Smelting separation furnace lining material and preparation method thereof

A furnace lining material and melting furnace technology, applied in the field of melting furnace lining material and its preparation, can solve the problems of fast corrosion rate of working lining, etc., and achieve good oxidation resistance, strong erosion ability, and good thermal shock stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

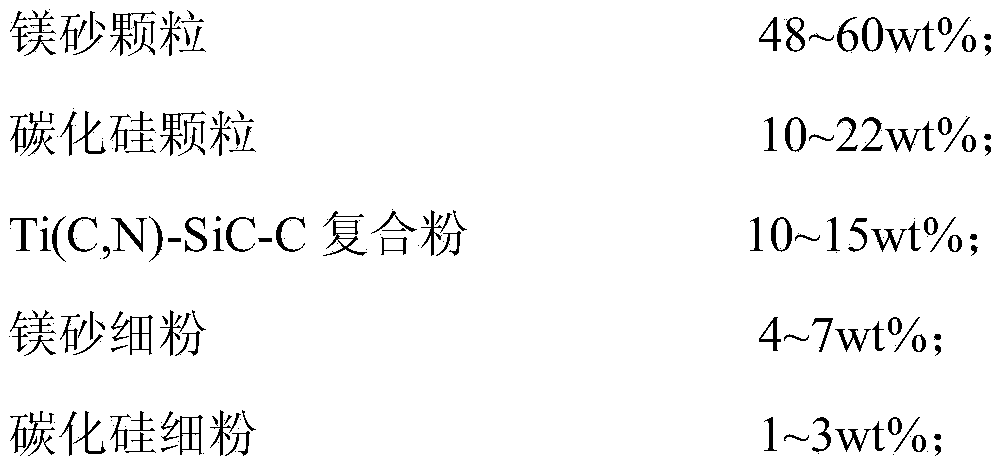

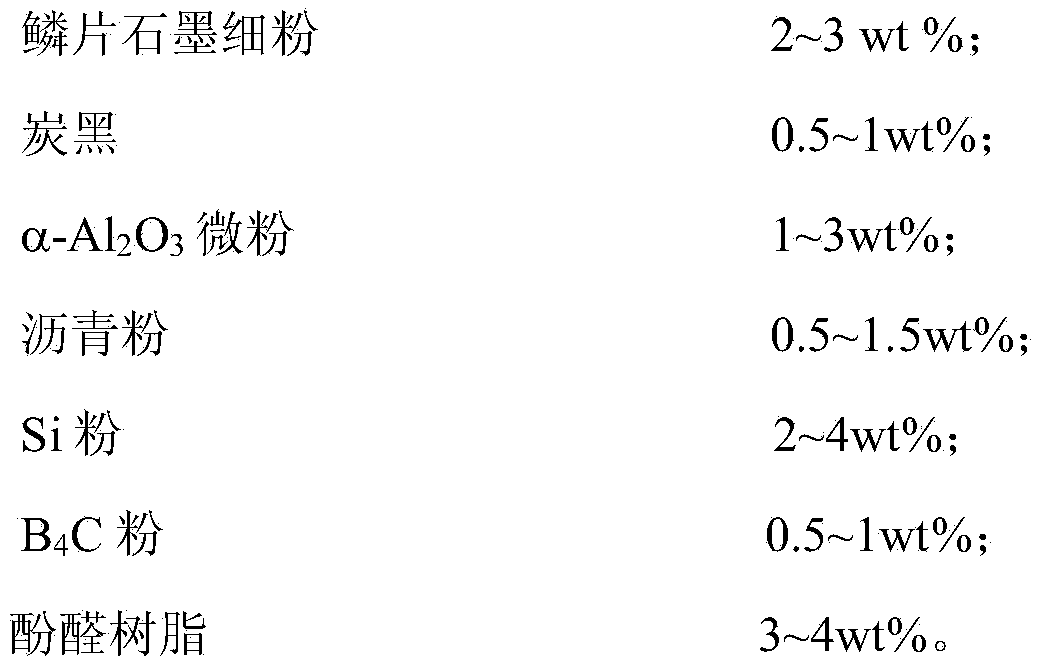

[0032] A melting furnace lining material and a preparation method thereof. The raw material and content thereof of described melting furnace lining material are:

[0033]

[0034] The preparation method of the melting furnace lining material is as follows: batching according to the above raw materials and their contents; first mixing magnesia particles and silicon carbide particles for 3 to 5 minutes, adding phenolic resin and mixing for 4 to 7 minutes, then adding mixed powder, mixing Refining for 12-18 minutes, forming, and then drying at 180-220°C for 24 hours, the melting furnace lining material is obtained.

[0035] The mixed powder is Ti(C,N)-SiC-C composite powder, magnesia fine powder, silicon carbide fine powder, flake graphite fine powder, carbon black, α-Al 2 o 3 Micropowder, asphalt powder, Si powder and B 4 C powder is mixed, and the mixing time is 3 to 5 minutes.

[0036]The melting furnace lining material prepared in this example 1 has a bulk density of 2...

Embodiment 2

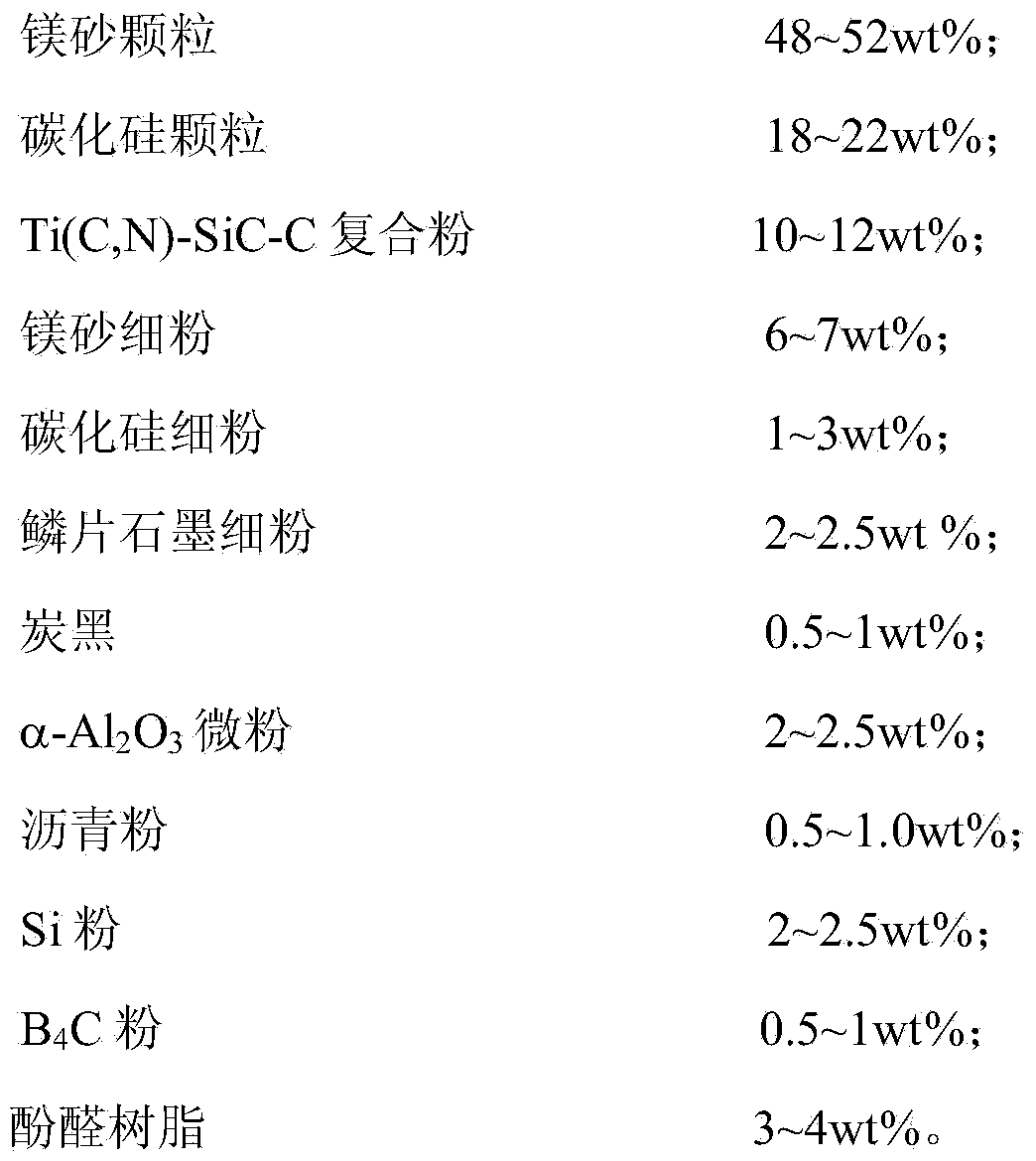

[0038] A melting furnace lining material and a preparation method thereof. The raw material and content thereof of described melting furnace lining material are:

[0039]

[0040] The preparation method of the melting furnace lining material is as follows: batching according to the above raw materials and their contents; first mixing magnesia particles and silicon carbide particles for 3 to 5 minutes, adding phenolic resin and mixing for 4 to 7 minutes, then adding mixed powder, mixing Refining for 12-18 minutes, forming, and then drying at 180-220°C for 24 hours, the melting furnace lining material is obtained.

[0041] The mixed powder is Ti(C,N)-SiC-C composite powder, magnesia fine powder, silicon carbide fine powder, flake graphite fine powder, carbon black, α-Al 2 o 3 Micropowder, asphalt powder, Si powder and B 4 C powder is mixed, and the mixing time is 3 to 5 minutes.

[0042] The melting furnace lining material prepared in this embodiment 2 has a bulk density ...

Embodiment 3

[0044] A melting furnace lining material and a preparation method thereof. The raw material and content thereof of described melting furnace lining material are:

[0045]

[0046]

[0047] The preparation method of the melting furnace lining material is as follows: batching according to the above raw materials and their contents; first mixing magnesia particles and silicon carbide particles for 3 to 5 minutes, adding phenolic resin and mixing for 4 to 7 minutes, then adding mixed powder, mixing Refining for 12-18 minutes, forming, and then drying at 180-220°C for 24 hours, the melting furnace lining material is obtained.

[0048] The mixed powder is Ti(C,N)-SiC-C composite powder, magnesia fine powder, silicon carbide fine powder, flake graphite fine powder, carbon black, α-Al 2 o 3 Micropowder, asphalt powder, Si powder and B 4 C powder is mixed, and the mixing time is 3 to 5 minutes.

[0049] The bulk density of the melting furnace lining material prepared in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com