Method and equipment for purifying recirculated cooling water or town B-grade sewage

A technology for circulating cooling water and secondary sewage, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, separation methods, etc., can solve the problems of large floor area, poor load impact resistance, and high one-time investment , achieve the effect of good purification degree, speed up and degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

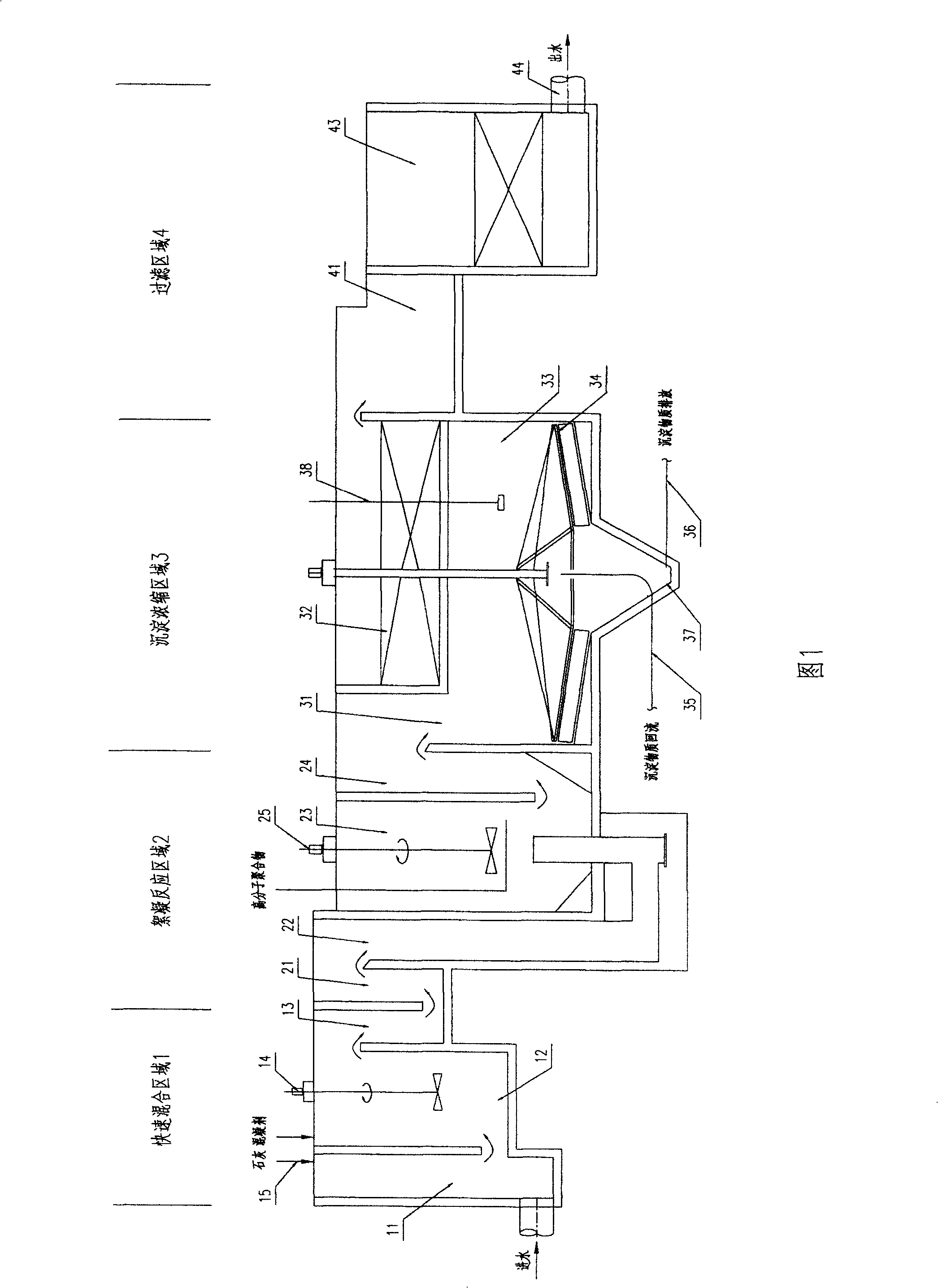

[0063] The purification method of circulating cooling water or urban secondary sewage is characterized in that it will go through the following steps:

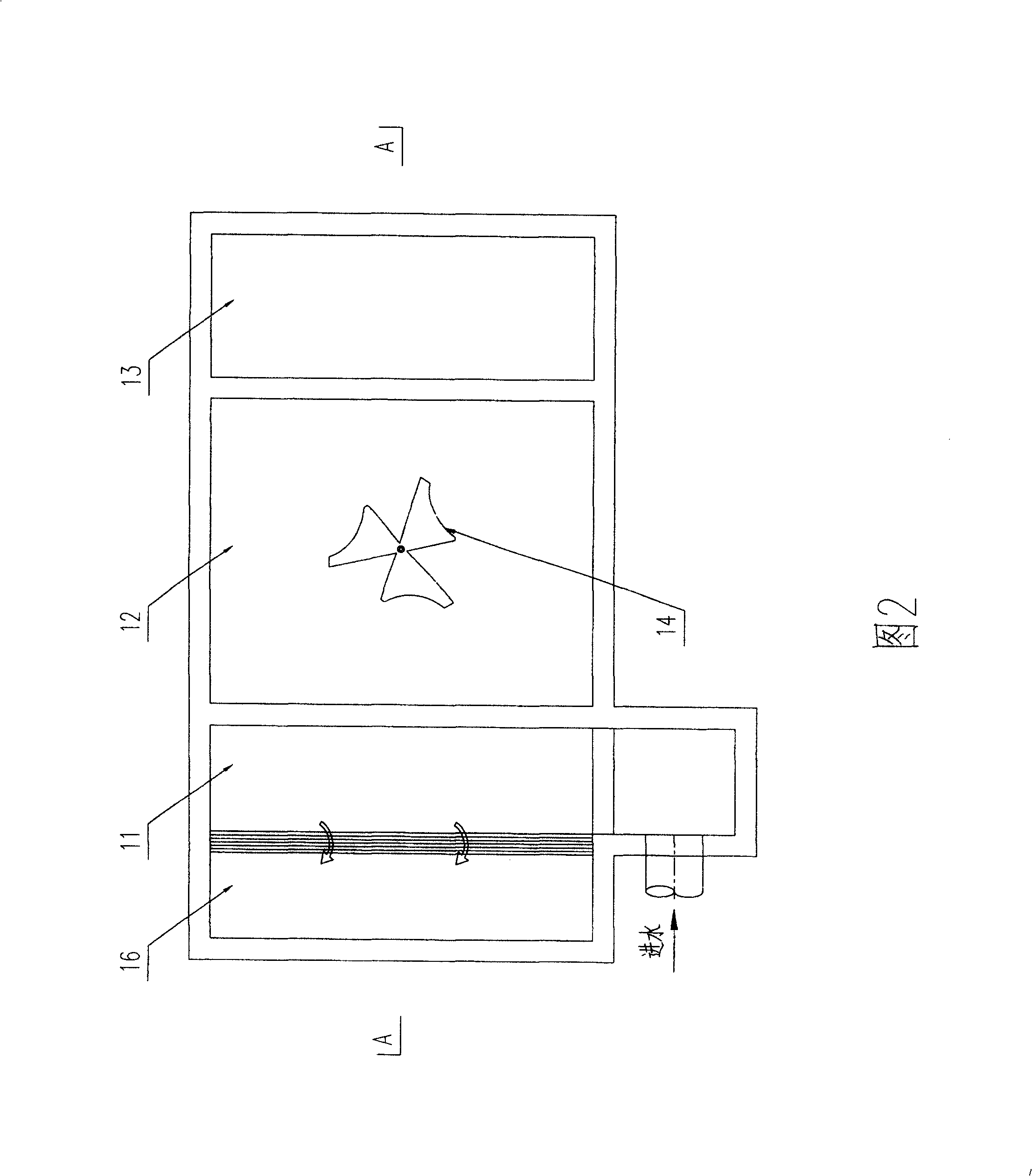

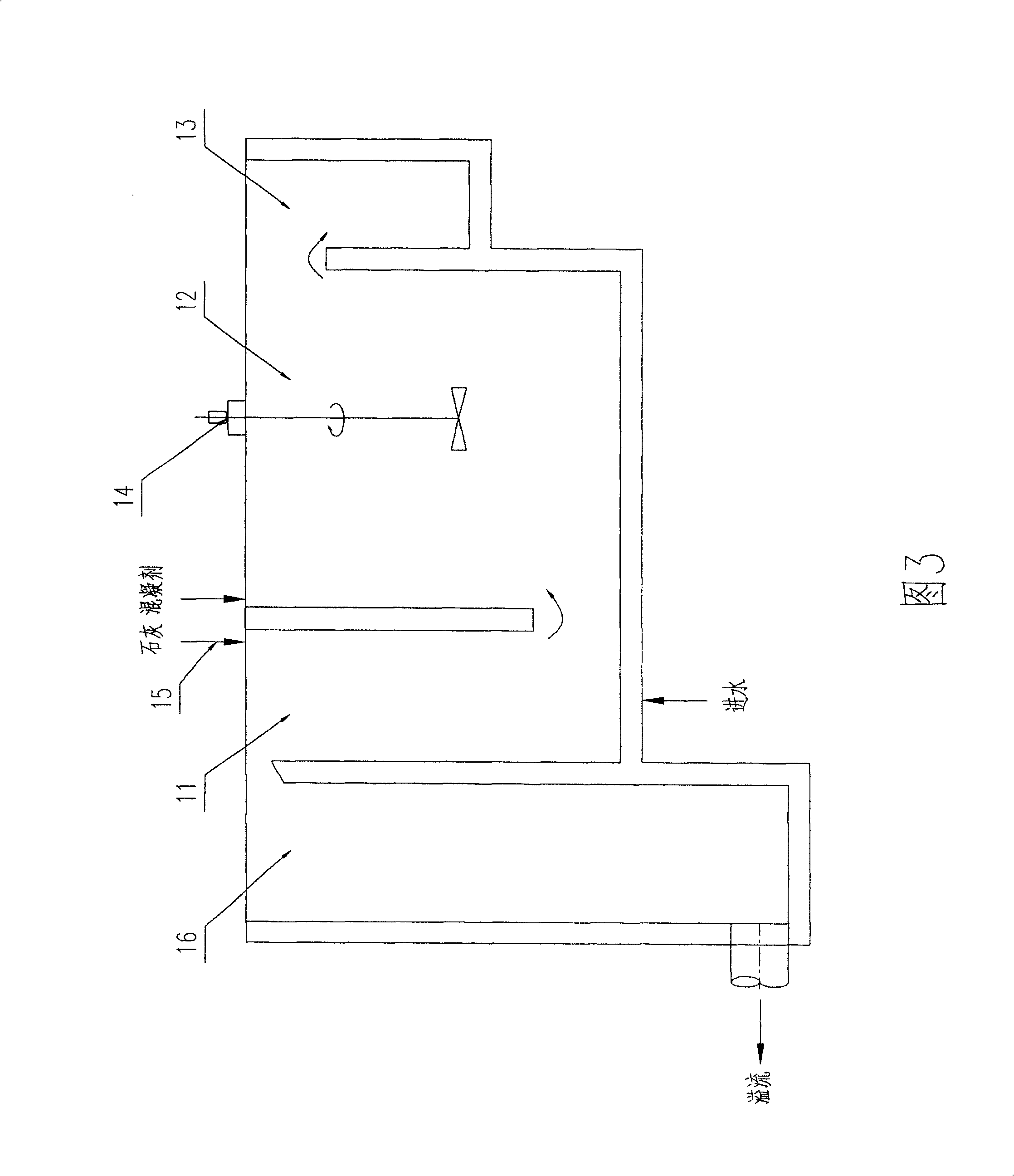

[0064] a. Introduce the liquid to be treated into the mixing area 1, add one or more reagents, and mix the reagents with the liquid to be treated uniformly, the multiple reagents are lime agents and one or more coagulants;

[0065] b. Perform high-speed clarification of the uniformly mixed liquid to be treated in the high-speed clarifier tank, the supernatant liquid rises at a flow rate of 10-30 m / hour, and the obtained supernatant liquid is drawn out;

[0066] c. introducing the above-mentioned supernatant into the filter area 4, and the filter area 4 is filled with filter materials.

[0067] After the liquid to be treated enters the mixing zone 12 of the mixing zone 1, the designed residence time of the liquid to be treated in the mixing zone 12 is 30-240 seconds, preferably 45-180 seconds.

[0068] The lime agent is added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com