Patents

Literature

37results about How to "Simple production process and equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for aired tobacco extracts and essential oil

InactiveCN102488318ASimple production process and equipmentImprove controllabilityTobacco preparationTobacco treatmentWaxAlcohol

The invention discloses a preparation method for aired tobacco extracts and essential oil. The preparation method includes extracting aroma components such as ester, wax compounds and the like in aired tobaccos by the aid of carbon dioxide supercritical fluid; adopting water as eluent to dynamically wash supercritical fluid extracts in a primary separating kettle so as to extract water soluble components; eluting the supercritical fluid extracts via ethanol in a secondary separating kettle to obtain alcohol soluble aired tobacco essential oil; and utilizing alcohol insoluble substances as cigarette aroma additives by an emulsion dispersion method. The preparation method can remarkably increase aired tobacco aroma component extracting efficiency and selectivity, aired tobacco aromatic characteristics of the extracts are remarkable, offensive and irritancy can be reduced, and sensory comfort can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

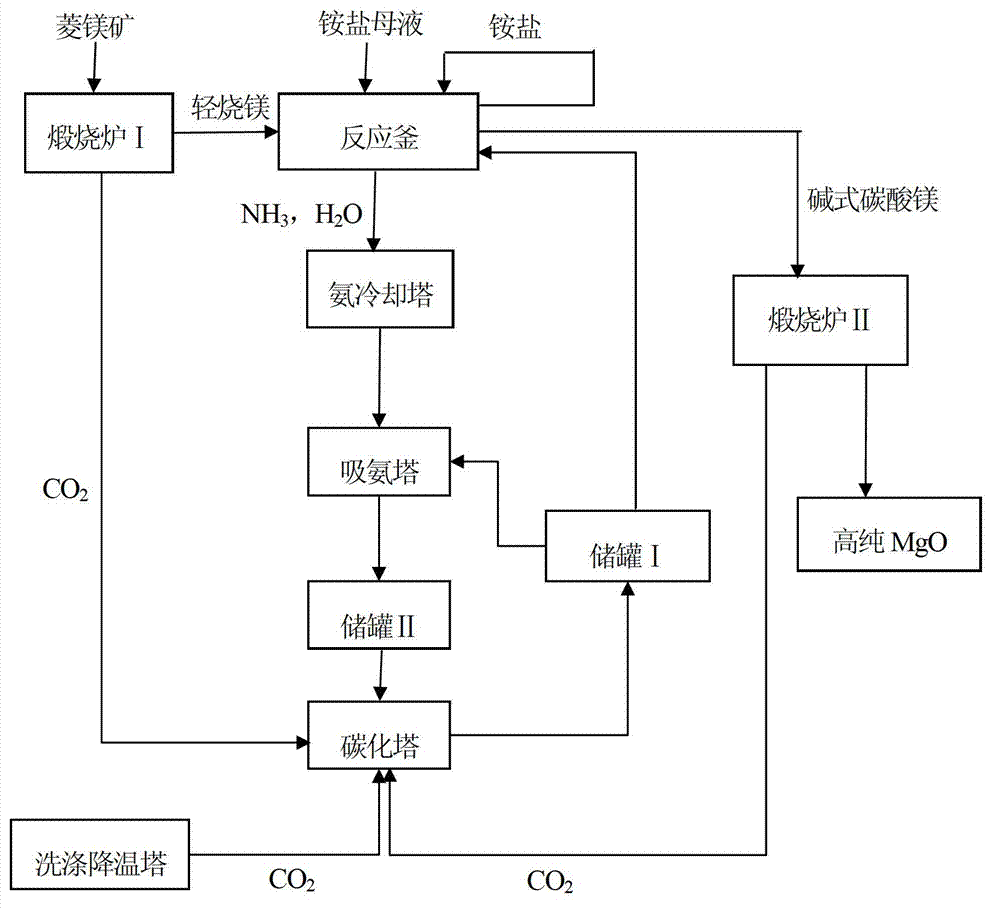

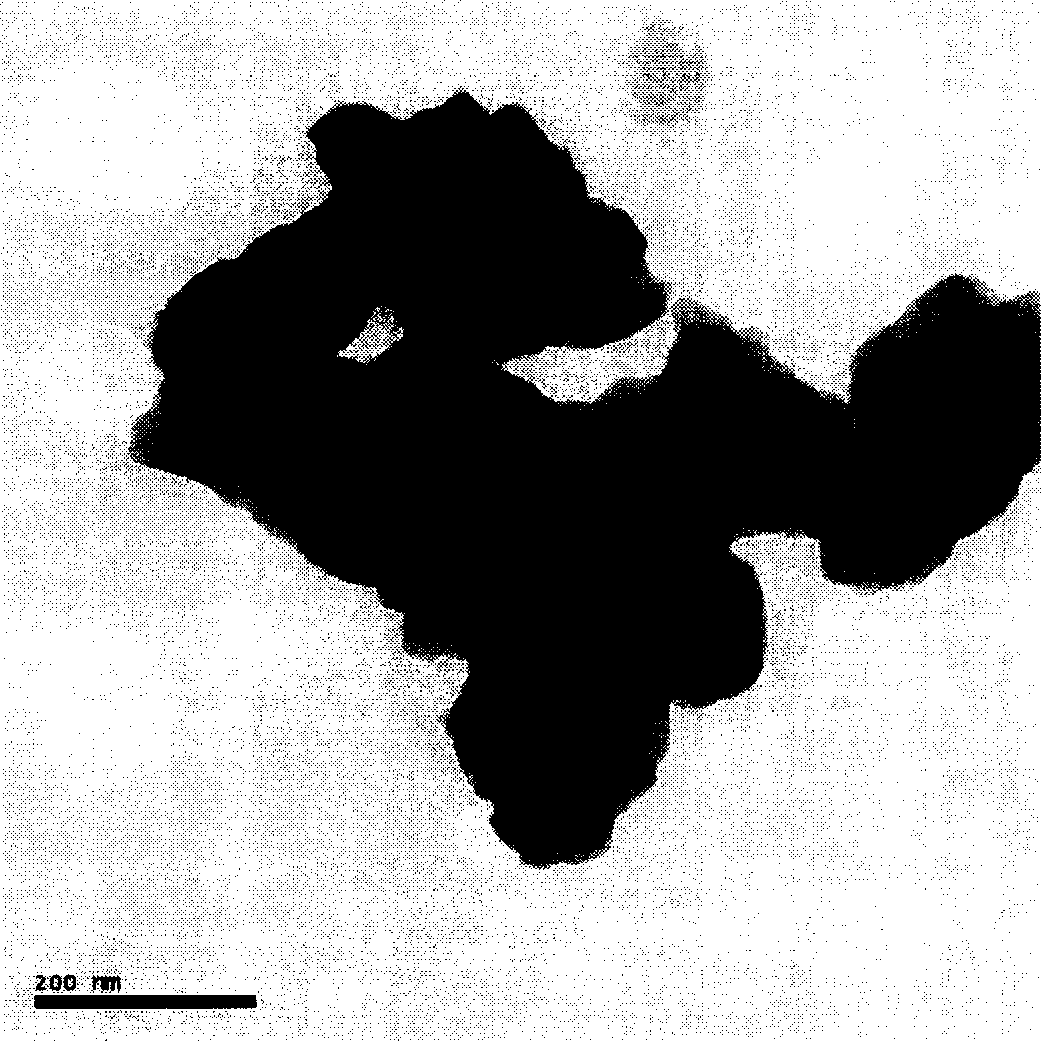

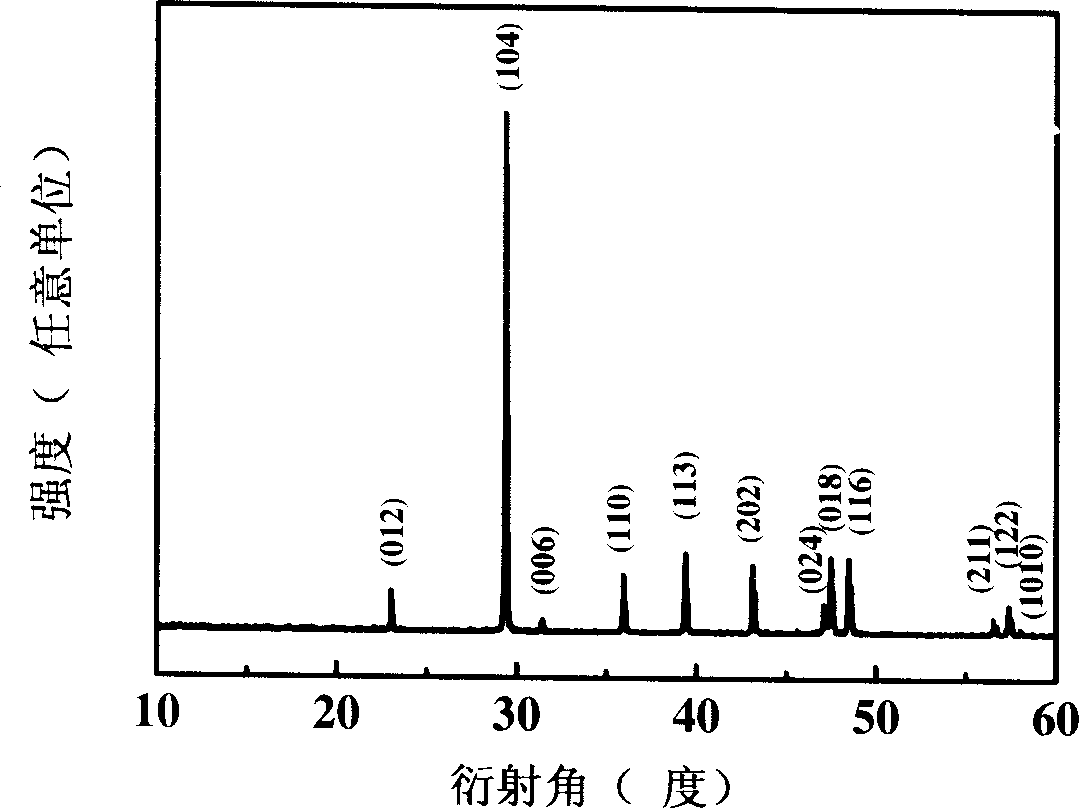

Preparation method for high-purity magnesium oxide

The invention discloses a preparation method for high-purity magnesium oxide. The preparation method for high-purity magnesium oxide comprises the following steps of: calcining magnesite to generate caustic calcined magnesite; heating the caustic calcined magnesite and ammonium salt mother liquor to boil, and distilling; absorbing the distilled mixture of ammonia gas and water by carbonated aqueous ammonia I to form carbonated aqueous ammonia II; carbonizing the carbonated aqueous ammonia II by CO2 from a calcining furnace or flue gas from a washing-cooling tower in a carbonization tower to generate the carbonated aqueous ammonia I, and conveying the carbonated aqueous ammonia I in a storage tank I; conveying a part of the carbonated aqueous ammonia I entering in the storage tank I in an ammonia absorption tower for recycling; mixing the other part of the carbonated aqueous ammonia I with the magnesium salt solution formed by distillation in a reaction kettle, so as to generate basic magnesium carbonate and ammonium salt; filtering and conveying the ammonium salt in the reaction kettle for recycling; and calcining basic magnesium carbonate to prepare high-purity magnesium oxide. According to the preparation method for high-purity magnesium oxide disclosed by the invention, by recycling CO2 and ammonia gas generated during the reaction process, the problem of high raw material consumption due to massive use for ammonium bicarbonate during the production process is solved, and the production cost is reduced; and moreover, the product is high in purity, and the production process is simple in equipment and capable of being used for industrial production for high-purity magnesium oxide.

Owner:SHAANXI NORMAL UNIV

Method for solid-state fermenting of soybean meal

The invention relates to a method for solid-state fermenting of soybean meal. The method comprises four steps such as strain selection, seed liquid preparation, fermentation broth preparation and solid-state fermentation. Compared with the method in the prior art, the method of the present invention has the following characteristics that solid-state fermentation is performed on soybean meal by combining Bacillus subtilis, Saccharomyces cerevisiae and Lactobacillus plantarum; during the fermentation process, the Bacillus subtilis secretes protease to degrade crude protein into small peptides, a large amount of the Saccharomyces cerevisiae grow to synthesize bacterial protein, and a large amount of the Lactobacillus plantarum breed to secrete organic acids so as to improves the flavor of the fermented soybean meal, improve the nutritive value, promote the digestion and absorption of the nutrients; and according to the fermented product, the feeding quality of the fermented soybean meal and the efficiency of the fermented soybean meal are substantially improved, and the characteristics of remarkable economy, remarkable environmental protection and high efficiency are provided.

Owner:上海邦成生物工程有限公司

Feed-level copper sulfate and production technology thereof

ActiveCN106348334ARealize comprehensive utilizationSimple production process and equipmentCopper compounds preparationCopper sulfatesEconomic benefitsIon exchange

The invention relates to the technical field of industrial wastewater treatment, in particular to feed-level copper sulfate and a production technology thereof. The production technology comprises the following steps of A, preparing rough purification etching waste liquid; B, neutralizing, pressing and filtering; C, extracting, and exchanging ions; D, acidifying and crystallizing. The production technology has the advantages that the environment-friendly and pollution-free effects are realized, the emission of waste gas and wastes is avoided, and the wastes are utilized; the mother liquor is recycled, and the subsidiary liquor is sold back to enterprises, so that the economic benefit is high; the equipment is simple, and the operation is simple and convenient; the content of copper ions in the prepared feed-level copper sulfate is 95%, and the prepared feed can improve digestion systems of livestock and poultry.

Owner:东莞市德睿工业废品处理有限公司

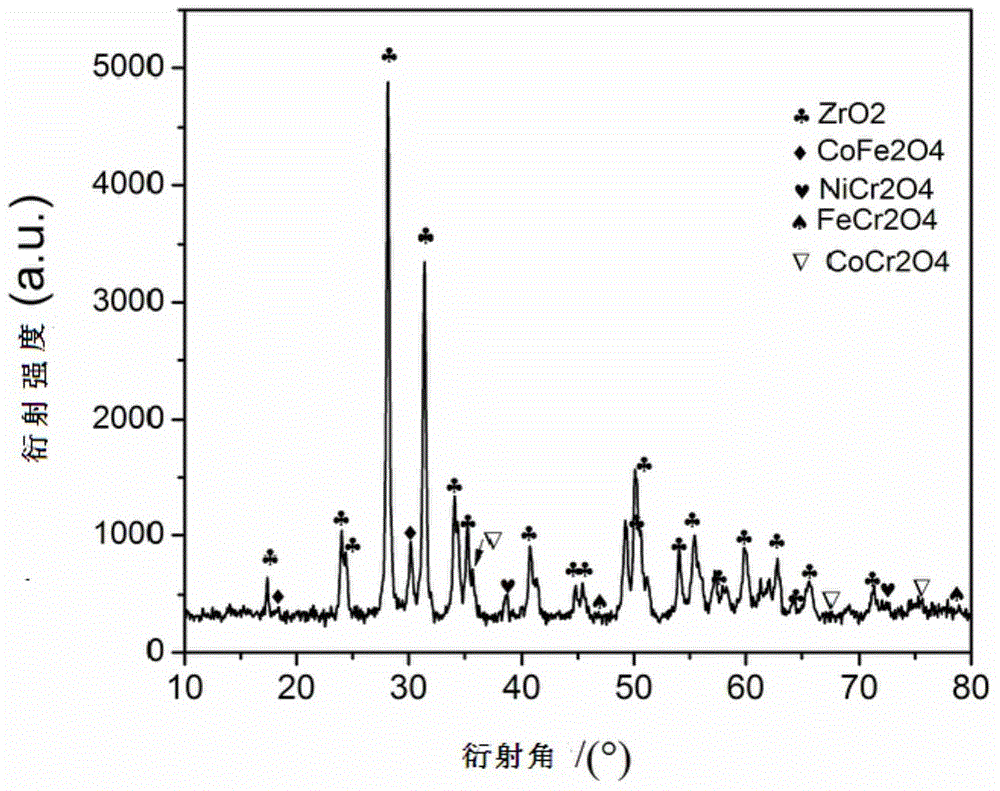

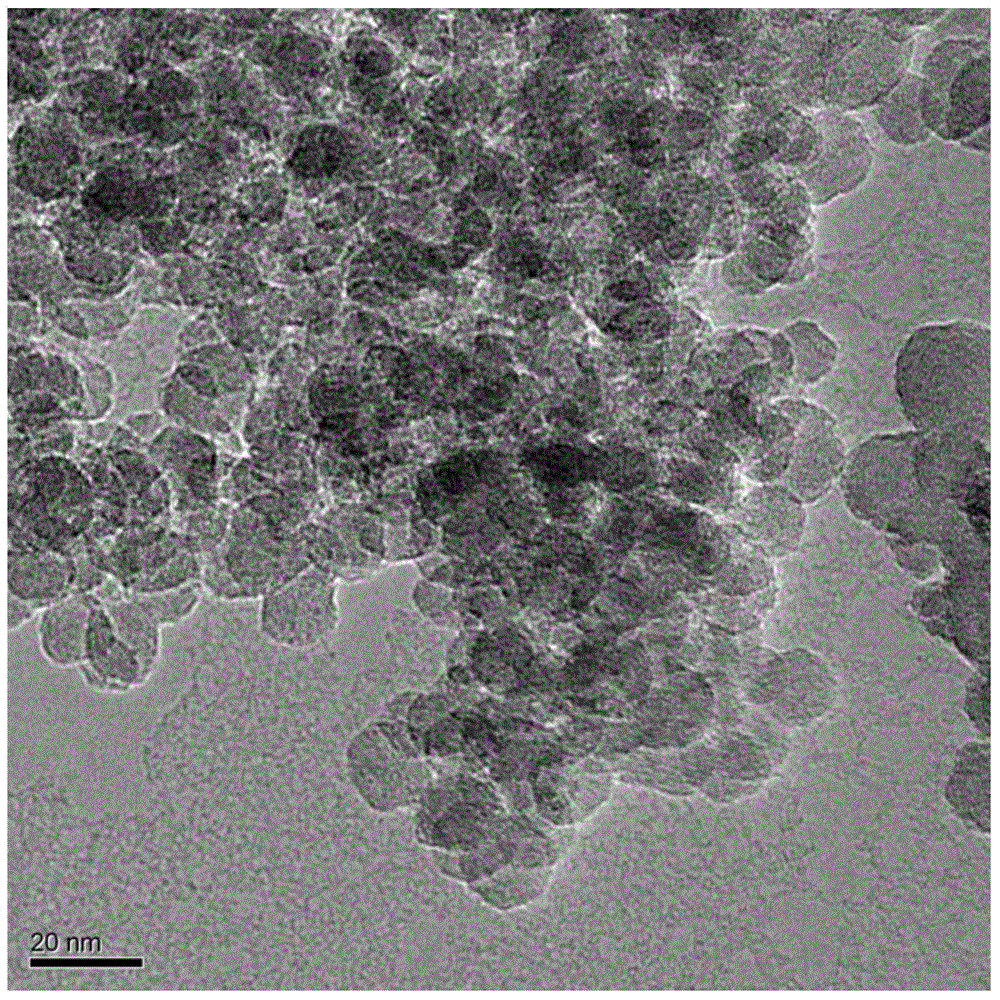

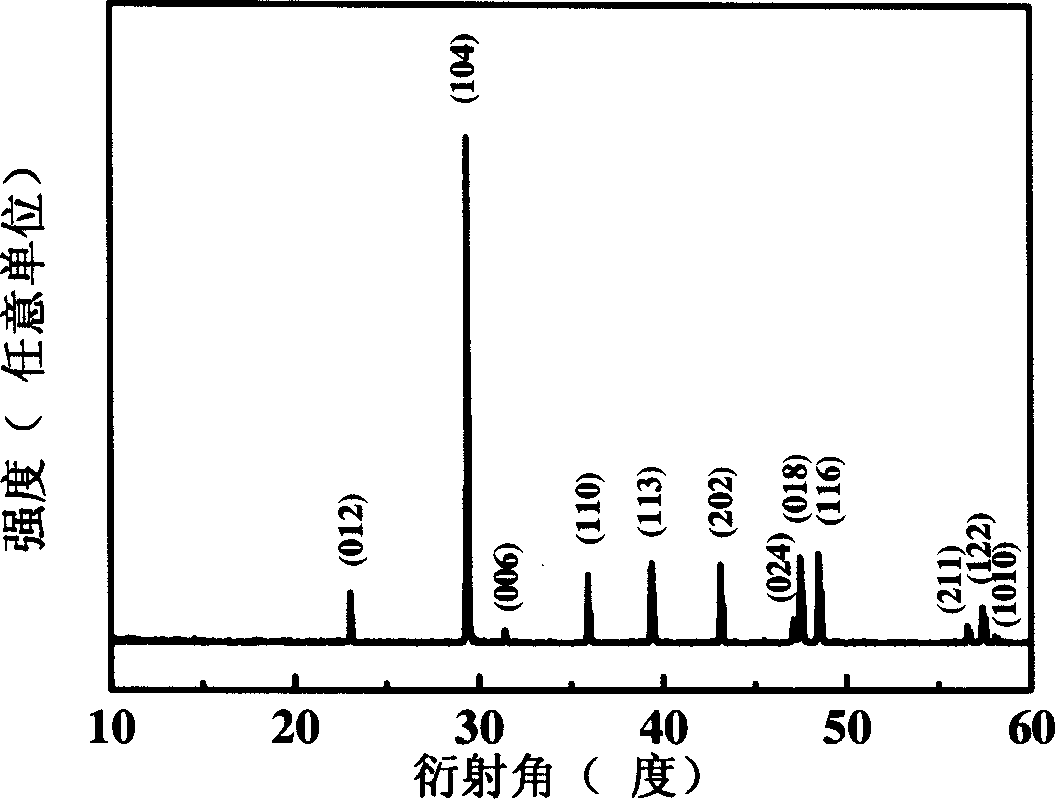

Method for synthesis of black zirconia ceramic powder by organic network process

InactiveCN104529437AWide range of sourcesSimple production process and equipmentMetallurgyNetwork structure

The invention relates to a method for synthesis of black zirconia ceramic powder by an organic network process. The method utilizes organic polymerization reaction to form a network structure by one-step synthesis. Specifically, inorganic Zr<4+>, Y<3+>, Fe<3+>, Cr<3+>, Co<2+>, and Ni<2+> ions occupy an organic three-dimensional network micro-region, and undergoes precipitation reaction with OH<-> diffusing therein, and finally heat treatment is carried out so as to obtain tetragonal crystal form black zirconia ceramic powder. The preparation method provided by the invention has the characteristics of simple technological operation, low cost, high powder purity, high mixability of coloring ions and zirconia, and good present color, is suitable for industrial mass production of black zirconia powder, and is used for production of various black zirconia ceramic products.

Owner:WUHAN UNIV OF TECH

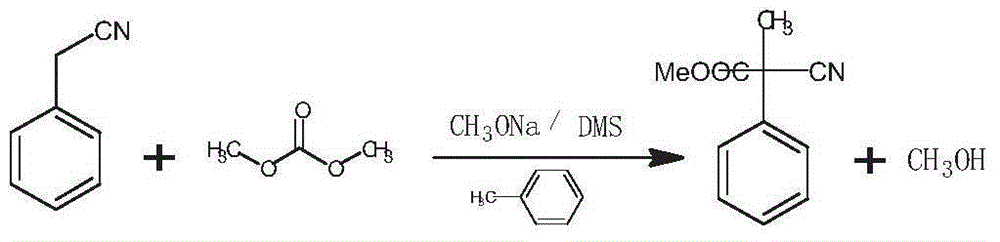

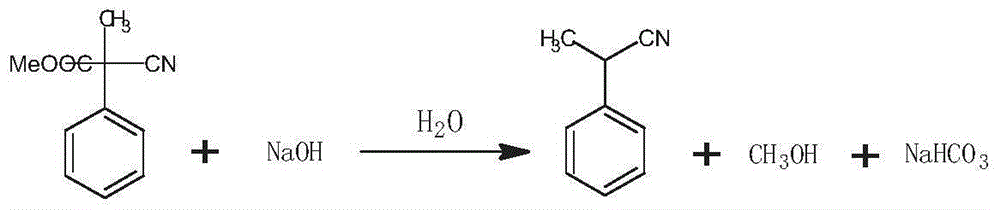

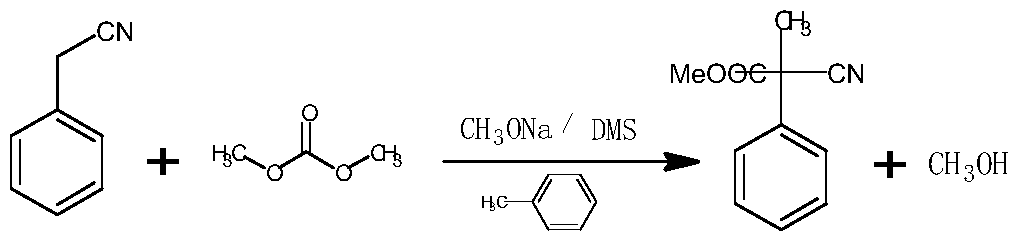

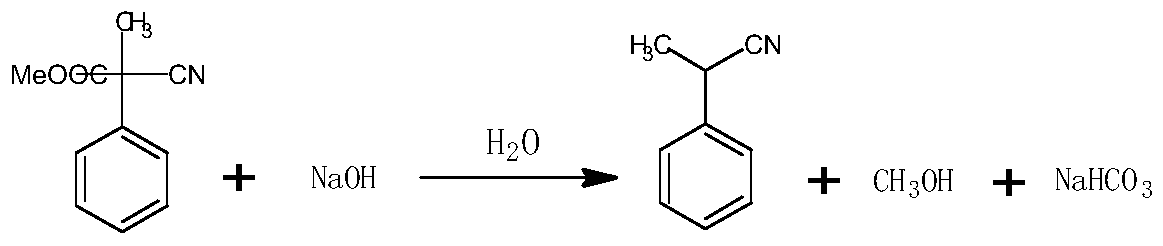

Preparation method for 2-phenylpropionic acid

ActiveCN105037139AHigh purity of finished productSimple equipmentCarboxylic acid nitrile preparationOrganic compound preparationDimethyl sulfateChemistry

The invention discloses a preparation method for 2-phenylpropionic acid. The preparation method is characterized by comprising a 2-phenyl-2-cyano methyl propionate preparation stage, a 2-phenyl propionitrile preparation stage and a 2-phenylpropionic acid preparation stage, wherein the 2-phenyl-2-cyano methyl propionate preparation stage comprises: mixing benzyl cyanide, dimethyl carbonate, methylbenzene and sodium methoxide to obtain a mixture, heating the mixture to 20-100 DEG C, controlling the pressure to 0.5-6MPa and carrying out thermal-insulation reaction for 1-10 hours; after the reaction is ended, steaming out a byproduct methanol under the normal pressure, cooling the mixture to 35 DEG C, dropwise adding dimethyl sulfate DMS at constant speed by controlling the temperature to 35-85 DEG C, and carrying out the thermal-insulation reaction for 1-10 hours at 45-105 DEG C after the dropwise-adding is ended; cooling to 35 DEG C, adding water, stirring, dissolving, and layering; desolventizing to recycle toluene, thereby obtaining compound ester; and carrying out basic hydrolysis reaction and acidification reaction to finally prepare a finished product, wherein the purity of the finished product is high, and the yield of the finished product is higher than 92%. Besides, the production process disclosed by the invention adopts simple equipment and is low in production cost.

Owner:ZHEJIANG BOJU NEW MATERIALS CO LTD

Electroplating-grade copper sulfate and production process thereof

ActiveCN106495205ARealize comprehensive utilizationSimple production process and equipmentCopper compounds preparationCopper sulfatesEnvironmental resistanceIon exchange

The invention relates to the technical field of industrial wastewater and particularly relates to electroplating-grade copper sulfate and a production process thereof. The production process comprises the following steps: (A) preparation of roughly purified etching waste liquid; (B) neutralization and filter pressing; (C) extraction and ion exchange; (D) acidification and crystallization; and (E) purification and crystallization. The production process is environmentally friendly and pollution-free, the waste gas and the waste are not discharged, the utilization of the waste is realized, the cyclic utilization of mother liquid is realized, and the child liquid is sold to enterprises, so that the economic benefit is high, the equipment is simple, and the operation is simple and convenient. The content of copper ions in prepared electroplating-grade copper sulfate reaches up to 98%, so that the digestive systems of livestock are beneficially improved.

Owner:东莞市德睿工业废品处理有限公司

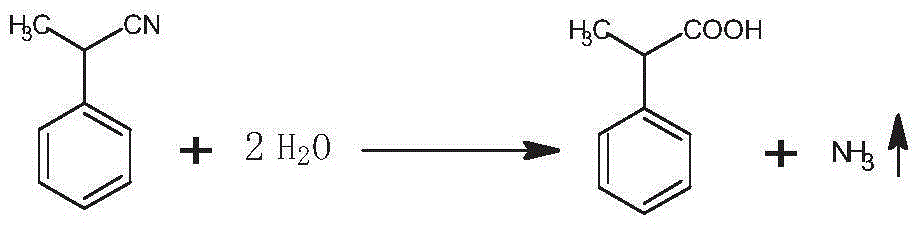

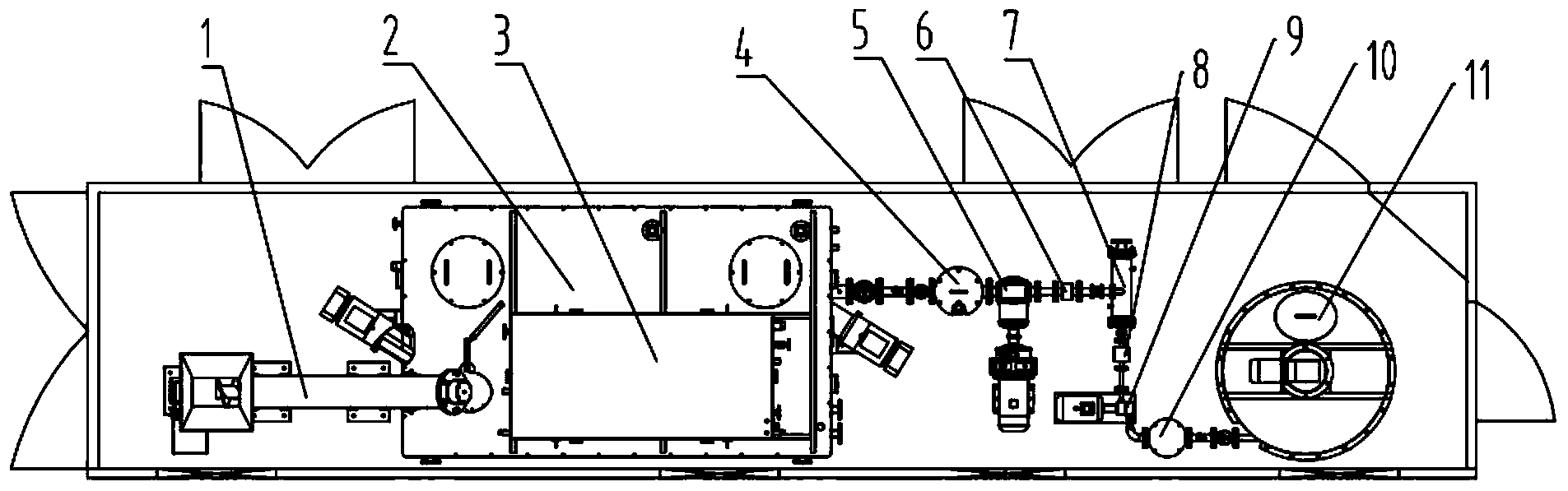

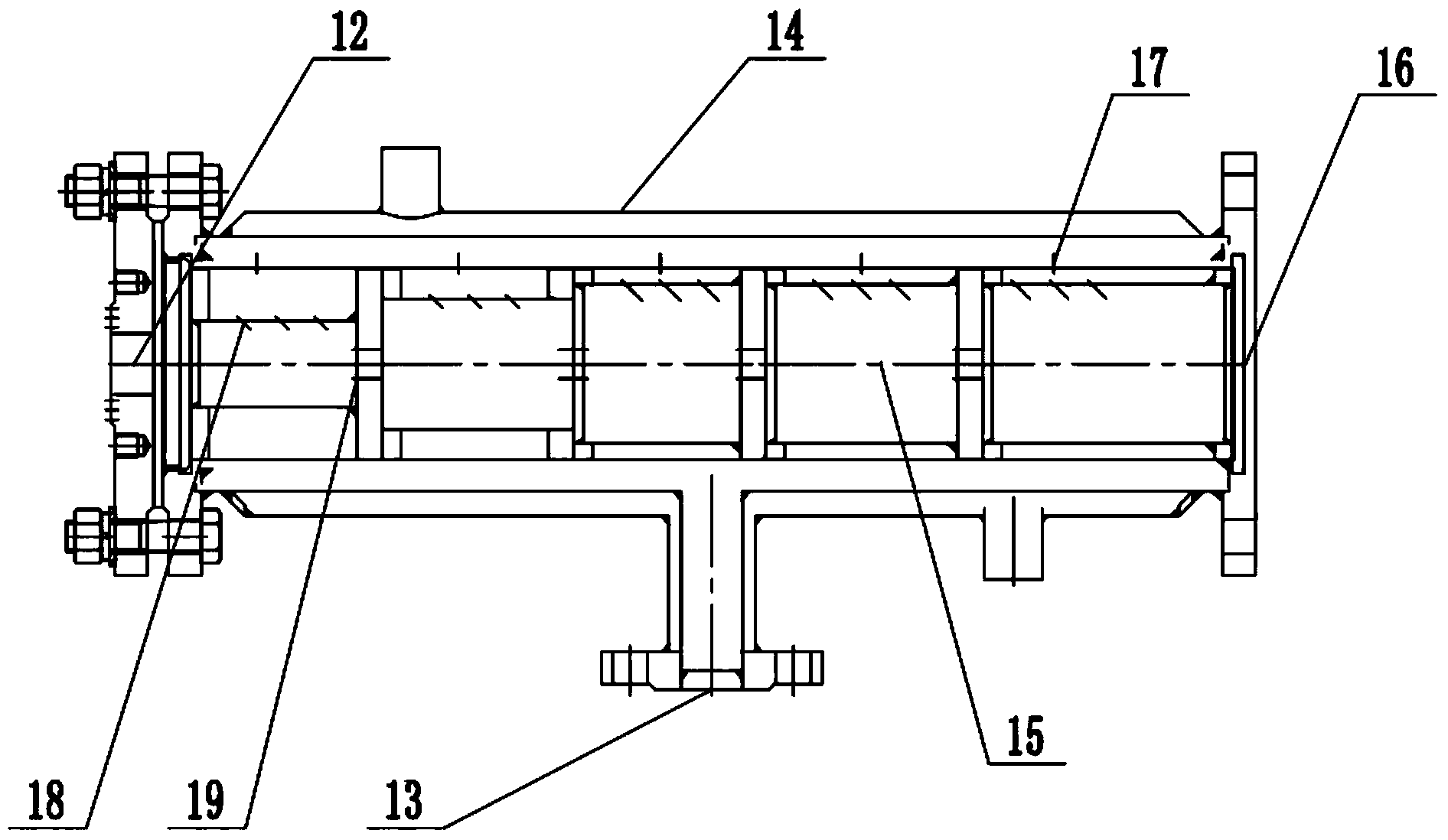

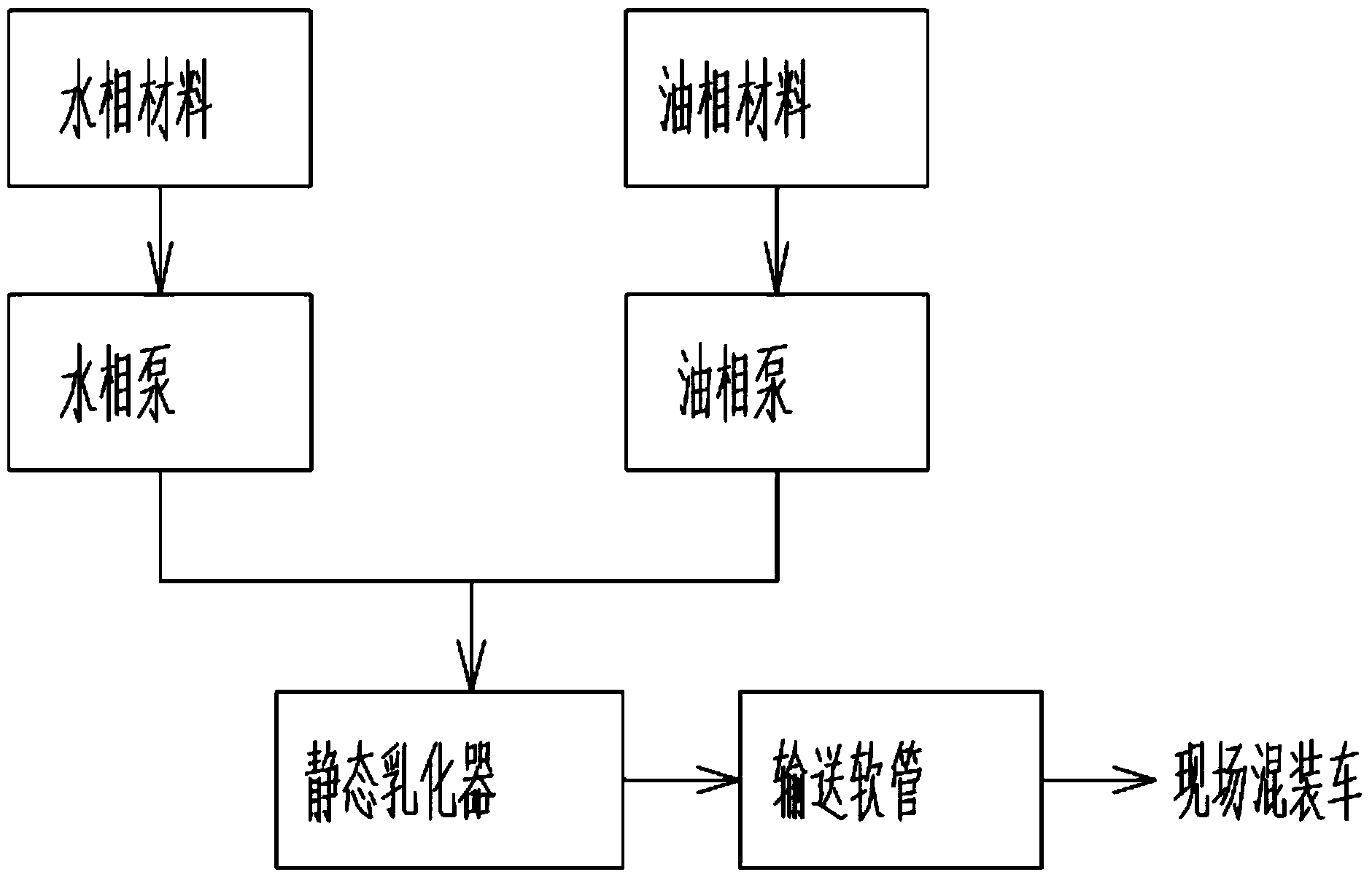

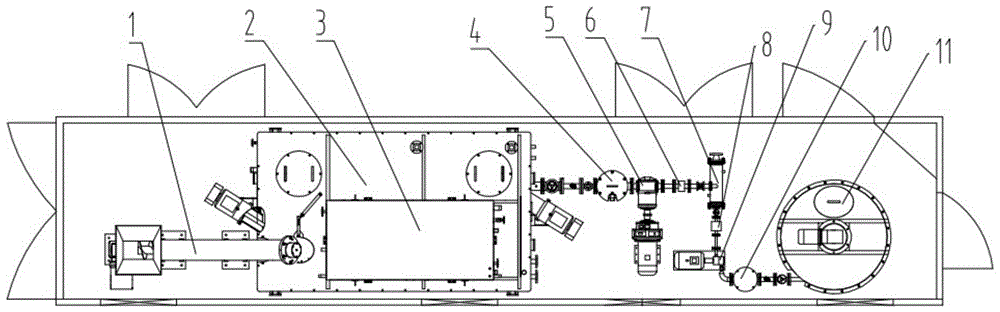

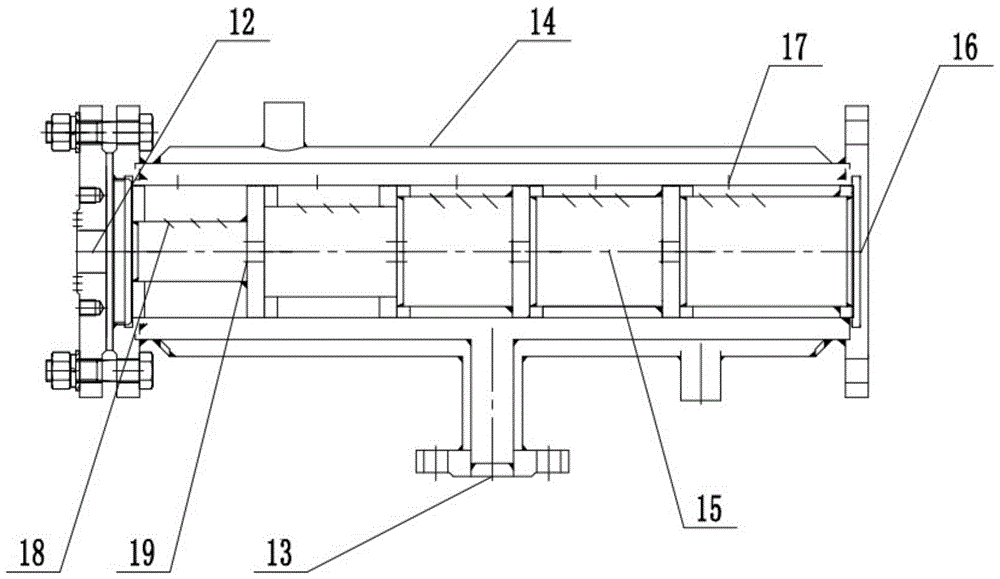

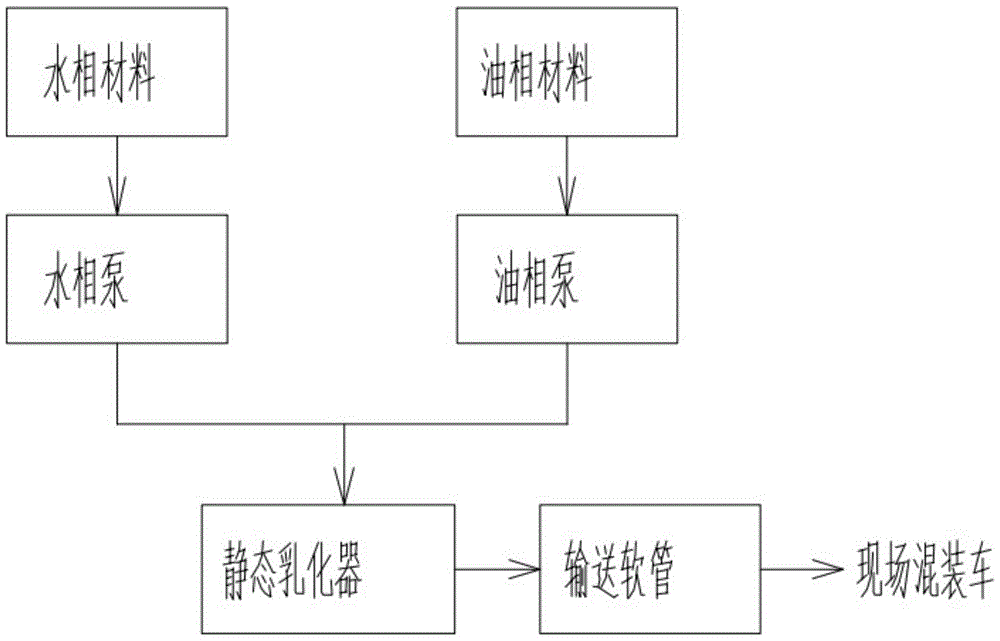

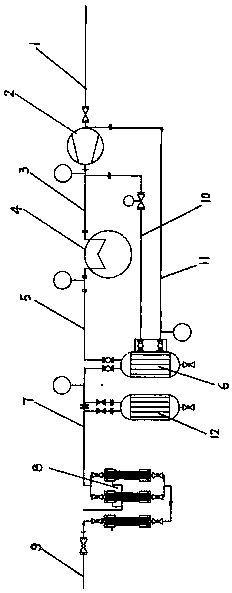

Intrinsically safe latex matrix ground station

ActiveCN104387214ASimple production process and equipmentEliminates the possibility of thermal explosionsExplosive working-up apparatusTruckThermal explosion

The invention belongs to the technical fields of latex matrix preparation technologies and apparatuses for mobile ground assisting facilities in the civil explosive industry, and relates to an intrinsically safe latex matrix ground station. The intrinsically safe latex matrix ground station includes a water phase tank, an oil phase tank, a water phase pump, an oil phase pump and a static emulsifier, the inlet and the outlet of the water phase pump are respectively connected with the outlet of the water phase tank and the water phase inlet of the static emulsifier through pipelines, and the inlet and the outlet of the oil phase pump are respectively with the outlet of the oil phase tank and the oil phase inlet of the static emulsifier through pipelines. The station uses the fully static emulsifier as an emulsifying device, and is a latex matrix preparation and conveying apparatus without stirring, mechanical shearing or matrix pump conveying of colloid in the matrix emulsifying process, the static emulsifier designed by using a jet eddy current emulsifying principle, and a latex matrix prepared in the invention is directly added into a colloid tank in an emulsifying mixing truck from the outlet of the static emulsifier through a flexible tube, so the thermal explosion possibility of mechanical friction is eliminated, and the total energy consumption of a whole production line is reduced.

Owner:SHIJIAZHUANG SUCCESS MACHINERY ELECTRICAL

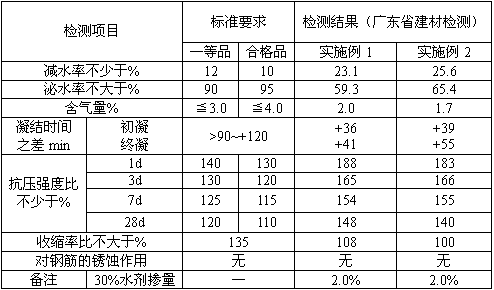

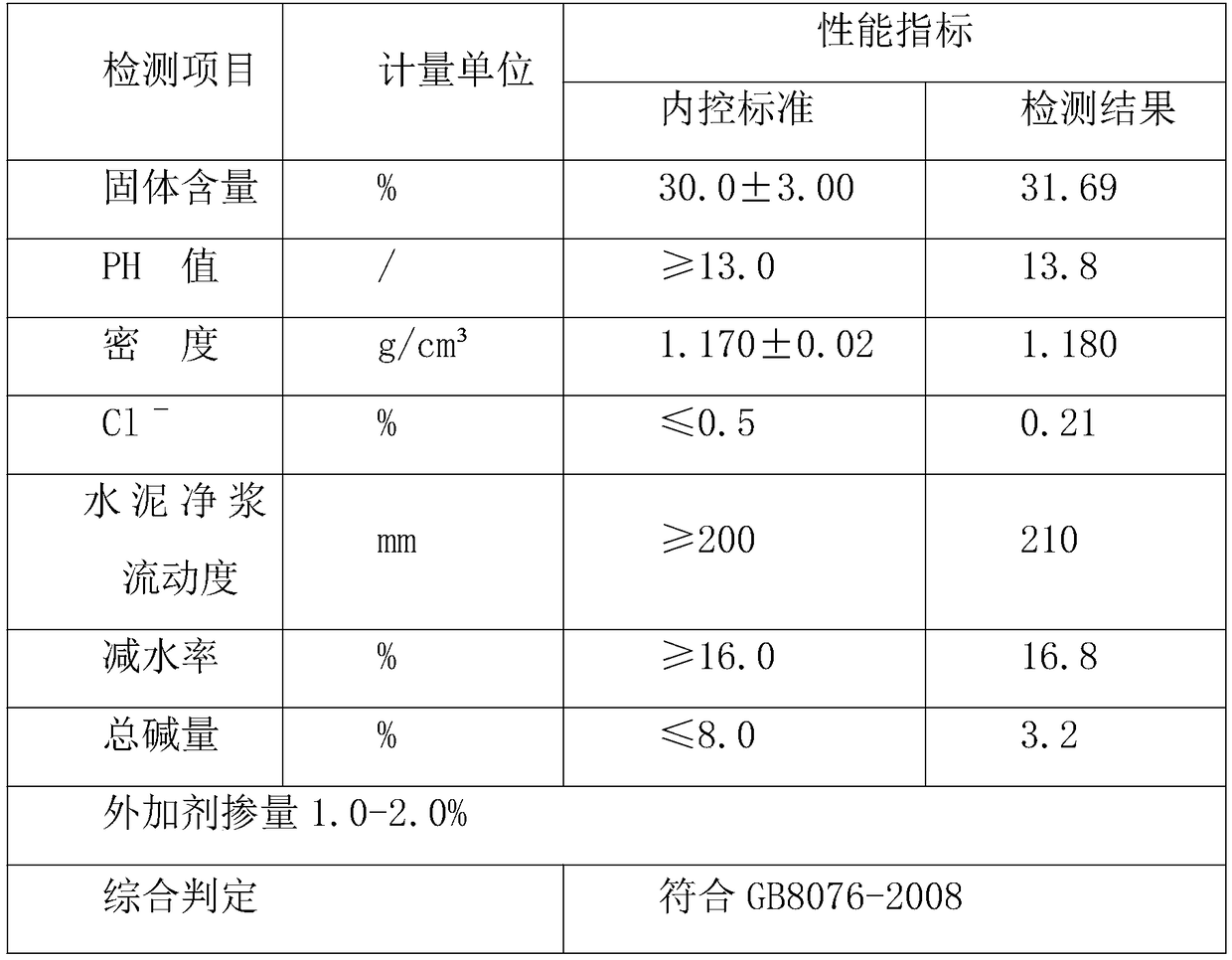

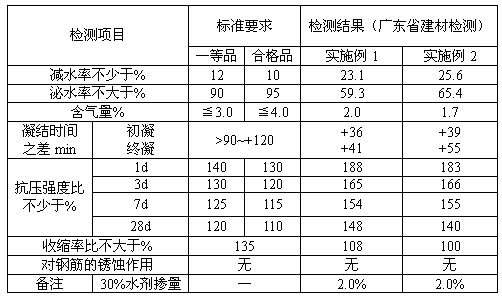

Aliphatic superplasticizer and preparation method thereof

The invention discloses an aliphatic superplasticizer and a preparation method thereof. According to the invention, a molecular structure with high water reducing rate and good slump retaining performance can be obtained mainly by performing condensation reaction on aldehyde and ketone under strong alkaline catalysis, performing sulfomethylation reaction on carbonylation alpha site and introducingsulfonyl, and controlling the optimal mixing proportion, and meanwhile, a cement activating agent is added in the later period so as to improve the performance of the concrete and improve the strength of the concrete, thus obtaining the novel superplasticizer with excellent performance. According to the preparation method disclosed by the invention, reaction is performed at a relatively low temperature, a heat source is not needed, production process equipment is simple, production is steady and quick, yield is high and investment is low; by using low-cost industrial byproduct, namely sodiumsulfite, material cost is lowered; and by adopting high-efficiency tail gas purifying and recycling method and device, emission without the three wastes is achieved, not only is environment improved,but also raw material consumption and production cost are lowered.

Owner:佛山柯杰科技实业有限公司

Coloring aid for jpolycinyl chloride plastic

A coloring agent for polyvinyl chloride plastic comprising diffusion lubricating agent, stabilizing agent, plasticizing agent and pigment, wherein the auxiliary agent comprises diffusion lubricating agent 1-60 parts, stabilizing agent 1-15 parts, plasticizing agent 20-100 parts, and right amount of pigment, the diffusion lubricating agent is preferably polyester adipate, the stabilizing agent is tribasic lead sulphate, the plasticizing agent is DOP.

Owner:SHANGHAI CHUNQING IND

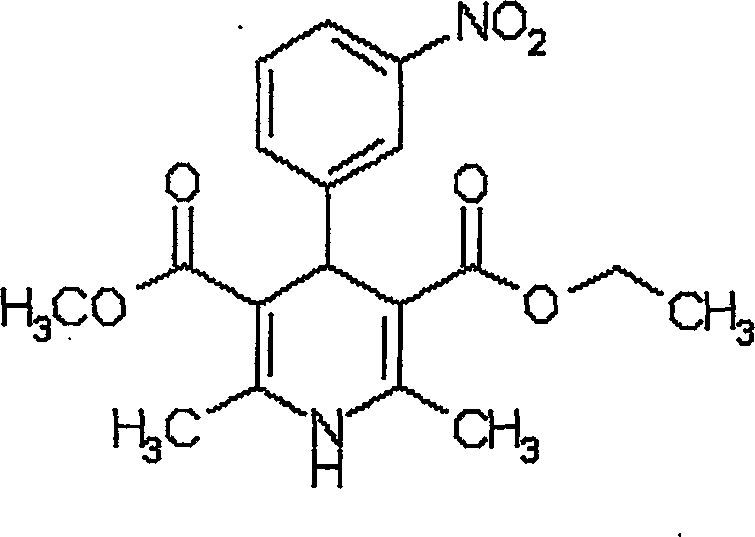

Drop pills of nitrendipine, and preparation method

InactiveCN1872060AIncrease surface areaHas a wetting effectOrganic active ingredientsPill deliveryMonoglycerideShellac

A dripping pill of nitrendipine for treating hypertension is proportionally prepared from nitrendipine and the matrix chosen from polyethanediol 4000, 6000 or 10000, stearic acid, sodium stearate, poloxamer, glycerin gelatin, monoglyceride stearate, shellac and polyoxyvinyl monostearate through thermally fusing said matrix, mixing it with nitrendipine, dripping in condensing agent, removing the condensing agent from their surface, drying in air and packing.

Owner:GUOSONG MEDICINES TECH NANJING

Carbidopa-levedopa sustained-release dropping pill and preparation method thereof

InactiveCN102961350AReduce volumeReduce weightOrganic active ingredientsNervous disorderOral medicationSide effect

The invention relates to a carbidopa-levedopa sustained-release dropping pill for the treatment of Parkinson's disease and a preparation method thereof. The invention aims to solve the insufficiencies of an oral preparation, and provides a carbidopa-levedopa sustained-release dropping pill, which has advantages of high bioavailability, rapid effectiveness, long action time, low frequency of drug taking, convenient administration, little toxic or side effect, convenient storage and transportation, and suitability for oral administration, and the preparation method thereof.

Owner:北京博智绿洲医药科技有限公司

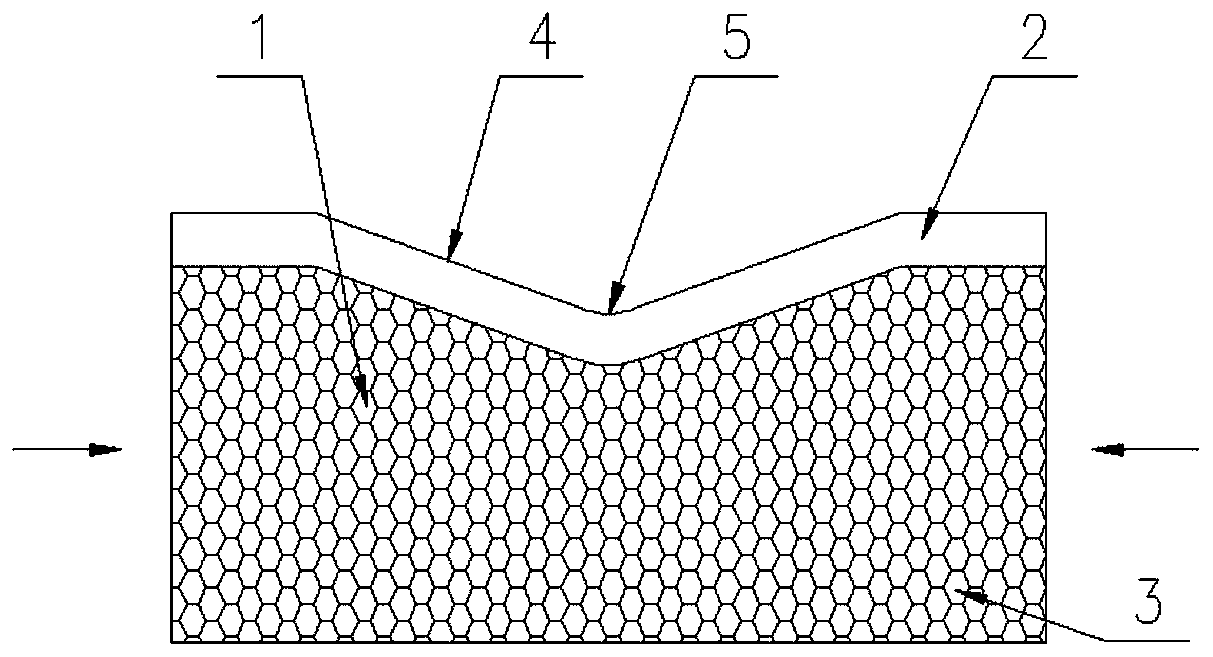

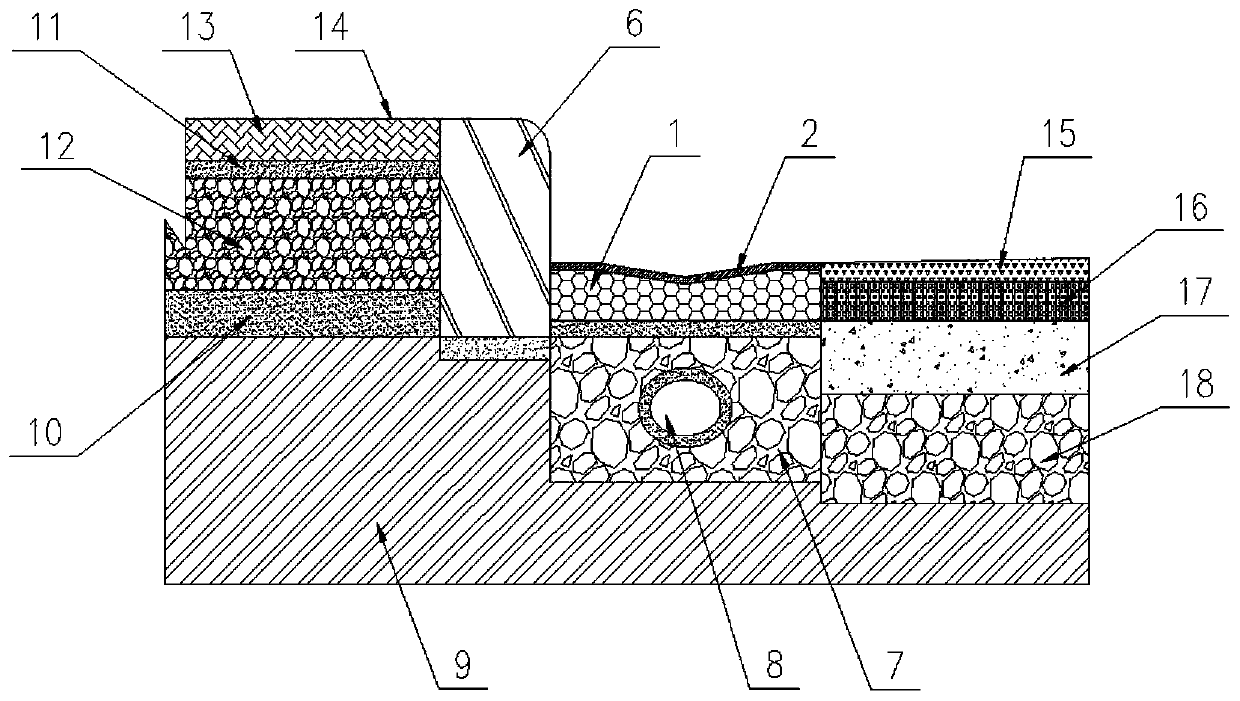

Asphalt pavement permeable diversion road flat stone and diversion road structure

PendingCN110761142AIncrease runoffPlay a retention roleIn situ pavingsSingle unit pavingsCompressive resistanceIn vehicle

The invention discloses an asphalt pavement permeable diversion road flat stone and a diversion road structure. The asphalt pavement permeable diversion road flat stone includes a diversion road flatstone body, a tamped soil layer, a pavement, a permeable road edge stone and an asphalt road surface layer. The pavement, the permeable road edge stone and the asphalt road surface layer and the diversion road flat stone are arranged above the tamped soil layer, the permeable road edge stone is arranged on one side of the pavement, one side of diversion road flat stone is close to the permeable road edge stone, the other side of the diversion road flat stone is connected with an asphalt road surface, and the diversion road flat stone is arranged above a sewage disposal well ditch. The size ofthe prepared diversion road flat stone can be changed according to the specific requirements of road traffic design, the thickness is no less than 60MM, diabase and the like or the other broken stonesare arranged on the bottom layer, permeable cement is of a porous structure, and the surface layer is arranged to be of a cement-based or polymer-silica sand fine hole structure. The compressive strength of the prepared diversion road flat stone is more than and equal to 45 MPa, the flexural strength is more than and equal to 4.0 MPa, the city vehicle-mounted load capacity can be completely met,and the surface layer is fine in holes and abrasion-resistant and attractive. All-directional seepage drainage is achieved, and the runoff volume is much higher than that of general flat stones.

Owner:江西亘森生态材料有限公司

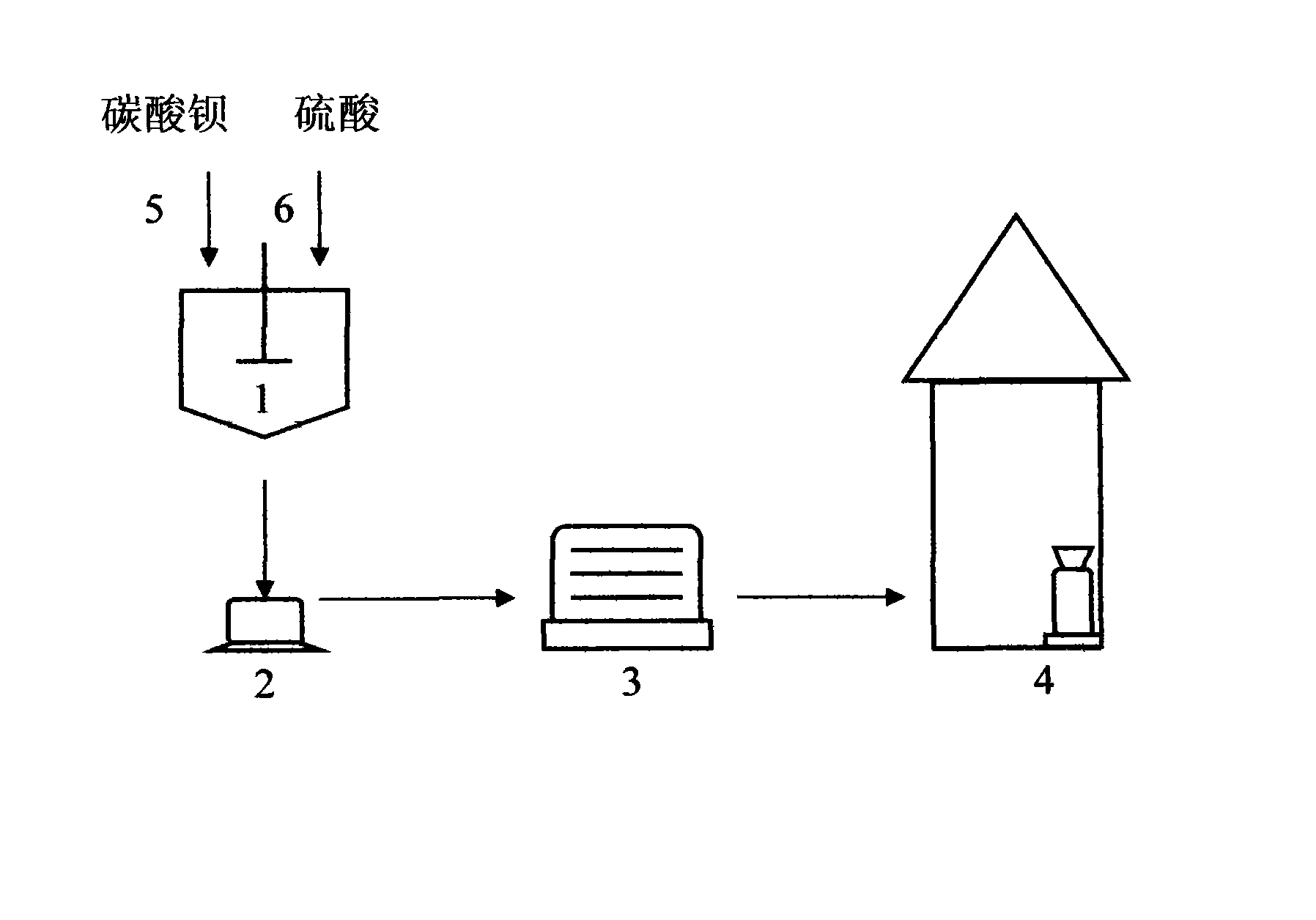

Method for co-producing carbon dioxide by using superfine precipitated barium sulfate prepared by barium carbonate

InactiveCN101638244ASimple production process and equipmentHigh yieldCalcium/strontium/barium sulfatesChemistryCarbon dioxide

The invention discloses a method for co-producing carbon dioxide by using superfine precipitated barium sulfate prepared by barium carbonate. The method is characterized in that barium carbonate and sulphuric acid react according to a specific proportion to generate barium sulfate and carbon dioxide, and the barium sulfate is dried, smashed and packaged to obtain a precipitated barium sulfate product; the carbon dioxide is compressed, liquefied and then filled into a steel cylinder to form a product. The method has the advantages of simple production technique and equipment, high yield and high profits, and overcomes the disadvantages of large operation amount of materials, low yield, complex and enormous technological equipment and the like of a conventional production method.

Owner:王嘉兴

Sustained-release dropping pills of Troxerutin and method for preparing the same

InactiveCN101273976AIncrease surface areaHas a wetting effectOrganic active ingredientsPharmaceutical delivery mechanismSide effectThrombus

The invention relates to a troxerutin sustained-release drop pill for the treatment of hemiplegia, aphasia, arteriosclerosis, central retinitis, thrombophlebitis, varicose veins and other symptoms caused by cerebral thrombosis and cerebral embolism, as well as a preparation method thereof. The invention aims at utilizing the sustained-release pharmaceutical technology to make up for the shortcomings of the prior art and providing the troxerutin sustained-release drop pill with high bioavailability, few administration times, long-term effect, no toxicity, no side effects and convenient usage and carrying, as well as the preparation method thereof. The troxerutin is taken as raw material, a hydrophilic skeleton material and a hydrophobic skeleton material are added according to certain weight percentages to be taken as matrixes and evenly mixed, the mixed materials are heated till melting, evenly stirred and arranged in a special pill dropping machine, and then dropped into condensate liquid at appropriate speed for preparation.

Owner:北京博智绿洲医药科技有限公司

Ginseng saponin drop balls and making method thereof

InactiveCN1939369AIncrease surface areaHas a wetting effectOrganic active ingredientsNervous disorderMedicineStearate

A dripping pill of ginsenoside is prepared from ginsenoside through proportional adding polyoxyvinyl monostearate, mixing, heating for fusing, stirring, and dripping in condensing liquid.

Owner:刘凤鸣

Puvatadin dropping balls and production thereof

InactiveCN1939287AIncrease surface areaHas a wetting effectPill deliveryEster active ingredientsStearatePravastatin

A dripping pill of pravastatin is prepared from pravastatin through proportional adding polyoxyvinyl monostearate, mixing, heating for fusing, stirring, and dripping in condensing liquid.

Owner:刘凤鸣

Lansoprazole sustained-release drop pills and preparation method thereof

ActiveCN101288654AAvoid first pass effectQuick effectPharmaceutical delivery mechanismSide effectBuccal administration

The invention relates to an antiulcer drug Lansoprazole sustained-release preparation and a preparation method thereof; the invention aims at overcoming the defect of oral preparation and providing a Lansoprazole sustained-release pill for oral administration which is characterized by high bioavailability, rapid effect, long acting time, less times of oral administration, convenient application, less toxic and side effect and convenient storage and transportation, and the preparation method thereof. In particular, the Lansoprazole sustained-release pill is added with a stabilizing agent, Vitamin E, which prevents the occurrence of pill aging and leads the pill to be more stable.

Owner:BEIJING JIUFA PHARMA

Aliphatic-series high-efficiency water reducing agent and preparation method thereof

The invention discloses an aliphatic-series high-efficiency water reducing agent and a preparation method thereof. The preparation method comprises the following steps: adding formaldehyde and sodiumpyrosulfite into one container and performing sulfonation reaction for 30 to 40 minutes under the reflux condensation condition; then adding acetone to keep reflux reaction for 20 to 40 minutes under30 DEG C to 50 DEG C to obtain a pre-melted material A; adding water and sodium sulfite into another container, evenly stirring and dissolving and obtaining a material B; dropwise adding the pre-melted material A into the material B, warming to 75 DEG C to 80 DEG C within 20 to 40 minutes of dropwise adding to performing condensation constant-temperature reaction and finishing reaction, wherein dropwise adding time is totally 2 to 3 hours; adding water to dilute, reducing temperature to 55 DEG C or below, adding acid to neutralize, adjusting a PH value to 11 to 13.5 and adding an activating agent. The preparation method has the advantages of no heat source, stable and quick production, large productivity, small investment, reduced material cost, good environmental friendliness and reducedcost; the prepared high-efficiency water reducing agent has excellent performance; furthermore, the prepared high-efficiency water reducing agent has little harmful impurities, and effects to reinforced concrete durability are reduced.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

Preparation method of modified rosin resin aqueous solution

PendingCN112795316ASimple production process and equipmentGood product stabilityMacromolecular adhesive additivesNatural resin chemical modificationChemistryOrganic acid

A preparation method of a modified rosin resin aqueous solution comprises the following steps: 1) crushing rosin, putting the crushed rosin into a reaction kettle, and heating for melting; 2) after the rosin is melted, adding unsaturated organic acid into the reaction kettle, controlling the temperature and keeping the temperature for a certain time; (3) raising the temperature and putting polyhydric alcohol into the reaction kettle for reaction; 4) cooling and adding organic amine into the reaction kettle for reaction; and (5) continuously cooling, adding deionized water into the reaction kettle, and stirring to obtain the modified rosin resin aqueous solution. The prepared modified rosin resin aqueous solution does not contain volatile organic solvents, is stable in storage, can replace traditional rosin emulsion and is added into a water-based adhesive for use, so that the adhesive force is improved, and the opening time is prolonged.

Owner:厦门中坤化学有限公司

A kind of aliphatic superplasticizer and preparation method thereof

The invention discloses an aliphatic superplasticizer and a preparation method thereof. According to the invention, a molecular structure with high water reducing rate and good slump retaining performance can be obtained mainly by performing condensation reaction on aldehyde and ketone under strong alkaline catalysis, performing sulfomethylation reaction on carbonylation alpha site and introducingsulfonyl, and controlling the optimal mixing proportion, and meanwhile, a cement activating agent is added in the later period so as to improve the performance of the concrete and improve the strength of the concrete, thus obtaining the novel superplasticizer with excellent performance. According to the preparation method disclosed by the invention, reaction is performed at a relatively low temperature, a heat source is not needed, production process equipment is simple, production is steady and quick, yield is high and investment is low; by using low-cost industrial byproduct, namely sodiumsulfite, material cost is lowered; and by adopting high-efficiency tail gas purifying and recycling method and device, emission without the three wastes is achieved, not only is environment improved,but also raw material consumption and production cost are lowered.

Owner:佛山柯杰科技实业有限公司

Disposable gymsum tableware

Disposable plaster tableware, including chopsticks, spoons, lunch boxes, cups, bowls, plates. It is mainly made of gypsum and water-soluble adhesives through tableware molding technology. It includes the following raw materials in percentage by weight: 60-97% of gypsum powder, 3-40% of water-soluble adhesive, and the water-soluble adhesive is selected from polyvinyl alcohol resin, starch, gelatin, modified polyethylene, organic silicon A combination of one or two or more binders. In addition, 25-40% of water accounting for the total weight of the gypsum powder and the water-soluble binder is added. Its utensils have a waterproof coating on the surface. Gypsum chopsticks raw materials: gypsum powder 71-84%, polyvinyl alcohol resin 4-15%, starch 3-7%, talcum powder 3-7%, fiber 0-8%; add water accounting for 30% of the total weight of the above raw materials . The gypsum chopsticks of the present invention are free from bending and deformation, comfortable to the touch, practical and hygienic, and can be made into high, medium and low grade varieties. Gypsum is an edible natural non-toxic and harmless raw material with low manufacturing cost. It will not cause pollution and damage to the environment after being used and discarded.

Owner:李想

Intrinsically safe latex-based ground station

ActiveCN104387214BReduce energy consumptionSimple production process and equipmentExplosive working-up apparatusProduction lineEddy current

The invention belongs to the technical fields of latex matrix preparation technologies and apparatuses for mobile ground assisting facilities in the civil explosive industry, and relates to an intrinsically safe latex matrix ground station. The intrinsically safe latex matrix ground station includes a water phase tank, an oil phase tank, a water phase pump, an oil phase pump and a static emulsifier, the inlet and the outlet of the water phase pump are respectively connected with the outlet of the water phase tank and the water phase inlet of the static emulsifier through pipelines, and the inlet and the outlet of the oil phase pump are respectively with the outlet of the oil phase tank and the oil phase inlet of the static emulsifier through pipelines. The station uses the fully static emulsifier as an emulsifying device, and is a latex matrix preparation and conveying apparatus without stirring, mechanical shearing or matrix pump conveying of colloid in the matrix emulsifying process, the static emulsifier designed by using a jet eddy current emulsifying principle, and a latex matrix prepared in the invention is directly added into a colloid tank in an emulsifying mixing truck from the outlet of the static emulsifier through a flexible tube, so the thermal explosion possibility of mechanical friction is eliminated, and the total energy consumption of a whole production line is reduced.

Owner:SHIJIAZHUANG SUCCESS MACHINERY ELECTRICAL

Dihydrocodeine tartrate sustained-release dropping pill and preparation method thereof

InactiveCN102961351AReduce volumeReduce weightOrganic active ingredientsNervous disorderSide effectOral medication

The invention relates to a dihydrocodeine tartrate sustained-release dropping pill for treatment of moderate pain and a preparation method thereof. The invention aims to solve the defects of an oral preparation, and provides the dihydrocodeine tartrate sustained-release dropping pill, which has advantages of high bioavailability, rapid effectiveness, long action time, low frequency of drug taking, convenient administration, little toxic or side effect, convenient storage and transportation, and suitability for oral administration, and the preparation method thereof.

Owner:北京博智绿洲医药科技有限公司

Method for preparing functional filling material of superfine calcium carbonate powder

InactiveCN1843928ASave raw materialsSimple production process and equipmentCalcium/strontium/barium carbonatesSodium acid carbonateFilling materials

The invention discloses a process for preparing functional filling material of fine calcium carbonate powder, and it is characterized in that the process comprises following steps: adding calcium chloride, calcium nitrate or calcium acetate and sodium acid carbonate with 0.001-0.007 mol into deioned water with 100 ml; stirring it; putting it into microwave reactor for chemical reaction under power of microwave with 100-200 W; sucting soild product, washing with deioned water, drying and getting said functional filling material. The invention is characterized by cheap raw materialn simple prepartion process and device, time saving, low energy consumption and cost, and product with pure diamond-shape phase, narrow granular size distribution, large specific surface area and high white content.

Owner:YANGZHOU UNIV

A kind of water-based flame retardant spray glue and its preparation process

ActiveCN103194154BSimple production process and equipmentSimple processNatural rubber adhesivesNon-macromolecular adhesive additivesHeat resistanceAdhesive

The invention relates to the technical fields of chemical engineering materials and preparation technologies thereof, and especially relates to an aqueous flame retardant spray adhesive and a preparation technology thereof. The preparation technology needs a simple device and has a simple process. The aqueous flame retardant spray adhesive which treats water as a diluting agent has the characteristics of no organic matter discharge, no pollution to human bodies or the environment, difficult spray gun obstruction, and no production or use danger. An aqueous resin which is the aqueous flame retardant spray adhesive has a high solid content high to 60%, saves a traffic transportation cost and also saves the liquid adhesive application amount of unit area. The aqueous spray adhesive has the advantages of strong heat resistance, excellent flame retardation performance, avoiding of the appearance of a sprayed product fire, and reduction of the continued diffusion of the fire.

Owner:东莞智炜新材料股份有限公司

System for preparing methane through methane temperature self-raising-based membrane separation method

PendingCN110563542ATake advantage ofReduce consumptionChemical industryDispersed particle separationProcess engineeringDual purpose

The invention discloses a system for preparing methane through a methane temperature self-raising-based membrane separation method. The problem of high production cost caused by high electric energy consumption in membrane separation methods for preparing methane in the prior art is solved. An air-to-air heat exchanger is arranged between a freezing dryer and a module to heat moisture and impurityremoved biogas output by the freezing dryer, and the heat source gas of the air-to-air heat exchanger adopts a high-temperature compressed biogas compressed by a compressor to realize self-raising ofthe temperature of the biogas, so the biogas compressed by the compressor has dual purposes, the working heat of the compressor is fully utilized, the link of an electric heater is omitted, and the effects of saving energy and reducing the production cost are achieved.

Owner:SHANXI FENXI HEAVY IND +1

Novel atenolol slow-release drop pill and preparation method thereof

InactiveCN109700776AReduce seizuresReduce incidenceOrganic active ingredientsPharmaceutical delivery mechanismBlood concentrationMortality rate

Hypertension is recognized by the medical community at home and abroad as the "most ferocious killer" that threatens the human life, the mortality rate of hypertension is higher than that of any otherdisease, and hypertension seriously affects the human health. Atenolol tablets are administered twice per day, and the blood concentration fluctuates greatly, thereby being necessary to prepare the atenolol tablets into a slow-release preparation. The invention relates to an atenolol slow-release drop pill capable of quickly taking effect and slowly releasing drugs and used for treating hypertension and angina, performing maintenance treatment of myocardial infarction and treating arrhythmia, hyperthyroidism and the like, and a preparation method of the atenolol slow-release drop pill. In order to make up for the deficiencies of the prior art, the invention provides an atenolol slow-release drop pill preparation. The atenolol slow-release drop pill provided by the invention is characterized in that a hydrophobic skeleton capable of slowly releasing drugs and Tween-80 with a solubilizing effect are added on the basis of the existing drop pill technology, the deficiencies of the prior art are effectively overcome, and the atenolol slow-release drop pill has the advantages of uniform drug dispersion, sufficient drug release, long drug release time, reduced patient medication frequency and high bioavailability.

Owner:ZHENGZHOU TAIFENG PHARMA CO LTD

A kind of preparation method of 2-phenylpropionic acid

ActiveCN105037139BHigh purityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationSodium methoxideThermal insulation

The invention discloses a preparation method for 2-phenylpropionic acid. The preparation method is characterized by comprising a 2-phenyl-2-cyano methyl propionate preparation stage, a 2-phenyl propionitrile preparation stage and a 2-phenylpropionic acid preparation stage, wherein the 2-phenyl-2-cyano methyl propionate preparation stage comprises: mixing benzyl cyanide, dimethyl carbonate, methylbenzene and sodium methoxide to obtain a mixture, heating the mixture to 20-100 DEG C, controlling the pressure to 0.5-6MPa and carrying out thermal-insulation reaction for 1-10 hours; after the reaction is ended, steaming out a byproduct methanol under the normal pressure, cooling the mixture to 35 DEG C, dropwise adding dimethyl sulfate DMS at constant speed by controlling the temperature to 35-85 DEG C, and carrying out the thermal-insulation reaction for 1-10 hours at 45-105 DEG C after the dropwise-adding is ended; cooling to 35 DEG C, adding water, stirring, dissolving, and layering; desolventizing to recycle toluene, thereby obtaining compound ester; and carrying out basic hydrolysis reaction and acidification reaction to finally prepare a finished product, wherein the purity of the finished product is high, and the yield of the finished product is higher than 92%. Besides, the production process disclosed by the invention adopts simple equipment and is low in production cost.

Owner:ZHEJIANG BOJU NEW MATERIALS CO LTD

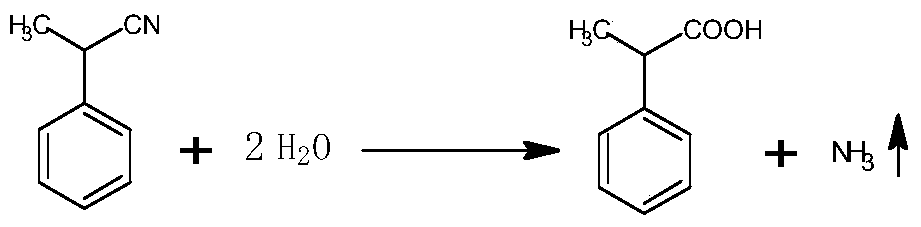

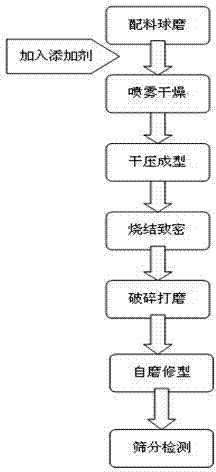

Preparation method of nanoscale zirconia ceramic powder for spraying

InactiveCN102584224BStable particle sizeSimple production process and equipmentNanotechnologyCrystal structureCompressive strength

The invention provides a preparation method of nanoscale zirconia ceramic powder for spraying. The preparation method provided by the invention comprises the following steps of ingredient ball milling, atomization drying, sieving gradation, dry-pressing molding, sintering compaction, crushing polishing, autogenous grinding trimming, and screening detection. The preparation method provided by the invention has the advantages that nanoscale yttria-stabilized zirconia ceramic powder for spraying is directly prepared by high temperature ceramic preparation and crushing and through high-temperature sintering at a temperature of 1500 to 1600 DEG C in preparation, ZrO2 has a yttria-stabilized zirconia (YSZ) crystal structure or a yttria-partially stabilised zirconia (PYSZ) crystal structure at ahigh temperature, in other word, ZrO2 comprises monoclinic crystals and cubic crystals; the YSZ crystal structure or the PYSZ crystal structure has high strength, high toughness, good wear resistance, good high temperature resistance, good corrosion resistance, high rigidity, no magnetic conductivity and an electrical insulating property; the nanoscale zirconia ceramic powder obtained by the preparation method has density of 6.00g / cm<3>, Moh's hardness of 9, compressive strength of 1170Mpa and good thermal shock resistance; and through granulator-based autogenous grinding trimming, the nanoscale zirconia ceramic powder obtained by the preparation method has volume density of 1.15 to 1.45g / m<2> (min)% and good fluidity.

Owner:重庆利特高新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com