Chitosan porous microballoon loaded copper iodide catalyst as well as preparation method and application thereof

A porous microsphere, cuprous iodide technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc. The production cost and environmental pollution are reduced, the equipment requirements are low, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 1. Preparation of mixed solution: Take 5g of pharmaceutical grade chitosan powder (molecular weight: 100,000, degree of deacetylation: 95%) and polyethylene glycol (molecular weight: 20,000), dissolve in 2% 100ml acetic acid solution to prepare Mix the solution; add an appropriate amount of glutaraldehyde aqueous solution dropwise to the solution under high-speed stirring, with a cross-linking degree of 0.3%, continue stirring for 2 hours to form a homogeneous solution, and let it stand for 12 hours to defoam.

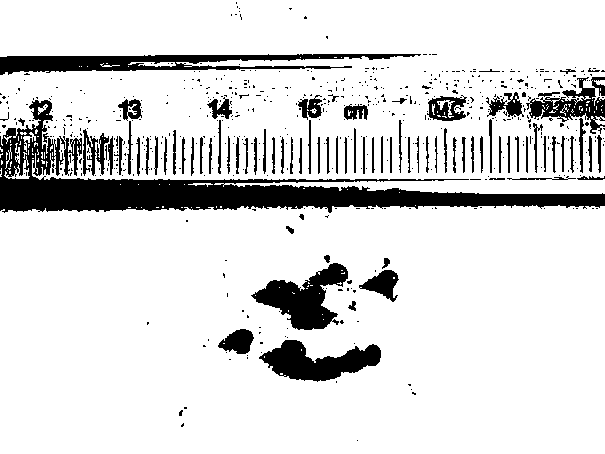

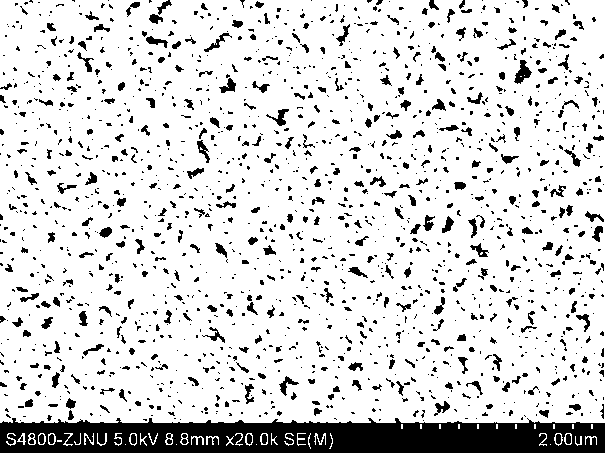

[0030] 2. Preparation of chitosan porous microspheres: drop the above mixed solution into a NaOH coagulation bath (concentration is 5%), and the droplets gradually precipitate in the coagulation bath to form white Semi-IPN microspheres; After the microspheres are washed with water until they are neutral, they are placed in a 90 oC water bath for continuous extraction for 6-8 hours to selectively dissolve the polymer porogen components to achieve pore formation; f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com