Nano-fiber for adsorbing heavy metal ions and preparation method thereof

A technology for adsorbing heavy metals and nanofibers, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of unseen preparations, and achieve good product stability, uniform size, and high-efficiency Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

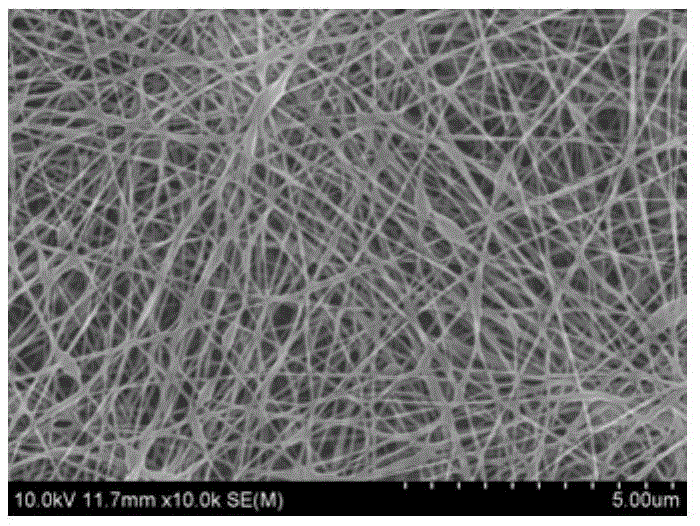

Embodiment 1

[0046] This embodiment provides a method for preparing nanofibers that absorb heavy metal ions based on electrospinning technology, including the following steps:

[0047] a. In the ethanol that is 2000 parts by mass, add 20 parts of dipalmitoylphosphatidylcholine, 10 parts of cholesterol, 30 parts of egg yolk lecithin;

[0048] b. Stir magnetically at 40°C for 30 minutes until completely dissolved and no obvious lumps;

[0049] c. in the water of 2000 parts by mass, add 20 parts of acetic acid, after mixing, add 100 parts of chitosan;

[0050] d. Stir magnetically at room temperature for 12 hours until completely dissolved and no obvious particles;

[0051] e. Add the solution obtained in b to the solution obtained in d, and continue stirring at 50° C. for 60 minutes to obtain a mixed solution of chitosan-dipalmitoylphosphatidylcholine;

[0052] f. Add the solution obtained in e into the syringe, and use the existing electrospinning equipment to carry out the electrospinnin...

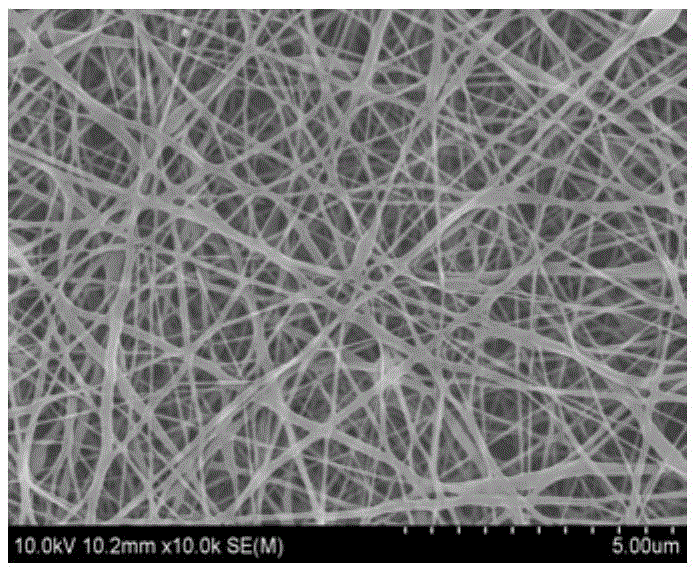

Embodiment 2

[0055] This embodiment provides a method for preparing nanofibers that absorb heavy metal ions based on electrospinning technology, including the following steps:

[0056] a. In the ethanol that is 2000 parts by mass, add 40 parts of dipalmitoylphosphatidylcholine, 10 parts of cholesterol, 50 parts of dilauroylphosphatidylcholine;

[0057] b. Stir magnetically at 50°C for 30 minutes until completely dissolved and no obvious lumps;

[0058] c. in the water of 2000 parts by mass, add 20 parts of acetic acid, after mixing, add 100 parts of chitosan;

[0059] d. Stir magnetically at room temperature for 12 hours until completely dissolved and no obvious particles;

[0060] e. Add the solution obtained in b to the solution obtained in d, and continue stirring at 70° C. for 60 minutes to obtain a mixed solution of chitosan-dipalmitoylphosphatidylcholine;

[0061] f. Add the solution obtained in e into a syringe (in a 5ml syringe, using a No. 7 needle), and use the existing electro...

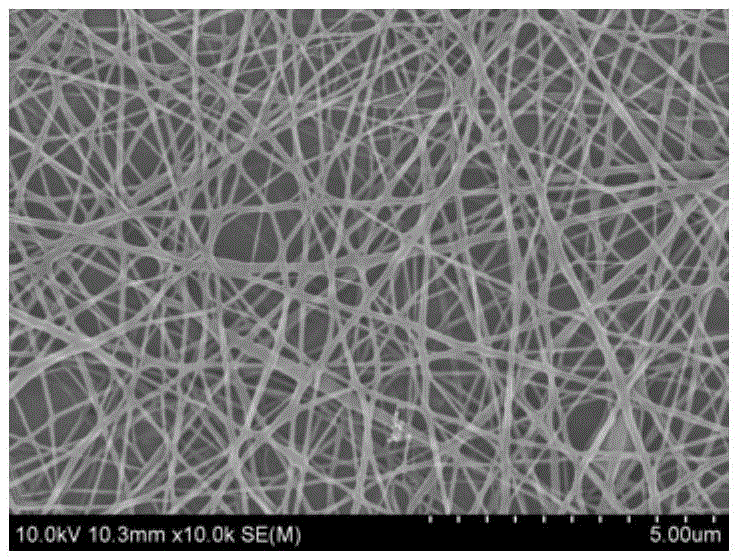

Embodiment 3

[0064] This embodiment provides a method for preparing nanofibers that absorb heavy metal ions based on electrospinning technology, including the following steps:

[0065] a. In the ethanol that is 2000 parts by mass, add 80 parts of dipalmitoylphosphatidylcholine, 100 parts of cholesterol, 10 parts of soybean lecithin;

[0066] b. Stir magnetically at 70°C for 50 minutes until completely dissolved and no obvious lumps;

[0067] c. in the water of 2000 parts by mass, add 40 parts of acetic acid, after mixing, add 80 parts of chitosan;

[0068] d. Stir magnetically at room temperature for 18 hours until completely dissolved and no obvious particles;

[0069] e. Add the solution obtained in b to the solution obtained in d, and continue stirring at 50° C. for 120 minutes to obtain a mixed solution of chitosan-dipalmitoylphosphatidylcholine;

[0070] f. Add the solution obtained in e into the syringe, and use the existing electrospinning equipment to carry out the electrospinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com