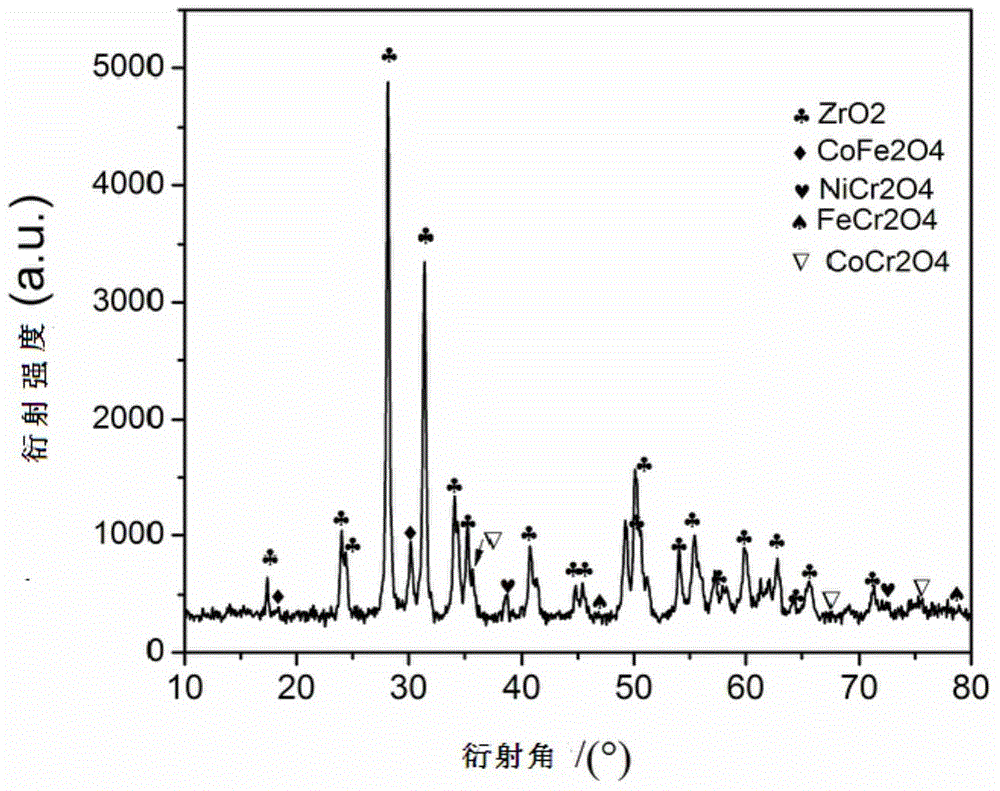

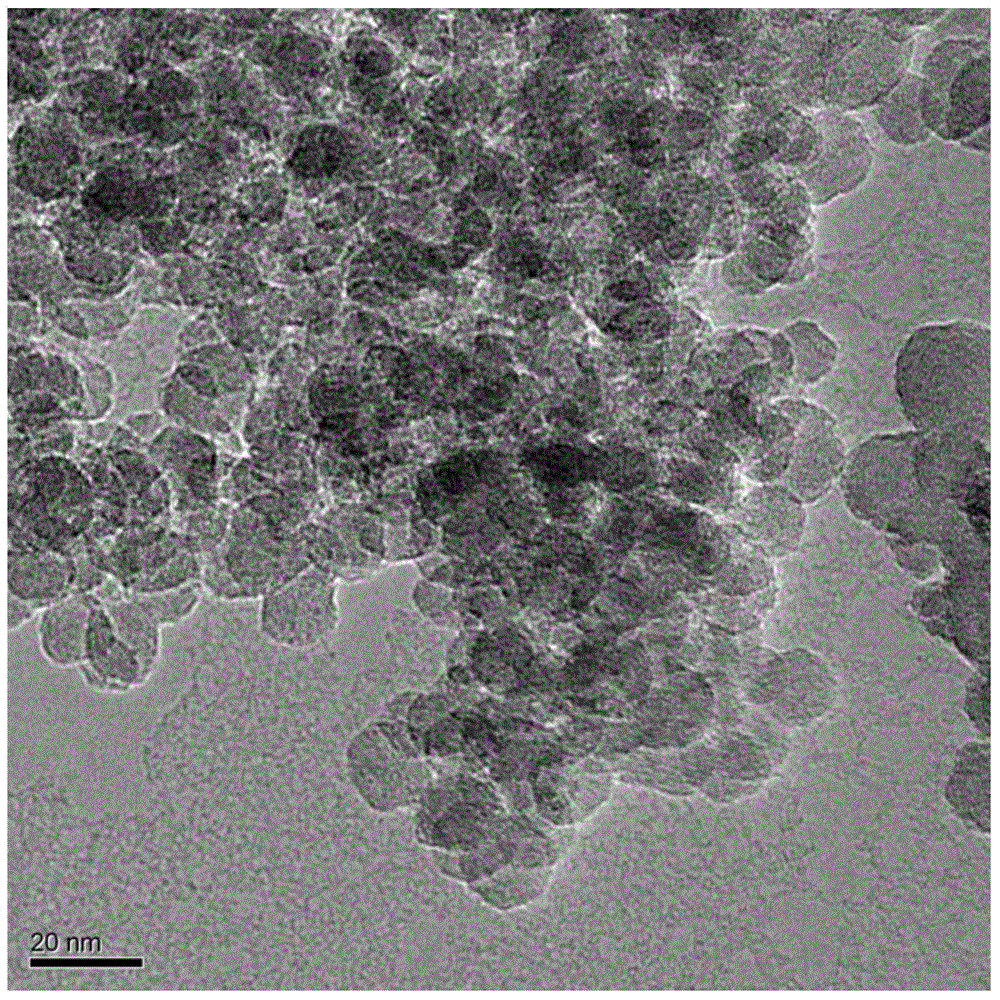

Method for synthesis of black zirconia ceramic powder by organic network process

The technology of black zirconia and ceramic powder is applied in the field of organic network preparation, and achieves the effects of convenient operation, simple production process equipment and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of organic network precursor:

[0041] The concentration of 4% polyvinyl alcohol and water are mixed in proportion, heated and stirred at about 85° C. for 2-3 hours, and then allowed to stand and cooled to room temperature to obtain a polyvinyl alcohol aqueous solution.

[0042] 2.Zr 4+ and preparation of colored ionic / organic network gels:

[0043] Take 70ml of the above-prepared polyvinyl alcohol solution, add 30g of zirconium oxychloride according to the proportion and stir until it is completely dissolved; then add 1.10g of yttrium nitrate hexahydrate and stir until dissolved; then add 1.60g of ferric nitrate nonahydrate, 2.59g of nonahydrate Chromium nitrate hydrate, 0.85g cobalt nitrate hexahydrate, 0.42g nickel nitrate hexahydrate and stir until uniform; after adding, add 3ml of glutaraldehyde, and stir quickly until a gel is formed;

[0044] 3. Zr 4+ and color ionic / organic network gel post-treatment:

[0045] After the above gel was left to s...

Embodiment 2

[0050] 1. Preparation of organic network precursor:

[0051] The concentration of 4% polyvinyl alcohol and water are mixed in proportion, heated and stirred at about 85° C. for 2-3 hours, and then allowed to stand and cooled to room temperature to obtain a polyvinyl alcohol aqueous solution.

[0052] 2.Zr 4+ and preparation of colored ionic / organic network gels:

[0053] Take 60ml of the above-prepared polyvinyl alcohol solution, add 40g of zirconium oxychloride according to the proportion and stir until it is completely dissolved; then add 1.46g of yttrium nitrate hexahydrate and stir until dissolved; then add 1.57g of ferric nitrate nonahydrate, Chromium nitrate hydrate, 0.71g cobalt nitrate hexahydrate, 0.29g nickel nitrate hexahydrate and stir until uniform; then add 3ml of glutaraldehyde, and stir quickly until a gel is formed;

[0054] 3. Zr 4+ and color ionic / organic network gel post-treatment:

[0055] After the above gel was left to stand for 3 hours, it was soake...

Embodiment 3

[0059] 1. Preparation of organic network precursor:

[0060] The concentration of 6% polyvinyl alcohol and water are mixed in proportion, heated and stirred at about 85° C. for 2-3 hours, and then left to cool to room temperature.

[0061] 2.Zr 4+ and preparation of colored ionic / organic network gels:

[0062] Take 50ml of the above-prepared polyvinyl alcohol solution, add 50g of zirconium oxychloride according to the proportion and stir until it is completely dissolved; then add 1.83g of yttrium nitrate hexahydrate and stir until dissolved; then add 2.40g of ferric nitrate nonahydrate, 3.96g of nonahydrate Chromium nitrate hydrate, 0.56g cobalt nitrate hexahydrate, 0.58g nickel nitrate hexahydrate and stir until uniform; then add 5ml of glutaraldehyde, and stir quickly until a gel is formed;

[0063] 3. Zr 4+ and color ionic / organic network gel post-treatment:

[0064] After the above gel was left to stand for 3 hours, it was soaked in ammonia water (25% concentration by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com