Purplish red pigment preparation method with golden silk jujube

A technology of golden jujube and jujube red, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as harm to human body, reduce environmental pollution, improve economic and social benefits, and achieve product stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

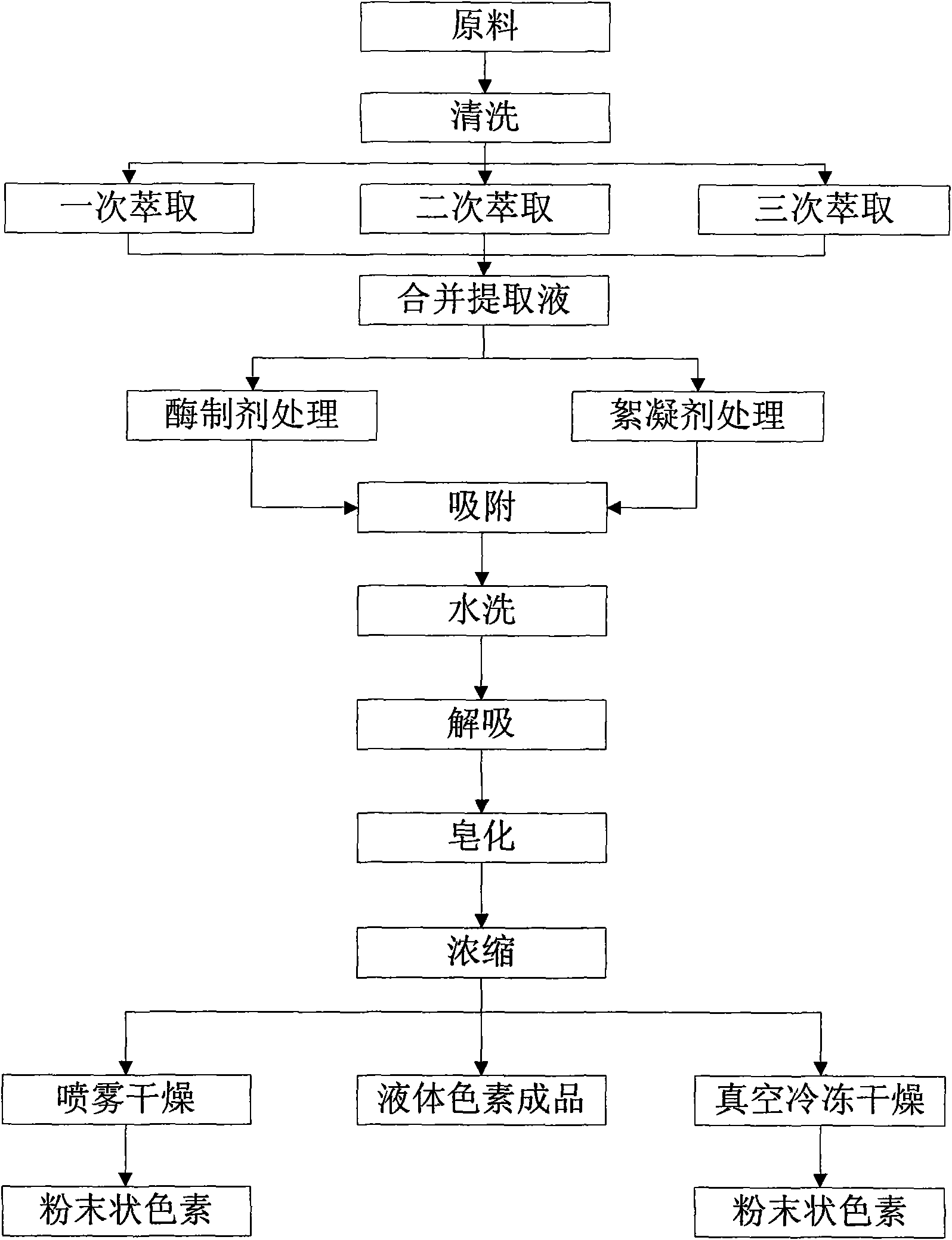

Method used

Image

Examples

preparation example Construction

[0032] 2 Preparation of jujube red pigment aqueous solution

[0033] The jujube skin that has been taken off is put into an extraction tank with a porous mesh surface, rinsed and extracted with an alkaline aqueous solution of jujube skin: solution=1: 3-9, the pH of the alkaline aqueous solution is 9-12, Aqueous solution of jujube red pigment extracted through mesh surface

[0034] 3 Refining of the aqueous solution of jujube red pigment

[0035] Adjust the pH value of the jujube red pigment solution extracted from the mesh surface to neutral or slightly acidic, add flocculant / enzyme preparation 1-5‰, stir evenly, let stand for 1-10 hours, and filter the supernatant to obtain refined jujube red pigment aqueous solution

[0036] 4 Adsorption and separation

[0037] Put the refined red pigment solution on the resin adsorption column, and fill the adsorption column with macroporous resin specially adsorbing bougainvillea pigment, the feed flow rate is 20-60m3 / h, absorb saturate...

Embodiment 1

[0047]700 kg of semi-dry golden jujube, after cleaning, peel off the skin with a peeling machine, and transport the separated jujube skin into the extraction tank by conveyor belt, according to the volume of jujube skin: lye = 1: 3-9 Add the lye that has been adjusted, measure the pH value after stirring, add sodium hydroxide to adjust the pH value to 9-12, extract the filtrate after 12 hours of extraction and put it into another extraction tank, add the same volume of solution to adjust the pH value value, extract the filtrate, repeat the leaching three times, combine the three filtrates, and adjust the pH value to neutral. Add 1-5‰ flocculant to the jujube red pigment solution extracted from the mesh surface, stir evenly, let it stand for 1-5 hours, filter the supernatant to obtain a refined jujube red pigment aqueous solution, pass the filtrate directly through the column, and pass through the resin before the column Treatment: Before loading the column, soak the resin in 2...

Embodiment 2

[0049] 500 kg of semi-dry golden jujube, after cleaning, peel off the skin with a peeling machine, and transport the separated jujube skin into the extraction tank by conveyor belt, according to the volume of jujube skin: lye = 1: 3-9 Add the lye that has been adjusted, measure the pH value after stirring, add sodium hydroxide to adjust the pH value to 9-12, extract the filtrate after 12 hours of extraction and put it into another extraction tank, add the same volume of solution to adjust the pH value value, extract the filtrate, repeat the leaching three times, combine the three filtrates, and adjust the pH value to neutral. Add 1-5‰ flocculant to the jujube red pigment solution extracted from the mesh surface, stir evenly, let it stand for 1-5 hours, filter the supernatant to obtain a refined jujube red pigment aqueous solution, pass the filtrate directly through the column, and pass through the resin before the column Treatment: Before loading the column, soak the resin in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com