Float glass melting furnace

A technology of float glass and melting furnace, which is applied in the field of float glass melting furnace, which can solve the problems of easy material leakage at the bottom of the pool, easy damage of bricks at the bottom of the pool, easy blockage of the bubbler tube, etc., to prolong the residence time and improve the melting quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

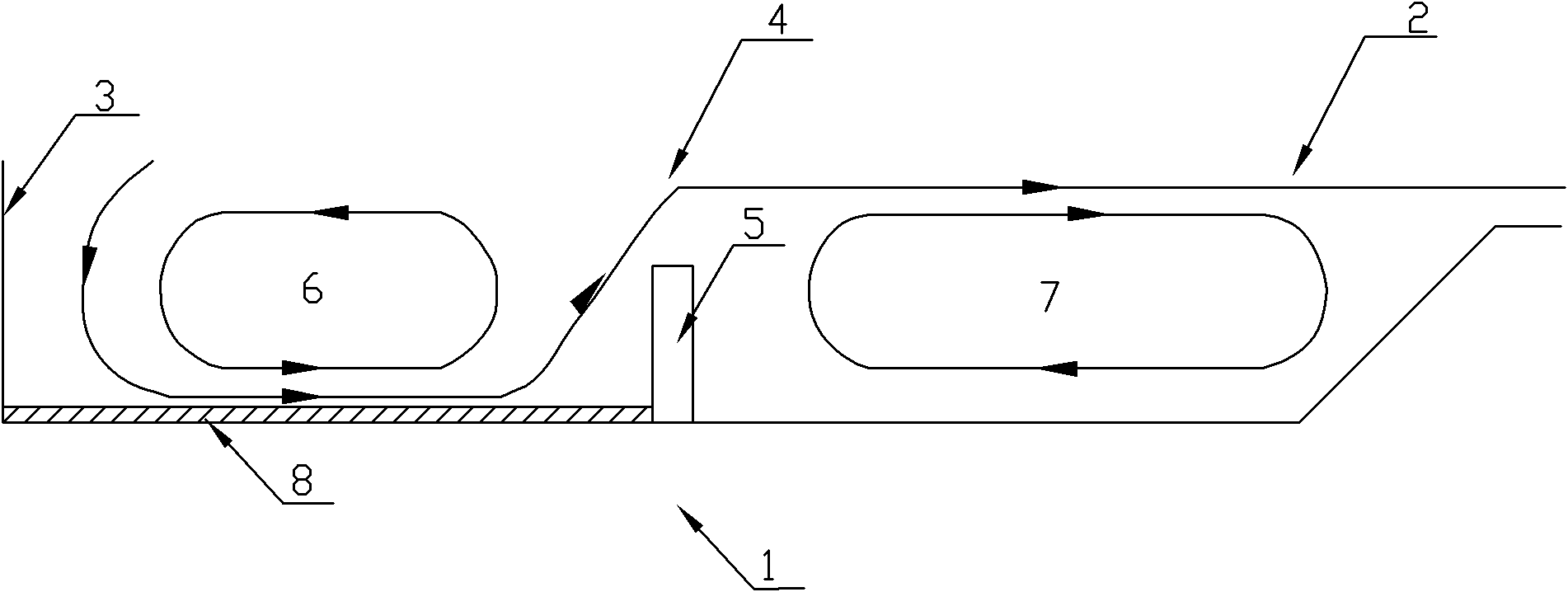

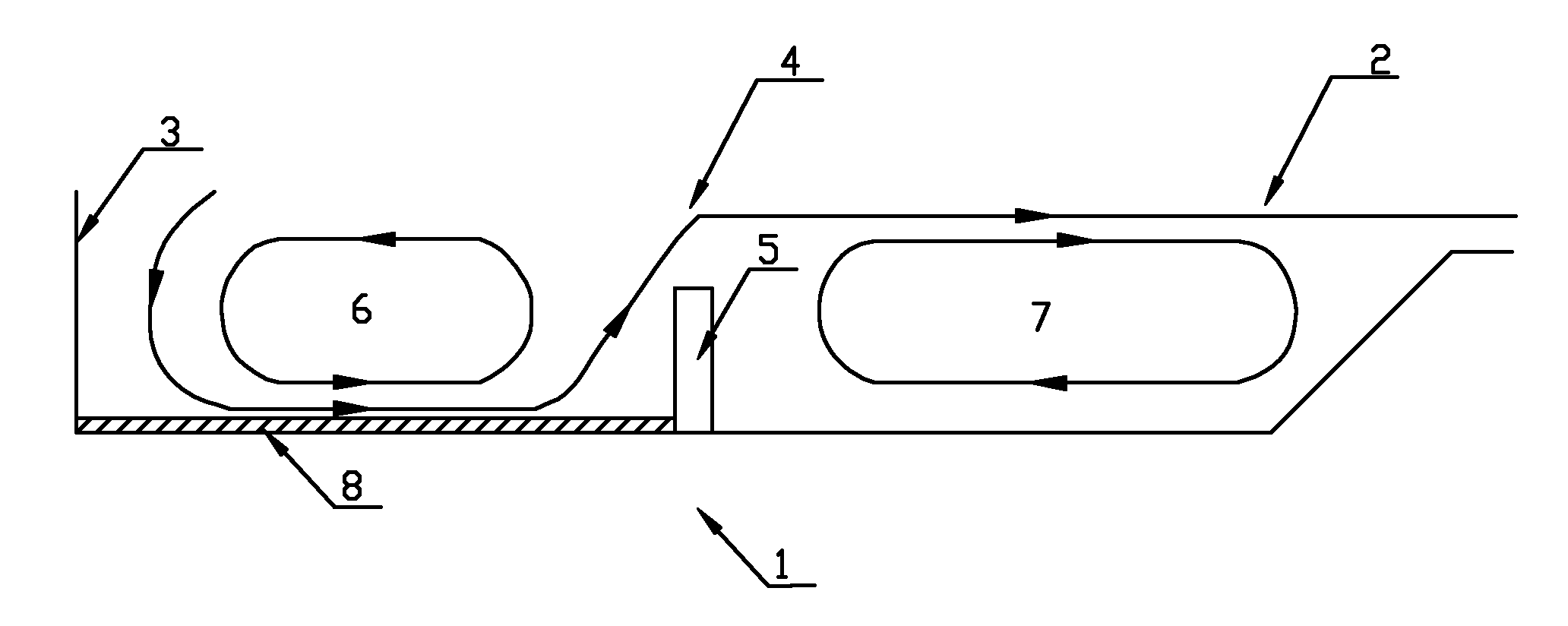

[0017] Example 1, please refer to figure 1 As shown, a float glass melting furnace of the present invention includes a melting part 1 arranged at the front section of the melting furnace; a feeding port 3 is provided at the front end of the melting part 1; a hot spot is arranged in the middle of the melting part 1 along the length direction 4. A kiln sill 5 is provided at the hot spot 4 of the melting part 1 to prevent the molten glass from flowing directly from the feeding port 3 to the cooling part 2 in the rear section of the melting furnace, so as to keep the circulation of the glass liquid on both sides of the hot spot stable; the kiln sill 5 The length dimension of the kiln is set to be the same as the width of the pool of the melting section 1; the height of the kiln sill 5 is set to 50% to 75% of the depth of the pool of the melting section 1; the thickness of the kiln sill 5 is set to 300 mm to 400 mm mm.

[0018] in,

[0019] The kiln ridge 5 is made of fused zirco...

Embodiment 2

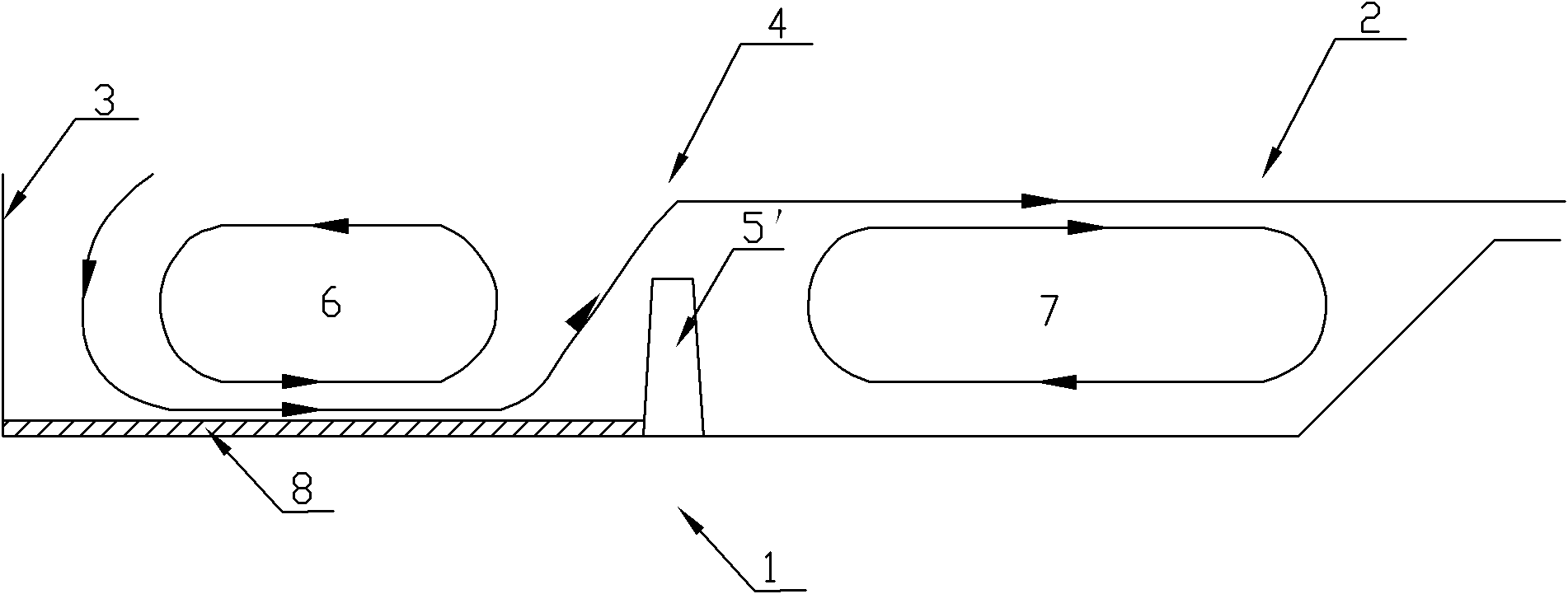

[0022] Example 2, please refer to figure 2 As shown, a float glass melting furnace of the present invention differs from the first embodiment above in that: the cross-sectional shape of the kiln ridge 5' is set as an isosceles trapezoid; and the height of the isosceles trapezoid is set as The height of the kiln ridge 5' and the kiln ridge 5' of this isosceles trapezoidal cross-section make the retaining wall of the kiln ridge 5' a slope structure. The trapezoidal kiln sill 5' can also maintain the stability of the first circulating glass liquid flow 6 and the second circulating glass liquid flow 7 in the melting furnace, and prolong the residence time of the glass liquid in the melting part 1, thereby facilitating the flow of the glass liquid. clarification and homogenization; it can prevent the bottom dirt 8 of the melting part 1 from flowing directly to the cooling part 2, and part of the molten glass in the cooling part 2 flows back into the melting part 1 to be reheated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com