Compound anti-aging composition, compound anti-aging tablet and preparation method and application of compound anti-aging composition and compound anti-aging tablet

An anti-aging and composition technology, applied in the field of compound anti-aging compositions, can solve the problems of human endocrine disorder, allergic or stress reaction, premature aging of human organs, etc., and achieves reduction of damp caking, improvement of fatigue relief, and promotion of fat metabolism. and protein synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

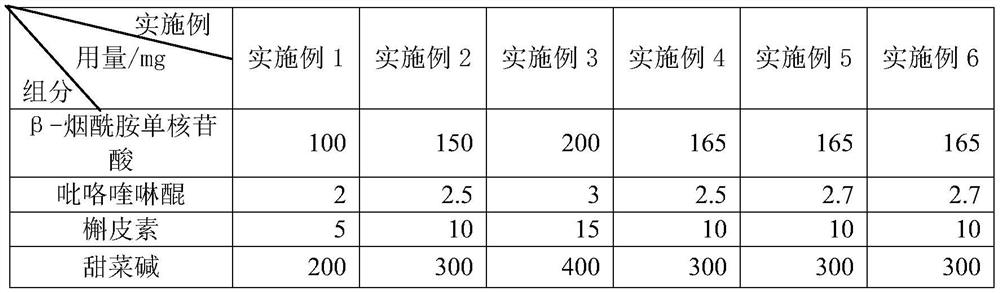

[0045] Example 1: A compound anti-aging composition, see Table 1 for the dosage ratio of the raw materials of the compound anti-aging composition.

[0046] The preparation method of the composition with anti-aging effect is as follows: separately grind the above-mentioned NMN, PQQ, quercetin and betaine according to the proportion and then mix them evenly.

Embodiment 2-6

[0047] Example 2-6: A compound anti-aging composition. The difference from Example 1 is that the amount and proportion of raw materials in the compound anti-aging composition are different. See Table 1 for details.

[0048] The consumption (mg) of each component in the compound antiaging composition of table 1 embodiment 1-6

[0049]

Embodiment a

[0050] Example a: A compound anti-aging tablet, see Table 2 for the ratio of raw materials used in the compound anti-aging tablet.

[0051] The preparation method of the above-mentioned compound anti-aging tablet comprises the following steps:

[0052] S1, make 30wt% betaine solution after adding deionized water in 1 / 3 weight betaine;

[0053] S2, NMN, calcium phosphate and silicon dioxide are mixed, ground and sieved, and then 30wt% betaine solution is added to make a powder slurry; then the powder slurry is quickly frozen, so that the center temperature of the powder slurry is -35°C;

[0054] S3, subjecting the product obtained in S2 to vacuum freeze-drying, the temperature of vacuum freeze-drying is -80°C, the pressure is -50Pa, and the time is 20h, to obtain a dry product with a water content of 3%;

[0055] S4. After pulverizing the dried product obtained in S3 with a mixer, add NMN mixed freeze-dried powder, PQQ, quercetin, stearate, and the remaining weight of betaine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com