Clarifying agent for reducing acid and gel in fruit and vegetable juice and liquors, and preparation method of clarifying agent

A technology of fruit and vegetable juice and clarifier, which is applied in the field of food processing, can solve the problems of not being able to achieve immediate glue dispensing, the long process time of the glue dispensing process, and the cumbersome process, and achieve the goals of reasonable structure, obvious glue dispensing effect, and accelerated process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

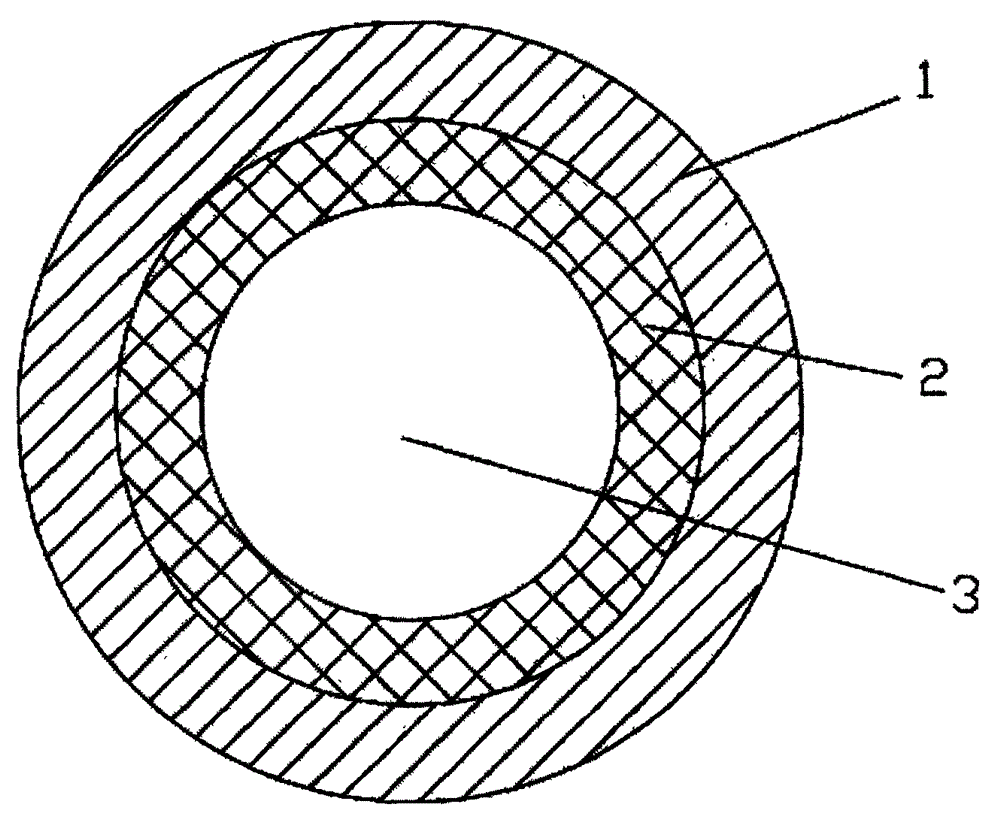

[0036] Specific embodiment 1, a kind of fruit and vegetable juice, wine acid-reducing gumming clarifier and its preparation method 1, comprise the following steps successively:

[0037] a) Weigh according to the formula ratio: 90g-110g of calcium carbonate, 5g-7g of xanthan gum, 110g-130g of sodium alginate.

[0038] b) Punch the calcium carbonate into uniform spherical pellets with a diameter of 2mm.

[0039] c) Xanthan gum was made into a 1.5% solution with deionized water.

[0040] d) Dissolve sodium alginate into a 1.8% solution with deionized water.

[0041] e) Apply the concentrated xanthan gum slurry evenly on the surface of the ball with a circulating wrapping machine, and dry it.

[0042] f) Apply the concentrated sodium alginate slurry evenly on the surface of the calcium salt sphere coated with a protective film with a circulating patcher, and dry it. The finished product is 205g to 247g.

Embodiment 2

[0044] A fruit and vegetable juice, wine acid-reducing gumming clarifying agent and its preparation method 2, comprising the following steps in sequence:

[0045] a) Weighing according to the formula ratio: 25g-35g of calcium carbonate, 15g-25g of anhydrous calcium chloride, 4g-6g of sodium carboxymethylcellulose, and 90g-110g of sodium alginate.

[0046] b) Mix calcium carbonate and anhydrous calcium chloride evenly, and punch them into uniform spherical pellets with a diameter of 2.5 mm.

[0047] c) Sodium carboxymethylcellulose was made into a 2.5% solution with deionized water.

[0048] d) Dissolve sodium alginate into a 1.8% solution with deionized water.

[0049] e) Apply the sodium carboxymethyl cellulose thick slurry evenly on the surface of the ball with a circulating wrapping machine, and dry it.

[0050] f) Apply the concentrated sodium alginate slurry evenly on the surface of the calcium salt sphere coated with a protective film with a circulating patcher, and dr...

Embodiment 3

[0052] A fruit and vegetable juice, wine acid-reducing gumming clarifying agent and its preparation method 3, comprising the following steps in sequence:

[0053] a) Weighing according to the formula ratio: 35g-45g of anhydrous calcium chloride, 3g-5g of carrageenan, and 100g-120g of sodium alginate.

[0054] b) Punch the anhydrous calcium chloride into uniform spherical pellets with a diameter of 3 mm.

[0055] c) The carrageenan was made into a 3.0% solution with deionized water.

[0056] d) Dissolve sodium alginate into a 1.6% solution with deionized water.

[0057] e) Apply the thickened carrageenan slurry evenly on the surface of the ball with a circulating patcher, and dry it.

[0058] f) Apply the concentrated sodium alginate slurry evenly on the surface of the calcium salt sphere coated with a protective film with a circulating patcher, and dry it. Obtain finished product 138g to 170g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com