A kind of preparation method of 2-phenylpropionic acid

A technology of phenylpropionic acid and phenylpropionitrile, which is applied in the field of 2-phenylpropionic acid preparation, can solve the problems of complex production process equipment and high production cost, and achieve the effects of low production cost, simple equipment and high purity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

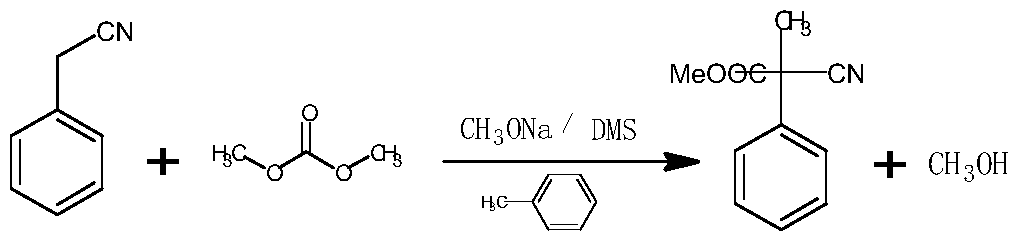

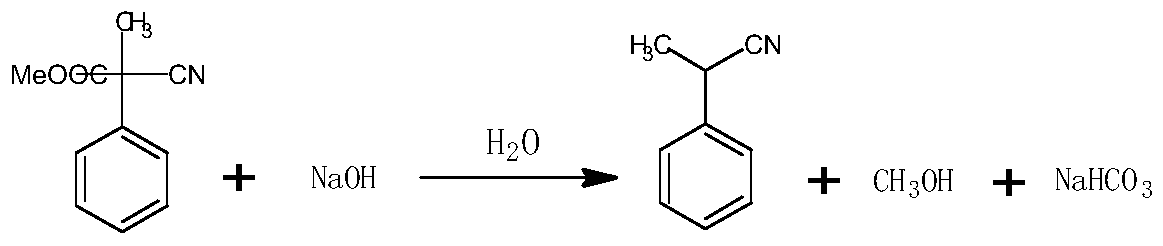

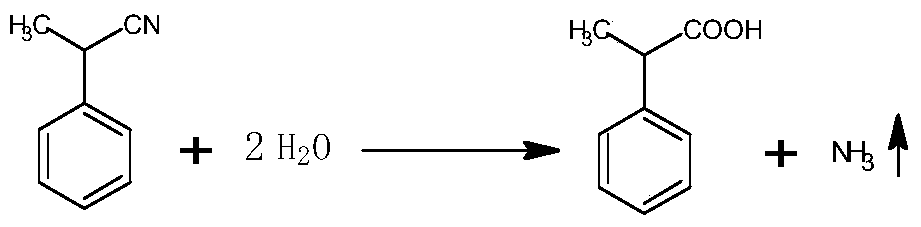

[0028] The preparation method of 2-phenylpropionic acid in this embodiment includes the preparation stage of methyl 2-(phenylcyano)propionate, the preparation stage of 2-phenylpropionitrile and the stage of 2-phenylpropionic acid, and the specific steps are as follows:

[0029] 1) Preparation stage of methyl 2-(phenylcyano)propionate

[0030] Add phenylacetonitrile: dimethyl carbonate: toluene: sodium methoxide with a molar ratio of 1:1.5:10:1.05 into the drying reactor. Under stirring, the temperature is raised to 75°C and the temperature is kept for 5 hours; after the reaction, the pressure is normal. Distill the by-product methanol until no methanol is distilled out, cool to 35°C, add dimethyl sulfate DMS with a molar ratio of 1.0 dropwise at a temperature of 50°C, and keep the reaction at 50°C for 5 hours. Cool down to 35°C, add 1.0 part by weight of water, stir, dissolve, and separate into layers. Recover toluene by distillation under reduced pressure, and distill off toluene...

Embodiment 2

[0036] The preparation method of 2-phenylpropionic acid in this embodiment includes the preparation stage of methyl 2-(phenylcyano)propionate, the preparation stage of 2-phenylpropionitrile and the stage of 2-phenylpropionic acid, and the specific steps are as follows:

[0037] 1) Preparation stage of methyl 2-(phenylcyano)propionate

[0038] Add phenylacetonitrile: dimethyl carbonate: toluene: sodium methoxide with a molar ratio of 1:3:15:1.2 into the dry reaction kettle. Under stirring, the temperature is increased to 90°C, and the reaction is kept for 2 hours; after the reaction, the pressure is normal. Distill the by-product methanol until no methanol is distilled out, cool to 35°C, add dimethyl sulfate DMS with a molar ratio of 1.0 dropwise at a temperature of 75°C, and keep the reaction at 70°C for 2 hours. Cool down to 35°C, add 2.0 parts by weight of water, stir, dissolve, and separate into layers. Recover toluene by distillation under reduced pressure, and distill off tol...

Embodiment 3

[0044] The preparation method of 2-phenylpropionic acid in this embodiment includes the preparation stage of methyl 2-(phenylcyano)propionate, the preparation stage of 2-phenylpropionitrile and the stage of 2-phenylpropionic acid, and the specific steps are as follows:

[0045] 1) Preparation stage of methyl 2-(phenylcyano)propionate

[0046] Add phenylacetonitrile: dimethyl carbonate: toluene: sodium methoxide with a molar ratio of 1:5:30:2 into the dry reaction kettle. Under stirring, the temperature is raised to 60°C and the reaction is kept for 10 hours; after the reaction, the pressure is normal Distill the by-product methanol until no methanol is distilled out, cool to 35°C, add dimethyl sulfate (DMS) with a molar ratio of 1.5 at a constant speed at 90°C, and keep the reaction at 80°C for 1 hour. Cool down to 35°C, add 2.0 parts by weight of water, stir, dissolve, and separate into layers. Recover toluene by distillation under reduced pressure, and distill off toluene to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com