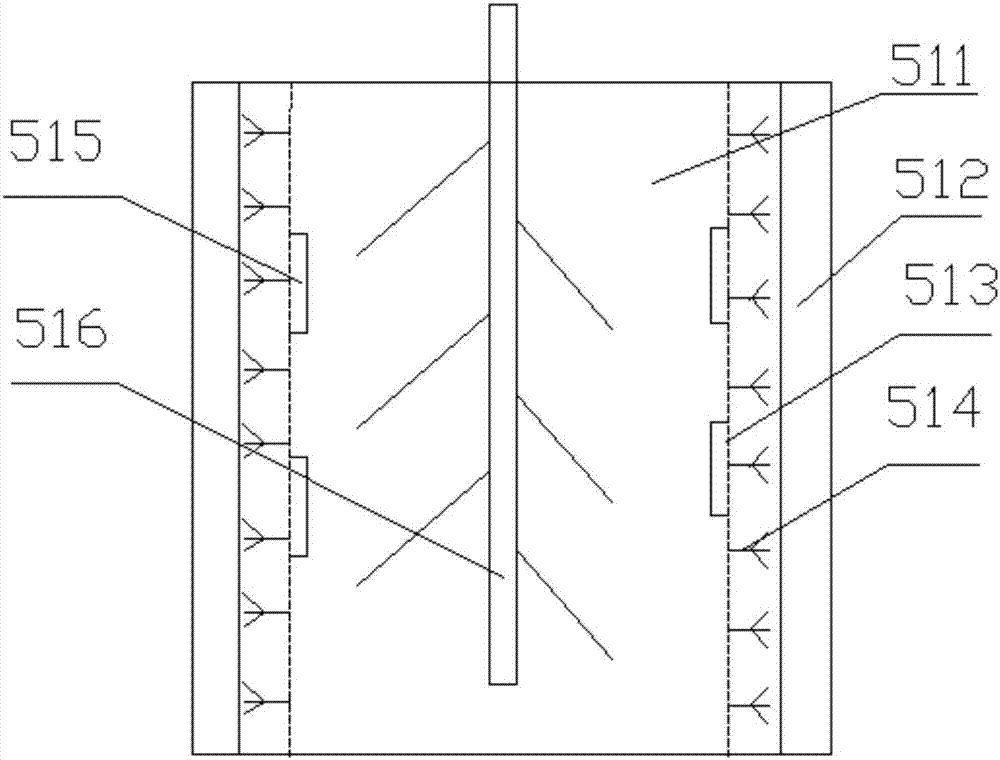

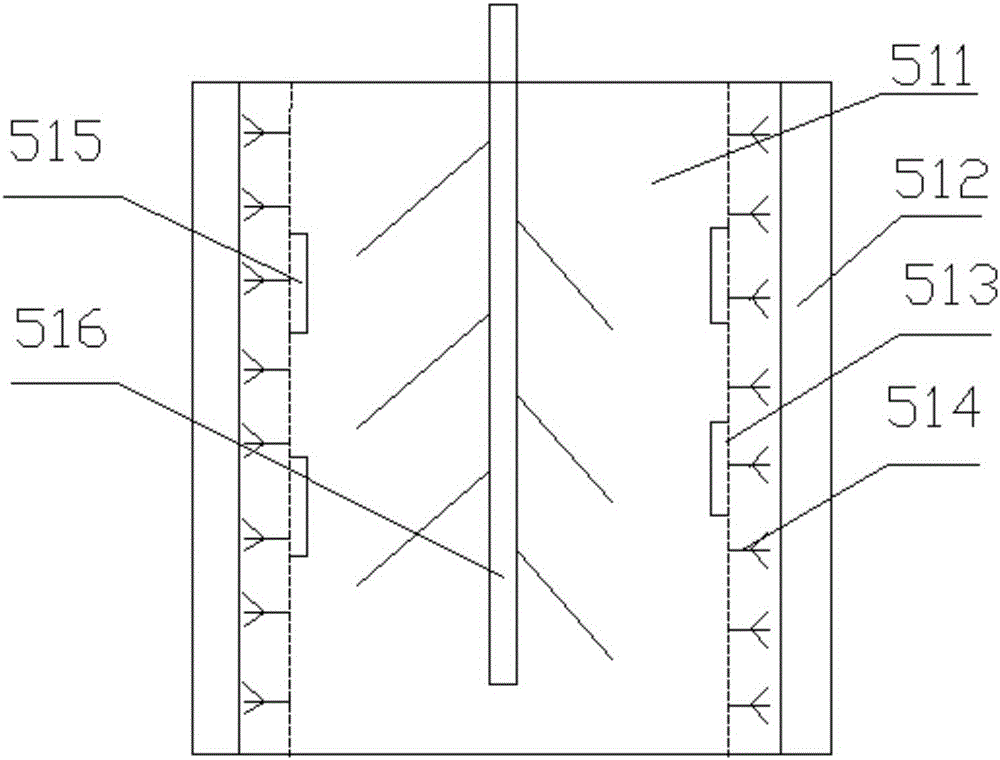

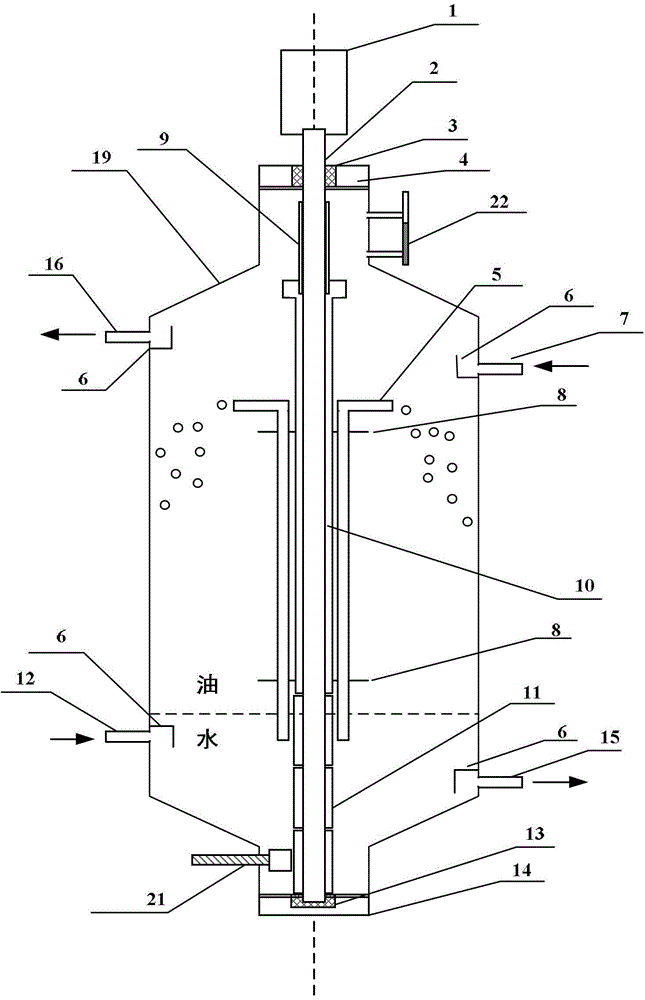

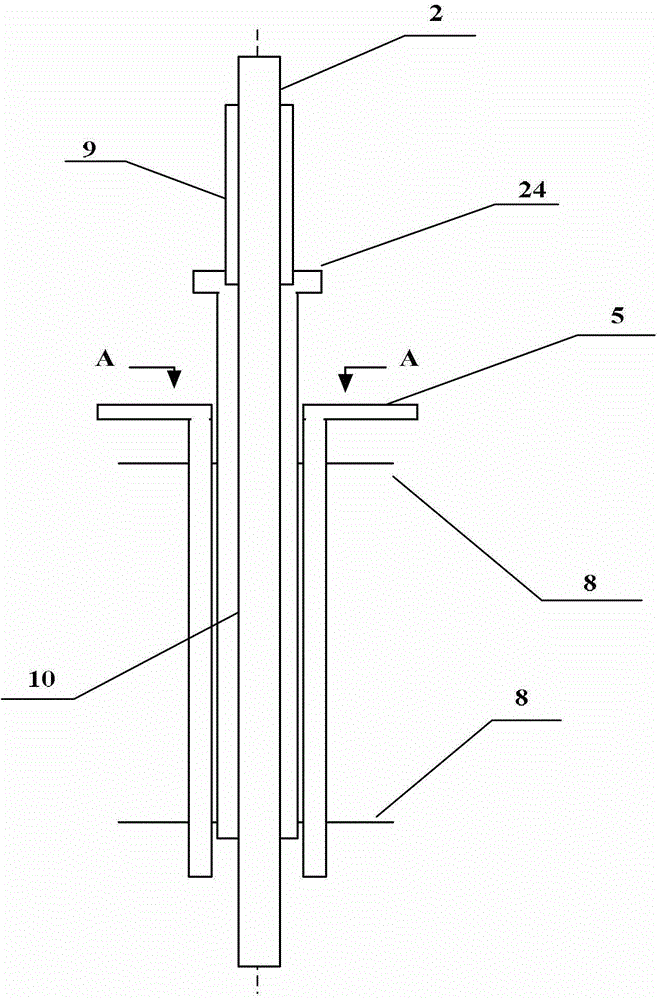

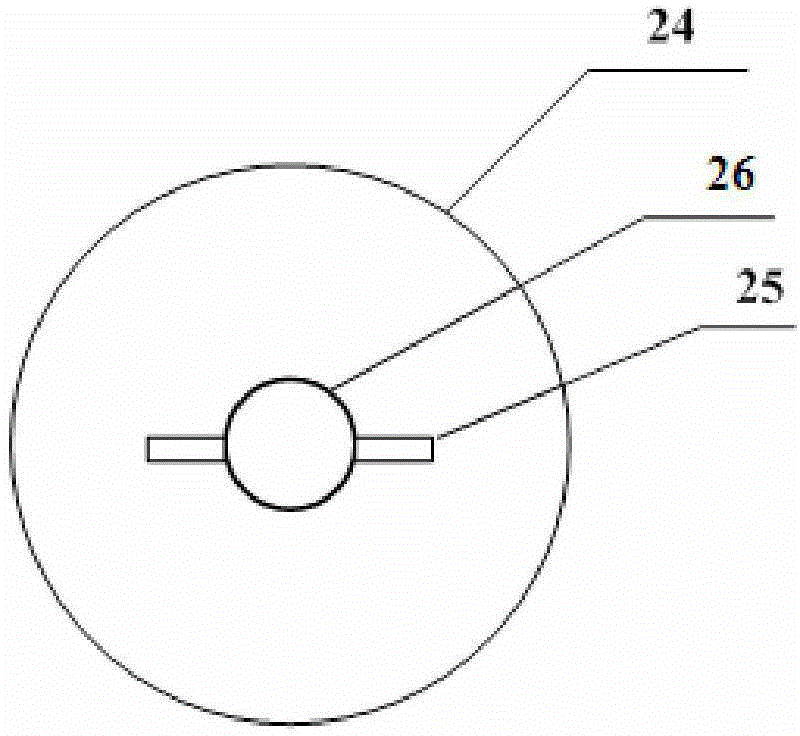

Column type extraction device for pipe bundle multi-channel phase-dispersing and extraction method thereof

InactiveCN102772913ALess prone to turbulenceSuitable for extraction operationLiquid solutions solvent extractionStraight tubeOil phase

The invention relates to a column type extraction device for pipe bundle multi-channel phase-dispersing; a main shaft is arranged inside the column type extraction device; two or at least three hollow thin tubes in parallel to the main shaft are distributed on the outer circumference of the main shaft; one end of each hollow thin tube is provided with a straight tube, and the other end of the hollow thin tube is bent to form a flanged bend; the bending direction of the flanged bend is the remote direction of a mounting shaft; the main shaft is connected with an electric motor, and drives the hollow thin tubes to carry out motion at a same speed with the main shaft when the main shaft rotates. The column type extraction device disclosed by the invention solves the difficult problems that a water phase or an oil phase with relatively small volume is difficult to disperse completely in the conventional mechanical stirring manner when the volume ratio of the water phase to the oil phase in an extraction process is large; and the difficult problems that the water phase and the oil phase are difficult to clarify and separate in an extraction system and the like caused by easy emulsification are also solved when the flow-rate ratio of the water phase to the oil phase is large.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

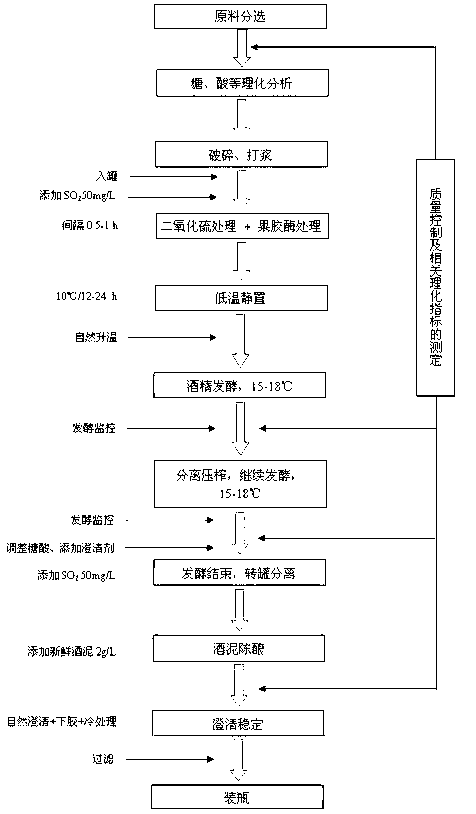

Low-yield methanol and higher alcohol fruit wine brewing process

ActiveCN103194354AFast clarificationReduce Methanol ContentAlcoholic beverage preparationPectinaseYeast

The invention relates to a fruit wine brewing method, and in particular relates to a low-yield methanol and higher alcohol fruit wine brewing process. The product prepared by the method disclosed by the invention fills blank of specific fruit wine brewing technology research in China, improves product quality of specific fruit wine, and enhances purity and typical aroma characteristic of wine and increases sense quality of the specific fruit wine, so as to make it possible to produce high-quality fruit wine products in many excellent fruit production zones. The technical scheme adopted by the invention comprises the following operation steps: (1) sorting fruit raw materials; (2) crushing, pulping and adding into a tank; (3) adding sulfur dioxide; (4) adding pectinase, and standing at low temperature; (5) naturally increasing temperature, adding a yeast culture liquor to start fermentation; (6) fermenting at controlled temperature, and monitoring fermentation; (7) separating, squeezing and continuing to ferment; (8) transferring to another tank, adding sulfur dioxide and storing; (9) aging in the presence of wine lees; and (10) clarifying, stabilizing, filtering and bottling.

Owner:福建猕尔康酒业有限公司

Method for clarifying liquid substance by using chitosan and carrageenan

InactiveCN101716011AImprove the effectGood product stabilityAlcoholic beverage preparationTeaMacromolecular SubstancesChemistry

The invention discloses a method for clarifying a liquid substance by using chitosan and carrageenan, and belongs to the technical field of food processing. The method comprises the following steps of: adding solution of chitosan and solution of carrageenan into the liquid substance to be clarified; mixing the solution of chitosan, the solution of carrageenan and the liquid substance to generate a floccule when the solution of chitosan is contacted with the solution of carrageenan in aqueous solution; and adsorbing and embedding macromolecular substances and suspended substances in the liquid substance to be clarified by using the floccule so as to clarify the liquid substance. The method is suitable for clarifying liquid beverage, such as fruit and vegetable juice containing phenols and protein with different precipitation mechanisms, tea beverage and the like. The method clarifies the liquid substance by using the chitosan and the carrageenan, so that the method can solve the problems of single function of a clarifier, long time consumption, high equipment investment, not high enough processing clarity and low solubility of the clarifier existing in the conventional clarification method; and the method has the advantages of little equipment investment, simple operation process, low price of raw materials, high clarifying speed, good effect and avoiding affecting the quality and flavor of a product and the like.

Owner:SOUTH CHINA UNIV OF TECH

Chaenomeles speciosa and glutinous rice wine and production technology thereof

ActiveCN104962418AKeep intactPromote fermentationAlcoholic beverage preparationBiotechnologyChaptalization

The invention provides chaenomeles speciosa and glutinous rice wine and a production technology thereof. The production technology includes the following steps of performing heating treatment on chaenomeles speciosa after peeling, stripping, slicing and cleaning of the chaenomeles speciosa; pulping the chaenomeles speciosa after heating treatment is finished; cooking and cooling down glutinous rice after soaking of the glutinous rice; adding distiller's yeast in the glutinous rice according to the weight of the glutinous rice and uniformly stirring the glutinous rice; saccharifying the glutinous rice; adding the processed chaenomeles speciosa pulp, sterile water and yeast in the saccharified glutinous rice after saccharifying is finished; uniformly stirring the mixture to obtain chaenomeles speciosa and glutinous rice wine mash; taking the same amount of glutinous rice; soaking, cooking, cooling down and saccharifying the glutinous rice according to the same technology; adding the glutinous rice in the chaenomeles speciosa and glutinous rice wine mash to perform fed-batch fermentation after saccharifying is finished; filtering the chaenomeles speciosa and glutinous rice wine mash by using a gauze after fermentation is finished; adding compound clarifier in filtered wind liquid; performing clarification to obtain the chaenomeles speciosa and glutinous rice wine; heating the chaenomeles speciosa and glutinous rice wine liquid; and ageing the chaenomeles speciosa and glutinous rice wine liquid to obtain the chaenomeles speciosa and glutinous rice wine. The alcoholic strength of the obtained wine is high; and the chaenomeles speciosa and glutinous rice wine is rich in triterpene and flavonoids compounds and is nutritional and functional healthcare wine.

Owner:宣城市宣海棠生物科技有限公司

Compound clarifying agent for high aluminosilicate glass

The invention discloses a compound clarifying agent for high aluminosilicate glass. The compound clarifying agent comprises the following raw materials in percentage by weight: 39 to 63 percent of sodium nitrate; 21 to 46 percent of sodium chloride; 10 to 26 percent of cerium dioxide. The compound clarifying agent comprises the sodium nitrate (NaNO3), sodium chloride (NaCl) and cerium dioxide (CeO2) with certain contents, can obviously improve the clarifying speed of glass, obviously reduce the quantity of minute bubbles (d is smaller than 0.2 micrometer), and further improve the light transmittance of glass, and is green and environmentally friendly, and particularly applicable to high aluminosilicate glass and high aluminosilicate glass containing boron. The compound clarifying agent canrealize rapid and thorough bubble elimination at an optimum proportion, thereby reducing the production cost and improving the production efficiency.

Owner:ZHEJIANG UNIV

Clarifying agent of wild grape wine

The invention discloses a clarifying agent of wild grape wine, and belongs to the technical field of foods. The clarifying agent of the wild grape wine provided by the invention, especially a protease clarifying agent and a compound clarifying agent, has the advantages that the clarifying speed is high, the clarifying effect is good, the wine body is stable, the influence to the main physical and chemical components of the wild grape wine and the content of amino acid is almost neglected, and the clarifying agent can be stored for a long time; the quality of the wild grape wine is improved, and the practice production is instructed.

Owner:HEZHOU UNIV

Colored glaze preparation method

InactiveCN106145672AFast clarificationImprove clarity and transparencySodium carbonateSodium nitrate

The invention discloses a method for preparing colored glaze. The colored glaze is composed of the following components in parts by mass: 60-80 parts of quartz sand, 12-18 parts of aluminum oxide, 24-36 parts of soda ash, and 3-5 parts of sodium nitrate parts, 1-3 parts of pigments, 6-10 parts of clarifiers, and adopt the processing technology of mixing, smelting, clarification and molding successively, the present invention can accelerate the clarification speed of materials, thereby effectively improving the clarification of the glass made And transparency, high use value.

Owner:TAICANG CITY SHUANGFENG TOWN BOCAI ARTWORK FACTORY

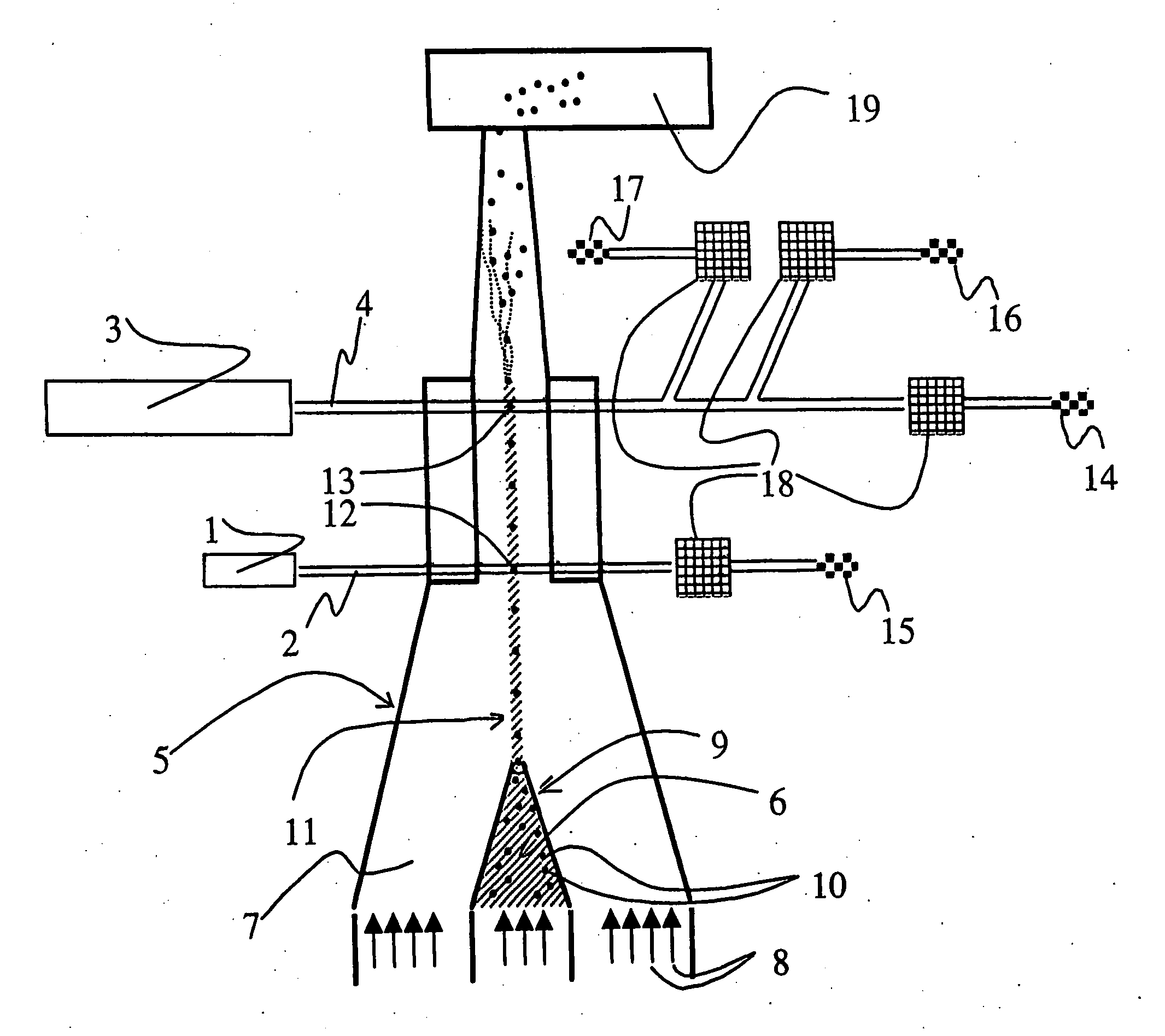

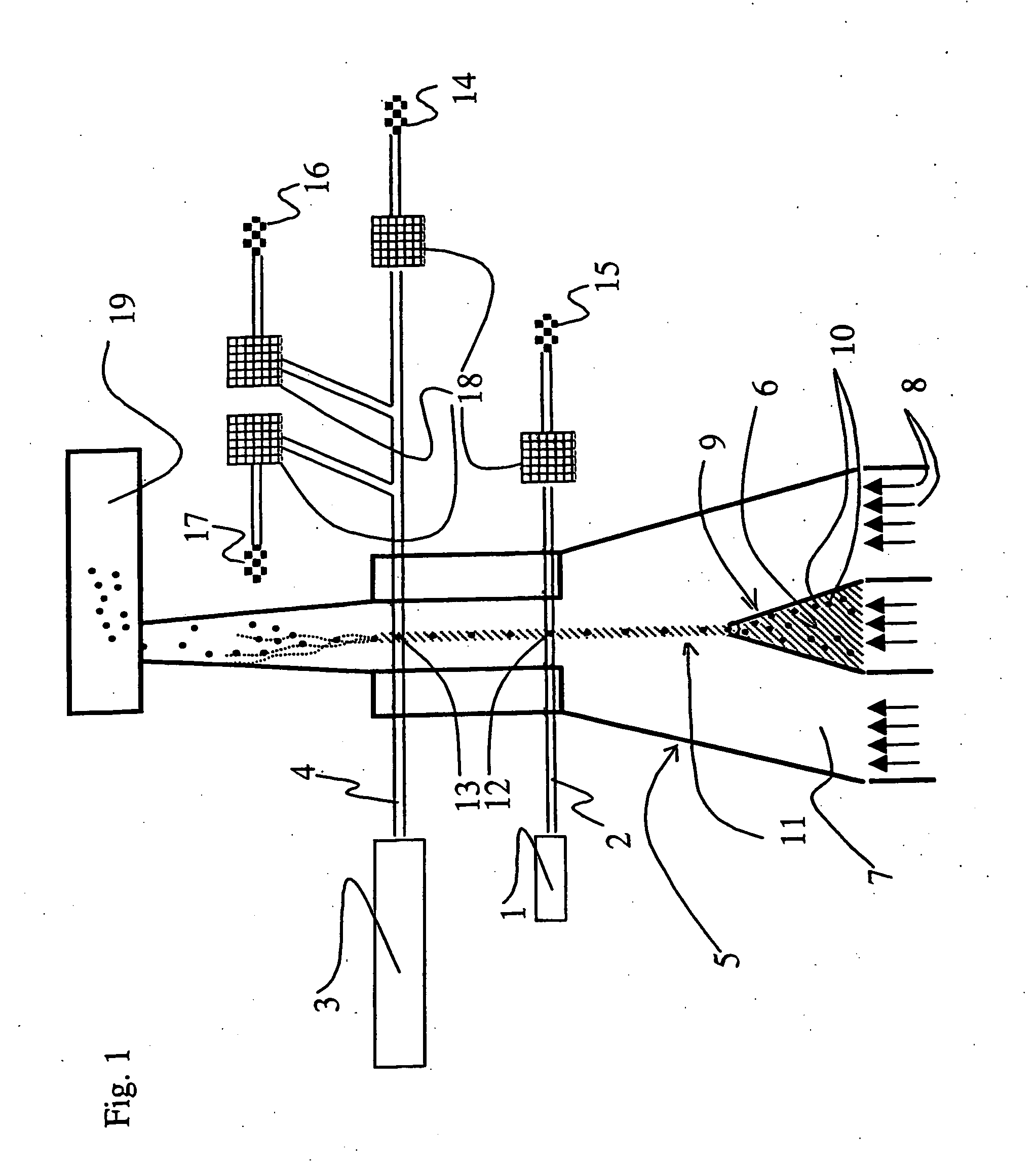

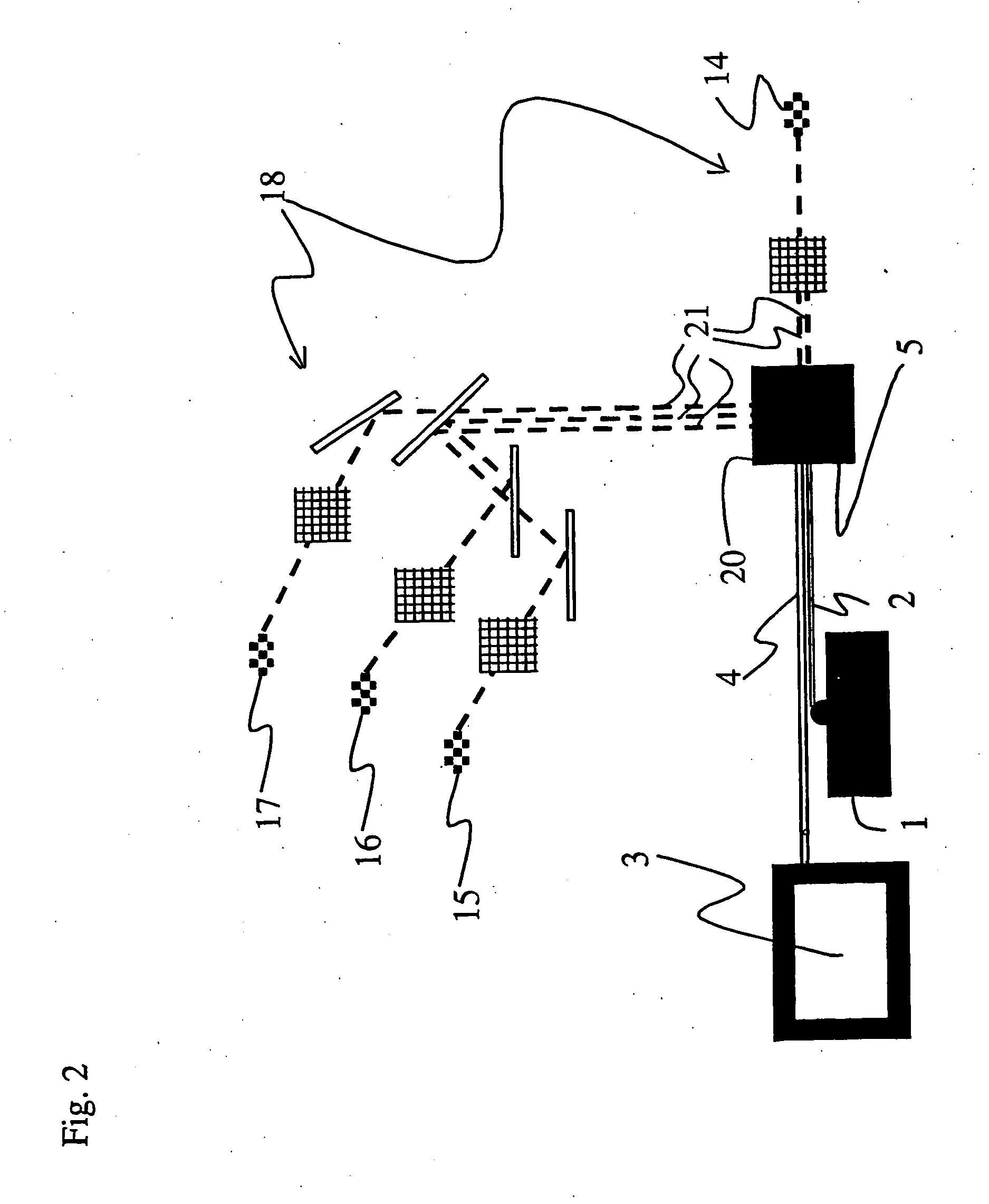

Method and device for identifying micro organisms

InactiveUS20060152721A1Quick analysisFast clarificationRadiation pyrometrySpectrum investigationMicroorganismFluorescence

The invention relates to a method and device for identifying at least one micro organism and / or micro organism species and for measuring the portion of at least one micro organism and / or micro organism species from a sample. The method includes the use of two different fluorescent agents and the excitation with light in two different wavelengths. The sample is subjected to a flow. Furthermore, the invention relates to the use of the aforementioned method and device for identifying micro organisms and for measuring their portions.

Owner:CYFLO

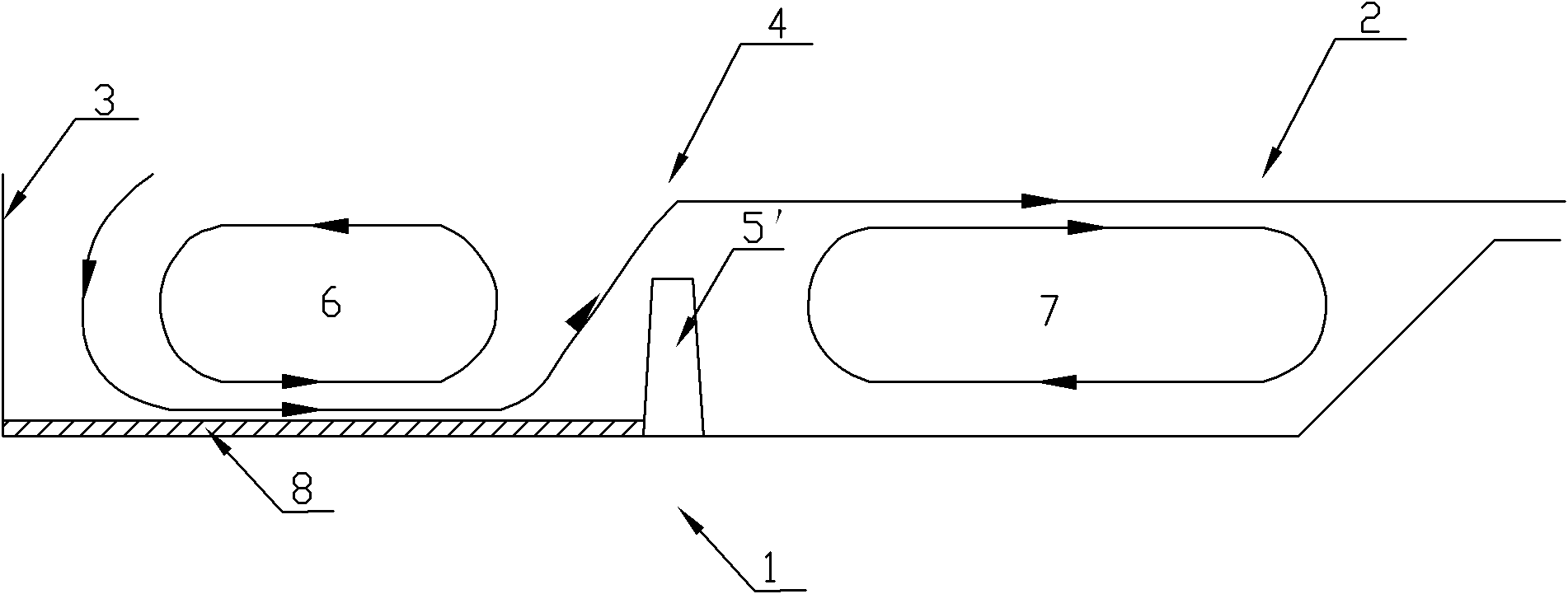

Float glass melting furnace

The invention discloses a float glass melting furnace, comprising a melting region which is arranged at the forepart of the melting furnace, wherein a charging opening is arranged at the front end of the melting region; a hot spot is arranged in the middle of the melting region along the length direction; a furnace bank is arranged at the hot spot of the melting region; the length dimension of the furnace bank is same as the width dimension of a pool of the melting region; the height of the furnace bank is 50-70% of the depth of the pool of the melting region; and the thickness of the furnace bank is 300-400mm. By adopting the structure, the float glass melting furnace can maintain the stability of two circulating glass melt flows in the melting furnace and prolong the residence time of the glass melt in the melting furnace to contribute to the clarification and the homogenization of the glass melt, and can prevent the dirty materials at the bottom of the pool of the melting region from directly flowing to a cooling region and prevent a part of the glass melt in the cooling region from reflowing to the melting region to be reheated, thereby improving the melting quality of the glass melt, saving the energy, and lowering the loss of the float glass melting furnace.

Owner:ZHANGZHOU KIBING GLASS +1

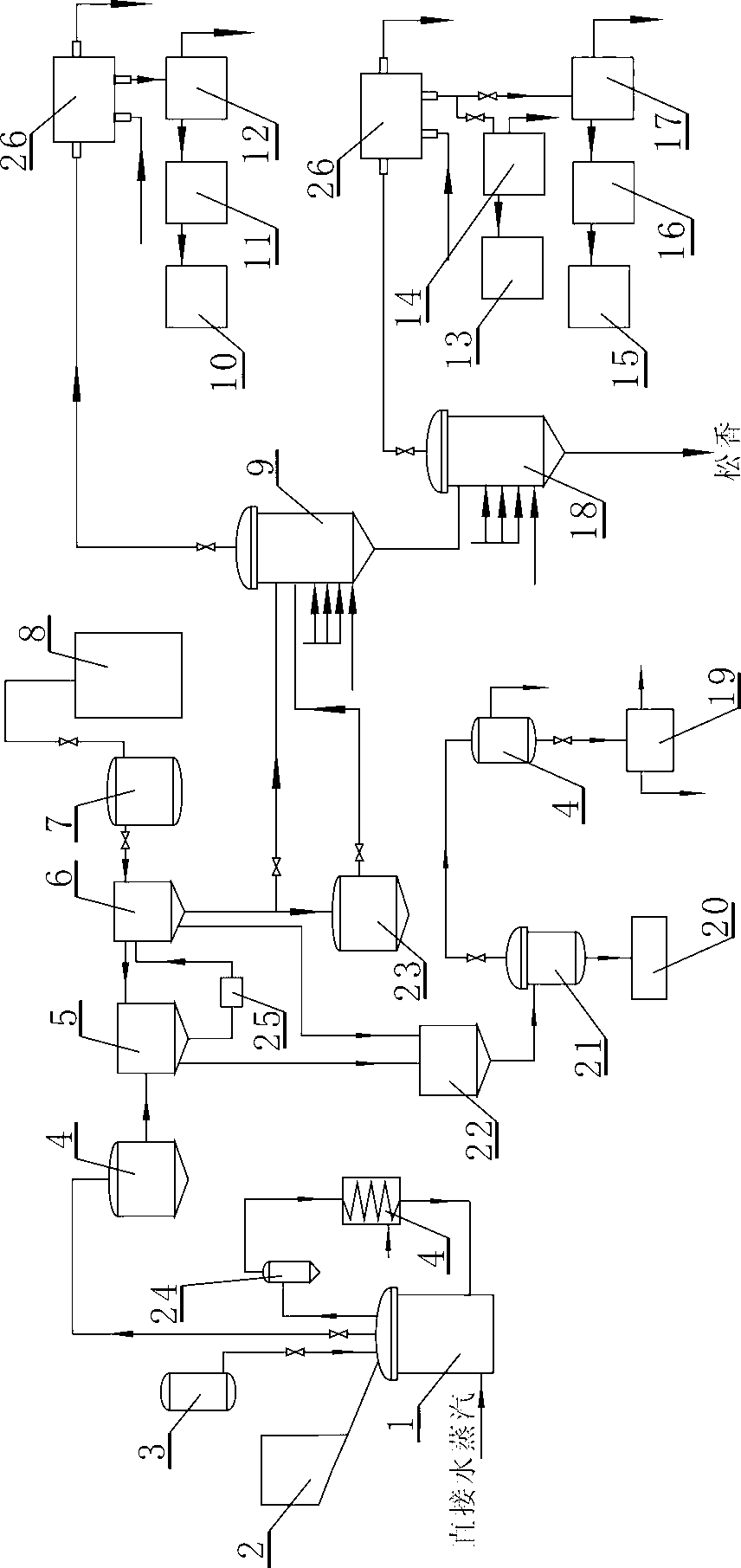

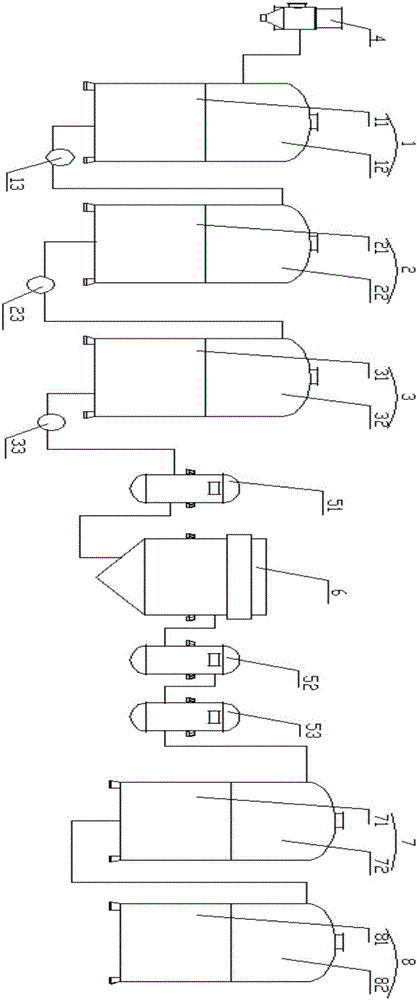

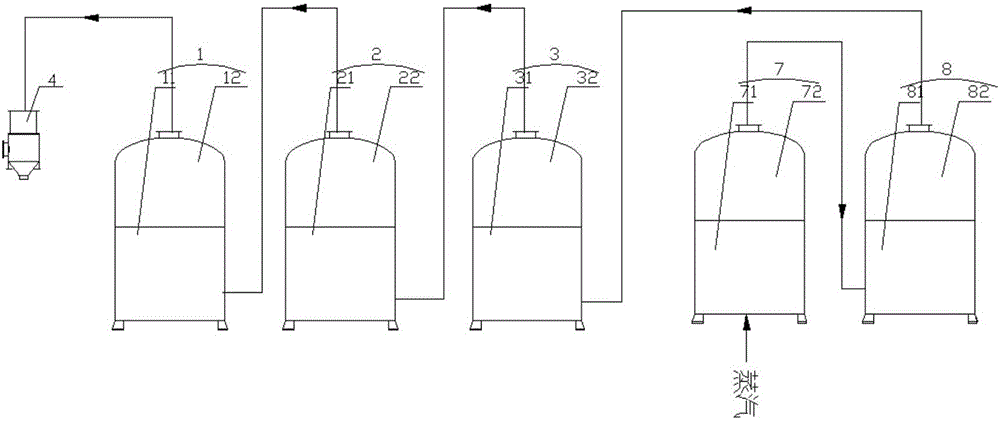

Reverse evaporating and concentrating system for molasses alcohol waste liquid

ActiveCN105771293ALow deposit hardnessEasy to cleanEvaporator accessoriesMultistage water/sewage treatmentChemistryEvaporator

The invention provides a reverse evaporating and concentrating system for molasses alcohol waste liquid. The flowing direction of a material is as follows in sequence: a V-effect evaporator, a IV-effect evaporator, a III-effect evaporator, a II-effect evaporator and a I-effect evaporator; low-concentration alcohol waste liquid at about 80 DEG C from a distillery enters the V-effect evaporator, and is pumped into the IV-effect evaporator and the III-effect evaporator in sequence; after medium-concentration alcohol waste liquid from the III-effect evaporator is heated to 95 DEG C or above through a first heater, the medium-concentration alcohol waste liquid precipitates and is clarified in a clarifying pond, then is heated to 105 DEG C through a second heater and a third heater, enters the I-effect evaporator, and then enters the II-effect evaporator. According to the reverse evaporating and concentrating system for the molasses alcohol waste liquid, the using amount of primary steam in alcohol production is reduced by utilizing an energy-saving transformation technical method of using secondary steam generated by multiple-effect evaporation of the waste liquid in alcohol distillation, so that the energy consumption of the alcohol production is reduced, and the production operation cost is reduced.

Owner:GUANGXI UNIV

Method for settling juice wine

ActiveCN103122303AFast clarificationStable bodyAlcoholic beverage preparationBiotechnologyActivated carbon

The invention provides a method for settling juice wine. The method comprises the following steps of: 1) settling and filtering by using chitosan and bentonite fining; 2) carrying out refrigeration filtration; and 3) carrying out adsorption filtration by using activated carbon. The juice wine settled by the method is clear and transparent, the method on the main physical and chemical components of the juice wine are hardly affected and the juice wine can be preserved for a long time.

Owner:江苏品王酒业集团股份有限公司

Clarifying agent for reducing acid and gel in fruit and vegetable juice and liquors, and preparation method of clarifying agent

ActiveCN104856184AEasy to separate by filtrationThe glue effect is obviousAlcoholic beverage preparationFood scienceCalcium EDTAFruits and vegetables

The invention discloses a clarifying agent for reducing acid and gel in fruit and vegetable juice and liquors, and a preparation method of the clarifying agent. The clarifying agent is prepared from the following ingredients in percentage by weight: 17%-45% of mixed calcium salt, 2%-6% of noncalcified gel, and 50%-80% of a sodium alga acid. The preparation method of the clarifying agent for reducing acid and gel in fruit and vegetable juice and liquors comprises the following steps: uniformly stirring the ingredients with mixed calcium salt, and enabling the mixed calcium salt to be made into particles by stamping; coating the surface of the mixed calcium salt with the noncalcified gel; and finally, coating the outer layer of the noncalcified gel with the sodium alga acid. The preparation method disclosed by the invention is simple and convenient in preparation process, the acid and gel reduction can be performed in real time, and the effects are obvious.

Owner:诸暨市凯诺食品添加剂厂 +1

Method for preparing beer bottles from cullet

The invention provides a method for preparing beer bottles from cullet. A powder material is added into every 1000 kg of cullet. During the preparation of a white beer bottle, the powder material comprises, by weight, 55-57 kg of quartz sand, and soda 15 - 19 kg of soda ash, 15-19 kg of calcite, 3-6 kg of dolomite, 6-8 kg of feldspar, 3-5 kg of mirabilite, 5-7 kg of fluorspar, and 1-2 kg of sodium nitrate or 0.5-1.5 kg of cerium dioxide. During preparation of a green beer bottle, the powder material comprises, by weight, 53-57 kg of quartz sand, 17-21 kg of soda ash, 7-10 kg of calcite, 3-5kg of dolomite, 4-6 kg of feldspar, 4-6 kg of mirabilite, 5-7 kg of fluorspar and 0.5-1.5 kg of chrome ore powder. During preparation of a brown beer bottle, the powder material comprises, by weight, 52 -56 kg of quartz sand, 17-20 kg of soda ash, 12-15 kg of calcite, 3-5 kg of dolomite, 4-6 kg of feldspar, 5-7 kg of mirabilite, 5-7 kg of fluorspar and 0.3-1.0 kg of carbon powder. The method of invention can improve the utilization rate of cullet and guarantee glass quality and allows the prepared glass to be applicable to the manufacturing of beer bottles.

Owner:刘书刚

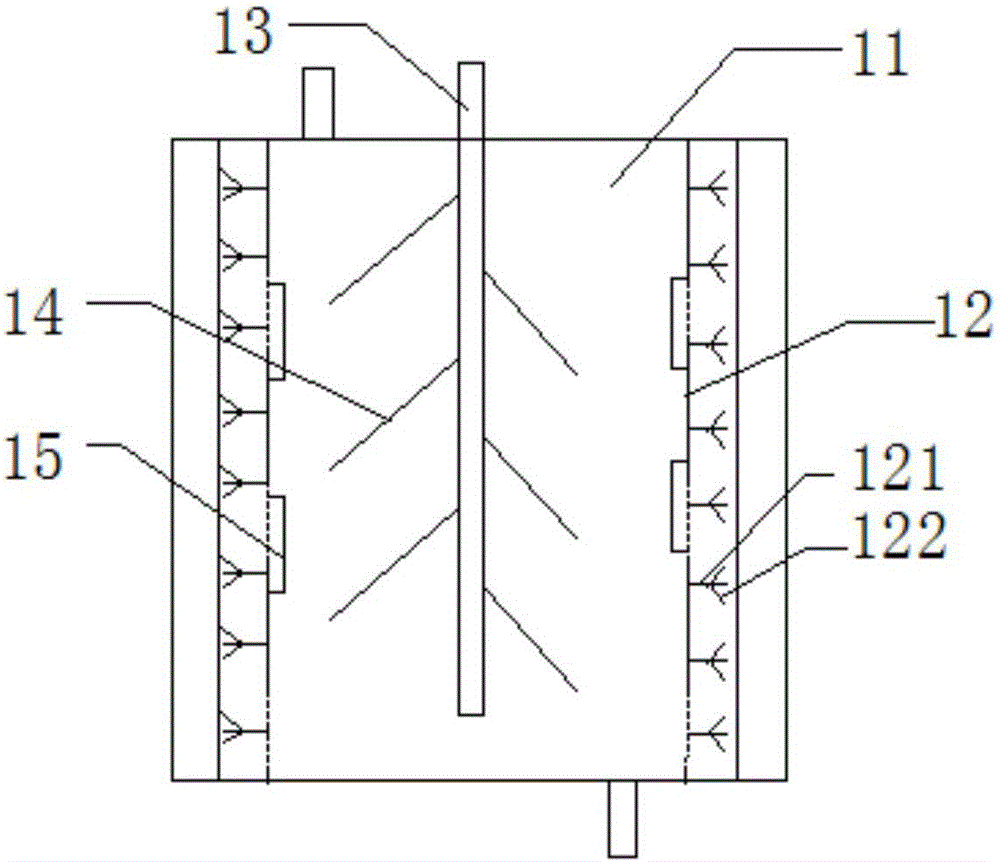

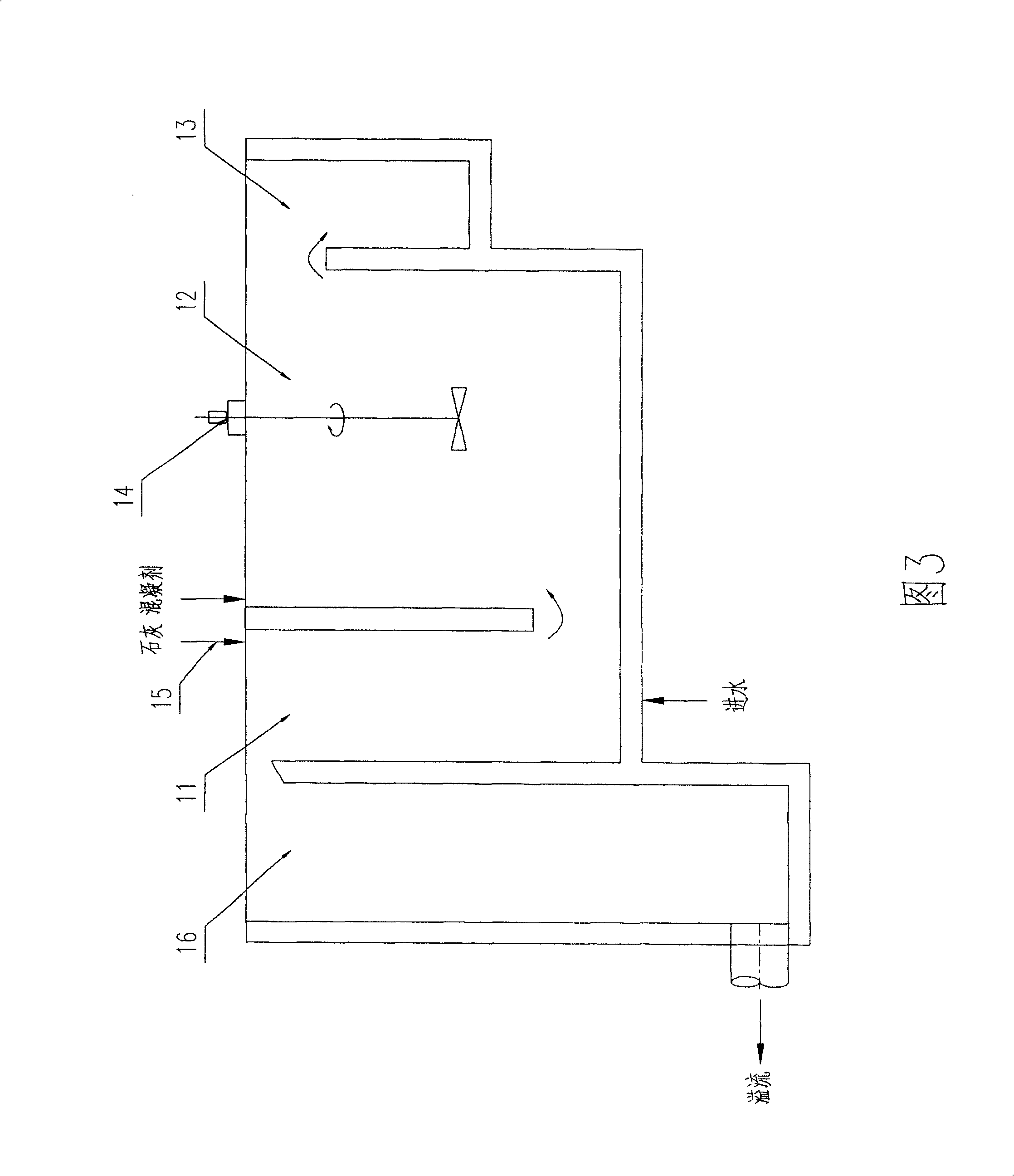

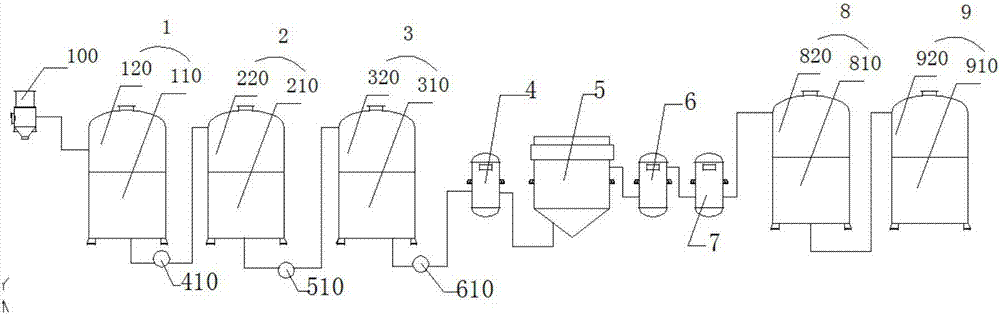

Gum rosin processing unit adopting vacuum filtration method

InactiveCN103059733AFast clarificationReduce chance of oxidationNatural resin purificationRosinChemistry

The invention discloses a gum rosin processing unit adopting a vacuum filtration method, and the gum rosin processing unit comprises a dissolving device, a clarification plant and a distilling device, wherein the dissolving device comprises a dissolving kettle, a hopper and a grease feed tank; the dissolving kettle is connected with a direct water vapor source; the clarification plant comprises a vacuum filtering device and a negative pressure device matched with the vacuum filtering device; the negative pressure device comprises a vacuum cylinder and a low-position water-jet vacuum unit; the distilling device comprises a distilling kettle and a fraction purifying device; a grease liquid outlet of the dissolving kettle is technically connected with an inlet of the vacuum filtering device; a pure grease liquid outlet of the vacuum filtering device is technically connected with the inlet of the distilling kettle; and a distillation outlet of the distilling kettle is technically connected with the fraction purifying device. By replacing the traditional natural sedimentation clarification method by a vacuum filtration method, the gum rosin processing unit disclosed by the invention increases the clarification speed, reduces the time of the grease liquid in a high-temperature environment, increases good quality rate, reduces the amount of intermediate-layer grease liquid, and increases the yield of the product. The method mentioned in the invention is suitable for production of gum rosin adopting an intermittent or continuous vapor method.

Owner:KUNMING GEMING COMMERCE & TRADE CO LTD

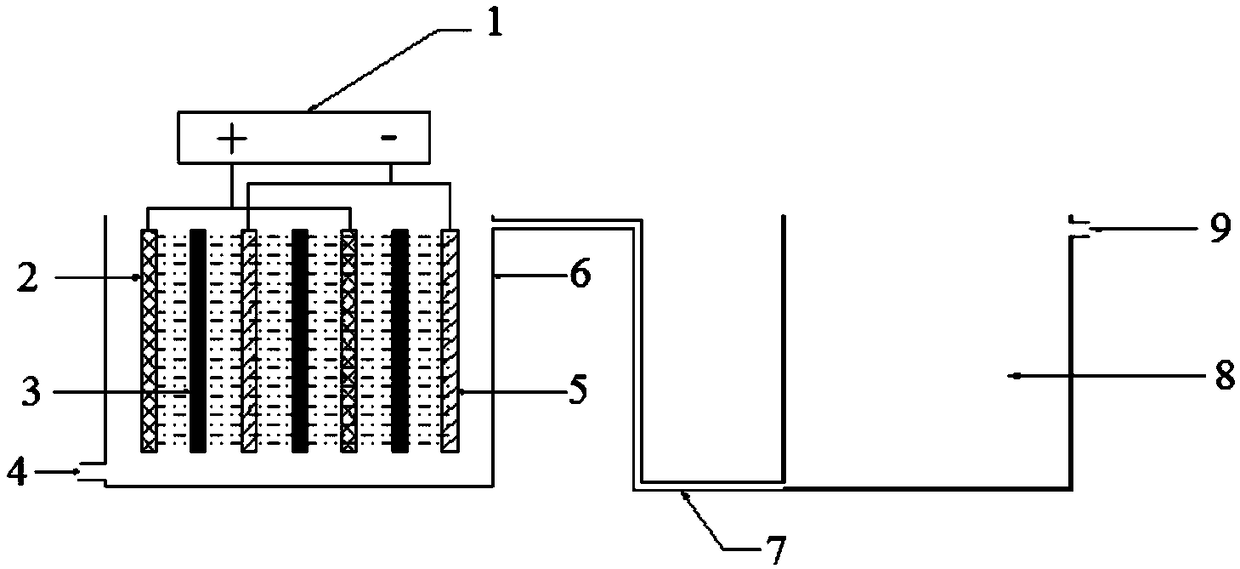

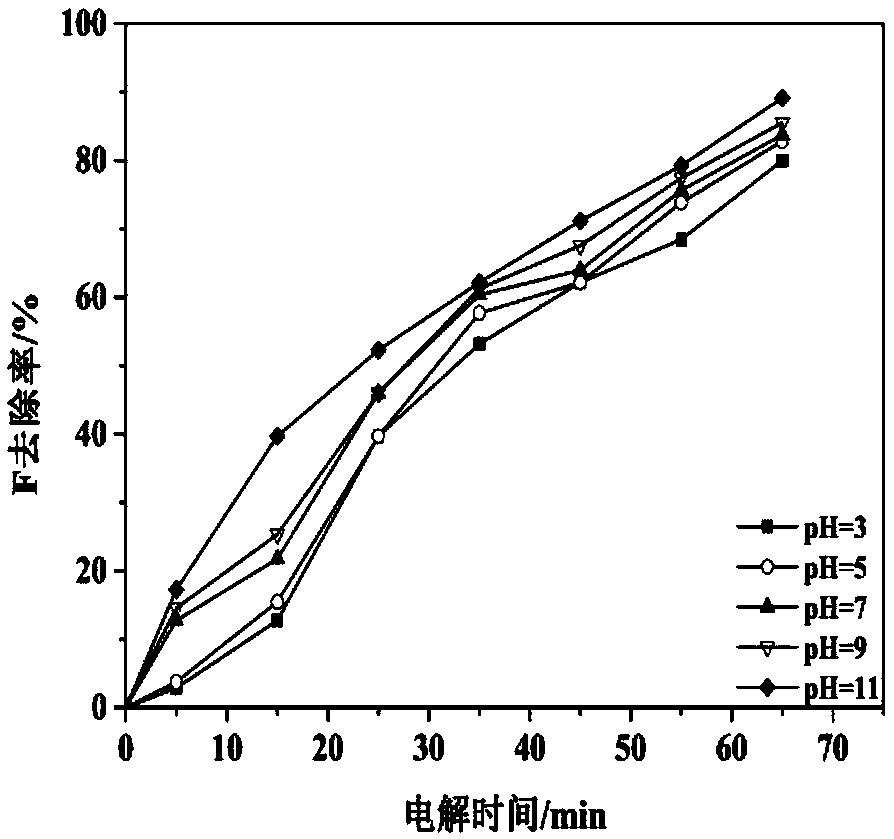

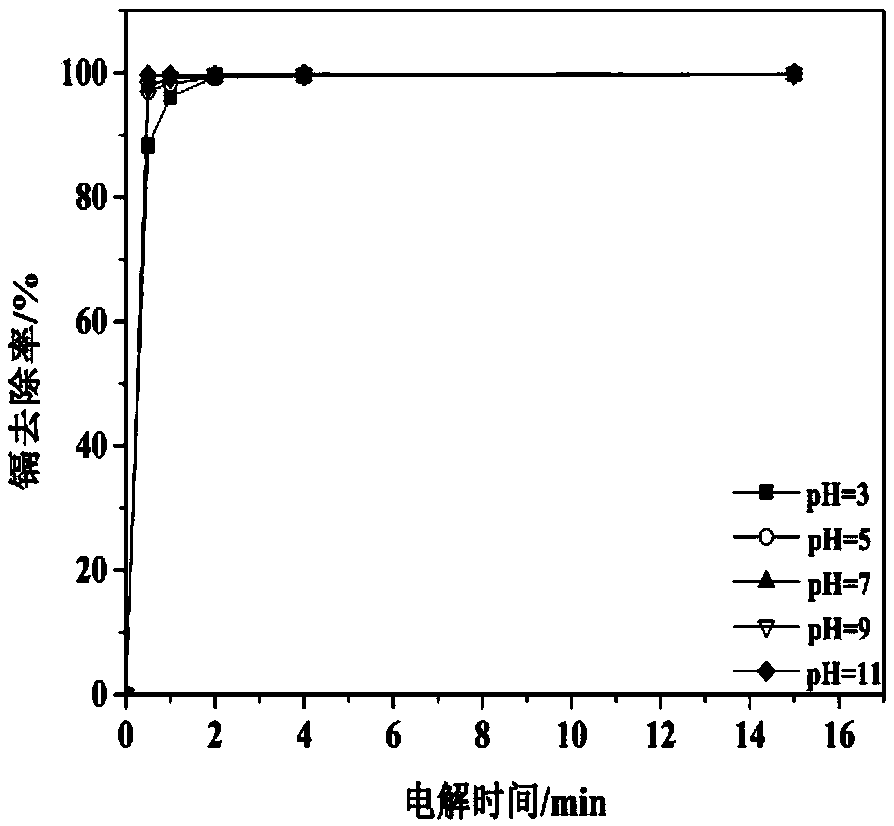

Electroflocculation method and device for simultaneously removing fluorine and cadmium from rural groundwater

PendingCN109384284AQuick removalImprove efficiencyWater contaminantsWater/sewage treatmentElectricityEngineering

The invention relates to an electroflocculation method and an electroflocculation device for simultaneously removing fluorine and cadmium from rural groundwater. The electroflocculation device comprises a power supply, an electroflocculation reaction tank, anode plates, cathode plates, bipolar plates, a clarification tank and a drainage pipe, wherein the cathode plates and the anode plates are incrossing interval placement; meanwhile, the bipolar plates are inserted between the cathode plates and the anode plates; the cathode plates and the anode plates are separately connected through conductive wires, and are connected to the negative electrode and the positive electrode of the power supply respectively; the polar plates are arranged inside the electroflocculation reaction tank; the electroflocculation reaction tank is connected with the clarification tank through the drainage pipe; a water inlet is formed in the lower part of the electroflocculation reaction tank. The electroflocculation method is simple; by the electroflocculation method, the pollutant removing efficiency is high; the electroflocculation method is a novel method for removing the fluorine and the cadmium from the groundwater, by which addition of a chemical is not required and operation is flexible and simple.

Owner:SOUTH CHINA UNIV OF TECH +1

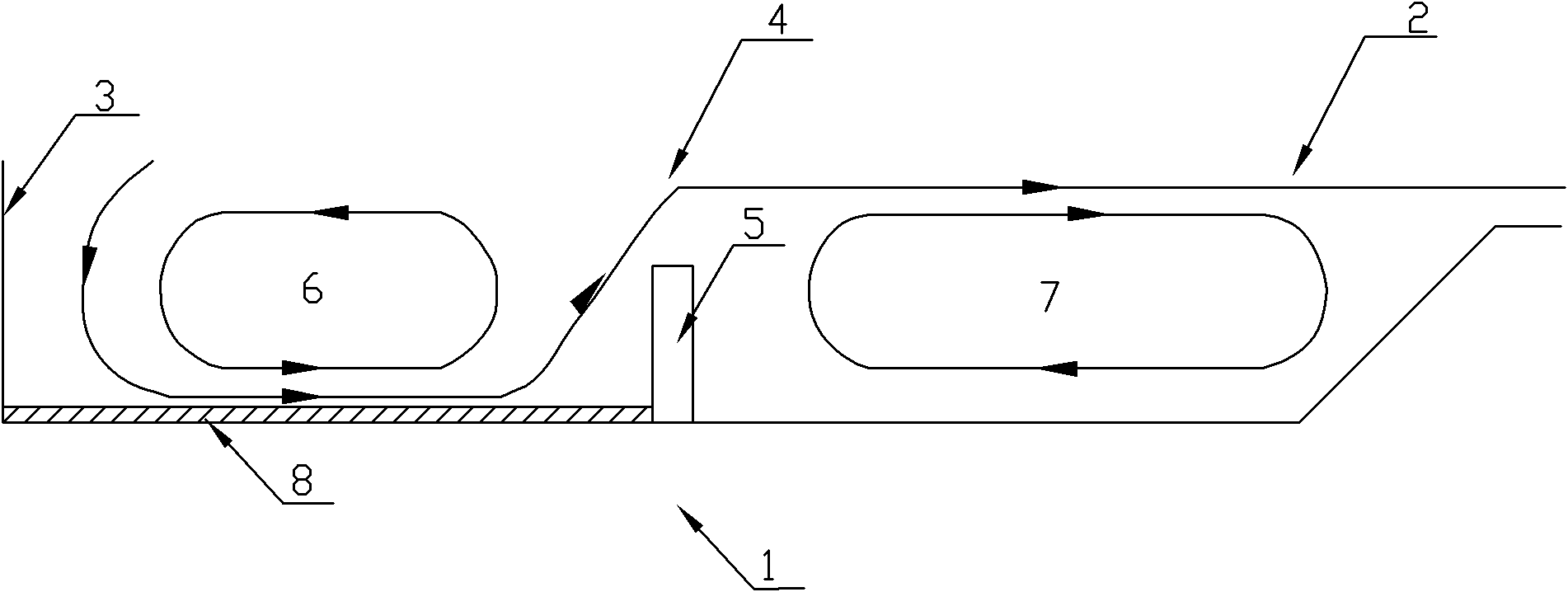

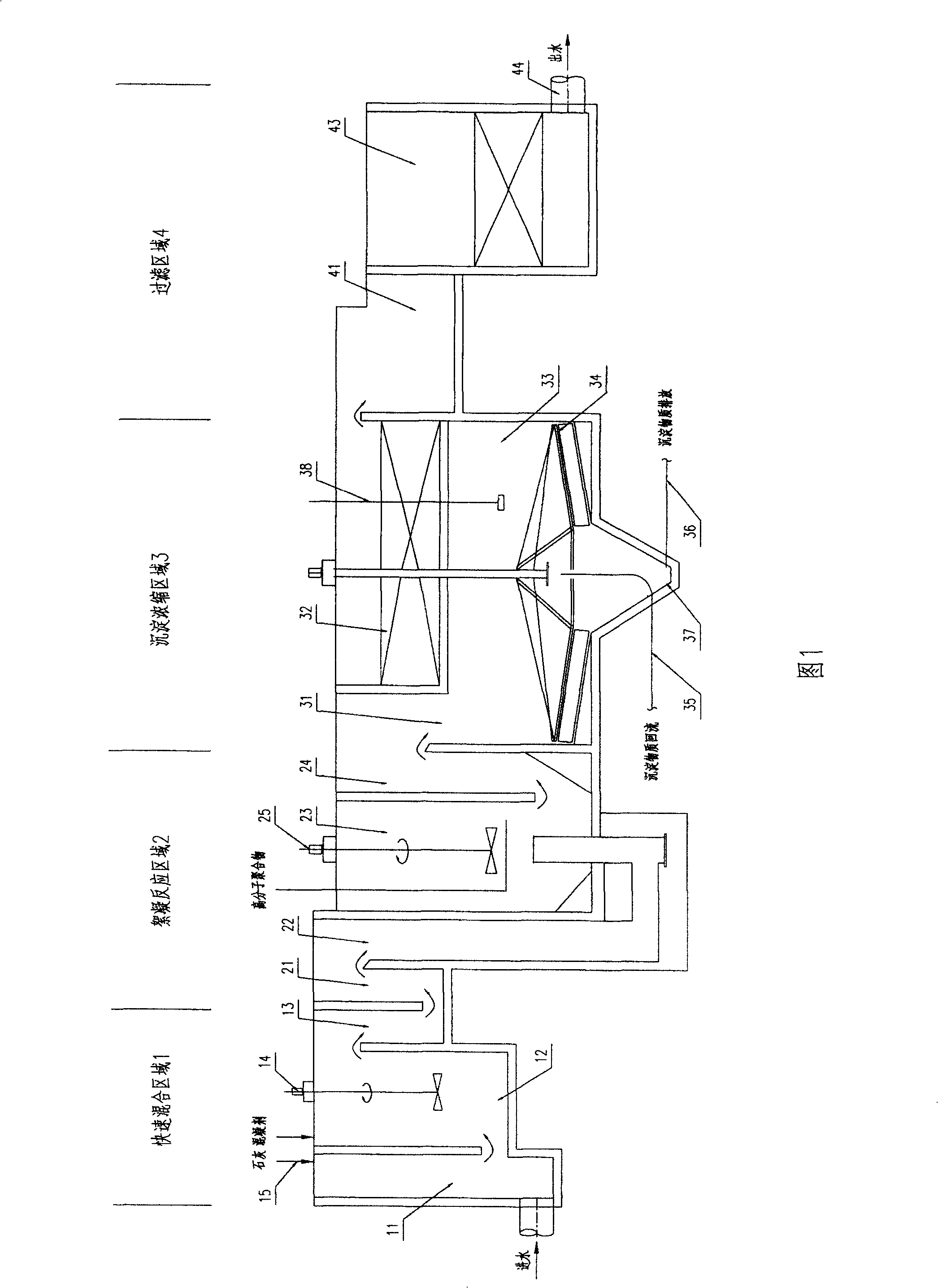

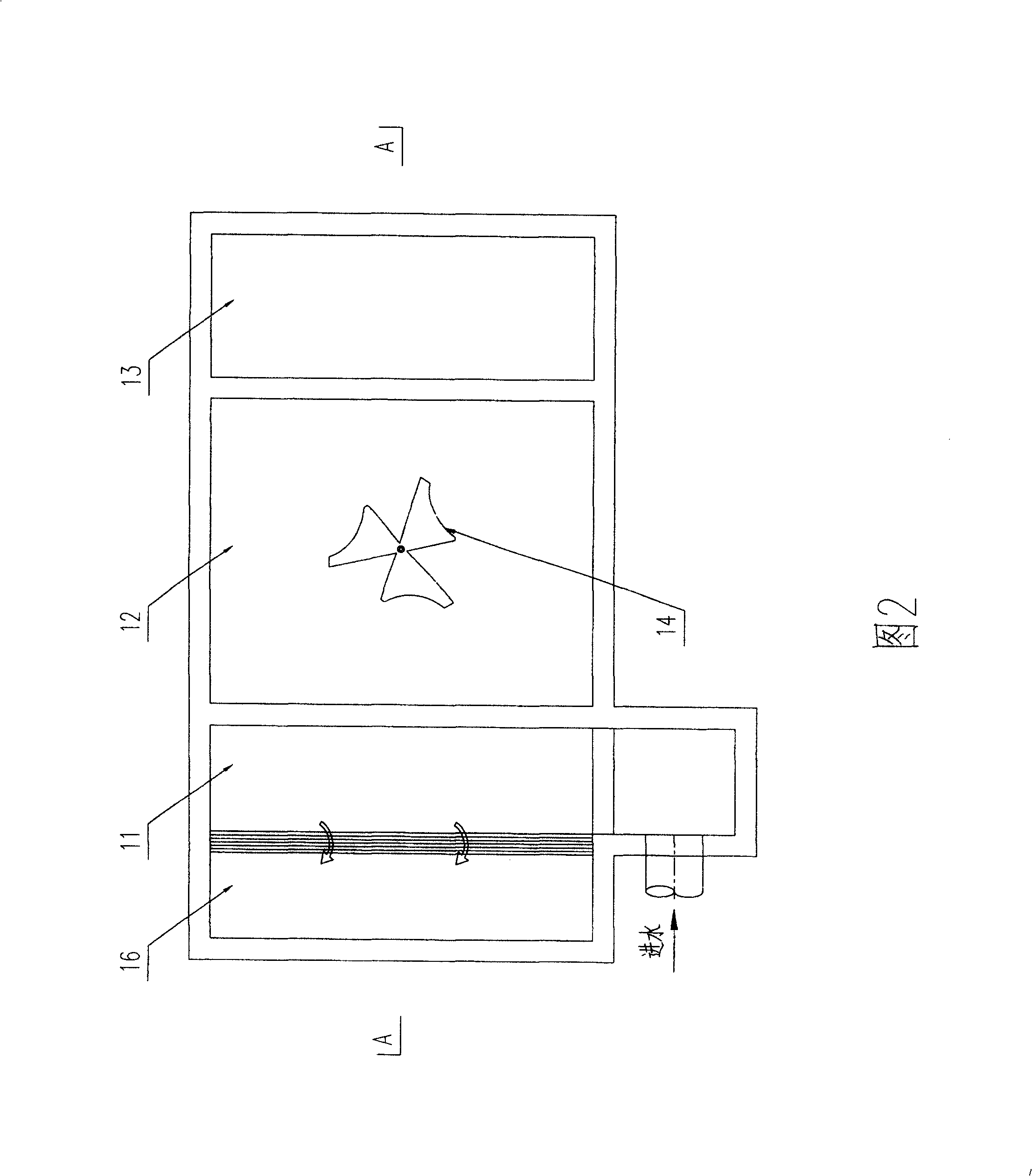

Method and equipment for purifying recirculated cooling water or town B-grade sewage

ActiveCN100415338CPromote productionEasy to quantifyWater/sewage treatment by flocculation/precipitationSedimentation settling tanksPurification methodsSewage

The invention relates to a purification method and equipment for cool circulating water or town secondary sewage water, and is characterized in that the invention has the following steps: a quick mixing zone 1 for mixing a ready treated liquid and a mixing medicament, a flocculating reaction zone 2 for mixing and flocculating a mixed liquid with a backflow deposit substance to get a compact alum at an outlet of the zone, a depositing and concentrating zone 3 for separating a supernatant liquor and a suspension solid and for returning and draining a deposit substance, and a filtering facility zone 4 for purifying the supernatant liquor; the equipment of the invention mainly comprises the quick mixing zone, a high efficient clarification tank and a filtering zone; the invention designs the purification method and equipment for liquid and water; the water quality from the invention is stable, the cost is lower, which changes the prior purification method for liquid and water.

Owner:华电水务(天津)有限公司

Apple composite fruit juice and preparation method thereof

InactiveCN109105695AIncrease the fragranceSweetness adjustmentNatural extract food ingredientsFood ingredient functionsFruit juiceAdditive ingredient

The invention discloses apple composite fruit juice and a preparation method thereof, and relates to the technical field of fruit juice. The apple composite fruit juice is prepared from the followingraw materials in parts by weight: 40 to 50 parts of apple, 20 to 30 parts of hawthorns, 20 to 30 parts of emblic leafflower fruits, 4 to 10 parts of fruits of Chinese wolfberry, 2 to 6 parts of arabian jasmine flowers, 4 to 10 parts of stevia rebaudiana, 5 to 12 parts of liquorice roots, 5 to 12 parts of herba lophatheri, 1 to 2 parts of clarifying agents, 7 to 13 parts of sweet agents and 100 to140 parts of water. The apple composite fruit juice prepared by the method has the advantages of transparent color and luster, pleasant faint scent, unique flavor, high nutrition content, storage resistance and high quality. Compared with fruit juice clarified by a clarifying agent prepared from tea residue and tannin through simple mixing, the apple composite fruit juice has the advantages that the light transmission rate is improved by 16.2 percent; after the placement for 6 months, no precipitates are generated; the light transmission rate is only reduced by 5.1 percent; a few of precipitates occur at the bottom of fruit juice clarified by the clarifying agent prepared from tea residue and tannin through simple mixing after the placement for 6 months in normal temperature.

Owner:ANQING CITY LYUYIN AGRI DEV

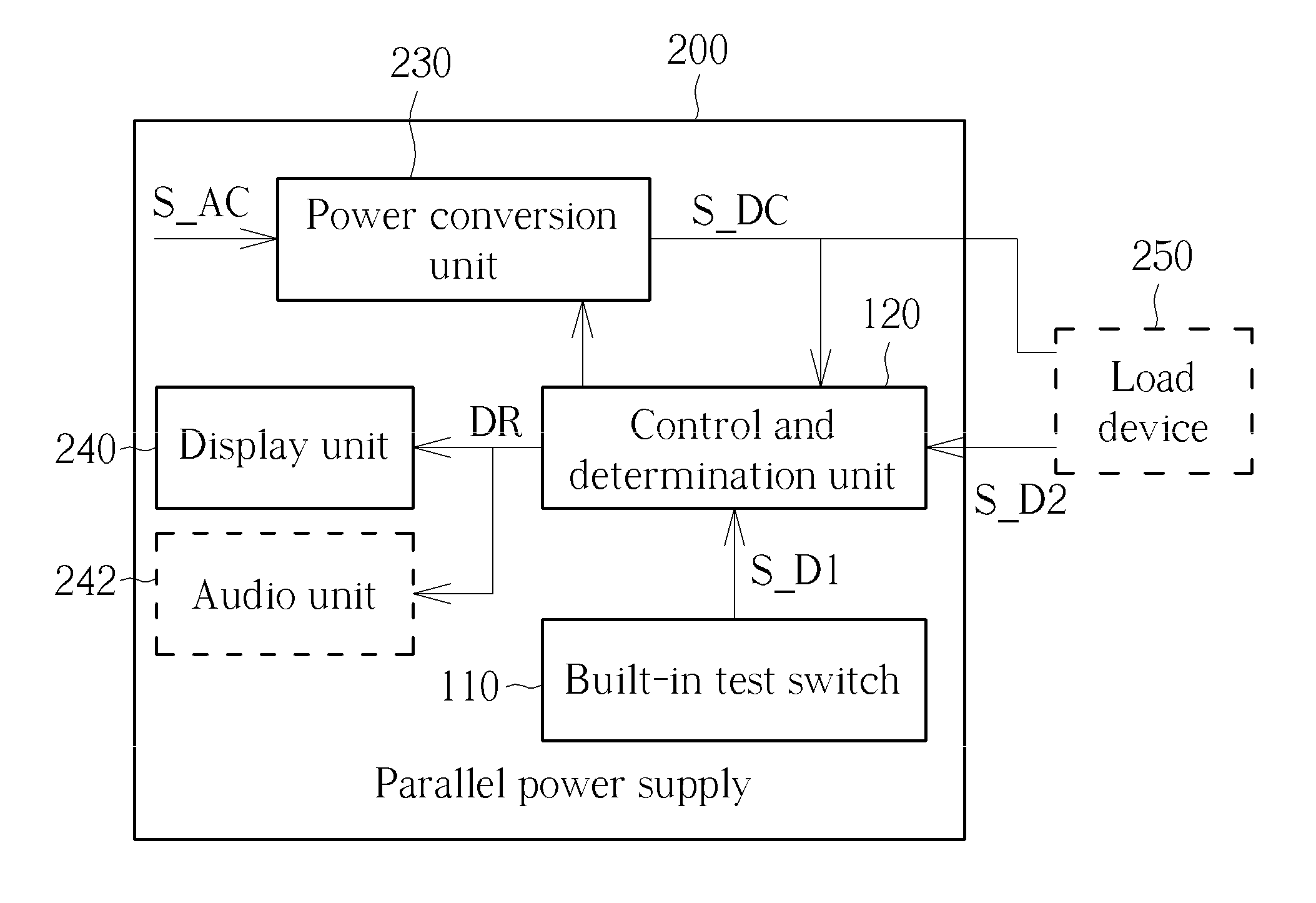

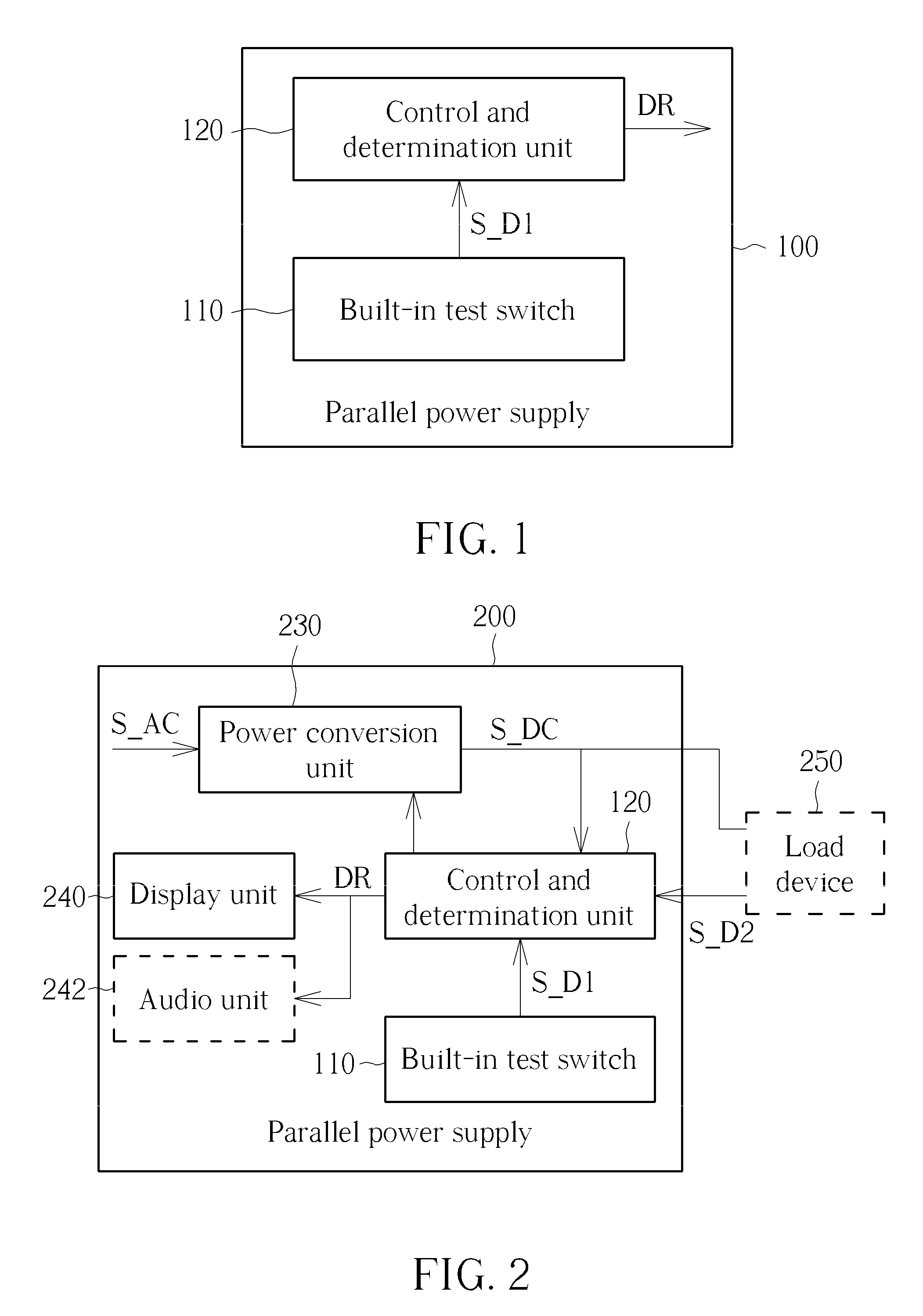

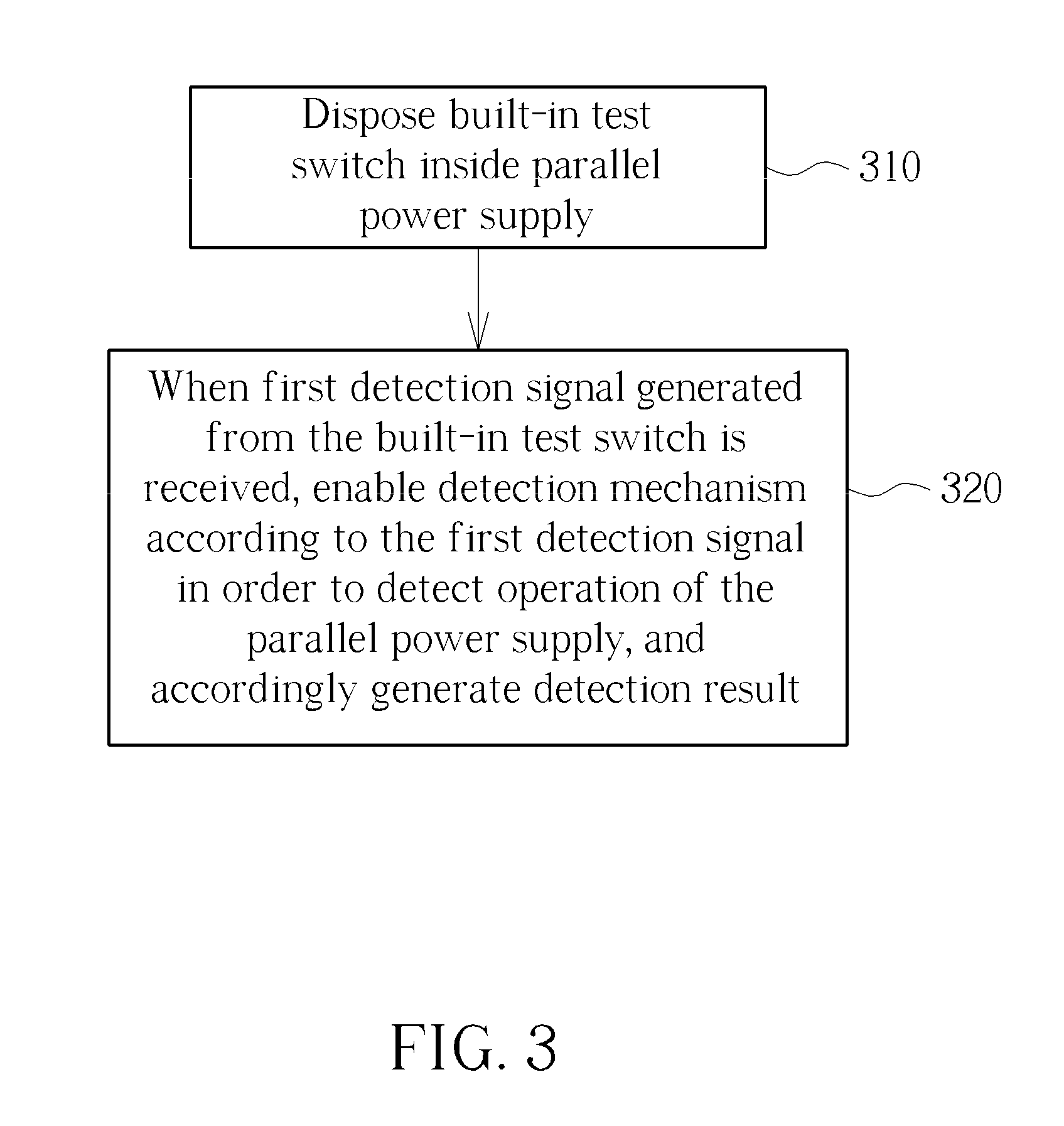

Parallel power supply and power detection method for parallel power supply

ActiveUS9280167B2Easy qualityLow costAc-dc conversionDc source parallel operationEngineeringElectrical and Electronics engineering

A parallel power supply includes a built-in test switch and a control and determination unit. The built-in test switch is arranged to generate a first detection signal. The control and determination unit is coupled to the built-in test switch. When receiving the first detection signal, the control and determination unit is operative for enabling a detection mechanism according to the first detection signal in order to detect an operation of the parallel power supply, and accordingly generating a detection result. A power detection method for a parallel power supply includes: disposing a built-in test switch inside the parallel power supply; and when receiving a first detection signal generated from the built-in test switch, enabling a detection mechanism according to the first detection signal in order to detect an operation of the parallel power supply, and accordingly generating a detection result.

Owner:3Y POWER TECH TAIWAN

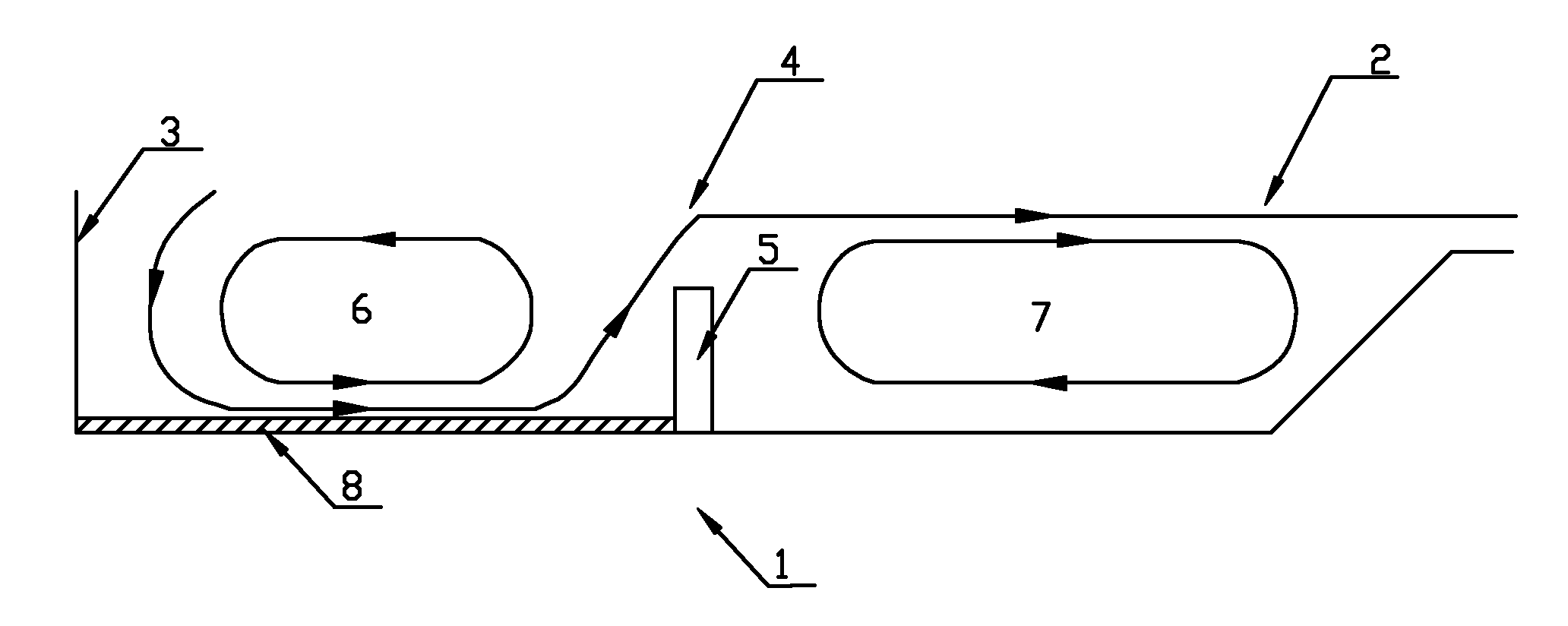

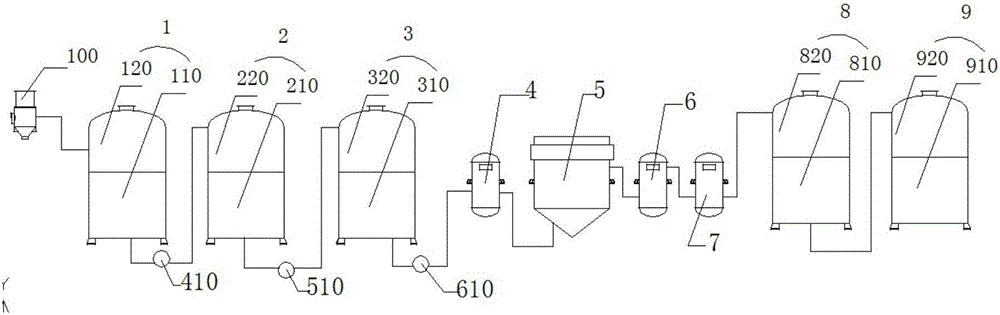

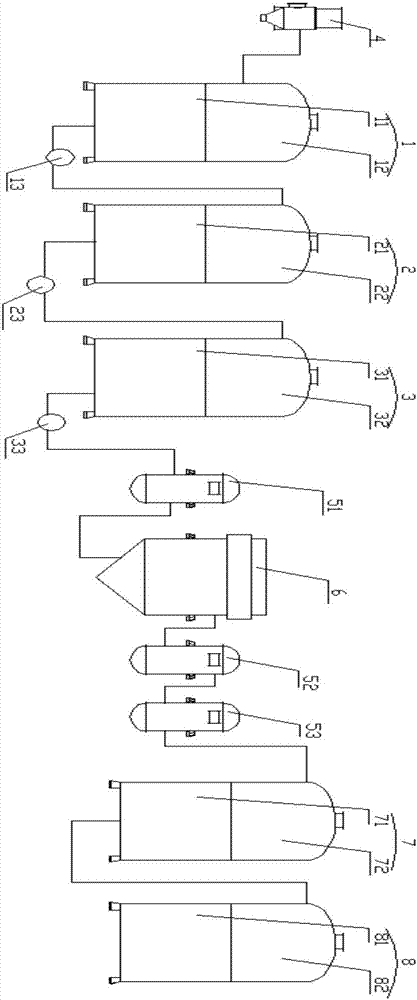

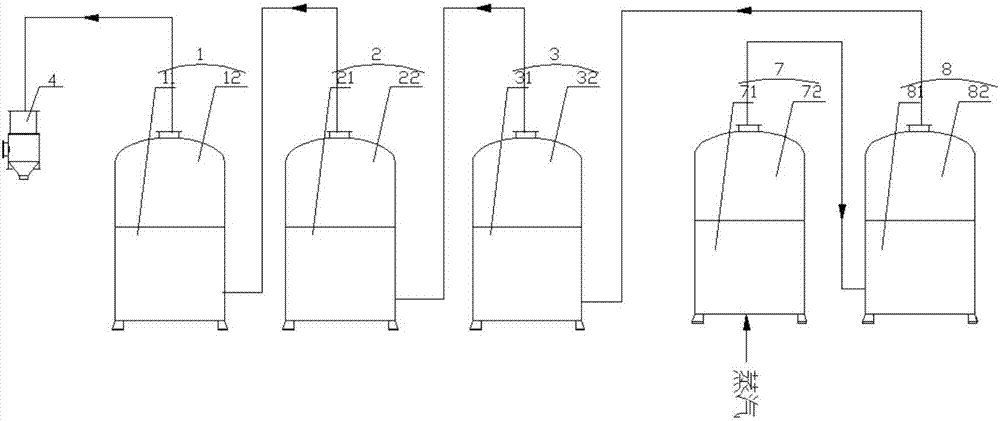

Evaporation and Concentration System of Molasses Alcohol Waste Liquid as Heat Source in Alcohol Distillation Room

ActiveCN105688431BReduced fouling and dehydrationEasy to cleanEvaporator accessoriesTreatment involving filtrationLiquid wasteDistillation

The invention discloses a molasses alcohol waste liquor evaporation and concentration system serving as a heat source of an alcohol distillery. Materials pass through a V-effect evaporator, an IV-effect evaporator, an III-effect evaporator, a first heater, a clarification tank, a second heater, a third heater, an I-effect evaporator and an II-effect evaporator in the flowing direction of molasses alcohol waste liquor; low-concentration alcohol waste liquor at the temperature of 80 DEG C from the distillery enters a V-effect evaporation tank and is pumped into an IV evaporation tank and an III-effect evaporation tank. Medium-concentration alcohol waste liquor from the III-effect evaporation tank is heated to 95 DEG C or higher by the II-effect juice steam and the first heater, enters the clarification tank to be clarified, is heated to 105 DEG C by the second heater, the third heater and I-effect juice steam and enters the I-effect evaporation tank and the II-effect evaporation tank. Secondary steam generated through multi-effect evaporation of the waste liquor is used for an energy-saving reconstruction technique for alcohol distillation, the use amount of primary steam during alcohol production is reduced, the energy consumption during alcohol production is reduced, and the production and operation costs are saved.

Owner:GUANGXI UNIV

Molasses Alcohol Waste Liquid Reverse Evaporation Concentration System

ActiveCN105771293BReduce usageReduce consumptionEvaporator accessoriesMultistage water/sewage treatmentLiquid wasteDistillation

The invention provides a reverse evaporating and concentrating system for molasses alcohol waste liquid. The flowing direction of a material is as follows in sequence: a V-effect evaporator, a IV-effect evaporator, a III-effect evaporator, a II-effect evaporator and a I-effect evaporator; low-concentration alcohol waste liquid at about 80 DEG C from a distillery enters the V-effect evaporator, and is pumped into the IV-effect evaporator and the III-effect evaporator in sequence; after medium-concentration alcohol waste liquid from the III-effect evaporator is heated to 95 DEG C or above through a first heater, the medium-concentration alcohol waste liquid precipitates and is clarified in a clarifying pond, then is heated to 105 DEG C through a second heater and a third heater, enters the I-effect evaporator, and then enters the II-effect evaporator. According to the reverse evaporating and concentrating system for the molasses alcohol waste liquid, the using amount of primary steam in alcohol production is reduced by utilizing an energy-saving transformation technical method of using secondary steam generated by multiple-effect evaporation of the waste liquid in alcohol distillation, so that the energy consumption of the alcohol production is reduced, and the production operation cost is reduced.

Owner:GUANGXI UNIV

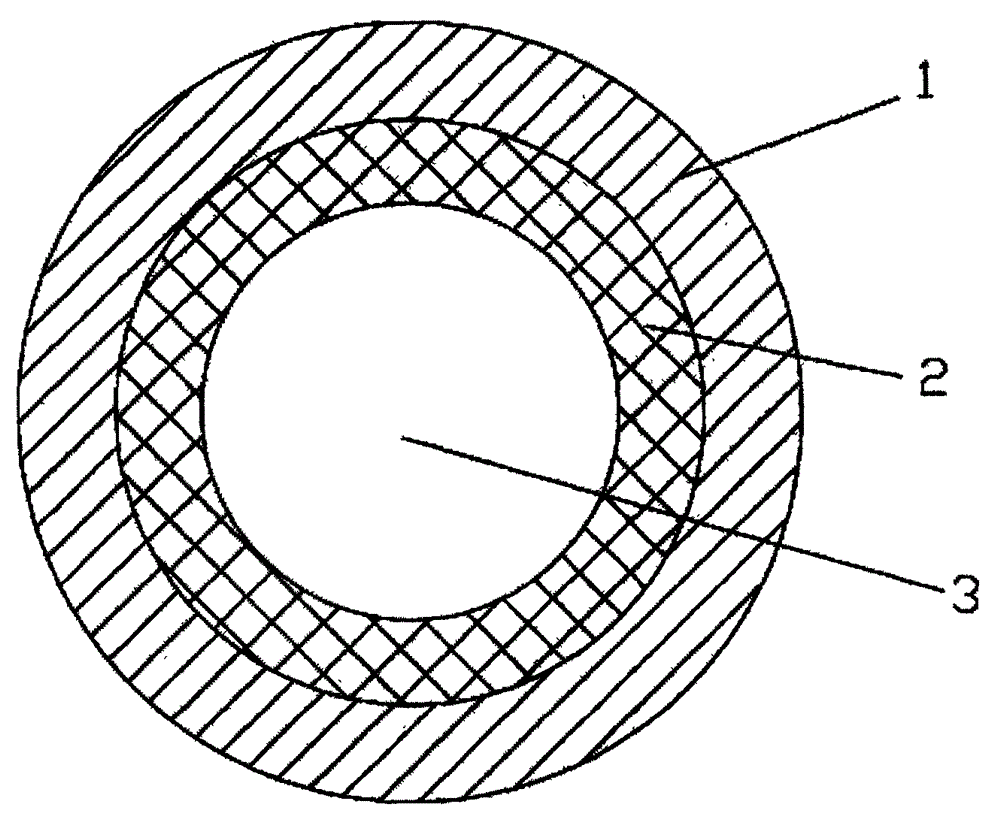

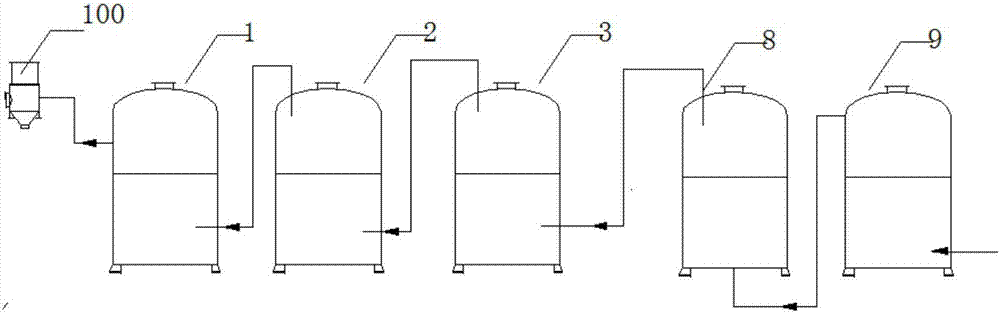

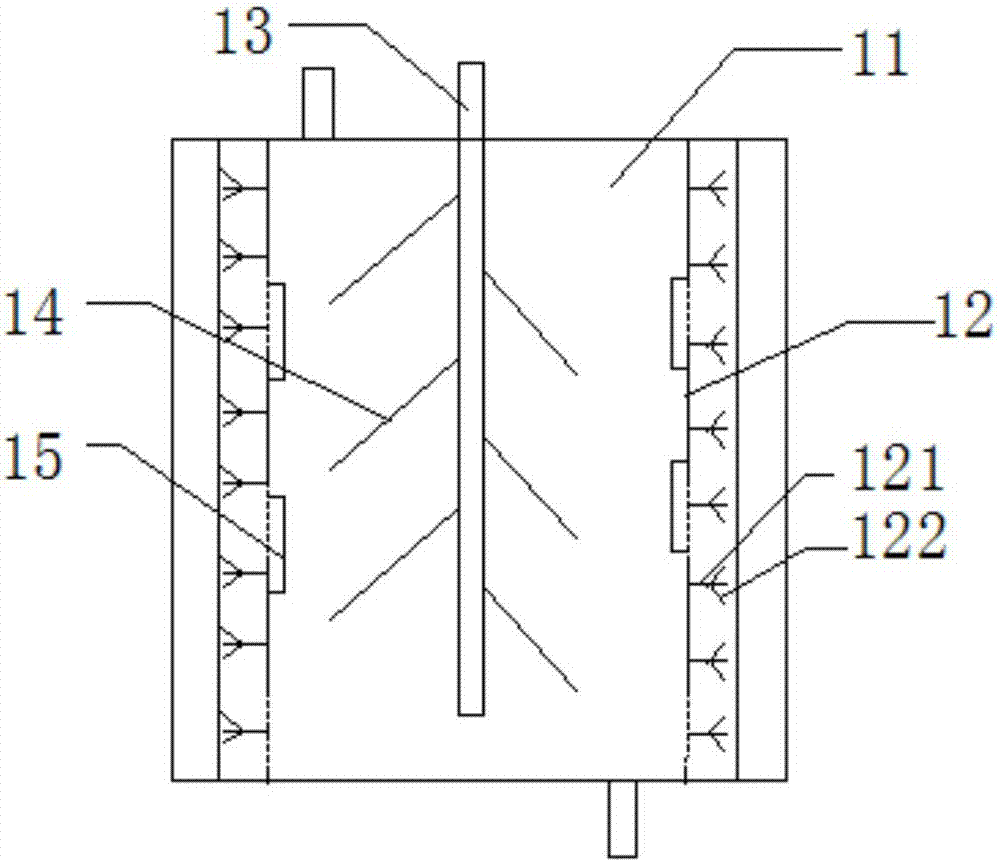

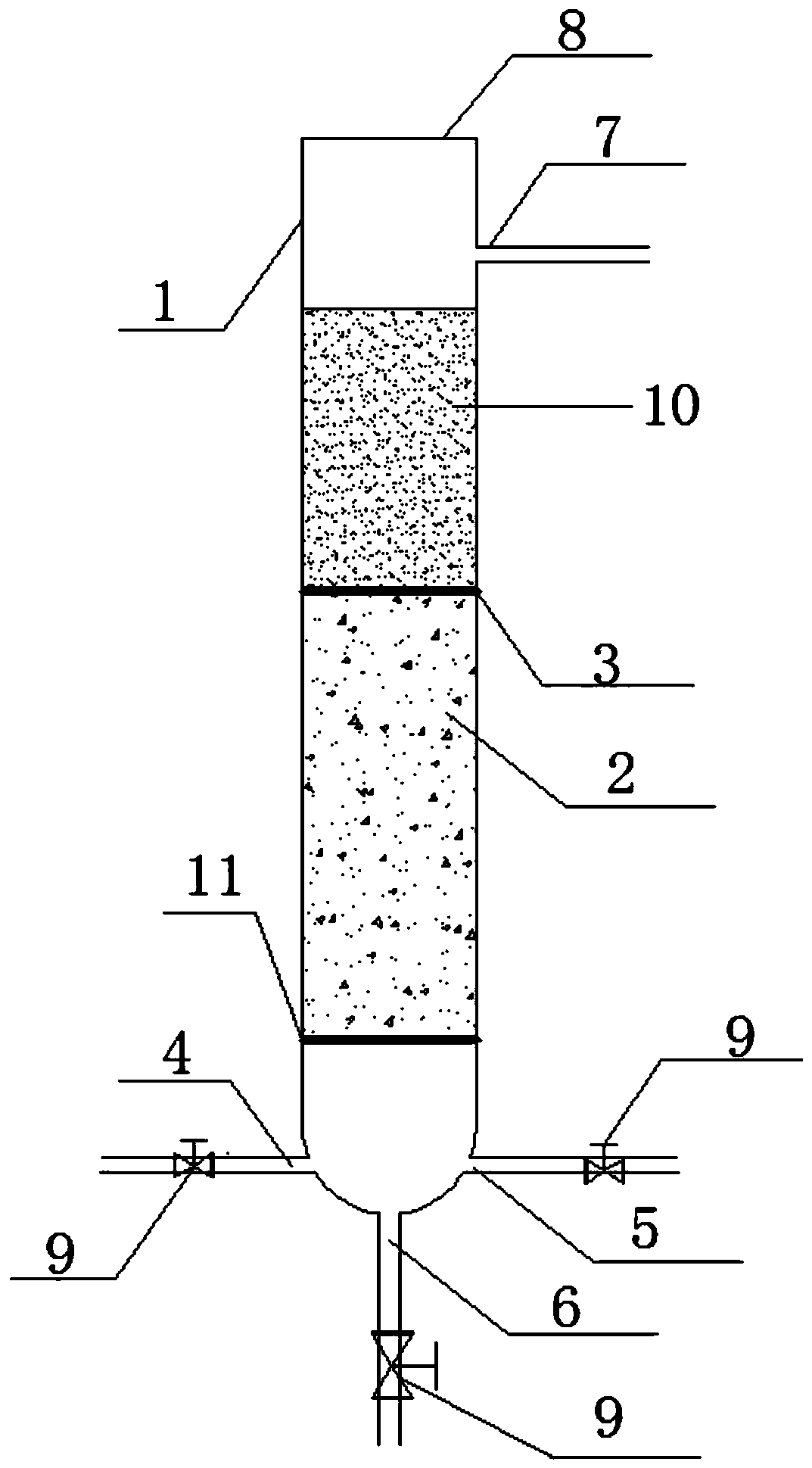

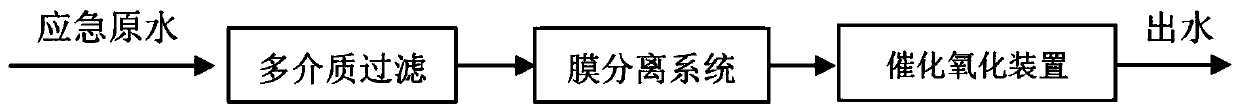

Catalytic oxidation device for water treatment, its manufacturing method and water treatment process

ActiveCN107285516BLarge adsorption capacityHigh speedTreatment involving filtrationMultistage water/sewage treatmentWater sourceFiltration

The present invention relates to a catalytic oxidation apparatus for water treatment, and a production method thereof, and a water treatment process. A purpose of the present invention is to solve the technical problems of difficult removal of organic pollutants from polluted water sources and low water purification efficiency in the existing water treatment technology. According to the present invention, active carbon and quartz sand are subjected to mixing alkalization activation to form the catalytic oxidation apparatus with characteristics of developed pore structure, large specific surface area, high adsorption capacity and high speed; the water treatment process comprises multi-medium filtration-membrane separation-catalytic oxidation and other links, wherein the polysilicic acid structure and the poly iron structure are formed on the surface during the iron supporting and alkalization activation process of the active carbon and the quartz sand in the catalytic oxidation link so as to provide catalysis effects for a variety of difficultly-degraded organic matters; and the apparatus can be used for the rapid and safe treatment of non-standard surface water, groundwater and other emergency water source water under emergency conditions so as to make the obtained water achieve the drinking water standard, and can further be used in the fields of deep treatment, reuse and the like of difficultly-degraded organic polluted wastewater.

Owner:SHANXI UNIV

Molasses alcohol waste liquor evaporation and concentration system serving as heat source of alcohol distillery

ActiveCN105688431AReduce consumptionReduce usageEvaporator accessoriesTreatment involving filtrationLiquid wasteDistillation

The invention discloses a molasses alcohol waste liquor evaporation and concentration system serving as a heat source of an alcohol distillery. Materials pass through a V-effect evaporator, an IV-effect evaporator, an III-effect evaporator, a first heater, a clarification tank, a second heater, a third heater, an I-effect evaporator and an II-effect evaporator in the flowing direction of molasses alcohol waste liquor; low-concentration alcohol waste liquor at the temperature of 80 DEG C from the distillery enters a V-effect evaporation tank and is pumped into an IV evaporation tank and an III-effect evaporation tank. Medium-concentration alcohol waste liquor from the III-effect evaporation tank is heated to 95 DEG C or higher by the II-effect juice steam and the first heater, enters the clarification tank to be clarified, is heated to 105 DEG C by the second heater, the third heater and I-effect juice steam and enters the I-effect evaporation tank and the II-effect evaporation tank. Secondary steam generated through multi-effect evaporation of the waste liquor is used for an energy-saving reconstruction technique for alcohol distillation, the use amount of primary steam during alcohol production is reduced, the energy consumption during alcohol production is reduced, and the production and operation costs are saved.

Owner:GUANGXI UNIV

Water clarifier

InactiveCN111233116AFast clarificationReduce labor maintenance costsWater/sewage treatment by flocculation/precipitationWater solubleNegative charge

The invention discloses a water clarifier. The water clarifier comprises the following components in parts by weight: 10%-15% of polyaluminum chloride, 0.05%-0.08% of a water-soluble pigment, 30.5%-35.5% of polydimethyldiallylammonium chloride and 61%-62% of water. The water clarifier is a latest water clarification auxiliary agent developed at present, in use, the water clarifier is put into a swimming pool, the water clarifier with positive charges belongs to a cationic clarifier and is easily combined with suspended particles with negative charges in swimming pool water, and suspended matters are filtered out through a swimming pool filtering system, so that the water becomes clear and blue. The water clarifier has a strong effect on turbidity and discoloration of pool water, is high inclarification speed, does not cause sedimentation at the pool bottom, and can save the manual maintenance cost to the maximum extent.

Owner:北京勒沃康体科技发展有限公司

Clarifying method for fruit wine or fruit vinegar

ActiveCN102433252BGood effectThe clarification method is simple and feasibleAlcoholic beverage preparationVinegar preparationBiotechnologyFruit wine

The invention discloses a clarifying method for fruit wine or fruit vinegar. The clarifying method comprises the following steps of: firstly, adding 100-300mg of pectase into each 1L of fruit wine or fruit vinegar according to the volume ratio and reacting at 20-40DEG C for 1-4 hours; secondly, adding 25-150mg of chitosan into each 1L of fruit wine or fruit vinegar according to the volume ratio and reacting within 20-40 minutes; thirdly, adding 200-1500mg of bentonite into each 1L of fruit wine or fruit vinegar according to the volume ratio and reacting within 20-40 minutes; and fourthly, naturally settling a feed liquid and filtering supernate. The clarifying method for the fruit wine or the fruit vinegar, which is disclosed by the invention, has the advantages of simpleness, feasibility, high clarifying speed and better effect.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

Column type extraction device for pipe bundle multi-channel phase-dispersing and extraction method thereof

InactiveCN102772913BLess prone to turbulenceSuitable for extraction operationLiquid solutions solvent extractionStraight tubeOil phase

The invention relates to a column type extraction device for pipe bundle multi-channel phase-dispersing; a main shaft is arranged inside the column type extraction device; two or at least three hollow thin tubes in parallel to the main shaft are distributed on the outer circumference of the main shaft; one end of each hollow thin tube is provided with a straight tube, and the other end of the hollow thin tube is bent to form a flanged bend; the bending direction of the flanged bend is the remote direction of a mounting shaft; the main shaft is connected with an electric motor, and drives the hollow thin tubes to carry out motion at a same speed with the main shaft when the main shaft rotates. The column type extraction device disclosed by the invention solves the difficult problems that a water phase or an oil phase with relatively small volume is difficult to disperse completely in the conventional mechanical stirring manner when the volume ratio of the water phase to the oil phase in an extraction process is large; and the difficult problems that the water phase and the oil phase are difficult to clarify and separate in an extraction system and the like caused by easy emulsification are also solved when the flow-rate ratio of the water phase to the oil phase is large.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com