Patents

Literature

37results about How to "Good product stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cation-type hydrophobic association polymer and its preparation method and application

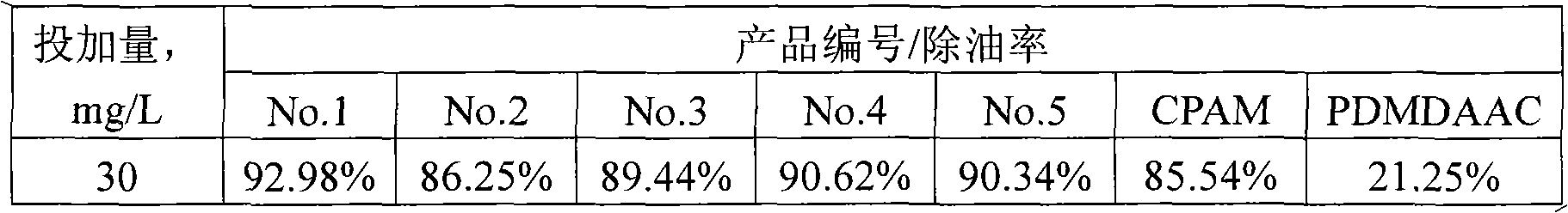

InactiveCN101260174AHigh molecular weightGood product stabilityWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationButyl acrylateUrea

The invention discloses a cation type hydrophobic association polymer and a preparation method and application thereof. Through adopting acrylamide, dimethyl diallyl ammonium chloride and butyl acrylate as synthesis monomer, the cation type hydrophobic association polymer is made through a common free radical micelle polymerization method and making use of a composite initiation system and additive auxiliary agent urea. Moreover, the cation type hydrophobic association polymer, which has the characteristics of high molecular weight, excellent product stability, strong adsorption bridging capacity of colloid matter, good flocculation effect, wide application scope, less generated sludge and hydrophobic association function, etc., can be widely used in the treatment of oil field oily wastewater.

Owner:SHANDONG UNIV

Flocculation agent of poly ferric-dimethyl diallyl ammonium chloride homopolymer inorganic organic composited and preparation process thereof

InactiveCN1724404AHigh molecular weightGood product stabilityWater/sewage treatment by flocculation/precipitationDimethyldiazeneAmmonium chloride mixture

A composite flocculant in the form of brown liquid is a homo-polymer poly-iron-dimethyl dially ammonium chloride consisting of iron (5.5-8.0 Wt%) and poly-dimethyldially ammonium chloride (3-16 Wt%). Its preparing process featuring the addition of PDMDAAC to PFC solution is also disclosed. Its advantages are high flocculating effect and stability and low cost.

Owner:SHANDONG UNIV

Soybean residue composite filter tip and manufacturing method thereof

The invention discloses a soybean residue composite filter tip and a manufacturing method thereof. Soybean residue particles are added to ordinary cigarette filter tips. The soybean residue particles are obtained by sieving dried or fried or expanded soybean residues or soybean curd residues or crushed soybeans. The soybean residue particles are uniformly added to a filter tip on a compound filter tip moulding machine; the adding amount of the soybean residue particles accounts for 5-30% of the total weight. The test and evaluation results show that the soybean residue composite filter tip reduces the tar in mainstream smoke of the cigarette by 8.1-20.3% , the NNK by 34.7-59.1%, the BaP by 6.9-21.7%, the crotonic aldehyde by16.2-32.3%, and other harmful ingredients in the cigarette smoke at different degrees. Meanwhile, cigarette smoke stimulation is reduced obviously, sweet feeling of cigarette smoke is increased and richness and smoothness of flavor in the cigarette smoke are increased.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

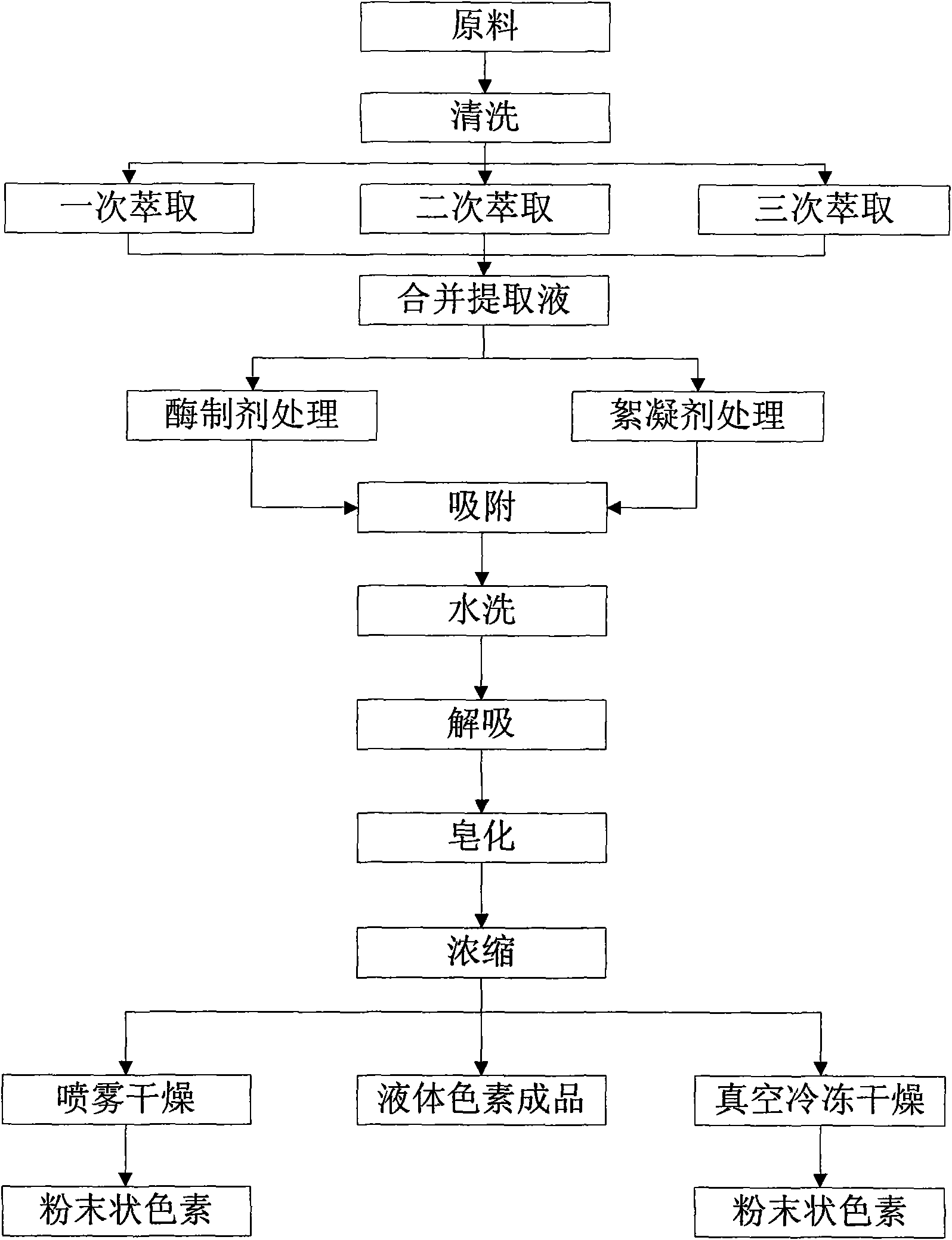

Purplish red pigment preparation method with golden silk jujube

The invention discloses a purplish red pigment preparation method with golden silk jujube, a natural plant, as raw material. The method comprises the following steps of: obtaining golden silk jujube-cleaning-peeling-immersing and extracting with the alkaline aqueous solution-processing with enzyme preparation and edible flocculant-filtrating-filtrate passing a column-eluting with ethanol-saponifying-vacuum concentration-vacuum freezing drying or spraying drying-obtaining the product. The purplish red pigment is a pure natural pigment resource which can make up for the shortage of the existingnatural pigments and meet the demand in the industries of cosmetic, food, dying, and drink. The method has the advantages of advanced technique, good product stability, being non-toxic and odor-free,maximum and comprehensive use of the pigment of silk jujube, reducing the use of organic solvents, saving energy, reducing environment pollution caused by the waste water, simplifying production technique and significantly reducing production cost and increasing the economic benefits, thus obtaining good economic benefits and social benefits.

Owner:QINGDAO PENGYUAN KANGHUA NATURAL PROD

Method for clarifying liquid substance by using chitosan and carrageenan

InactiveCN101716011AImprove the effectGood product stabilityAlcoholic beverage preparationTeaMacromolecular SubstancesChemistry

The invention discloses a method for clarifying a liquid substance by using chitosan and carrageenan, and belongs to the technical field of food processing. The method comprises the following steps of: adding solution of chitosan and solution of carrageenan into the liquid substance to be clarified; mixing the solution of chitosan, the solution of carrageenan and the liquid substance to generate a floccule when the solution of chitosan is contacted with the solution of carrageenan in aqueous solution; and adsorbing and embedding macromolecular substances and suspended substances in the liquid substance to be clarified by using the floccule so as to clarify the liquid substance. The method is suitable for clarifying liquid beverage, such as fruit and vegetable juice containing phenols and protein with different precipitation mechanisms, tea beverage and the like. The method clarifies the liquid substance by using the chitosan and the carrageenan, so that the method can solve the problems of single function of a clarifier, long time consumption, high equipment investment, not high enough processing clarity and low solubility of the clarifier existing in the conventional clarification method; and the method has the advantages of little equipment investment, simple operation process, low price of raw materials, high clarifying speed, good effect and avoiding affecting the quality and flavor of a product and the like.

Owner:SOUTH CHINA UNIV OF TECH

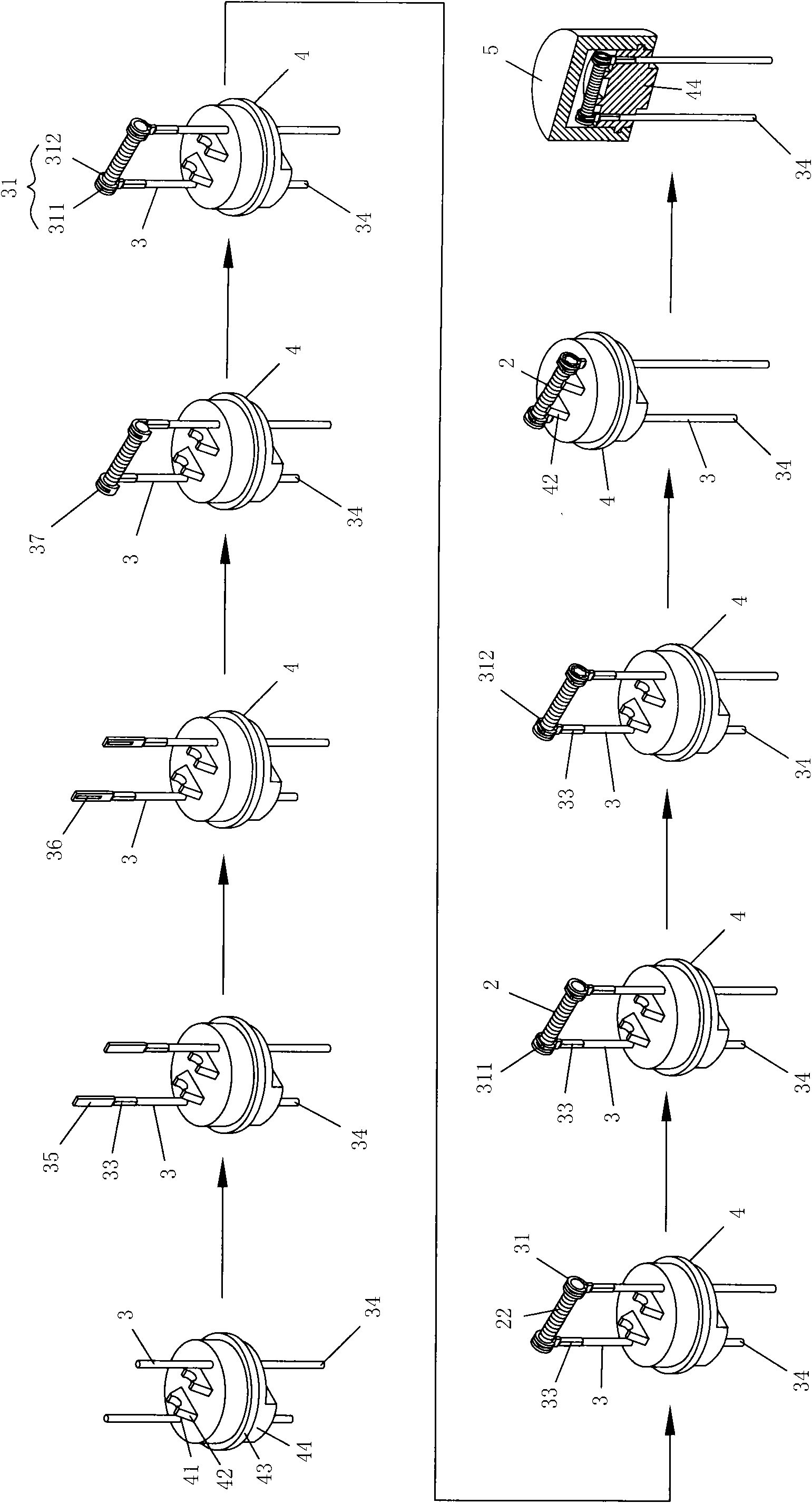

Manufacturing method and finished product of micro-fuse

The invention relates to a micro-fuse which comprises a melting part, two electrode parts, a seat body and a cover body, wherein the melting part is provided with a column body surrounding a melting wire body to form a surrounding melting wire; one end of the electrode parts is provided with two ring bodies with closed end parts and bearing and fixing surfaces; the seat body is provided with through holes for the two electrode parts to pass through, the upper end of the seat body is provided with a bearing platform, sides of the seat body are provided with buckling rings, the lower end of the seat body is provided with a positioning block; and the cover body is buckled on the seat body to form a close space. The invention also relates to a fabricating method of the micro-fuse, which comprises the following steps: providing the seat body, arranging the two electrode parts in a penetrating way; forming planes and the bearing and fixing surfaces at the end parts of the two electrode parts, and bending through hole grooves to form the two ring bodies, wherein the inner ring body is pressed and fixedly connected to the inner side of the melting part, the outer ring body is welded and fixedly connected to the end part of the melting part; bearing the melting part by the bearing platform at the upper end of the seat body; and forming the close space by the cover body correspondingly covering the seat body. The micro-fuse has high yield, high quality and high safety.

Owner:邱鸿智

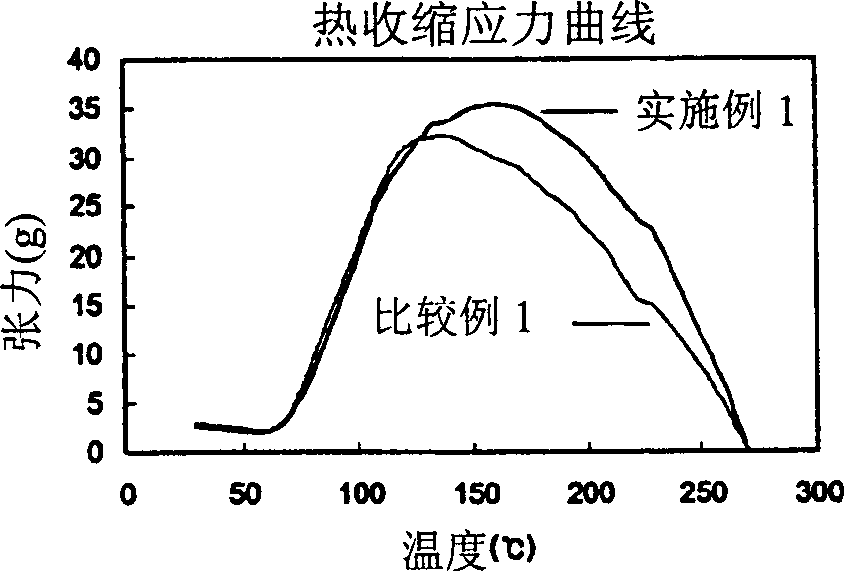

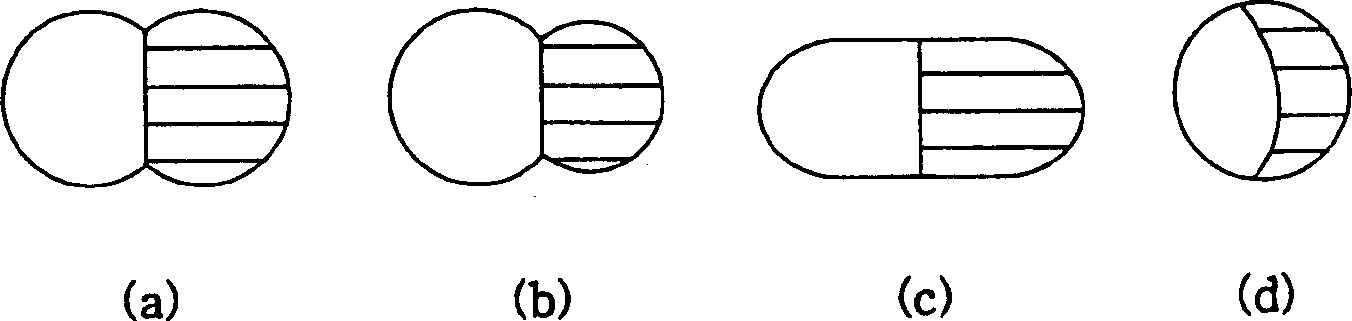

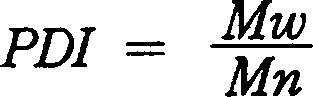

Composite fibre and producing method thereof

ActiveCN1673426AGood product stabilityThe reduction of the physical properties and stretchability of the raw silk is minimizedArtificial filament heat treatmentMelt spinning methodsWeight distributionThermal contraction

This invention provides a crimp forming conjugate fiber excellent in stretchability and improved in product stability in post processing and a method for producing the same. The crimp forming conjugate fiber is a side-by-side or an excentric sheath-core type fiber remarkably stable for heat hysteresis, tension and the like given to the fiber in knitting, weaving and dyeing processing. The stretchable conjugate fiber produced by the invention is remarkably excellent in product stability during post processing as the fiber has high stretchability with >=40% rate of crimp stretch, >=70% elastic recovery factor, >=155[deg.]C maximum temperature of thermal contraction stress and <=3% iron shrinkage of the finally processed fabric. Different fiber forming polymers having 5,000-70,000 number average molecular weight difference and 1.5-2.5 molecular weight distribution index in each fiber are used as the polymer.in the invention.

Owner:HYOSUNG CORP

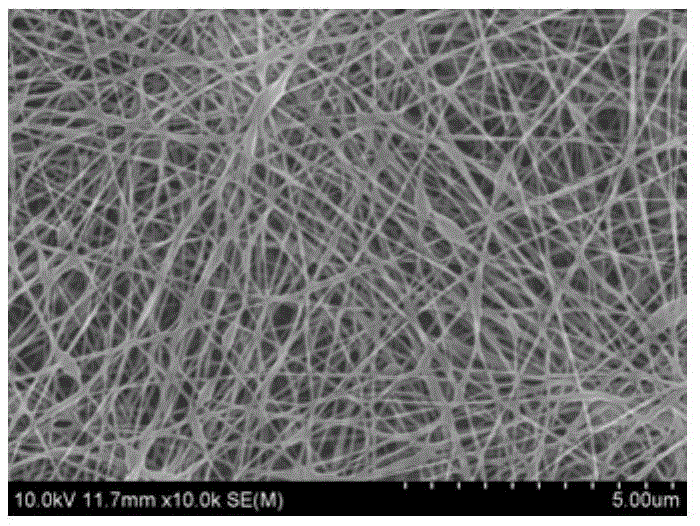

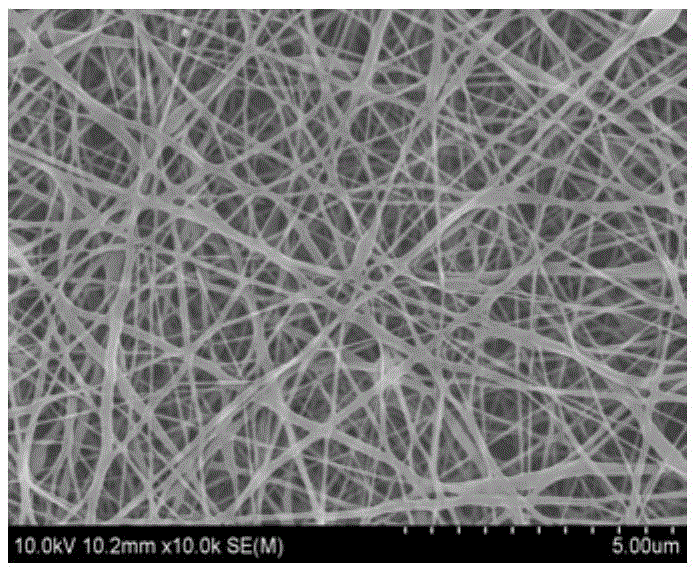

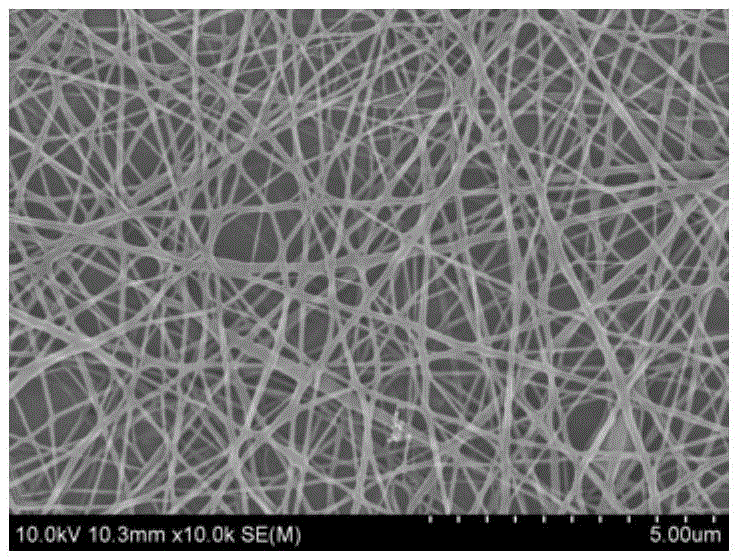

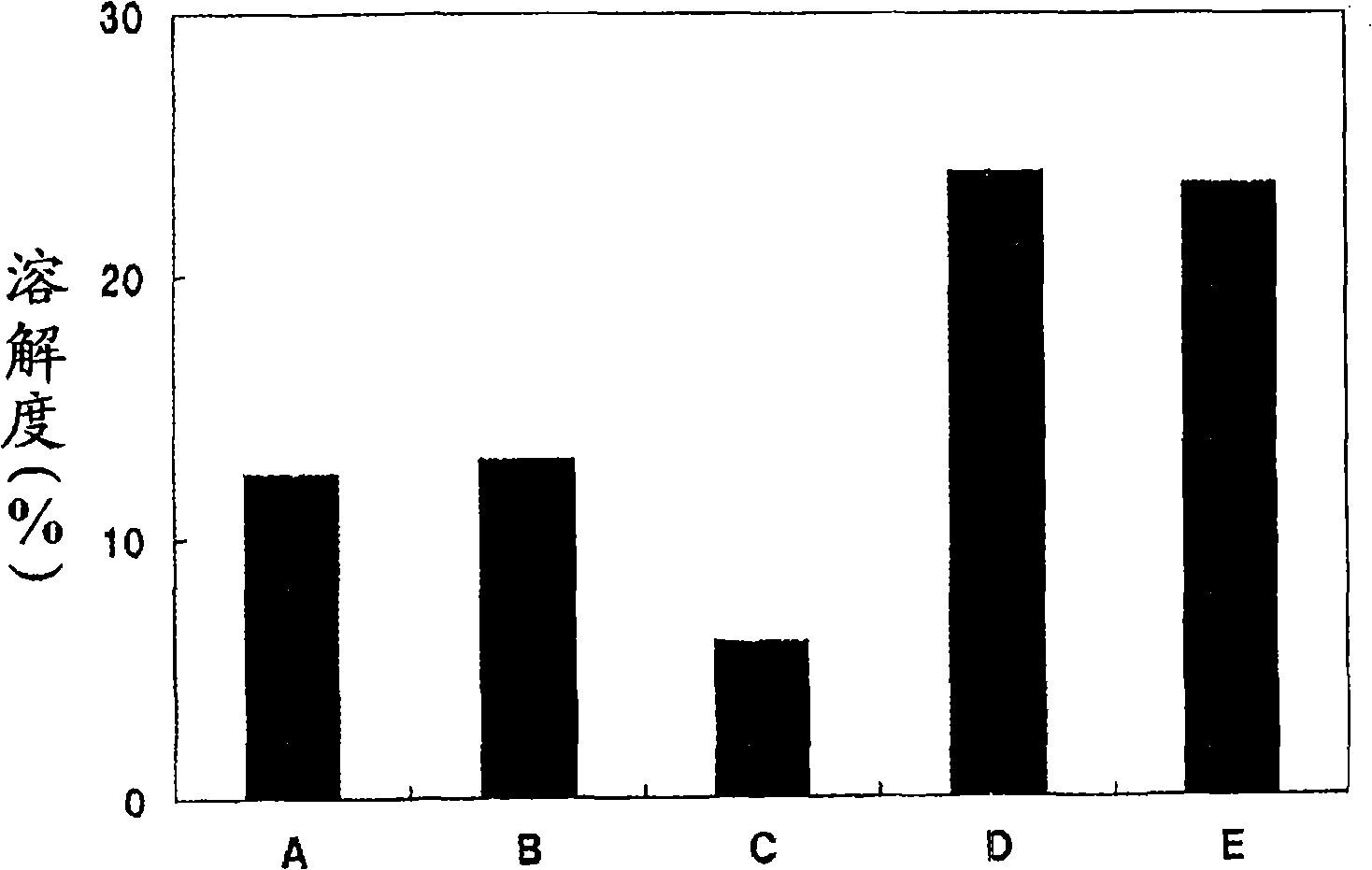

Nano-fiber for adsorbing heavy metal ions and preparation method thereof

InactiveCN105457603AEasy to prepareGood product stabilityOther chemical processesAlkali metal oxides/hydroxidesIonElectrospinning

The present invention provides a nano-fiber for adsorbing heavy metal ions and a preparation method thereof. The method comprises the steps of: S1. adding 20-80 parts by weight of dipalmitoyl phosphatidylcholine, 10-100 parts by weight of cholesterol and 10-100 parts by weight of phospholipid into 2000 parts by weight of ethanol; and conducting magnetic stirring at 20-70 DEG C until complete dissolution without obvious lumps; S2. adding 20-50 parts of acetic acid in 2000 parts by weight of water, uniformly mixing, adding 40-100 parts by weight of chitosan; conducting magnetic stirring at room temperature until complete dissolution without significant particles; S3. adding the solution obtained in the S1 into the solution obtained in the S2, and continuing stirring to obtain a mixed solution of chitosan-dipalmitoyl phosphatidylcholine; S4. conducting electrostatic spinning by utilizing the mixed solution obtained in the S3 to obtain the nano-fiber. The obtained fiber has the advantages of high efficiency, low cost and adsorption of a large amount of ions.

Owner:SHANGHAI JIAO TONG UNIV +1

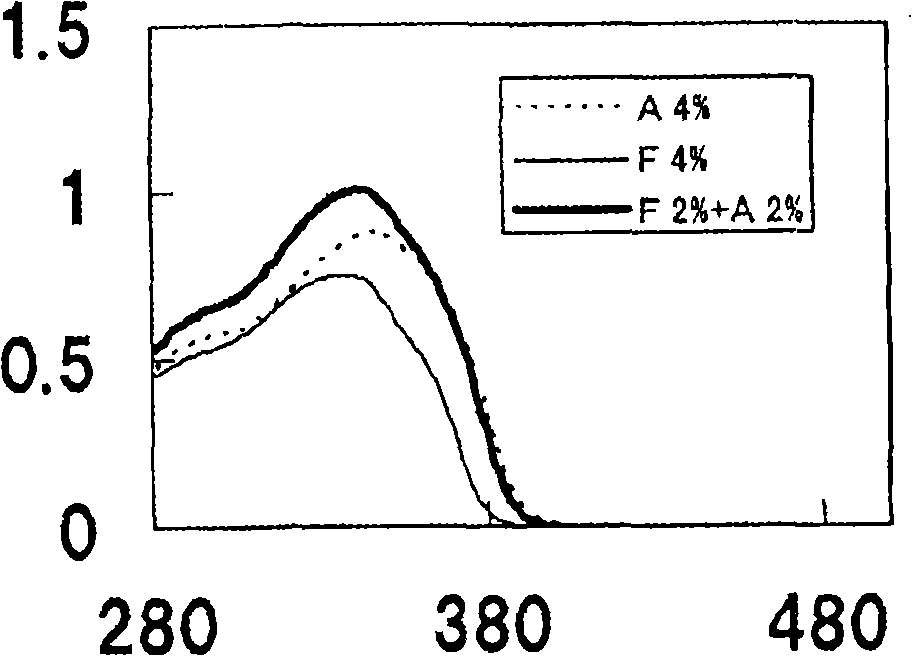

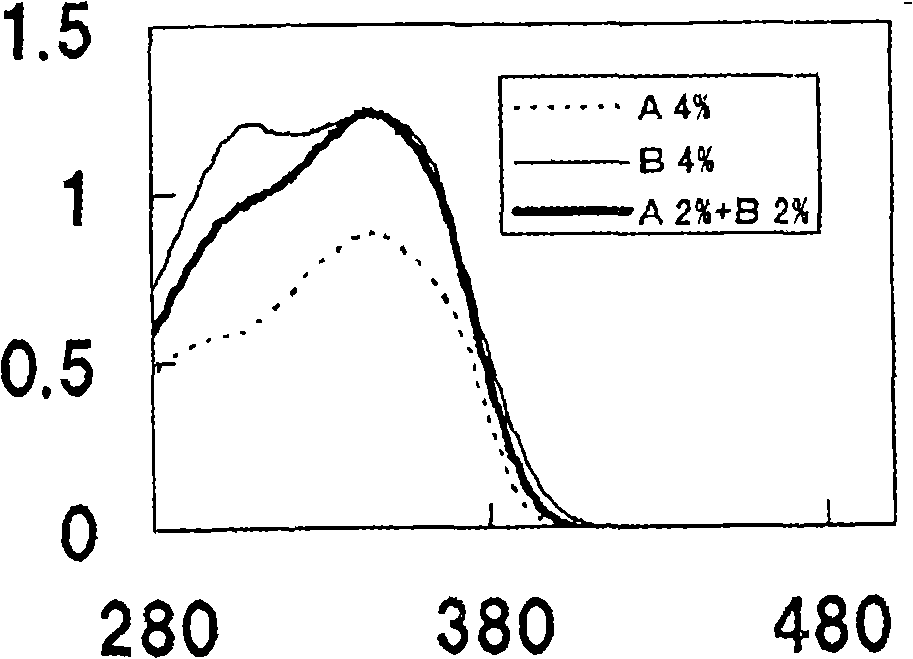

Sunscreen cosmetic composition

InactiveCN101277676AGood product stabilityExcellent UV absorption performanceCosmetic preparationsToilet preparationsPhenyl groupSolubility

Disclosed is a sunscreen cosmetic composition characterized by containing 2,4-bis[[4-(2-ethylhexyloxy)-2-hydroxy]phenyl]- 6-(4-methoxyphenyl)-1,3,5-triazine and a specific benzotriazole derivative. Also disclosed is a sunscreen cosmetic composition characterized by containing a specific benzotriazole derivative and a specific alkylaryl 1,3-propanedione silicone derivative. The present invention aims to provide a sunscreen cosmetic composition having excellent UV-A absorbing ability and extremely excellent stability wherein 2,4-bis[[4-(2- ethylhexyloxy)-2-hydroxy]phenyl]-6-(4-methoxyphenyl)-1,3,5-triazine, which has low solubility and is likely to be crystallized, is sufficiently dissolved. The present invention also aims to provide a sunscreen cosmetic composition capable of synergistically improving ultraviolet absorbing ability of a conventional ultraviolet absorbent.

Owner:SHISEIDO CO LTD

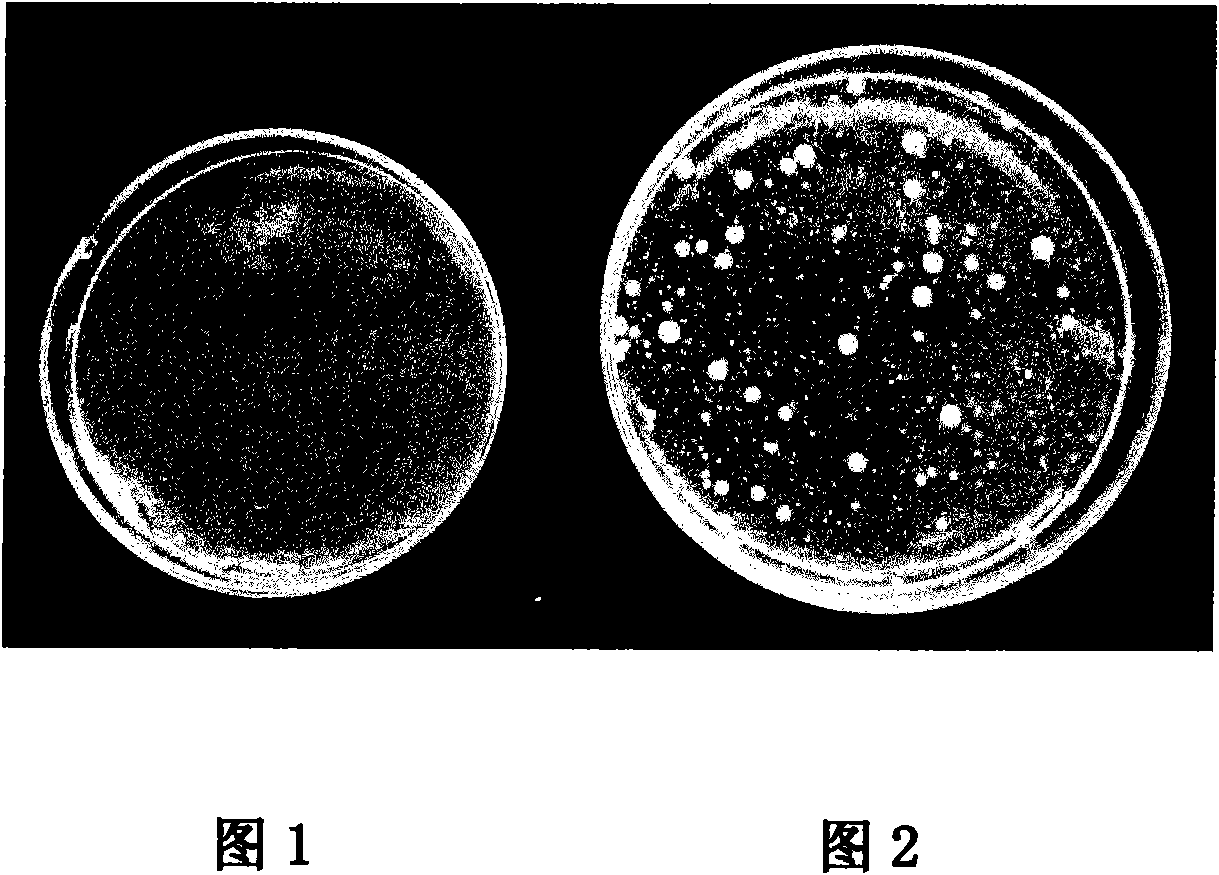

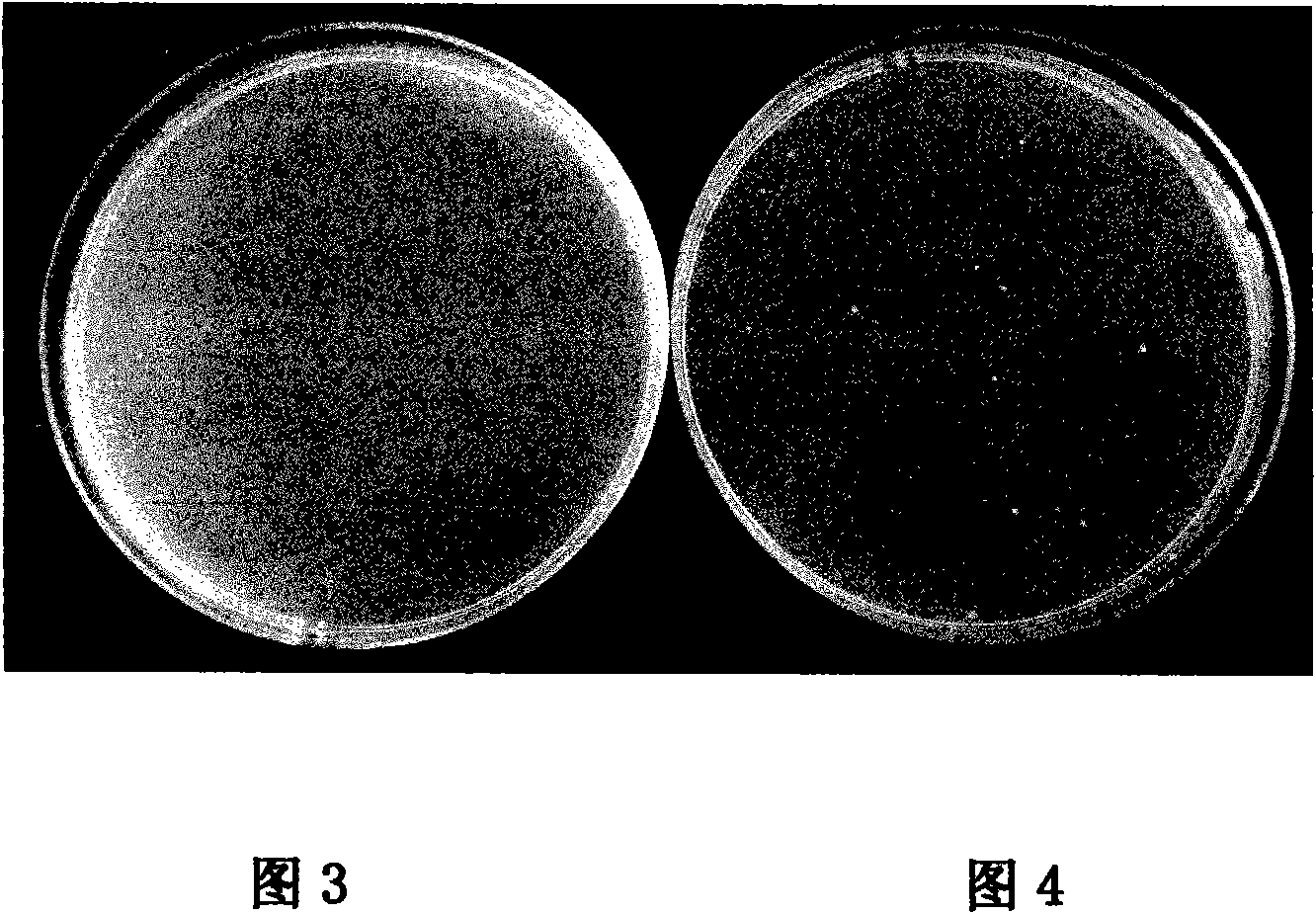

Antibacterium paint and preparation method thereof

InactiveCN101585980AGood antibacterial effectGood product stabilityAntifouling/underwater paintsPaints with biocidesElectrically conductiveNanometre

The invention relates to antibacterium paint and a preparation method thereof. 0.1-20 percent of conductive macromolecule polyaniline nanometer powder doped with inorganic acid or organic sulfoacid is added into a paint base body according to the weight percent. The preparation method of the antibacterium paint comprises the following steps: adopting the conductive macromolecule polyaniline nanometer powder doped with inorganic acid or organic sulfoacid as raw materials, grinding the conductive macromolecule polyaniline nanometer powder doped with inorganic acid or organic sulfoacid, sieving by a 100-500 mesh standard sieve, continuously grinding the raw materials which are not sieved, repeating the sieving step, mixing the sieved raw materials with the paint base body, and ball-milling mixture for 6-8h by a ball mill. The invention has remarkable antibacterium effect, good product stability, simple preparation process and wide application range without toxic and side effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Bacterial cellulose-polylactic acid composite film and its preparation method, drug-carrying gauze based on composite film and its preparation method

PendingCN107177048AImprove compound efficiencyGood product stabilityMicroorganism based processesCoatingsElectrospinningChemistry

The invention provides a bacterial cellulose-polylactic acid composite film and its preparation method. The preparation method includes steps of (1), preparing a polylactic acid film by a static spinning method; (2), preparing a bacterial cellulose-polylactic acid composite film by an in-situ composite method. The bacterial cellulose-polylactic acid composite film avoids use of toxic chemical crosslinking agent in preparation process, and has high compounding efficiency and good product stability. The invention further provides a drug-carrying gauze based the bacterial cellulose-polylactic acid composite film and its preparation method; the preparation method includes steps of A), preparing the bacterial cellulose-polylactic acid composite film; preparing a drug solution; B), soaking the bacterial cellulose-polylactic acid composite film in the drug solution, and performing oscillation absorption under a vacuum condition; C), taking out the bacterial cellulose-polylactic acid composite film. The drug-carrying gauze has good drug-carrying performance and can be degraded in a body.

Owner:SHAANXI UNIV OF SCI & TECH

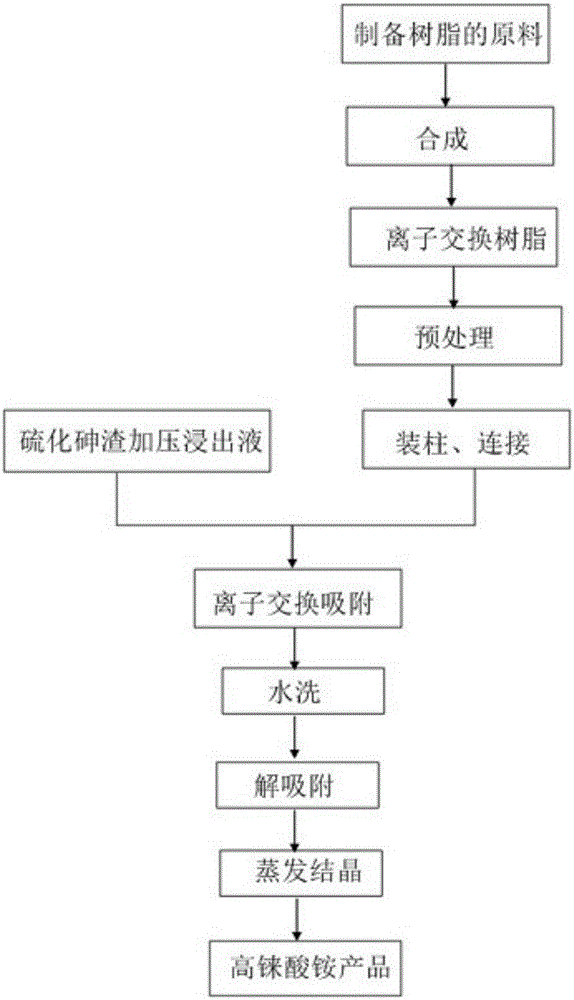

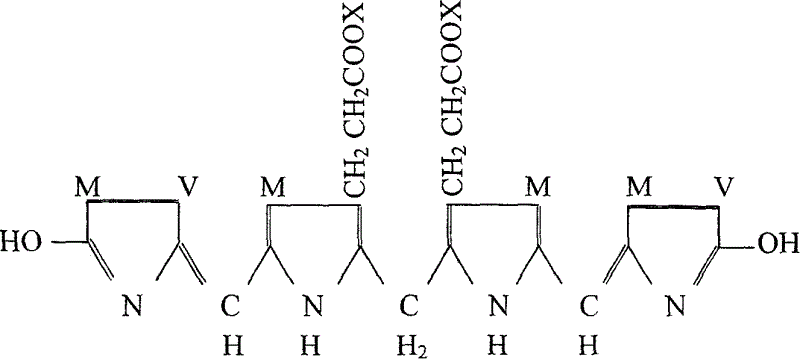

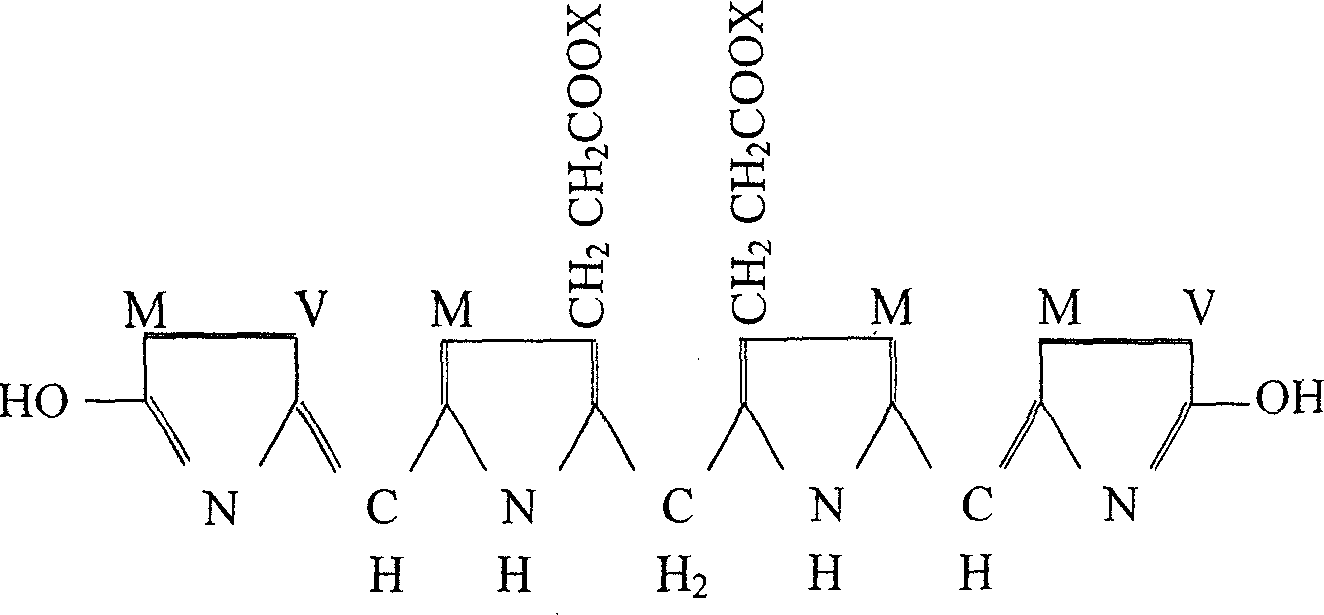

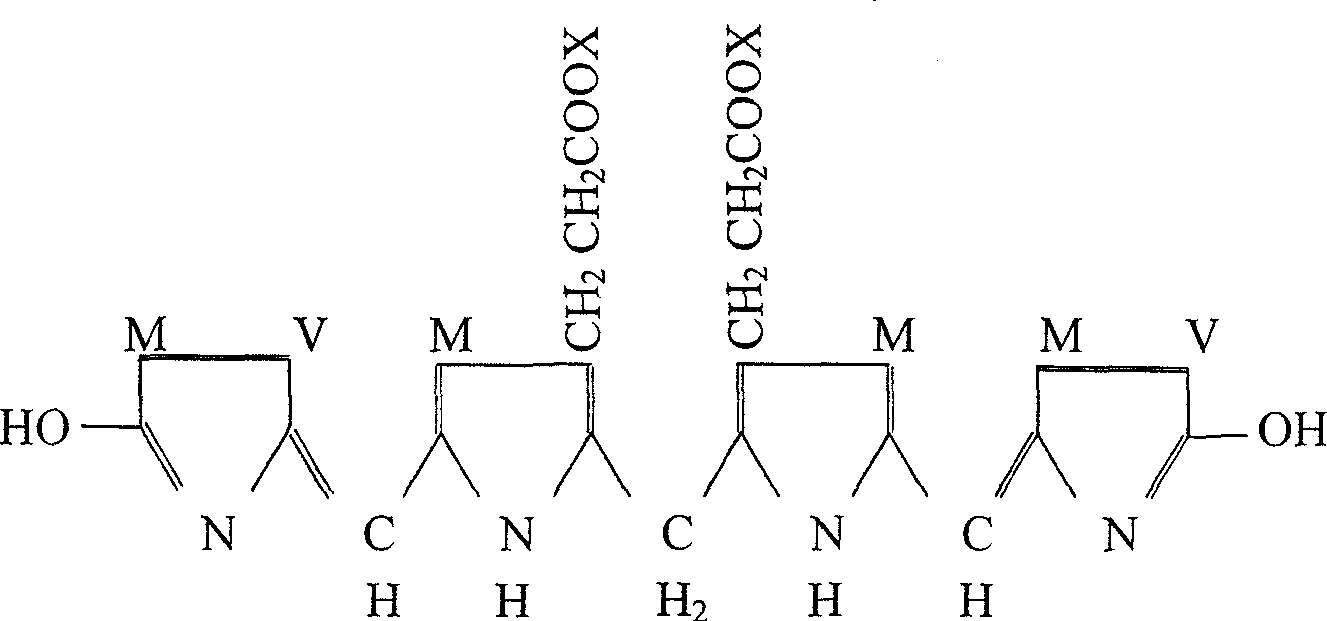

Composite amido weak-base aion exchange resin and method for recycling rhenium from arsenic sulfide residue extracting solution

ActiveCN107519948ALow costGood product stabilityAnion exchangersProcess efficiency improvementSelective adsorptionHigh concentration

The invention relates to a composite amido weak-base aion exchange resin and a method for recycling rhenium from arsenic sulfide residue extracting solution, and belongs to the fields of wet type metallurgy and comprehensive recycling of secondary resources. The composite amido weak-base aion exchange resin is prepared by a preparation method with the following steps of enabling chloride spheres, diethanol amine, N,N-dioctyl amine, N-methylimidazole and diglycol anhydride to react in an organic solvent for 6 to 12h at the temperature of 50 to 80 DEG C according to a mass ratio of 10:(8 to 20):(20 to 40):(5 to 15):(8 to 12) and then performing filtration. The composite ammine weak alkaline ion exchange resin has the advantages that the raw materials are common chemical reagents, the cost is low, the product stability is good, and the good selective adsorption on rhenium in the rhenium-containing solution with higher acidity and high concentration of impurity ions is realized.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Piracetam freeze-dried powder injection for injection and preparation method thereof

InactiveCN104013585AHigh purityGood product stabilityOrganic active ingredientsPowder deliveryChemistryFreeze dry

The invention discloses a preparation method of a piracetam freeze-dried powder injection for injection. The preparation method comprises the following steps: 1, adding piracetam into injection water to dissolve, adding 0.05% active carbon to stir for 30 minutes at the room temperature and filter, subsequently filtering the injection water into a filtrate A through a filtration membrane with micro pore diameter being 0.22 micron; 2, detecting PH value of the filtrate A in the step 1, carrying out freeze drying on the filtrate A with the PH value meeting the injection requirements in a freeze dryer, namely putting a tube-type bottle filled with the filtrate A on a plate layer of the freeze dryer to carry out heat preservation for 6-7 hours at the temperature being 45 DEG C below zero; opening a vacuum pump, increasing the temperature of the plate layer to 0 DEG C and carrying out heat preservation for 30 hours when a vacuum degree is less than 10 Pa, increasing the temperature of the plate layer to 35 DEG C and carrying out heat preservation for 30 hours when the temperature in the tube-type bottle is close to the temperature of the plate layer, ending freeze-drying to prepare the freeze-dried powder B when the temperature in the tube-type bottle reaches 35 DEG C; (3) crushing the freeze-dried powder B in the step (2) in the environment with the humidity being less than 50%, sieving powder through a 30-mesh sieve after crushing, and carrying out aseptic packaging, bundling cover and packaging.

Owner:HAINAN GENERAL & KANGLI PHARMA

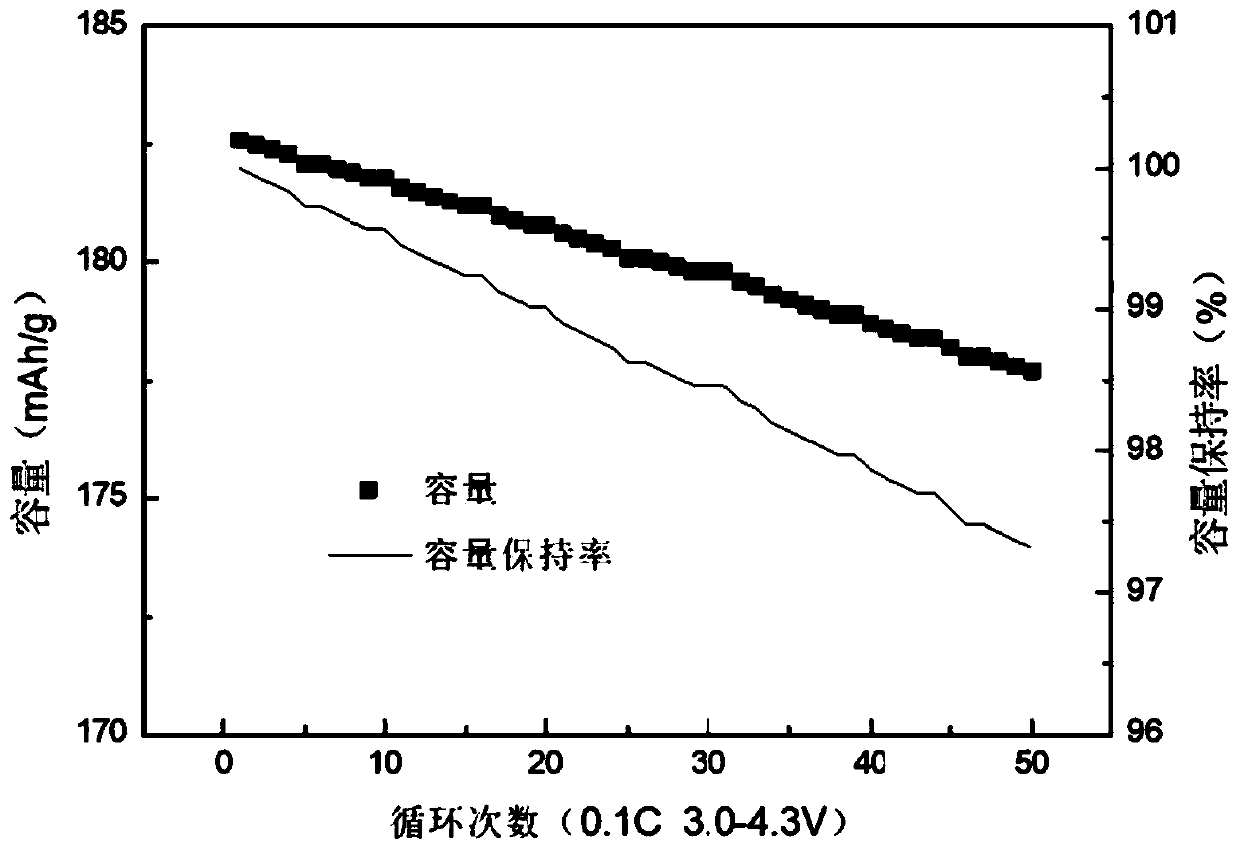

Preparation method of Ni-Co-Al ternary precursor with continuous concentration gradient

The invention relates to the field of preparation of a lithium ion battery positive electrode material, in particular to a preparation method of a Ni-Co-Al ternary precursor with continuous concentration gradient. The preparation method is characterized by comprising the steps of (1) combining and adding a mixed solution of a nickel solution, a cobalt solution, an aluminum solution, a complexing agent and a precipitant into a reaction kettle; (2) adding deionized water into the nickel solution during the material addition process, adding a high-concentration cobalt solution into the cobalt solution until the concentration of the nickel solution is 0.1M or the concentration cobalt solution is 1M, stopping adding a raw material, constantly stirring to ensure uniform solution during the wholeprocess, controlling a pH value of a reaction system to 10.5-12 and temperature to 55-65 DEG C, and continuing to age for 6-24 hours after material addition is stopped; and (3) taking out the material for solid-liquid separation, washing and drying to obtain the Ni-Co-Al ternary precursor with continuous concentration gradient after aging.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

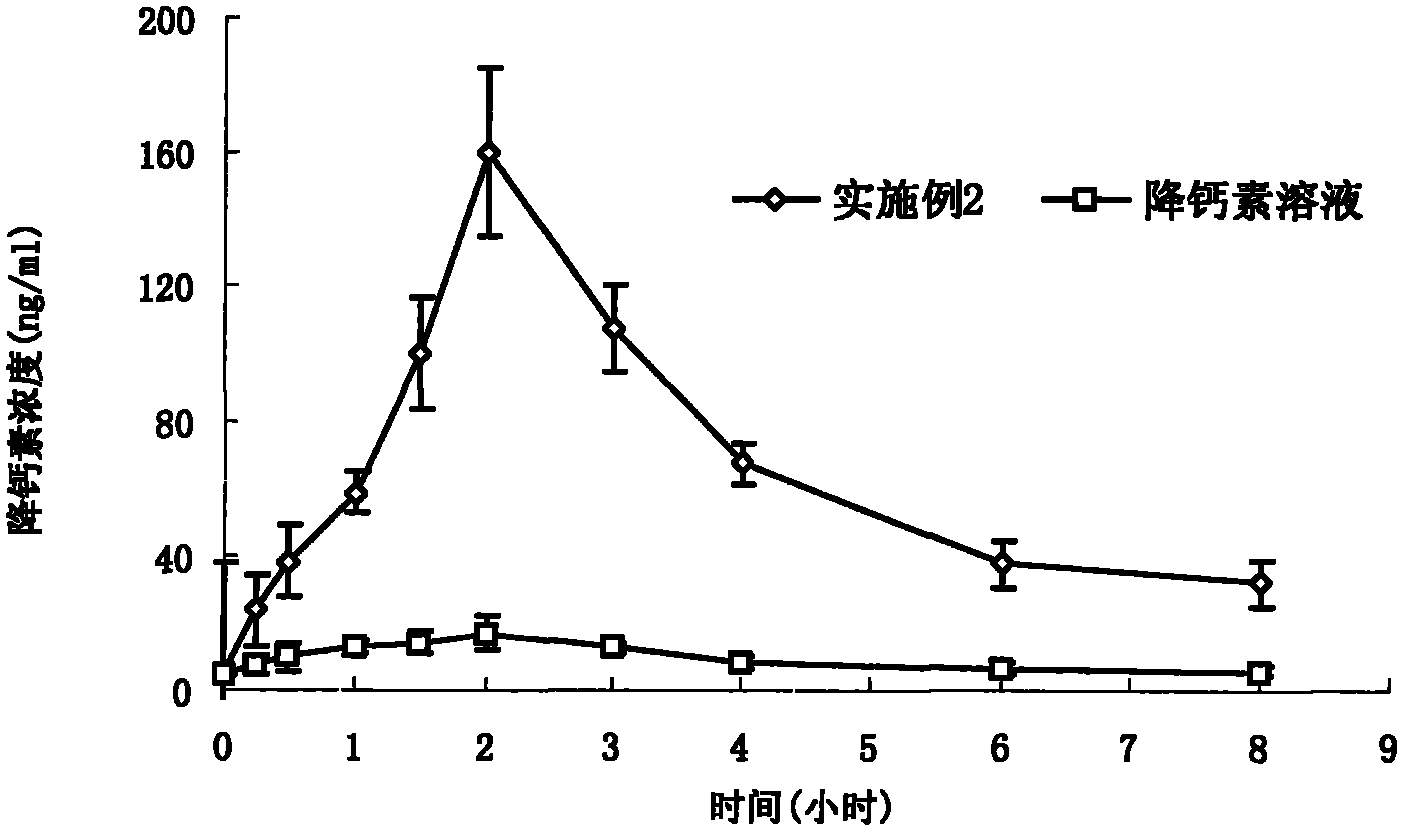

Composition of oral pharmacologic active agent

InactiveCN102100907AImprove permeabilityGood product stabilityOrganic active ingredientsPeptide/protein ingredientsDrugOral medication

The invention relates to a composition of an oral pharmacologic active agent, a method for improving oral bioavailability and a method for treating and / or preventing diseases of mammals and particularly humans by the oral administration of the medicinal composition. The composition comprises water-soluble macromolecular medicaments, a dispersing agent, an auxiliary stabilizing agent, a hydrophobic medium, water and other optional pharmaceutic adjuvants. The preparation method of the composition is simple, and the oral bioavailability of the medicaments can be greatly improved.

Owner:刘青松

Novel water purifying agent and preparation method thereof

InactiveCN106565001AGood effectGood product stabilityWater/sewage treatment by flocculation/precipitationSodium silicateChemistry

The invention relates to a chemical agent, in particular to a novel water purifying agent for sewage treatment. The novel water purifying agent is composed of, by weight, 20-40 parts of sodium sulfate, 10-20 parts of polyacrylamide, 5-15 parts of sodium silicate and 20-50 parts of sodium chloride. According to the novel water purifying agent, the selected polyacrylamide has the advantages of being capable of being easily dissolved in water, excellent in coagulation effect, good in product stability and the like. The pH value applicable range of the novel water purifying agent is wide, and the pH value of water is hardly lowered after treatment; and meanwhile, inorganic components and organic components are cooperatively used as flocculating agents, so that the novel water purifying agent has an excellent flocculent effect. The novel water purifying agent has the advantages of being high in purifying speed, good in effect, environmentally friendly, free of toxicity and the like.

Owner:广西新六合环保有限责任公司

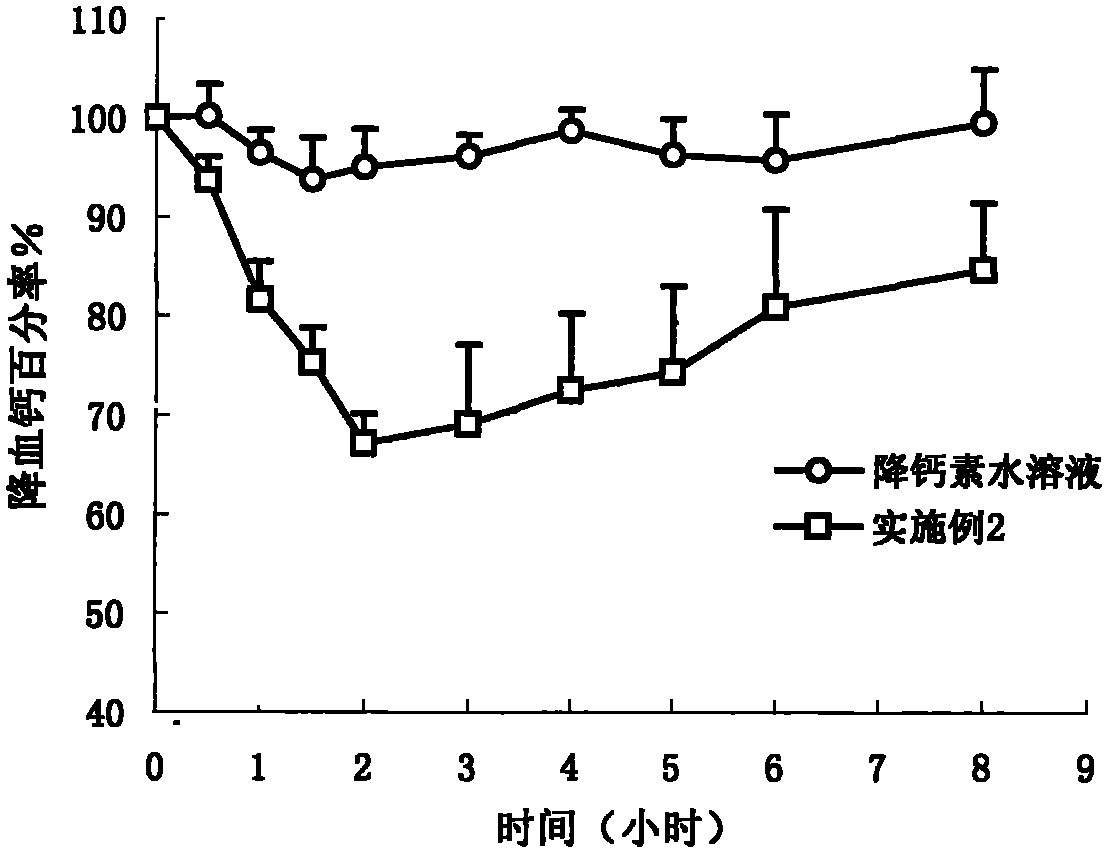

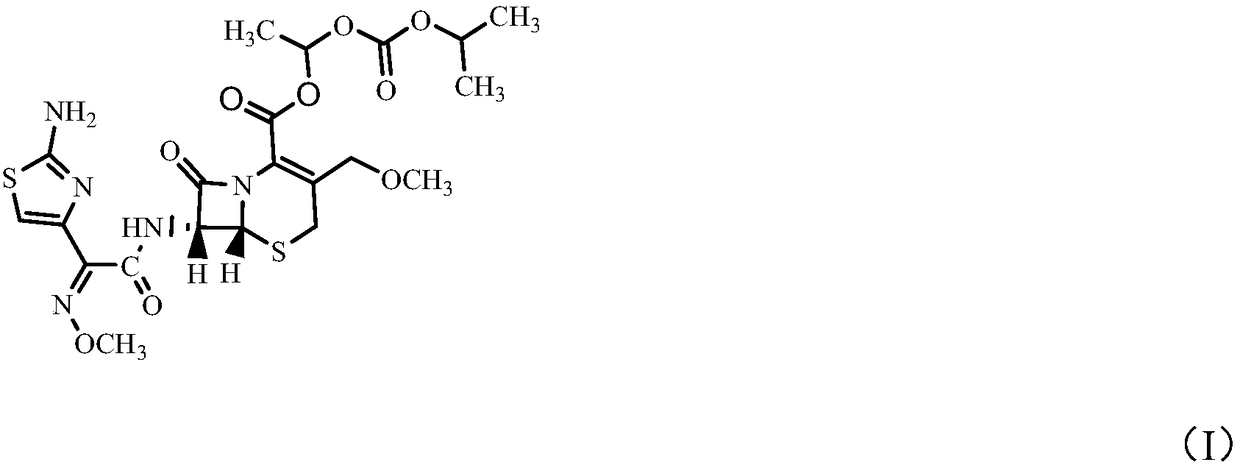

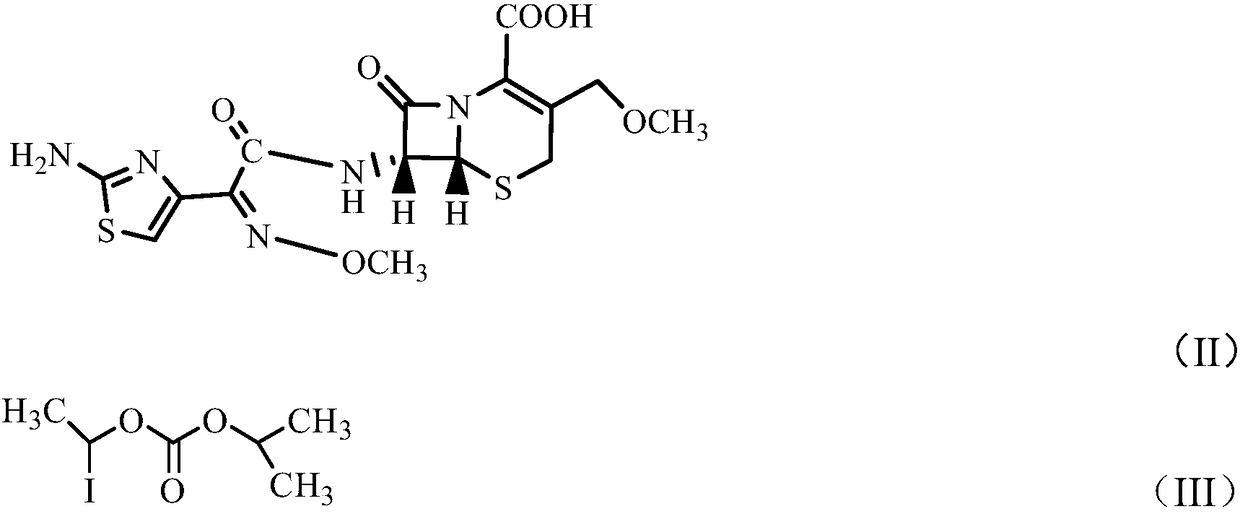

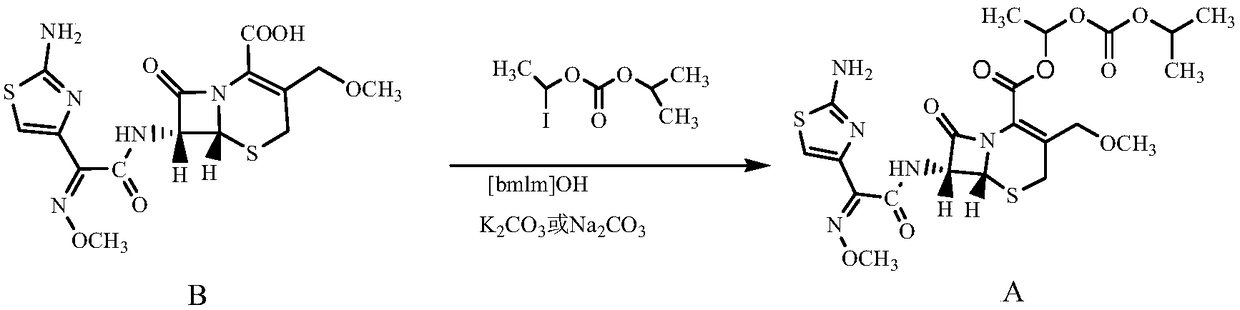

Method for preparing high-purity cefpodoxime proxetil

ActiveCN109232609AGood product stabilityHigh yieldOrganic chemistryCefpodoxime ProxetilMedicinal chemistry

The invention discloses a method for preparing high-purity cefpodoxime proxetil. The method comprises the following steps: reacting cefpodoxime proxetil with iodo ester in an organic solvent in the presence of carbonate and basic ionic liquid; and performing post-treatment to obtain the cefpodoxime proxetil after reaction is completed. The cefpodoxime proxetil product prepared by the method has total impurities of less than 3 percent, and delta 3 isomer of 1.5 percent or less (EP7.0 specified total impurities are less than 4 percent, and USP35 specified total impurities are less than 6 percent), has good stability, molar ratio of 78.3-83.7 percent and high yield, is simple and convenient to operate, and is suitable for industrial production.

Owner:ZHEJIANG APELOA TOSPO PHARMA +1

Teeth whitening strip and preparation method thereof

PendingCN110721118ACompact structureGood product stabilityCosmetic preparationsToilet preparationsPolyamideStyrene-ethylene-butylene-styrene-block copolymer

The invention discloses a teeth whitening strip, which is composed of the following raw materials (by weight): 5-15% of a gelatinizing agent, 1-10% of gel, 5-20% of a humectant, 1-10% of a solubilizer, 1-20% of a whitener, and the balance anhydrous ethanol. The gelatinizing agent is one of a thermoplastic polyurethane elastomer, a styrene-ethylene-butene-styrene block copolymer, a styrene-isoprene-styrene block copolymer, ethylene propylene diene monomer, thermoplastic polyolefin, thermoplastic vulcanized rubber, silicone rubber, polyamide and thermoplastic acrylic acid. The gelatinizing agentis a polyether type thermoplastic polyurethane elastomer. The invention also discloses a preparation method of the teeth whitening strip. The prepared teeth whitening strip has good stability and strong water resistance, can ensure that the whitener in the teeth whitening strip can act on teeth for a longer time, and has a more obvious whitening effect.

Owner:广州玮弘祺生物科技有限公司

Continuous production method of high imino methylated melamine formaldehyde resin

PendingCN113461890AGood product stabilityLow degree of automationChemical industryParaformaldehydeDistillation

The invention discloses a continuous production method of high imino methylated melamine formaldehyde resin. The continuous production method comprises the following steps: mixing para-formaldehyde and methanol, and de-polymerizing para-formaldehyde into formaldehyde under an alkaline condition; continuously feeding the de-polymerized mixture and melamine into a pipeline for reaction, and ensuring that the pH value of the material is alkaline in the reaction process, the reaction temperature is 65-70 DEG C, and the heat preservation reaction time is 10-12 minutes; after the reaction is finished, keeping the materials continuously flowing in the pipeline, cooling the materials to 39-41 DEG C, adjusting the pH value to 3-4, carrying out etherification reaction, keeping the temperature for 8-10 minutes, adjusting the pH value to be alkaline after the temperature is kept, and terminating the reaction; and taking out the material from the pipeline, carrying out reduced pressure distillation, removing water and methanol, then adding isobutanol, adjusting to a proper solid content, and filtering to obtain the product. The method has the advantages of being easy to operate, high in automation level, environmentally friendly, high in yield and the like.

Owner:SHANDONG YANGGU HUATAI CHEM

Sewage treating agent

InactiveCN106809929AGood effectGood product stabilityWater/sewage treatment by flocculation/precipitationChemistryToxicity

The invention relates to a chemical reagent, in particular to a novel sewage treatment agent for sewage treatment. The present invention is configured by the following ratios in parts by weight: polyaluminum chloride 10-25; polyacrylamide 20-25; polyethyleneimine 7-12; bentonite 20-25. The polymeric ferric chloride selected by the present invention is easily soluble in water and has excellent coagulation effect and good product stability. agent, so that the present invention has an excellent flocculation effect, and the present invention has the advantages of fast purification speed, good effect, environmental protection and non-toxicity.

Owner:周子童

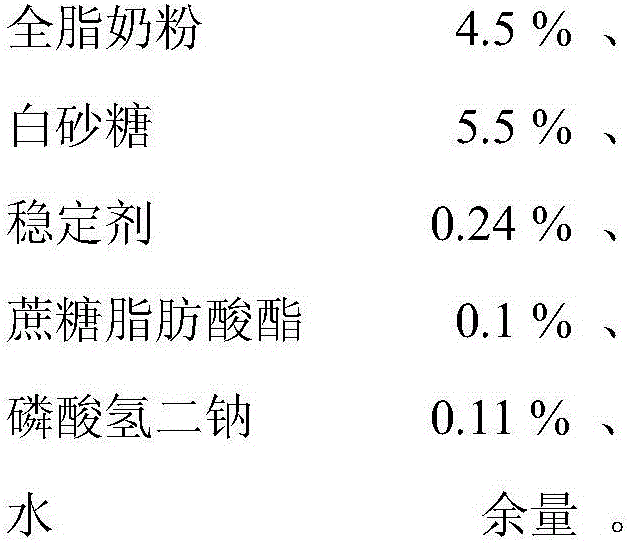

Coffee with maca and method for preparing coffee

InactiveCN106234725AEnsure microbiological indicatorsGood product stabilityCoffee extractionNutrientChemistry

The invention relates to coffee with maca and a method for preparing the coffee. The coffee comprises, by weight, maca powder, coffee powder, whole milk powder, white granulated sugar, stabilizers, sucrose fatty acid ester, disodium hydrogen phosphate and water. The coffee with the maca and the method have the advantages that the coffee with the maca is instantaneously sterilized at ultrahigh temperatures, containers are filled with the coffee by the aid of sterile cold filling equipment, and accordingly microbial indicators of products can be guaranteed; requirements of sterile cold filling processes for coffee beverage with the maca can be met by microcrystalline celluloses, and the products are good in stability; problems of failure of stabilization effects of existing microcrystalline celluloses and destruction of stable systems of existing products due to the traditional processes for mixing ingredients in a non-cooling manner can be solved, and the stability of the products can be guaranteed in a cooling and mixing mode; problems in the aspects of reasonableness of nutrient proportions of the existing products and the stability of final products can be solved.

Owner:上海鑫蓝地生物科技股份有限公司

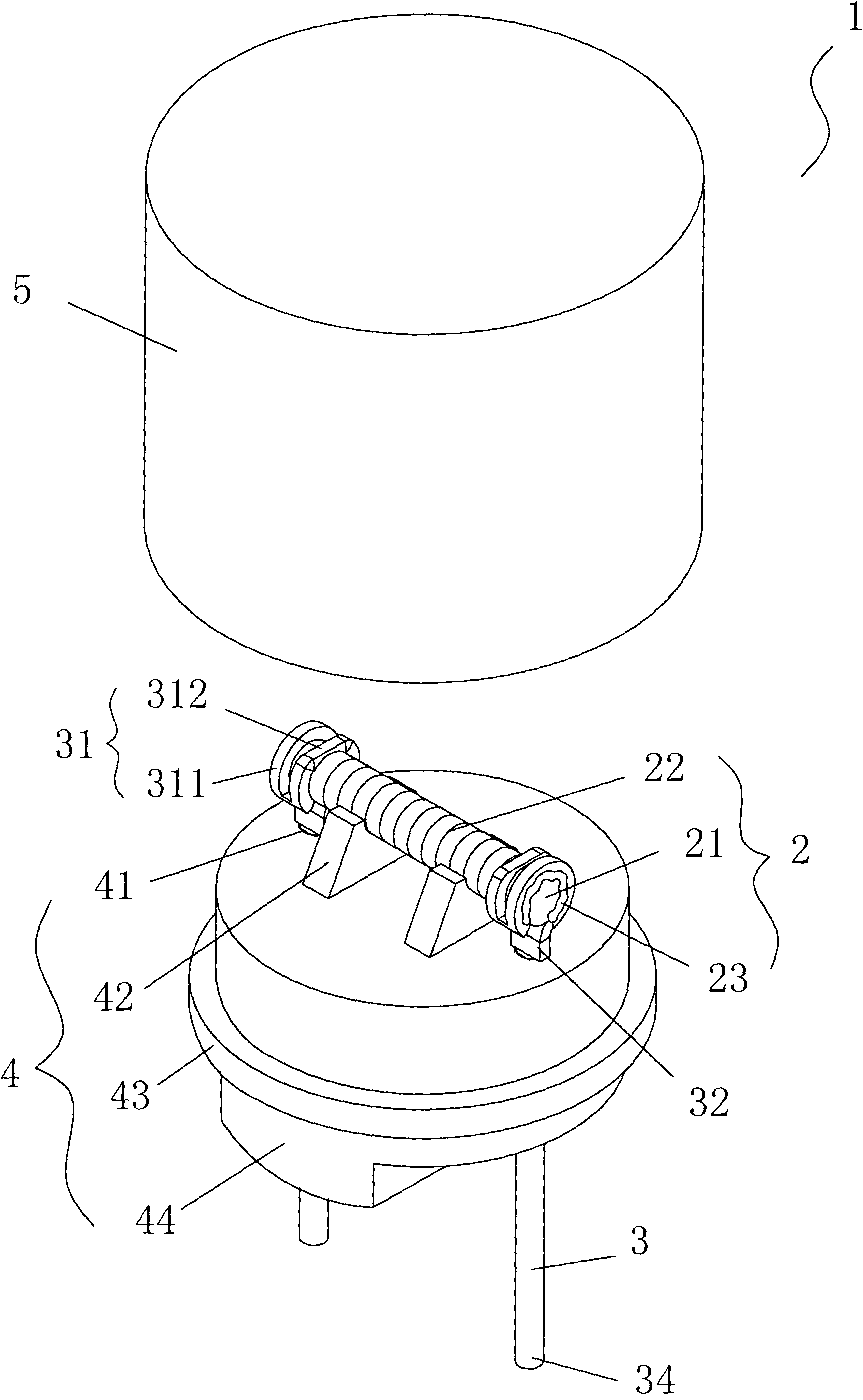

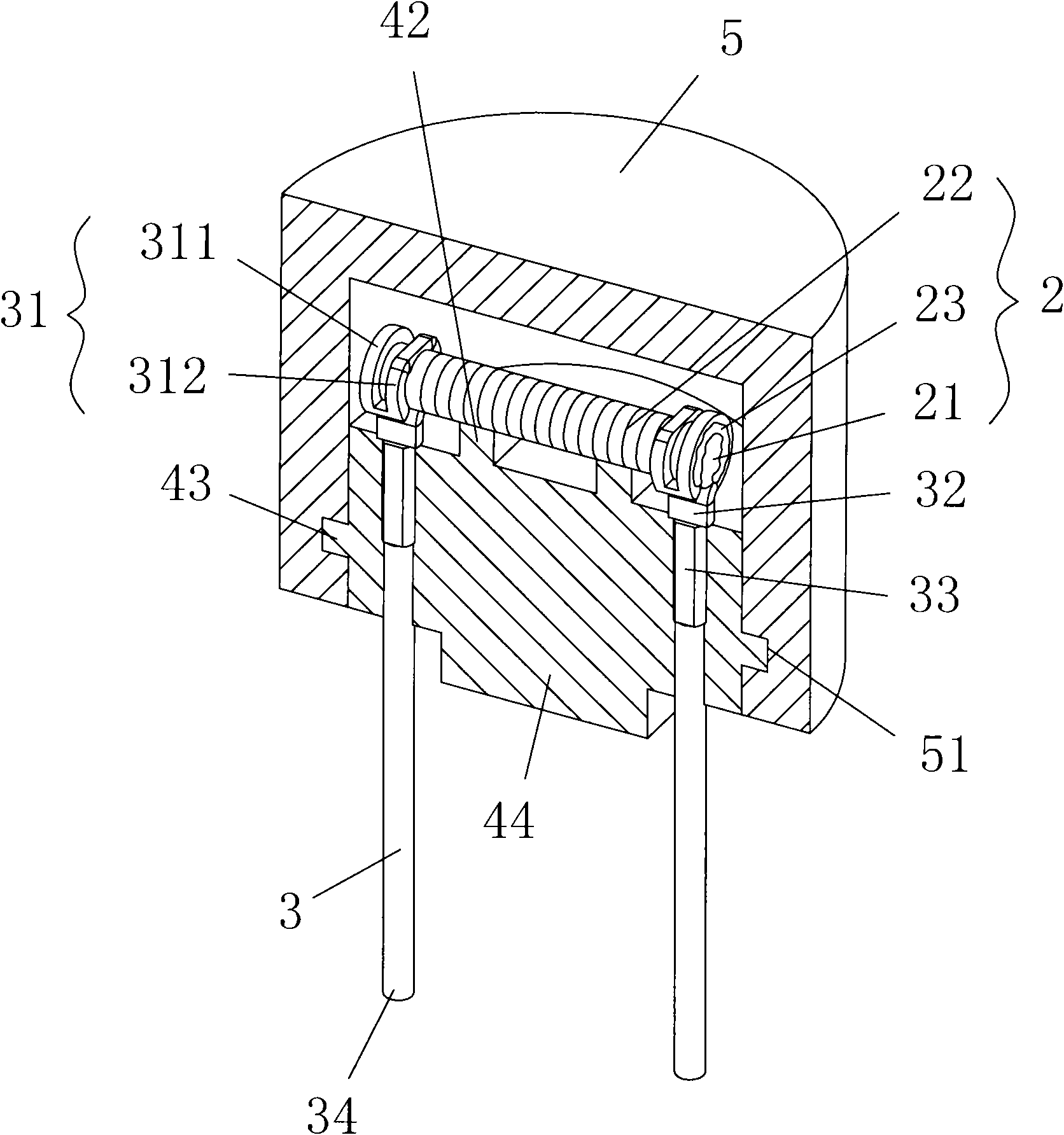

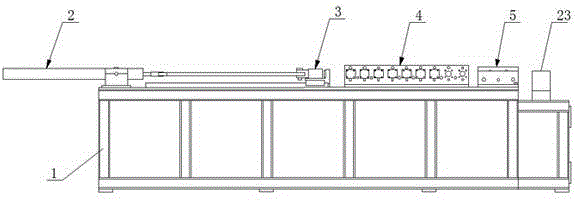

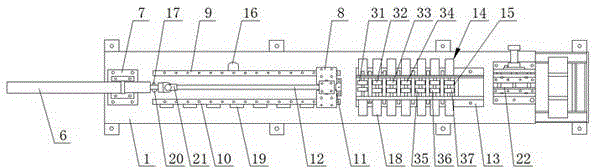

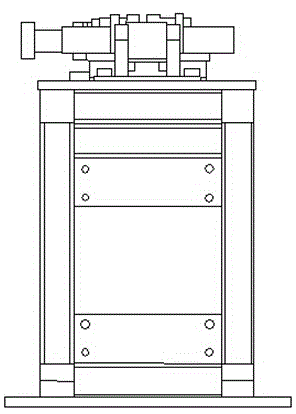

Fixedly-assembling body

ActiveCN104624824AImprove machining accuracyGood product stabilityMetal-working feeding devicesPositioning devicesForcepsEngineering

The invention discloses a fixedly-assembling body. The fixedly-assembling body comprises a body, a driving device, a guide device, a clamping mechanism and a copper tube holding device. The driving device is formed by a hydraulic air cylinder. The guide device comprises a guide rail and a supporting frame, and a connecting hole is formed in the supporting frame. An output shaft of the hydraulic air cylinder is connected with the front end of a core rod, and the back end of the core rod penetrates through the connecting hole. The clamping mechanism comprises a clamping guide device fixing base and a clamp forcep set. Driving control optoelectronic switches are installed on the left side of the guide rail and matched with a first induction generator. A driving air cylinder is correspondingly connected to clamping forceps and electrically connected with clamping control optoelectronic switches, and the distance between every two adjacent clamping control optoelectronic switches are equal to the distance between every two adjacent clamping forceps. The copper tube holding device is arranged at the back end of the clamping mechanism, and a clamp forcep holding connector is formed in the copper tube holding device. The fixedly-assembling body has the advantages of being high in machining accuracy, good in product stability, convenient to use, wide in application range and low in manufacturing cost.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

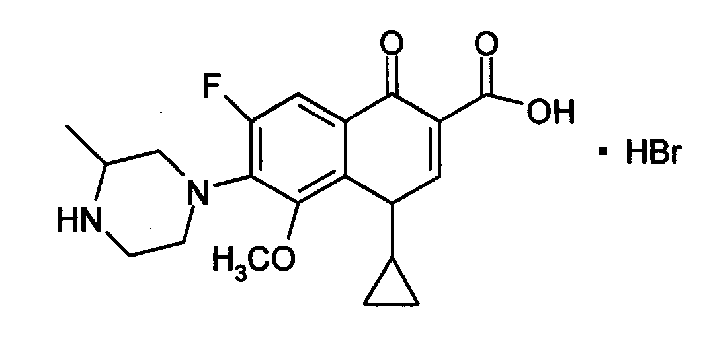

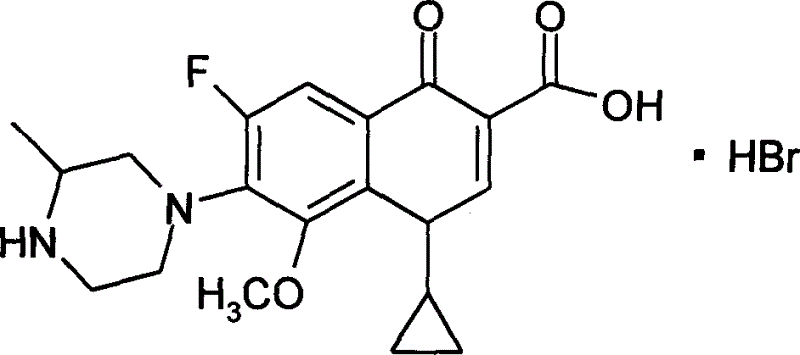

Preparation method of spherical mesoporous carbon-loaded noble metal catalyst

InactiveCN107754792AGood product stabilityExtended service lifeSulfonic acid preparationMetal/metal-oxides/metal-hydroxide catalystsNoble metalEconomic benefits

The invention discloses a preparation method of a spherical mesoporous carbon-loaded noble metal catalyst. According to the preparation method, by changing a raw material ratio, a mesoporous carbon carrier with a controllable structure is obtained; meanwhile, soaking and loading conditions are adjusted, the reaction pH value is 4-5, the mass ratio of noble metals to mesoporous carbon is (0.35-0.45) to 1, the comprehensive optimization is carried out, and finally, the catalyst with high catalytic performance is obtained; and the prepared catalyst is utilized for catalyzing and synthesizing 4,4'-Diamino-2,2'-stilbenedisulfonic acid, and the yield is 99.5%. According to the preparation method, the preparation is simple, an environment-friendly effect is achieved, the catalyst is good in stability and long in service life, the problems that active metals are agglomerated and are not uniformly dispersed in the industrial preparation process of the catalyst at present are solved, the catalytic performance, the large-scale industrial production can be realized, good economic benefits can be brought to enterprises, and the preparation method has wide prospect.

Owner:上海泰坦科技股份有限公司

Preparation method of modified rosin resin aqueous solution

PendingCN112795316ASimple production process and equipmentGood product stabilityMacromolecular adhesive additivesNatural resin chemical modificationChemistryOrganic acid

A preparation method of a modified rosin resin aqueous solution comprises the following steps: 1) crushing rosin, putting the crushed rosin into a reaction kettle, and heating for melting; 2) after the rosin is melted, adding unsaturated organic acid into the reaction kettle, controlling the temperature and keeping the temperature for a certain time; (3) raising the temperature and putting polyhydric alcohol into the reaction kettle for reaction; 4) cooling and adding organic amine into the reaction kettle for reaction; and (5) continuously cooling, adding deionized water into the reaction kettle, and stirring to obtain the modified rosin resin aqueous solution. The prepared modified rosin resin aqueous solution does not contain volatile organic solvents, is stable in storage, can replace traditional rosin emulsion and is added into a water-based adhesive for use, so that the adhesive force is improved, and the opening time is prolonged.

Owner:厦门中坤化学有限公司

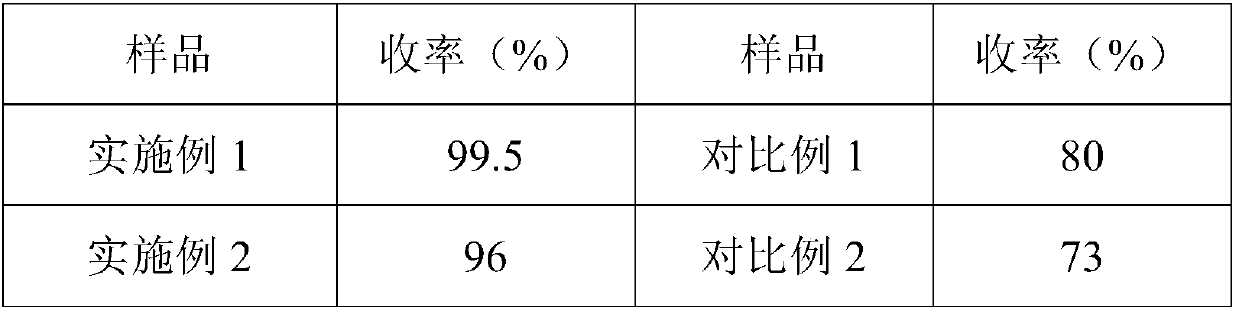

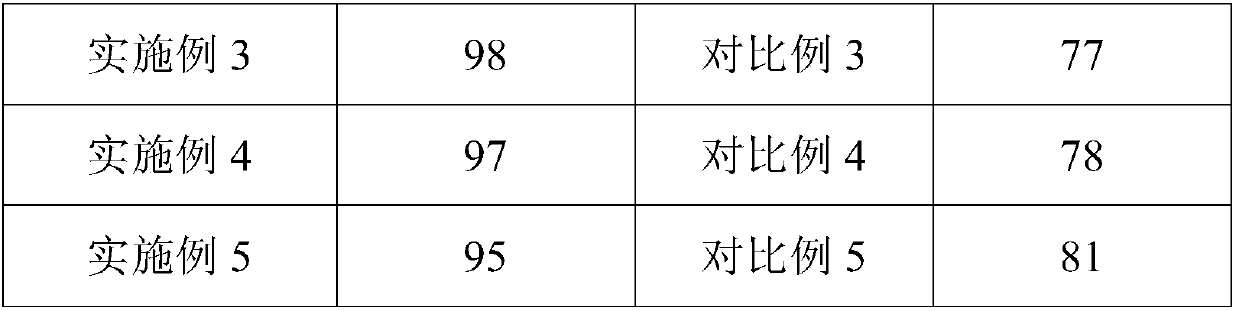

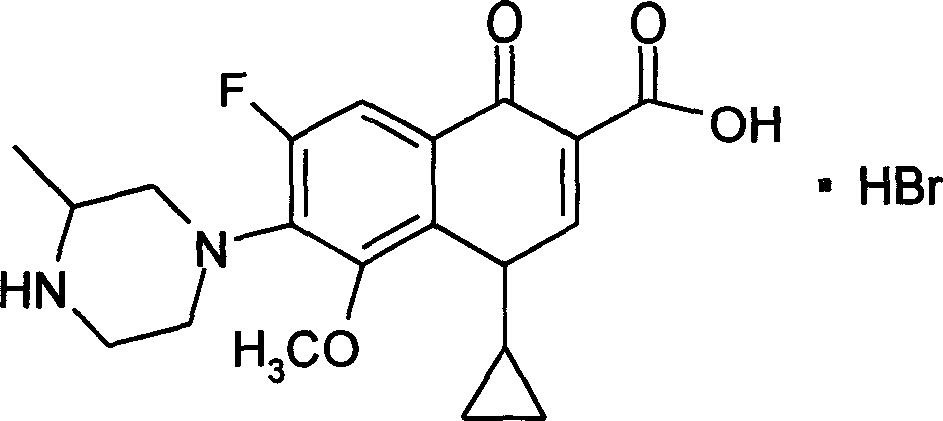

Gatifloxacin hydrobride as quinolone compound and its prepn and application as antibacterial agent

InactiveCN1548435AGood water solubilityGood product stabilityAntibacterial agentsOrganic active ingredientsQuinoloneSolubility

The present invention discloses Gatifloxacin hydrobromate as one kind of quinolone compound and its chemical structural expression, preparation and application. The preparation process adopts Gatifloxacin as main material, and includes reaction with hydrobromic acid in organic solvent or water at 40-50 deg.c for 1-5 hr to produce salt, and subsequent crystallization to obtain Gatifloxacin hydrobromate product. The compound has high water solubility, high stability and less irritation, and its Gatifloxacin component produces antibacterial effect in human body to treat various infectious diseases.

Owner:海南康福中正发展有限公司 +1

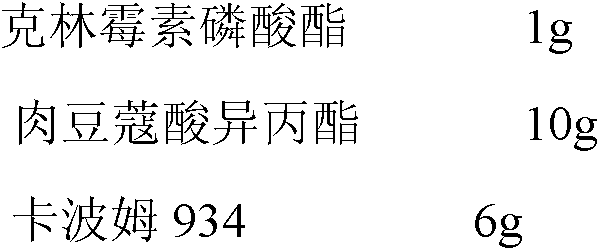

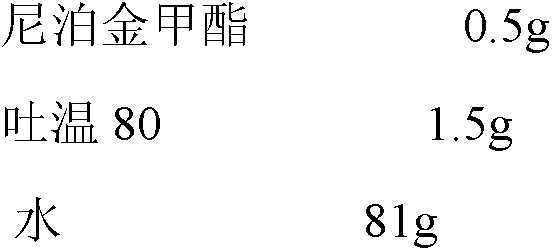

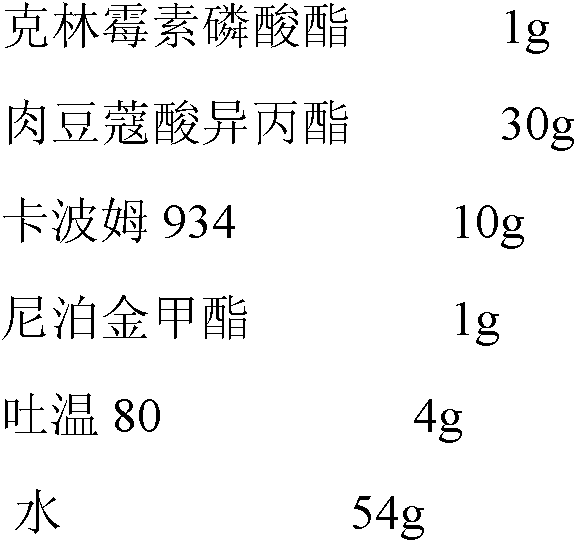

External preparation containing clindamycin phosphate

ActiveCN103893766ASimple preparation processGood product stabilityOrganic active ingredientsAerosol deliveryClindamycin PhosphateChemistry

The invention discloses an external preparation containing clindamycin phosphate. The external preparation comprises a component A and a component B, wherein the component A is isopropyl myristate liquor of clindamycin phosphate; the component B is aqueous liquor of a water-based gel matrix, an emulsifier and a preservative. The external preparation disclosed by the invention is simple in preparation process, free of a special storage condition, good in product stability and easy for large-scale industrial production.

Owner:GUANGZHOU DAGUANG PHARMA

Manufacturing method of woodgrained decorative board material

InactiveCN107780304AExpand the scope of applicationGood product stabilityLamination ancillary operationsLaminationWood grainCardboard

The invention discloses a method for making a wood-grain decorative cardboard material. The surface of the stone cardboard is compounded with cardboard, and the surface of the cardboard is directly printed with a highly simulated and textured wood grain pattern. The invention relates to a method for making a wood grain decorative cardboard material.

Owner:天门顺康纸业有限公司

Water soluble bilirubin and its synthesis process and use

The present invention relates to new compound, and is especially one kind of water soluble cholerythrin and its synthesis process and use. Cholerythrin is made to combine with matter with hydrophilic group to form one new matter comprising cholerythrin and two hydrophilic groups, and the new matter may be used in preparing medicine for preventing and treating cardiac, cerebral and nephric vascular diseases and Parkinson's disease.

Owner:张恒洲

Novel antibacterial and mildew-proof coating as well as preparation and application methods thereof

InactiveCN106118318AReasonable compositionGood product stabilityAntifouling/underwater paintsPaints with biocidesChemistryKetone

The invention provides a novel antibacterial and mildew-proof coating as well as preparation and application methods of the novel antibacterial and mildew-proof coating. The novel antibacterial and mildew-proof coating comprises ethyl acrylate-styrene copolymers, silicon dioxide, barium sulfate, calcium carbonate, casein, magnesium chloride, magnesium hydroxide, pyridine ketone copper sulfate, dimethyl benzyl dodecyl ammonium bromide, titanium dioxide, carbon black, talcum powder and water. The novel antibacterial and mildew-proof coating is reasonable in components, high in stability and excellent in effect, is extremely antibacterial and mildew-proof, and is capable of isolating damp and retaining warmth. The preparation method of the novel antibacterial and mildew-proof coating is simple and practicable in process, high in production efficiency, low in application cost, simple to operate and easy to implement; the produced novel antibacterial and mildew-proof coating is stable in quality, convenient to use and high in compatibility, and has high popularization and application values.

Owner:SUZHOU TIANJIANHENG ELECTRONICS INFORMATION TECH CO LTD

Oil-soluble high molecular surfactant and preparation method thereof

The invention provides an oil-soluble high molecular surfactant and a preparation method thereof. The preparation method comprises the following three steps: firstly, preparing a mixture A, preparing a mixture B, and dropping the mixture into the mixture A droplet by droplet, so as to obtain the oil-soluble high molecular surfactant. The oil-soluble high molecular surfactant prepared by using the method provided by the invention can be used as a stabilizer of a reversed phase suspension polymerization process, and has the advantages of being good in stability, good in high temperature resistance, acid-alkali resistance and uniform and stable in particle size of formed granular products.

Owner:山东鲁岳化工集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com