System for preparing methane through methane temperature self-raising-based membrane separation method

A technology of self-elevating and separation method, which is applied in the field of high-purity methane preparation system, can solve the problems of high production cost and power consumption, and achieve the effects of reducing power consumption, simplifying production process equipment, and simple and easy temperature adjustment and control operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

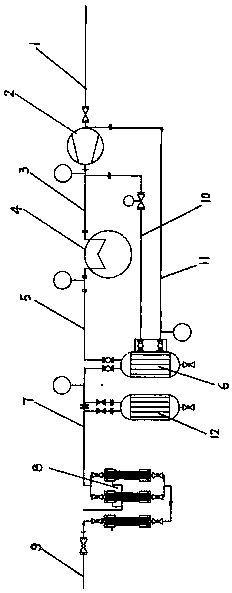

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

[0011] A methane preparation system based on a biogas temperature self-raising membrane separation method, including a biogas input pipeline 1, a compressor 2, a cold dryer 4 and a membrane group 8, and a biogas input pipeline is connected to the gas source input port of the compressor 2 1. A compressed biogas output pipeline 3 is connected to the compressed gas output port of the compressor 2, and the other end of the compressed biogas output pipeline 3 communicates with the input port of the cold dryer 4, and is connected to the output port of the cold dryer 4. There is a low-temperature biogas delivery pipeline 5, and the other end of the low-temperature biogas delivery pipeline 5 is connected with the heat exchange gas input port of the air-to-air heat exchanger 6, and the heated biogas is connected to the heat-exchange gas output port of the air-to-air heat exchanger 6 De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com