Asphalt pavement permeable diversion road flat stone and diversion road structure

A technology for diverting road flat stone and asphalt pavement, applied in the direction of pavement, gutter/curb stone, road, etc., can solve the problems of increasing production cost, difficult bonding and mixing, long preparation process, etc., and achieves easy cleaning and wear resistance. High degree of resistance and slip resistance, and the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. In the examples, the components involved are in parts by mass or in mass ratio, and the concentrations involved are all mass concentrations.

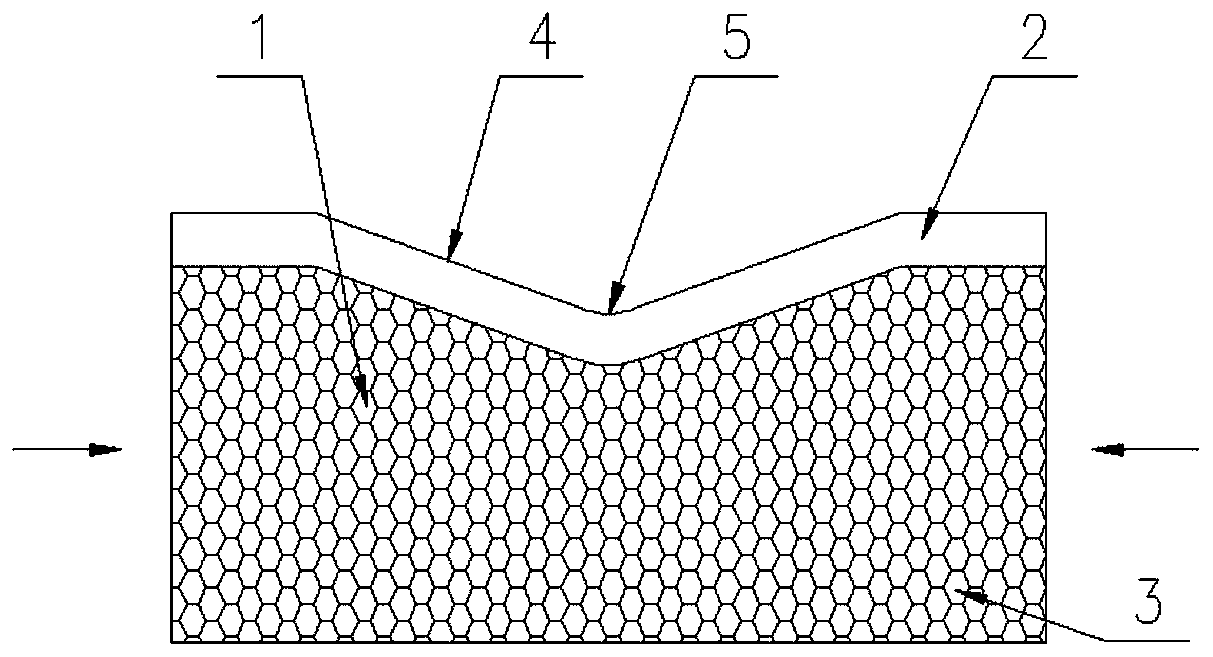

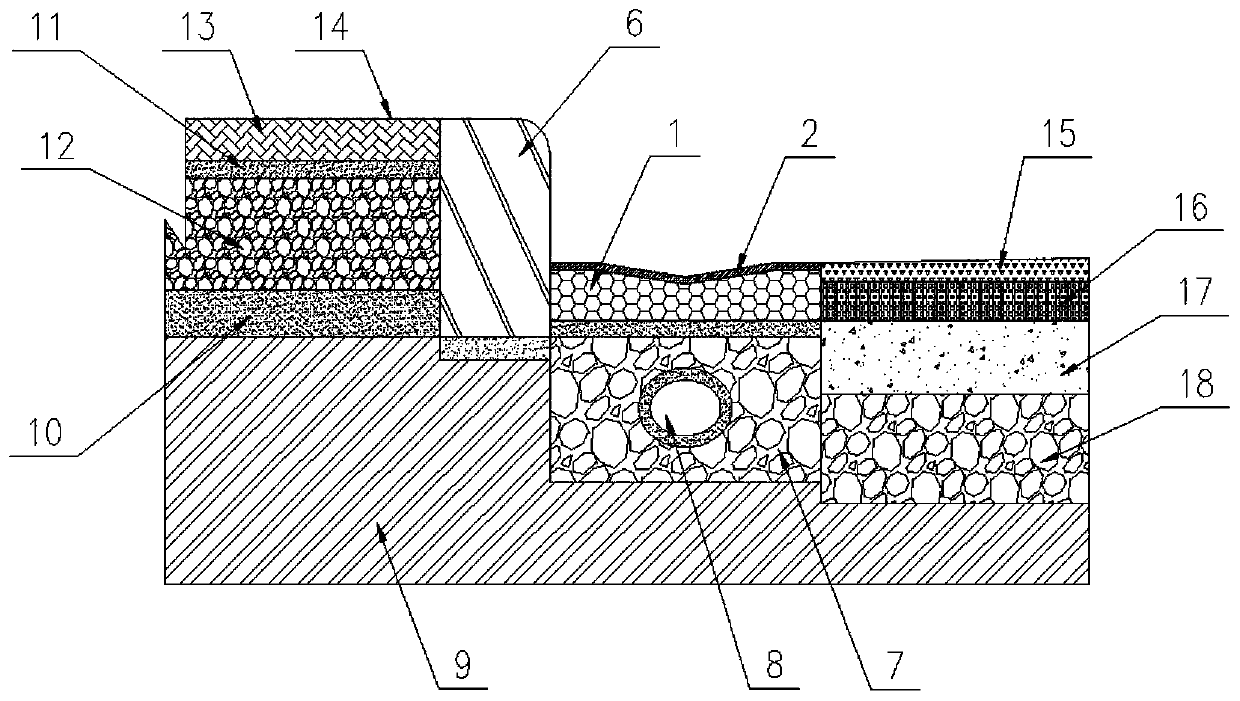

[0023] The present invention discloses an asphalt pavement permeable diversion path flat stone and diversion path structure, such as figure 1Shown is a schematic diagram of the structure of the asphalt pavement permeable diversion road flat stone 1 of the present invention. The diversion road flat stone 1 includes a permeable bottom layer 3 and a wear-resistant surface layer arranged on the top of the water-permeable bottom 3. The wear-resistant surface layer described in this example is silica sand. Wear-resistant surface layer 3, the surface of described wear-resistant surface layer is designed as silica sand surface layer, is provided with inorganic toner pigmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com