Preparation method of nanoscale zirconia ceramic powder for spraying

A nano-zirconia, ceramic powder technology, applied in nanotechnology and other directions, can solve the problems of low equipment requirements, spalling failure, coating cracking, etc., and achieve the effect of simple production process equipment, good wear resistance, and avoidance of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific examples, which are not intended to limit the present invention.

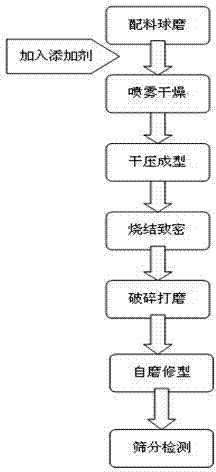

[0031] A preparation method of nano zirconia ceramic powder for spraying, comprising the steps of:

[0032] 1) Ingredients ball milling: Mix yttrium oxide partially stabilized zirconia powder with a particle size of 100nm (produced by Shenzhen CSG Group) and binder at a mass ratio of 95:5, and add 1.5 times the weight of the mixture. Water, prepared into a slurry and ball milled for 24 hours;

[0033] 2) Atomization drying: Add the slurry obtained in step 1) to a dispersant with a mass ratio of 0.5%, atomize and dry in a spray drying tower, and control the outlet temperature of the drying tower within the range of 110°C to make granulated powder ;

[0034] 3) Sieving and grading: Sieve the agglomerated granulated powder obtained in step 2), take the fine powder between 200 mesh sieves, and recover the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com