Method for removing impurities in phosphoric acid and deposition purificant used in the method

A purifying agent and impurity technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as unsatisfactory effect and difficult sediment filtration and separation, and achieve the effect of easy mechanization, high product purity and good filtration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

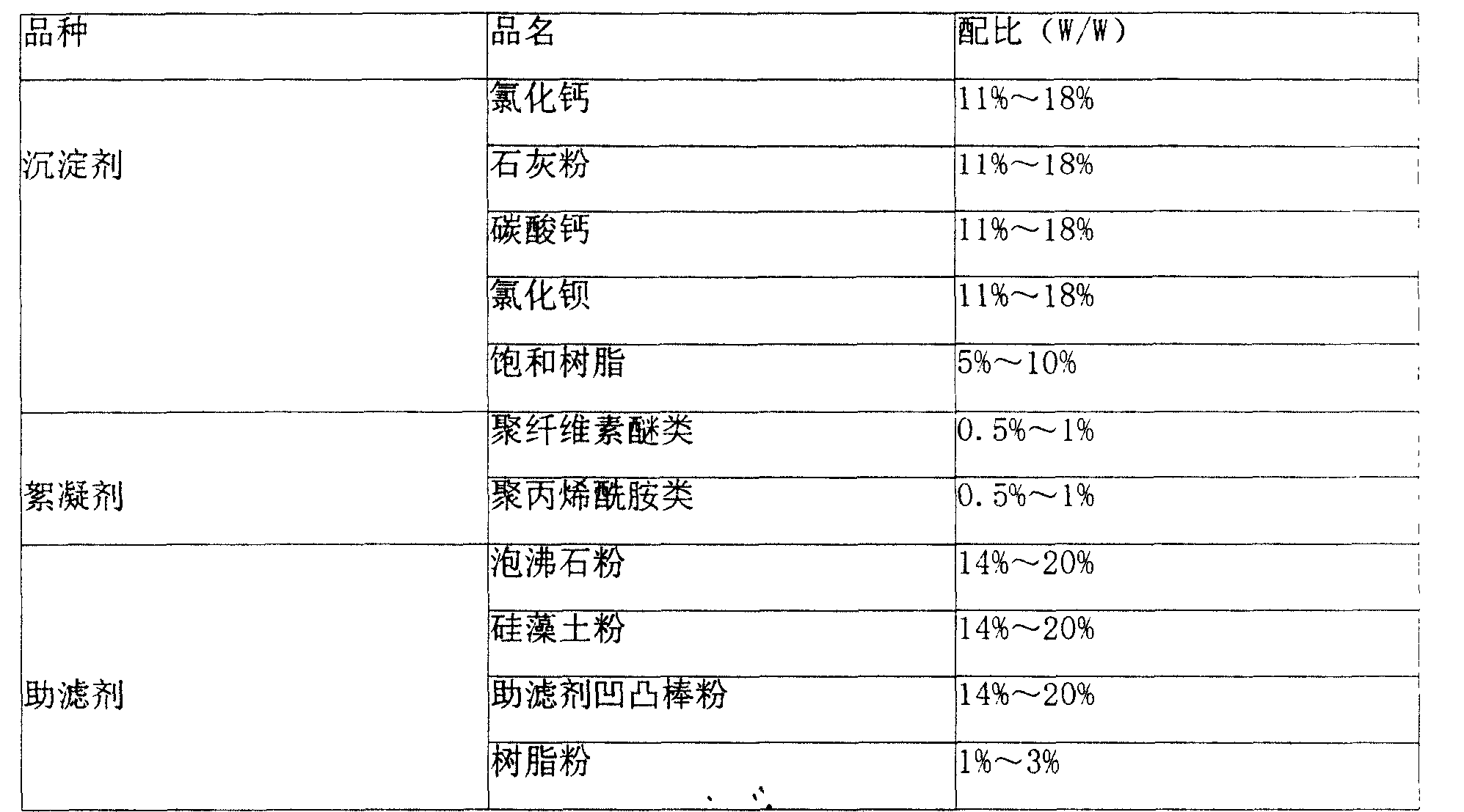

[0019] Embodiment 1: To manufacture 100 kilograms of precipitation purifiers for removing impurities contained in phosphoric acid and ammonium phosphate products, the components in the following formula are mixed uniformly according to the amount.

[0020]

Embodiment 2

[0021] Embodiment 2: To manufacture 100 kilograms of precipitation purifying agent for removing impurities contained in phosphoric acid and ammonium phosphate products, the components in the following formula are mixed uniformly according to the amount.

[0022]

Embodiment 3

[0023] Embodiment 3: the method for removing phosphoric acid impurity.

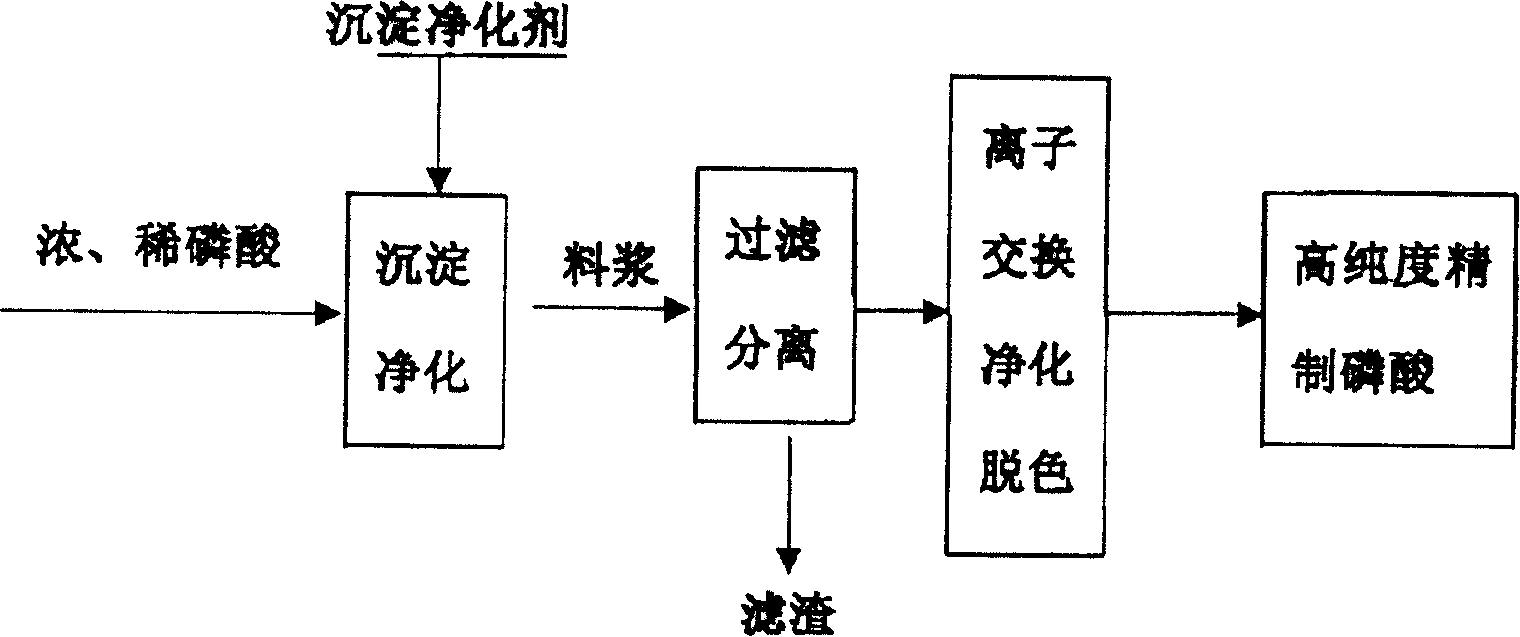

[0024] Such as figure 1 As shown, phosphoric acid is placed in the precipitation purification device, and the precipitation purification agent of the above-mentioned embodiment 1 or 2 is added in a proportion of 1% to 5%, and it is left to stand for 12 to 24 hours, and then the sediment in the slurry is removed by a high-speed centrifuge Separated from the solution, the resulting precipitate can be used as a compound fertilizer. The resulting solution is placed in an exchange tower and refined with an ion exchange resin. After treatment, refined phosphoric acid with high purity is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com