Method for co-producing carbon dioxide by using superfine precipitated barium sulfate prepared by barium carbonate

A technology for precipitating barium sulfate and carbon dioxide, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of complex process equipment, large operation volume, low yield, etc., to overcome large material operation volume, high profit, and low yield big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

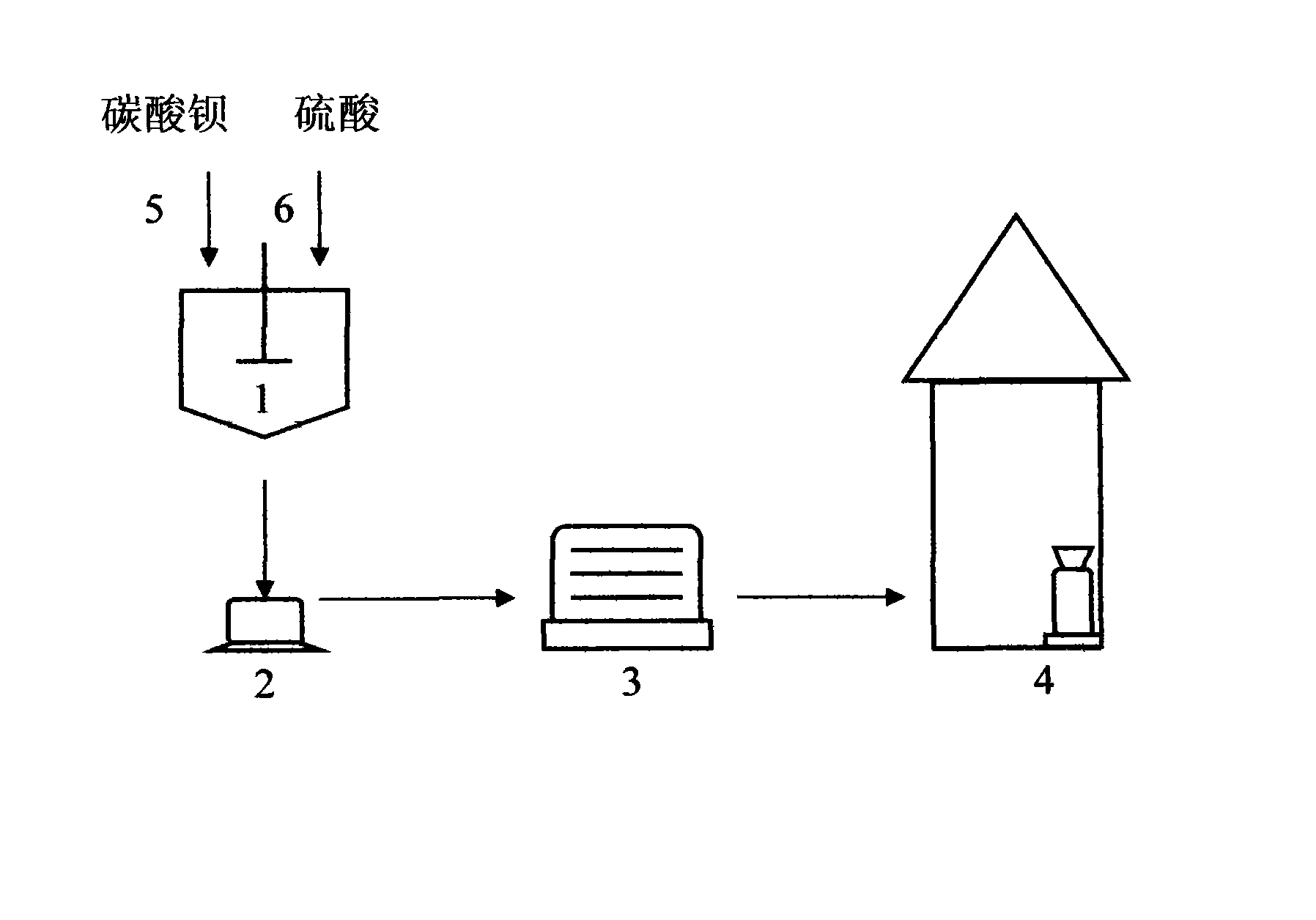

[0011] Embodiment one: 500 gram barium carbonates are dissolved in water and make it become aqueous solution and act in reactor (1) with dilute sulfuric acid with the mass ratio of pure substance 1: 0.2 with the rotating speed of 120 rev / mins , In the reaction, barium sulfate is used to remove impurities, resulting in the formation of precipitated barium sulfate and carbon dioxide. Filter (2) to obtain the chlorine cake as barium sulfate and then dry (3), pulverize (4), and pack to obtain 237.76 kilograms of precipitated barium sulfate. And 44.9 kilograms of carbon dioxide are packed into rigid bottle packaging products (5) through compression canning.

[0012] Implement two: 500 gram barium carbonates are dissolved in water and make it become aqueous solution and act in reactor (1) with the mass ratio 1: 0.7 of pure substance with dilute sulfuric acid after 3% tensio-active agent, In the reaction, barium sulfate is used to remove impurities, resulting in the formation of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com