A kind of aliphatic superplasticizer and preparation method thereof

A high-efficiency water-reducing agent and aliphatic technology, applied in the field of aliphatic high-efficiency water-reducing agent and its preparation, can solve the problem of high production cost, and achieve the effects of less harmful impurities, simple production process equipment, and reduced influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

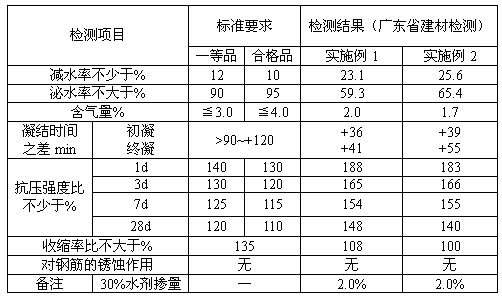

Examples

Embodiment 1

[0031] In the preheating pot with cooling water, start the exhaust device to form a slight negative pressure in the system, put in 29 parts of formaldehyde in parts by mass, and then throw in 3.5 parts of sodium metabisulfite, stir and dissolve for about 30 minutes under reflux reaction; then add acetone 8.5 parts, controlled at 30°C~40°C for 30 minutes under reflux to form a mixed solution for later use.

[0032] Add 27 parts of water (25 parts of water, 2 parts of recovered water) into the cooling water and the condensation pot with insulation layer, and then add 9 parts of sodium sulfite, stir evenly to obtain an aqueous solution of sodium sulfite.

[0033] Slowly add the above mixed solution into the sodium sulfite aqueous solution dropwise, let the material naturally heat up to above 75°C in about 20 minutes and maintain a constant temperature under reflux conditions for condensation reaction. The above mixed material is finished in about 3 hours, the heat preservation rea...

Embodiment 2

[0035]In the preheating pot with cooling water, start the tail gas device to form a slight negative pressure in the system, put in 25 parts of formaldehyde in parts by mass, and then throw in 4.5 parts of sodium metabisulfite, stir and dissolve for about 40 minutes; then add 9.5 parts of acetone Parts, controlled at 40~50°C for 30 minutes under reflux to form a mixed solution for later use.

[0036] Add 20.5 parts of water (18.5 parts of water, 2 parts of recovered water) into the cooling water and the condensation pot with insulation layer, and then add 10 parts of sodium sulfite, and stir evenly to obtain an aqueous solution of sodium sulfite.

[0037] Slowly add the above mixed solution into the sodium sulfite aqueous solution dropwise, let the material naturally heat up to 80°C for about 30 minutes and maintain a constant temperature under reflux conditions for condensation reaction, finish adding the above mixed material in about 2 hours, after the heat preservation reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com