Aliphatic-series high-efficiency water reducing agent and preparation method thereof

A high-efficiency water reducer and aliphatic technology, applied in the field of aliphatic high-efficiency water reducer and its preparation, can solve the problems of high production cost, achieve the effects of less harmful impurities, improve economic benefits, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

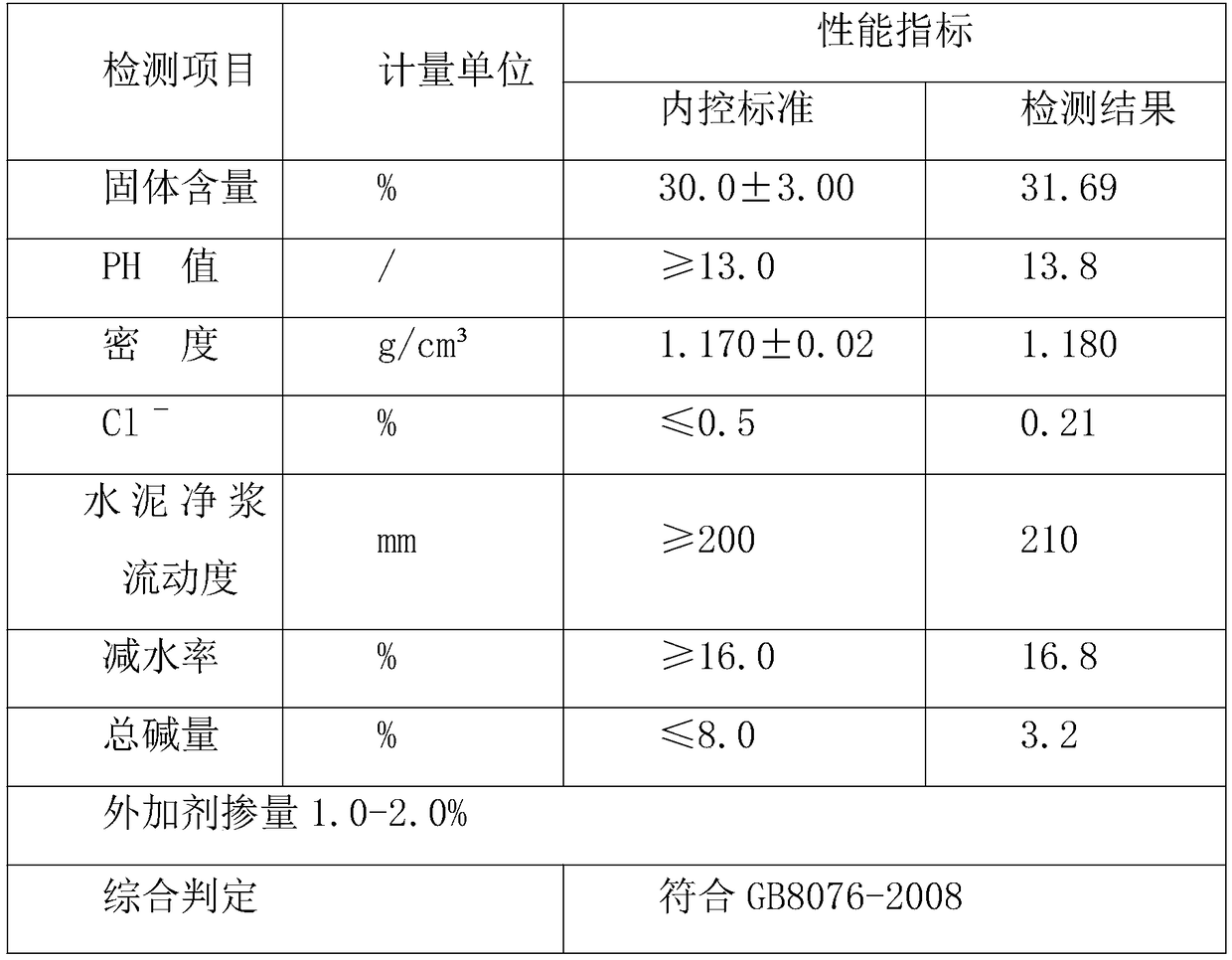

Image

Examples

Embodiment 1

[0016] An aliphatic high-efficiency water reducer and a preparation method thereof, the preparation method of the aliphatic high-efficiency water reducer comprises the following steps:

[0017] Put formaldehyde and sodium metabisulfite into a container, carry out sulfonation reaction under condensing and reflux conditions for 30-40 minutes; then put in acetone and keep reflux reaction for 20-40 minutes at 30°C-50°C to obtain prechemical material A;

[0018] Put water and sodium sulfite into another container, stir and dissolve evenly, and obtain material B;

[0019] Add prechemical material A dropwise to material B, and heat up to 75°C-80°C within 20-40 minutes to carry out condensation constant temperature reaction. The dropping time is 2-3 hours in total, and the reaction is ended;

[0020] Add water to dilute, lower the temperature to below 55°C, add acid to neutralize, adjust the pH value to 11-13.5, and add activator.

[0021] Furthermore, the mass component ratio of ace...

Embodiment 2

[0028] An aliphatic high-efficiency water reducer, which is obtained by the aliphatic high-efficiency water reducer described in Example 1 and its preparation method.

[0029] For example, in the pre-heating pot with cooling water, when the tail gas device is started to form a slight negative pressure in the system, 29 parts of formaldehyde is added in parts by mass, and then 3.5 parts of sodium metabisulfite are added, and the reaction is stirred for about 30 minutes to dissolve and reflux; then add 8.5 parts of acetone, controlled at 30°C-40°C for reflux reaction for 30 minutes to form a mixed solution for use. Add 27 parts of water (25 parts of water, 2 parts of recovered water) into the cooling water and the condensation pot with insulation layer, and then add 9 parts of sodium sulfite, and stir evenly to obtain an aqueous solution of sodium sulfite. Slowly add the above mixed solution into the sodium sulfite aqueous solution dropwise, let the material naturally heat up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com