A deep purification process of high-concentration sodium aluminate solution

A technology of deep purification and solution purification, which is applied in the field of aluminum metallurgy and can solve problems such as the removal of impurities in sodium aluminate solution and deep purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

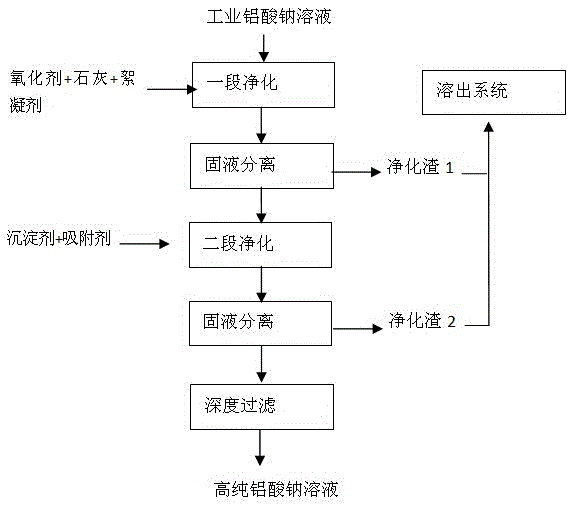

[0023] The deep purification process of the high-concentration sodium aluminate solution of the present embodiment is as follows:

[0024] (1) One-stage solution purification: take industrial high-concentration sodium aluminate solution, alkali concentration (taken as Na 2 O meter), the alumina concentration is 150g / L, 165g / L respectively. After adding 5mL / L hydrogen peroxide with a concentration of 20% at 90°C and reacting, the positive electrode is connected with direct current and the voltage is 5V, and the electrophoresis principle is used to enrich the iron-containing hydroxide colloid for 30min, then add 10g / L quicklime, stir vigorously for 1h, and then add 2ml / L of 1‰ hydroxamic acid-containing flocculant HX300, flocculation and sedimentation for 1 hour, suction filtration to obtain a section of purified clear liquid;

[0025] (2) Second-stage solution purification: Add 0.5g / LNa to the first-stage purification solution at 70°C 2 S, 1g / LNa 3 PO 4 , 2g / LNaF, add activ...

Embodiment 2

[0028] The deep purification process of the high-concentration sodium aluminate solution of the present embodiment is as follows:

[0029] (1) One-stage solution purification: take industrial high-concentration sodium aluminate solution, alkali concentration (taken as Na 2 O meter), the alumina concentration is 172g / L, 185g / L respectively. Add 20% hydrogen peroxide 2mL / L and 2g / L sodium peroxide as oxidants at 90°C, connect the positive electrode with direct current, voltage 2V, time 30min, use the principle of electrophoresis to enrich the iron-containing hydroxide colloid, and then heat the solution to 100°C, add 10g / L quicklime and stir vigorously for 1h, then add 5ml / L 1‰ polyacrylamide flocculant KM800 (French Essen Company), flocculate and settle for 1h, then suction filter to obtain a purified clear liquid;

[0030] (2) Second-stage solution purification: add 1g / L Na to the first-stage purification solution at 50°C 2 S, 3g / LNa 3 PO 4 , 6g / LNaF, 4g / L sodium carbonate...

Embodiment 3

[0033] The deep purification process of the high-concentration sodium aluminate solution of the present embodiment is as follows:

[0034] (1) One-stage solution purification: take industrial high-concentration sodium aluminate solution, alkali concentration (taken as Na 2 O meter), the alumina concentration is 131g / L, 142g / L respectively. Add 10g / L sodium peroxide and 10g / L sodium persulfate at 90°C, connect the positive electrode with direct current, voltage 20V, time 10min, use the principle of electrophoresis to enrich the iron-containing hydroxide colloid, then raise the temperature of the solution to 95°C and add 10g / L quicklime, stir vigorously for 1 hour; then add 5ml / L 1‰ polyacrylamide-containing flocculant KM800 (French Eisen Company) and hydroxamic acid-containing flocculant HX300 (American Cytec Company), flocculate and settle for 1 hour and pump Filter to obtain a section of purified clear liquid;

[0035] (2) Second-stage solution purification: add 0.1g / L Na ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com