Fixedly-assembling body

An assembly and guiding device technology, which is applied in positioning devices, feeding devices, storage devices, etc., can solve the problems of easy scratches on copper pipes, bending and deformation of copper pipes, etc., and achieve good product stability and high processing accuracy , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

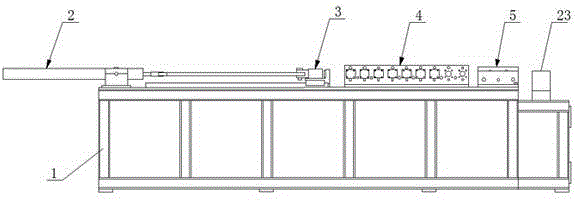

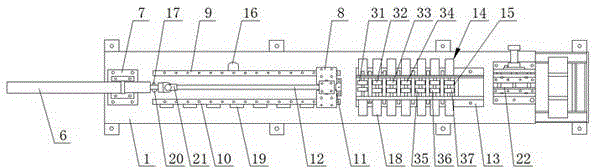

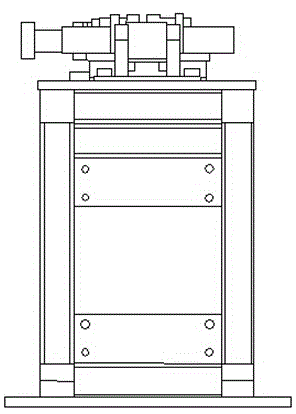

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a fixed assembly includes a bed 1 with a steel frame structure. The upper end surface of the bed 1 is a platform on which various assembly components are placed and installed. A driving device 2, a guiding device 3, a clamping mechanism 4 and a brass tube clamping device 5 are installed on the bed 1. The driving device 2 is composed of a hydraulic cylinder 6 arranged horizontally, the hydraulic cylinder 6 is fixed on the driving base 7, the bottom of the driving base 7 is fixed to the bed 1 by bolts, and the output shaft of the hydraulic cylinder 6 is along the bed. Lateral stretch of body 1. The guide device 3 includes a guide rail and a support frame 8. There are two guide rails, wherein the first guide rail 9 is located on the left side of the output shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com