Intrinsically safe latex matrix ground station

A latex matrix and ground station technology, which is applied to explosives processing equipment, offensive equipment, explosives, etc., can solve the problems of high requirements for supporting systems of mobile ground stations, uneven product efficacy, hidden safety hazards, etc., to eliminate the possibility of thermal explosion efficiency, simplification of production process and equipment, and the effect of energy saving in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] see Figure 1 to Figure 3 .

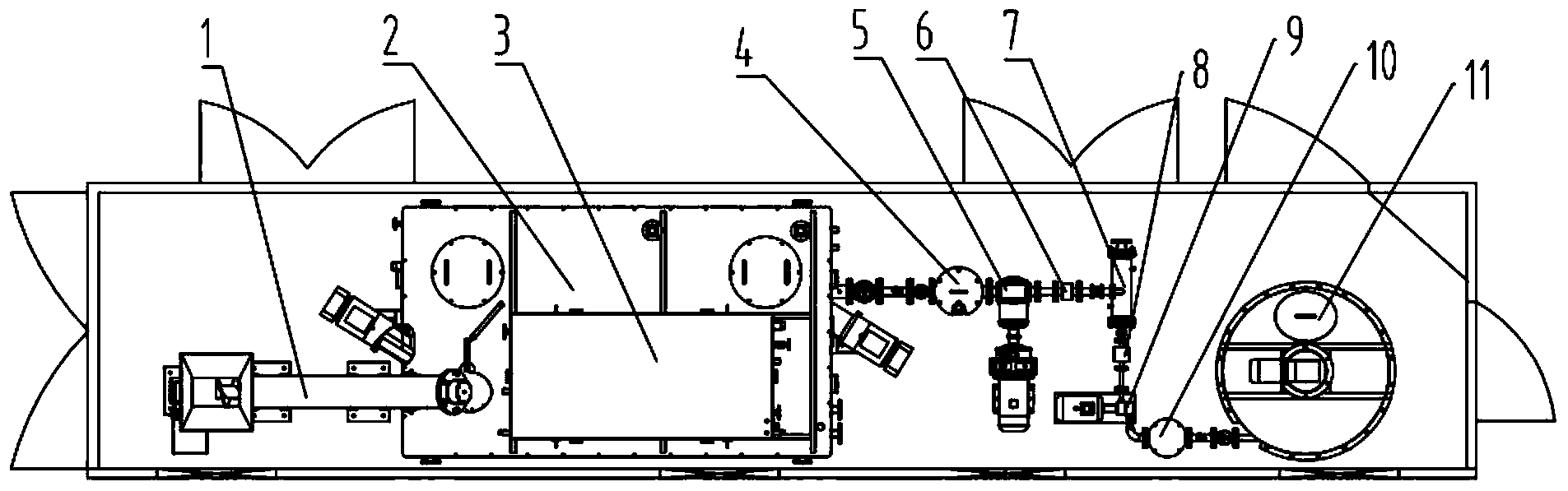

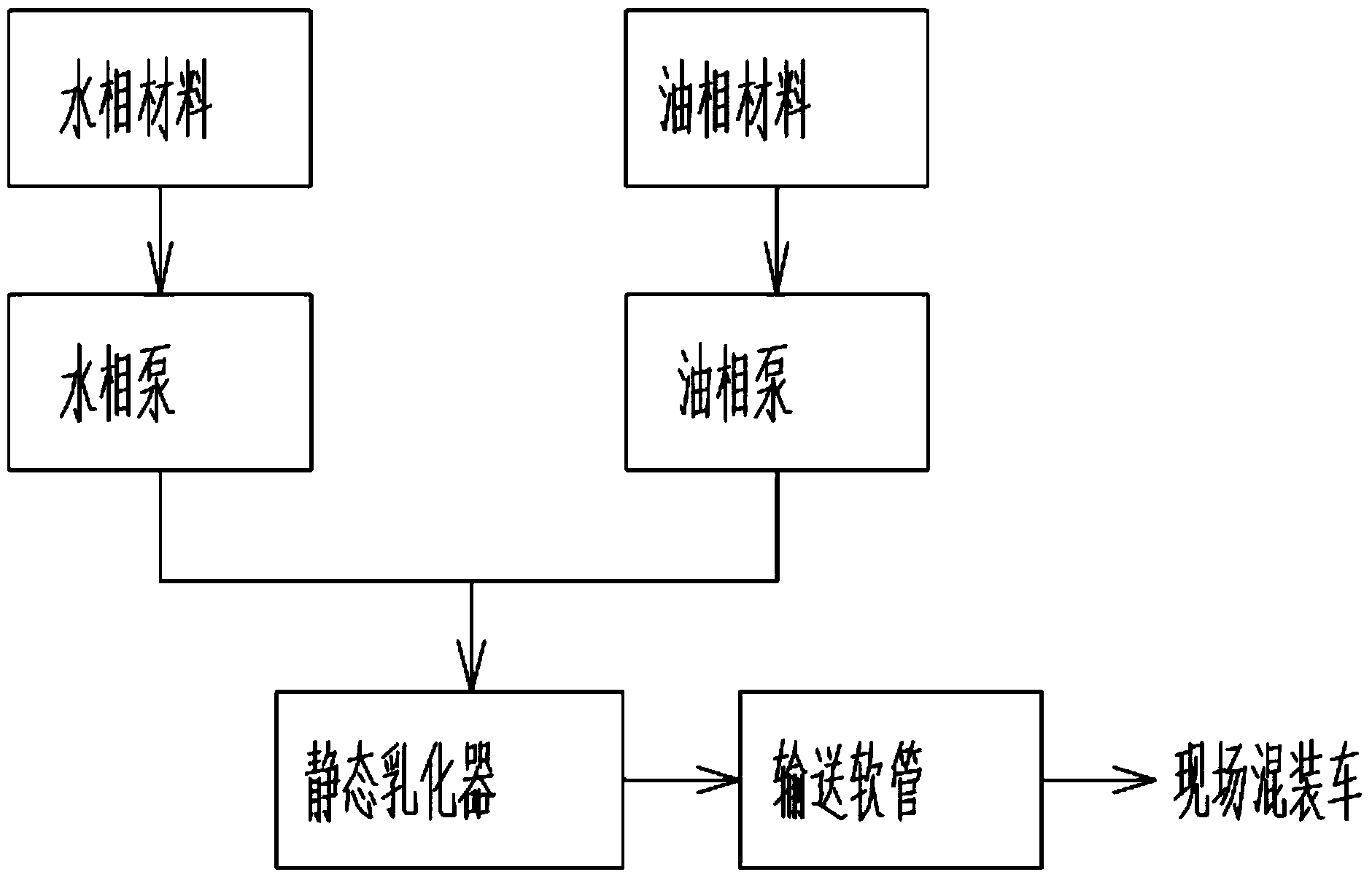

[0018] An intrinsically safe latex matrix ground station, which includes a water phase tank 2, an oil phase tank 11, a water phase pump 5, an oil phase pump 9 and a static emulsifier 7, and the inlet and outlet of the water phase pump 5 are respectively connected by pipelines It is connected with the water phase inlet 13 of the water phase tank 2 outlet and the static emulsifier 7, and the oil phase pump 9 inlet and outlet are respectively connected with the oil phase tank 11 outlet and the oil phase inlet 12 of the static emulsifier 7 by means of pipelines (see attached figure 1 ).

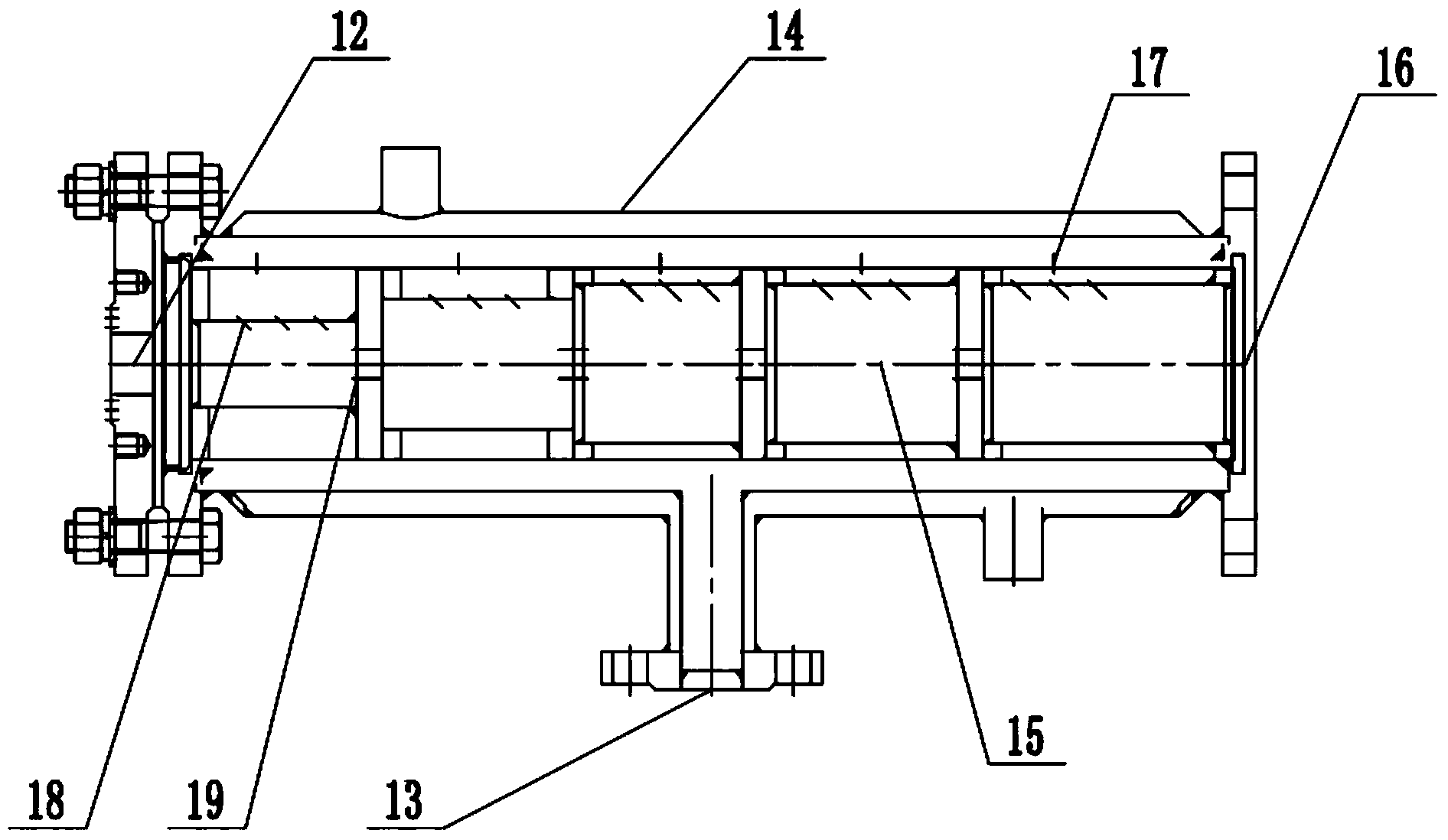

[0019] Described static emulsifier 7 (see attached figure 2 ) includes an oil phase inlet 12, a water phase inlet 13, a flange cylinder 14, an emulsification inner core 15 and an emulsifier outlet 16, the flange cylinder 14 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com